System and method used for intermittently and dynamically weighing and measuring small flow

A dynamic weighing and metering system technology, applied in the direction of weighing equipment, weighing, and measuring devices for continuous material flow, can solve problems such as inability to measure and small material flow, and achieve inaccurate measurement, accurate measurement, and improved The effect of metering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

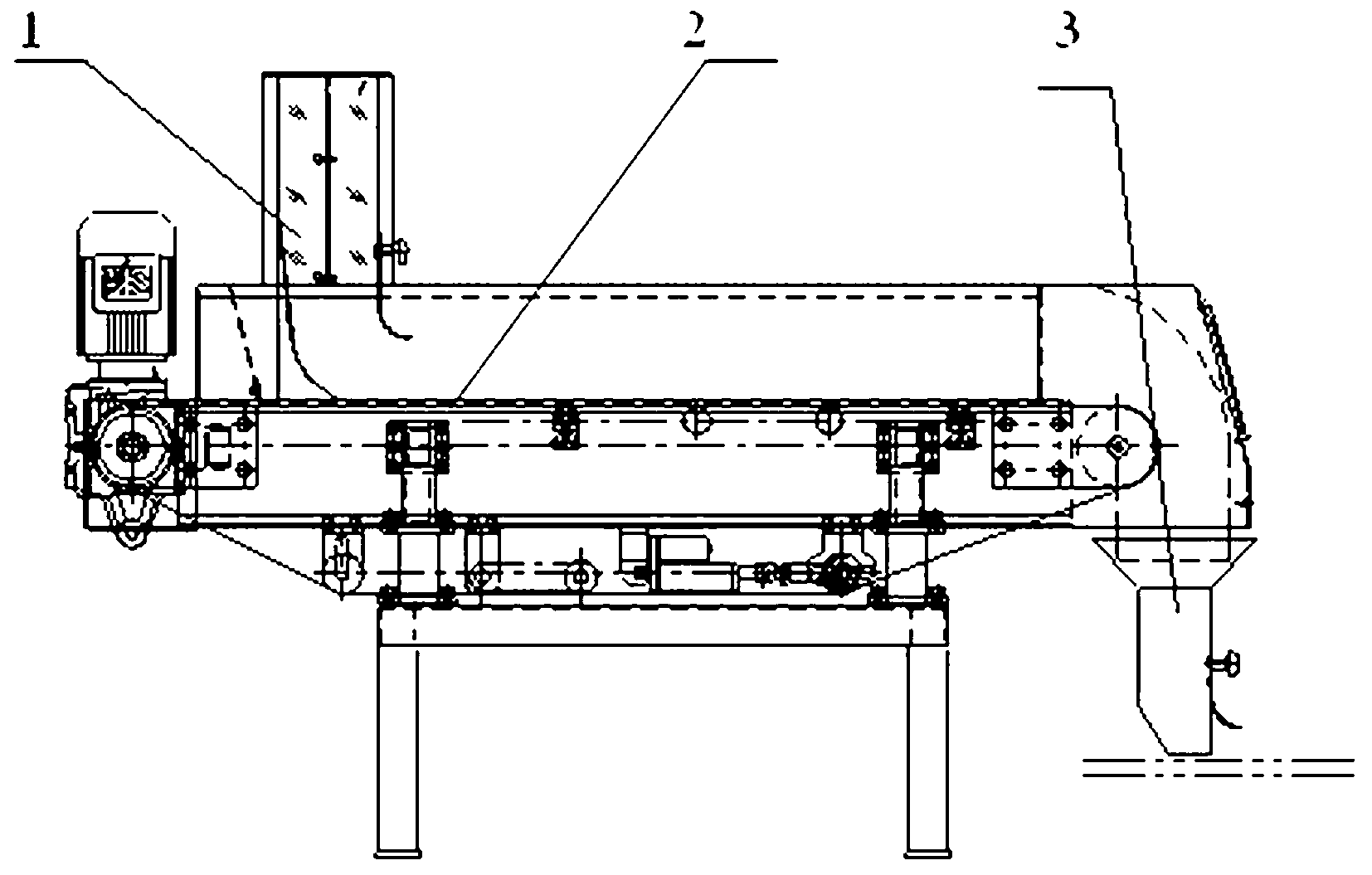

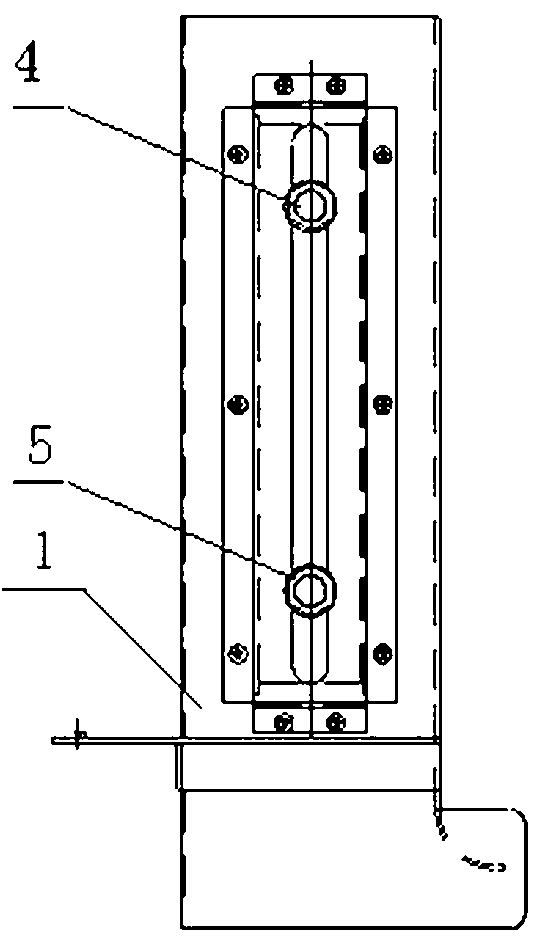

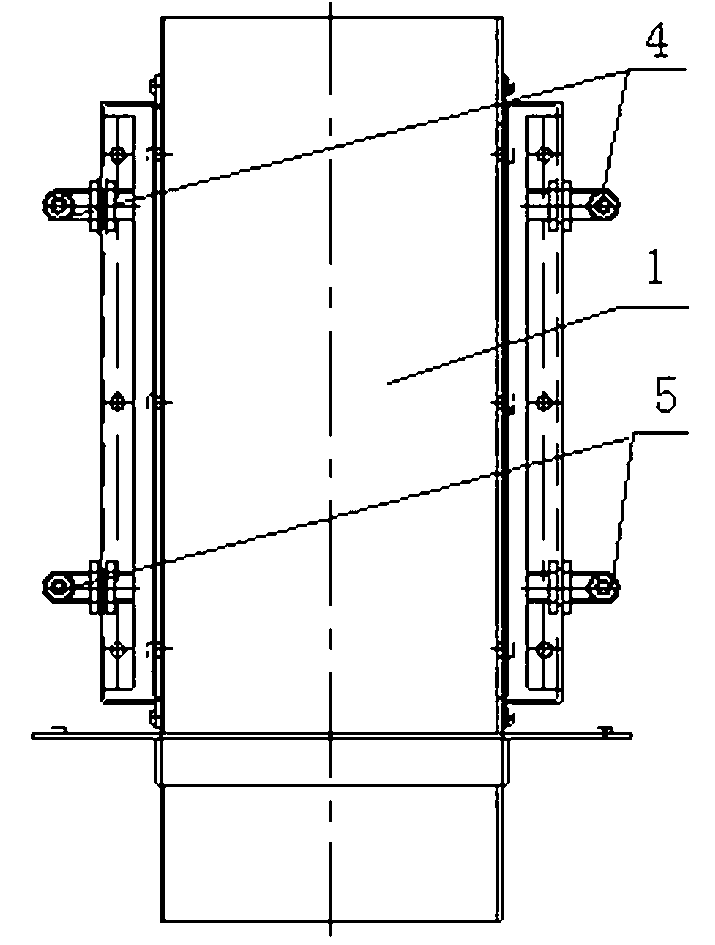

[0014] Such as Figure 1-Figure 4 As shown, the intermittent dynamic weighing and metering system for small flow rate of the present invention is composed of three units: the buffer bucket 1 at the feed end, the electronic belt scale 2, and the buffer bucket 3 at the discharge end. The buffer bucket 1 at the feed end and the buffer bucket 3 at the discharge end at the feed end and the discharge end are respectively provided with a high-level photoelectric cell 4 and a low-level photoelectric cell 5 at different heights of the buffer bucket 1 at the feed end. The discharge port of the buffer bucket 3 at the feed end is equipped with a height-adjustable vertical movable door 6, and a pair of high-level photoelectric cells 4 and low-level photoelectric cells 5 are respectively arranged on the opposite sides of the buffer hopper 1 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com