Wire jacket tearing detection device

A detection device and electric wire technology, which is applied in the direction of measuring device, measuring electricity, measuring electric variables, etc., can solve problems such as difficult to simulate the extrusion of sharp wires, a large amount of manpower input, and inability to distinguish, so as to avoid manual errors or external interference, The effect of accurate test results and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

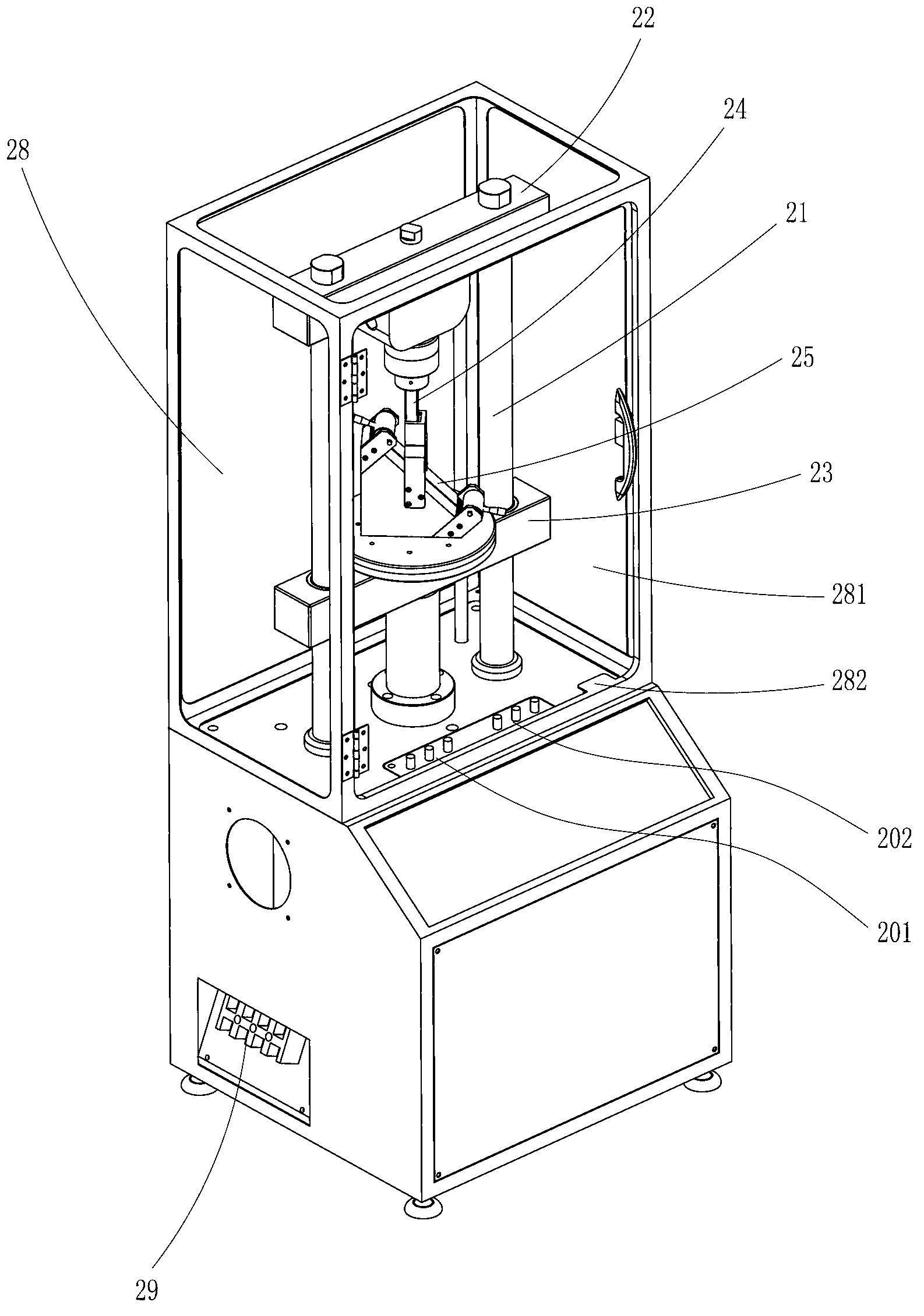

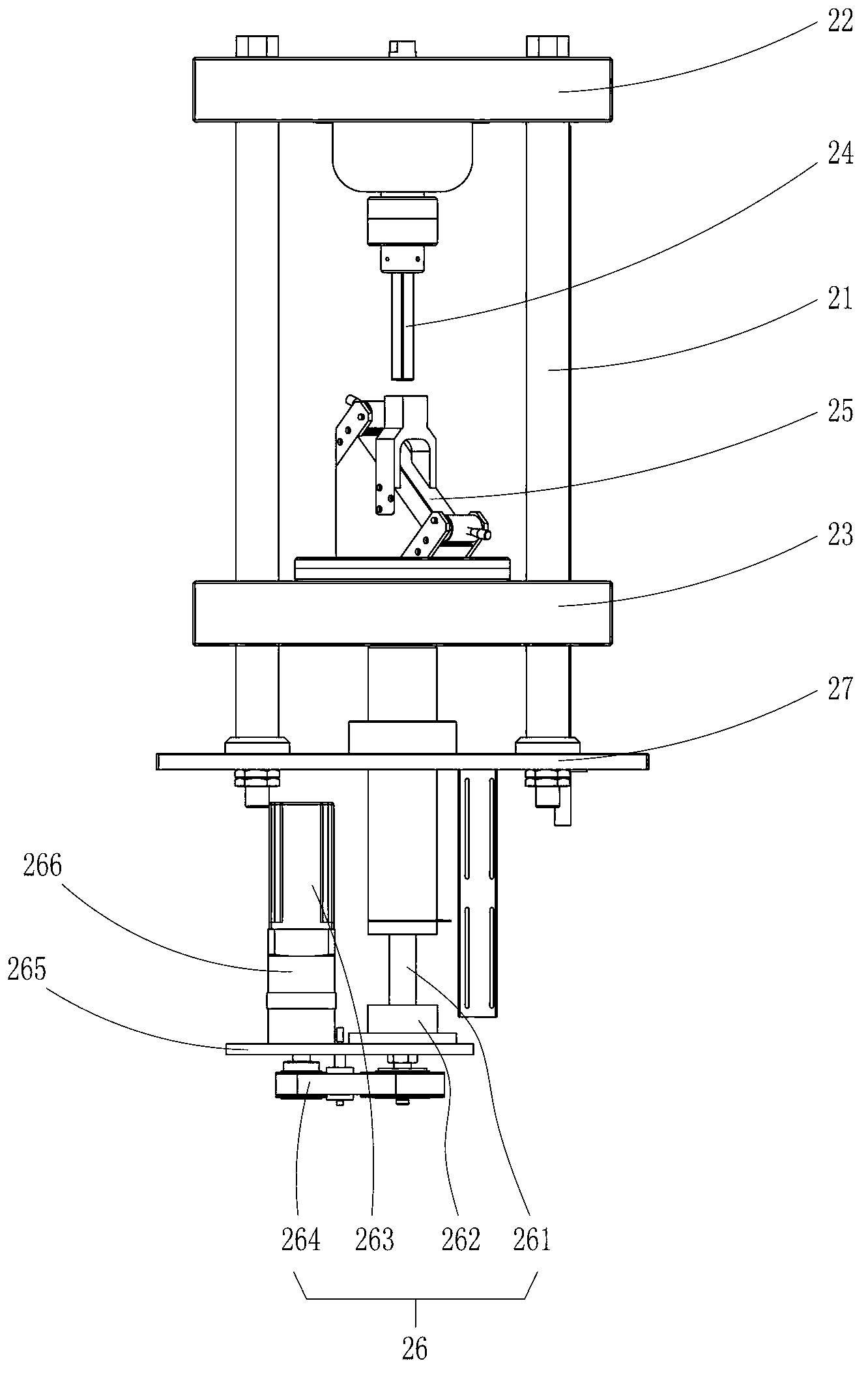

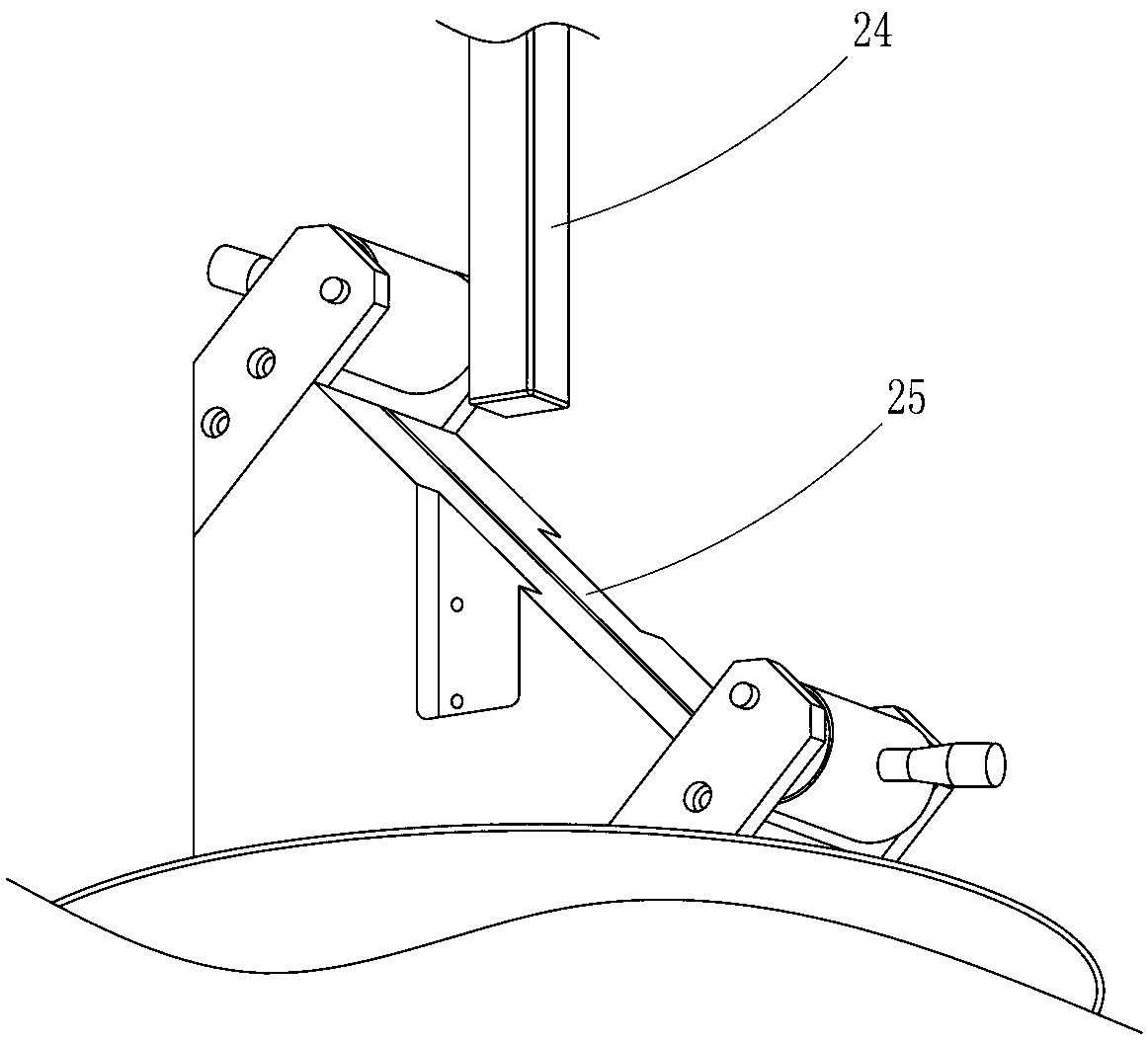

[0029] Such as Figure 1~Figure 7 As shown, the embodiment of the present invention provides a wire sheath tear detection device, including a control unit 10 , a simulation unit 20 and a detection unit 30 .

[0030] The simulation unit 20 is connected with the control unit 10 for simulating the state that the electric wire 100 under test is squeezed by an external lateral sharp instrument under the control of the control unit 10 . Please refer to figure 1 , the simulation unit 20 is provided with a first terminal 201 and a second terminal 202, which are respectively used to electrically connect the first test terminal 101 and the second test terminal 102 of the tested electric wire 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com