Special high-voltage testing device for transformers

A special device and transformer technology, applied in the field of high-voltage special devices for transformer testing, can solve the problems of the truck itself being easy to collide with objects, affecting the progress of the test process, and inconsistent wiring methods, so as to prevent mechanical damage, protect safety, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

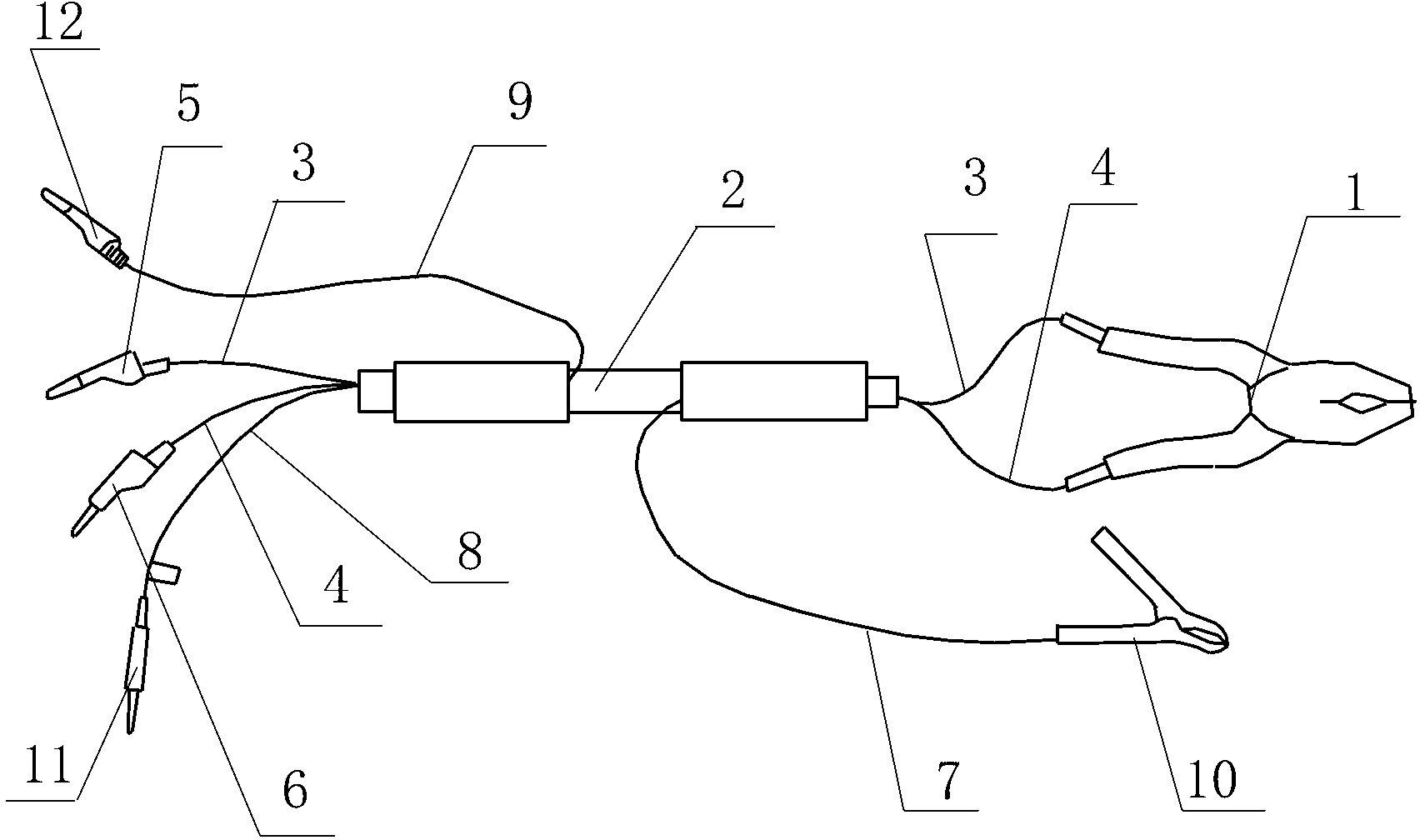

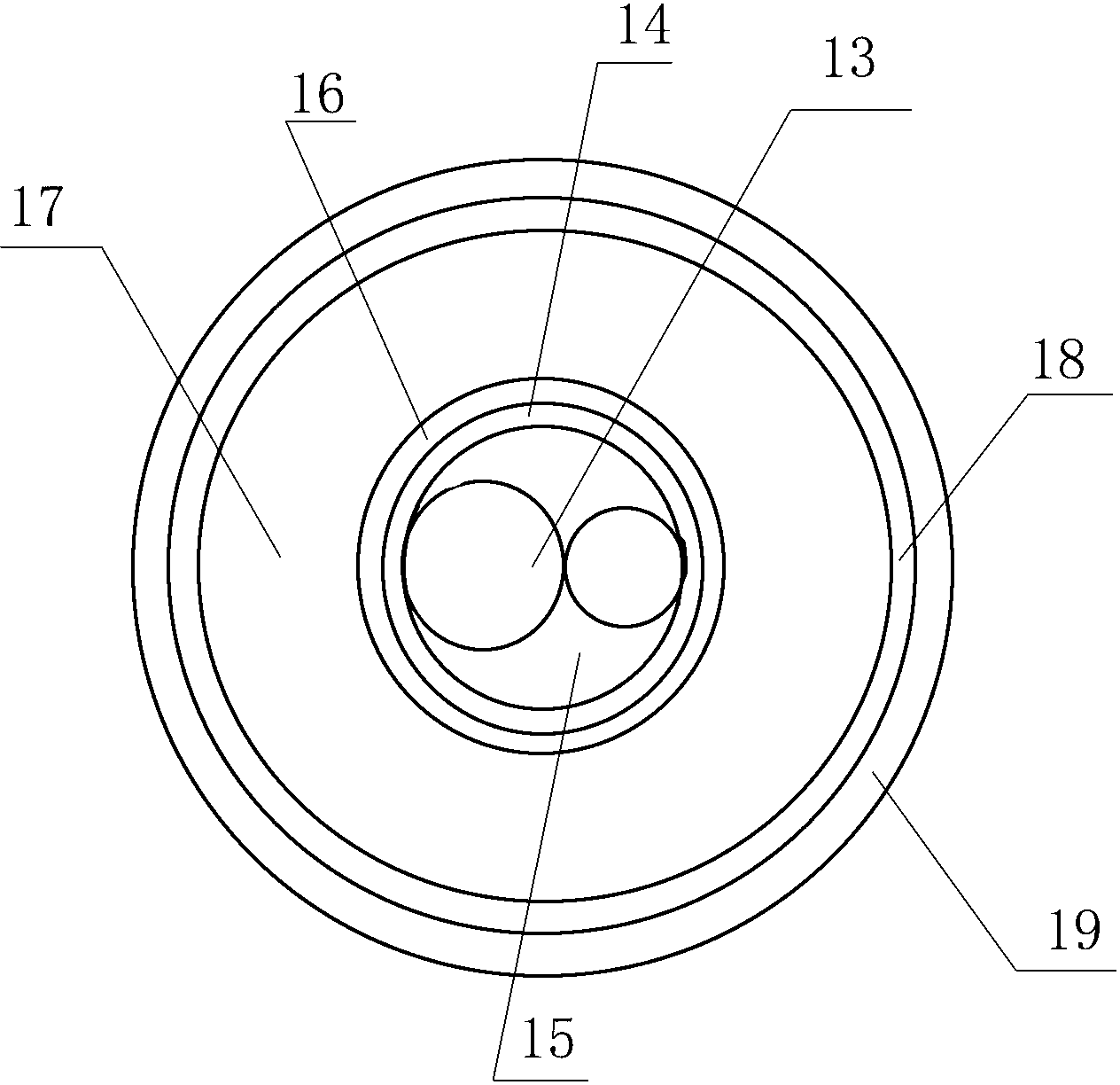

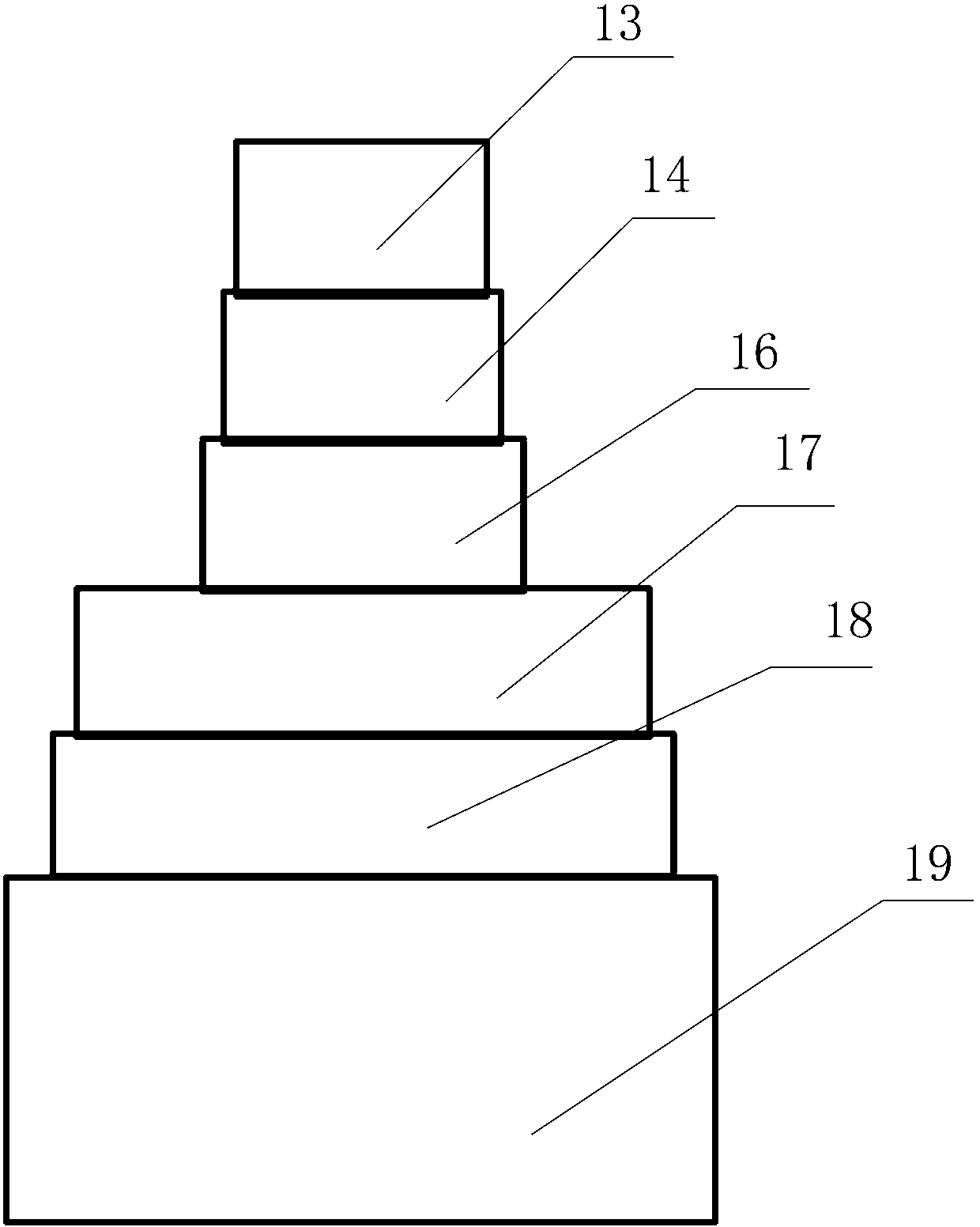

[0010] exist figure 1 , figure 2 with image 3 Among them, the present invention provides a special device for transformer test high voltage, which includes wiring clamp 1, test high voltage lead bushing 2, voltage line 3 and current line 4, and the two terminals of wiring clamp 1 are connected with voltage line 3 and current line respectively. Line 4, voltage line 3 and current line 4 extend into the test high-voltage lead bushing 2 and are respectively connected with a voltage line plug 5 and a current line plug 6. In the test high-voltage lead bushing 2, an upper shielding line 7 and a lower shielding line are also provided. Wire 8 and outer shielding wire 9, one end of voltage wire 3 and current wire 4 is connected with upper shielding wire 7, one end of upper shielding wire 7 is connected with voltage wire 3 and current wire 4, and the other end of upper shielding wire 7 is connected with The terminal clamp 10 is connected with the lower shielded wire 8 and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com