Connection processing method of ACSR (aluminum cable steel reinforced) and copper wire

A steel-cored aluminum stranded wire and processing method technology, applied in the direction of connection, connection contact material, line/collector parts, etc., can solve problems such as unsafe, laborious operation, etc., to reduce operation time and improve work Safety, eliminate the effect of poor connection contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

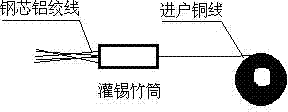

[0009] There are 98 buildings in a village in Xiangtan County, Hunan Province, each with 3 wires (live wire, neutral wire, ground wire) 16mm 2 Steel-cored aluminum stranded overhead wire power supply, two 10mm incoming wires 2 (live wire, neutral wire), one 4mm 2 (Ground wire) Copper-plastic wire. Joint processing steps: cut about 300mm long steel-cored aluminum stranded wire (remove the steel core) and connect it with the incoming copper-plastic wire → put the connected steel-cored aluminum stranded wire and the incoming copper-plastic wire into the prepared in advance The bamboo tube (its inner diameter is 6mm larger than the outer diameter of the steel-reinforced aluminum stranded wire, and the length is 100mm) → seal the end of the bamboo tube near the copper wire with dry mud → pour the tin liquid into the bamboo tube → turn the bamboo tube upside down, put Remove the mud that blocked the end of the bamboo tube, and pour tin liquid into the bamboo tube → cut open the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com