Assembly welding tool generally used for hot blast main pipe elbows

A technology for assembling welding fixtures and elbows, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of wasting steel raw materials, affecting production efficiency, increasing production costs, etc., and achieves improved welding work efficiency, compact structure, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

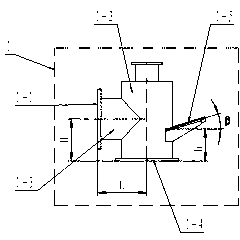

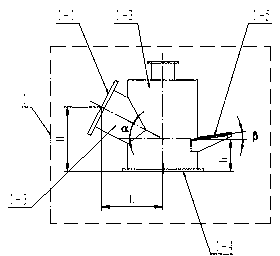

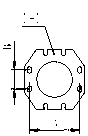

[0034] See Figure 6, Figure 7 , Figure 8 , the present invention includes a welding platform base 2, an outlet flange positioning plate 3, an inlet flange center distance adjustment mechanism 4, an inlet flange height adjustment mechanism 5, an inlet flange angle adjustment mechanism 6, and an inlet flange assembly hole center distance adjustment Mechanism 7 and support frame adjustment mechanism 8, the welding platform base 2 of the group is fixed on the horizontal plane, the outlet flange positioning plate 3 and the support frame adjustment mechanism 8 are installed on the welding platform base 2, the center distance of the inlet flange The adjustment mechanism 4 is installed on one side of the base 2 of the welding platform, and the inlet flange height adjustment mechanism 5 and the inlet flange angle adjustment mechanism 6 are fixed on the inlet flange center distance adjustment mechanism 4 .

[0035] see Figure 9 , the outlet flange positioning plate 3 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com