Corpus-fibrosum-fraction-changeable gum dipping device

A technology of a dipping device and a fiber body, which is applied in the field of fiber bundle dipping, can solve the problem that the accuracy of the amount of glue attached to the fibers cannot be guaranteed, and achieve the effects of reducing costs and simplifying the structure of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Describe the present invention below in conjunction with specific embodiment:

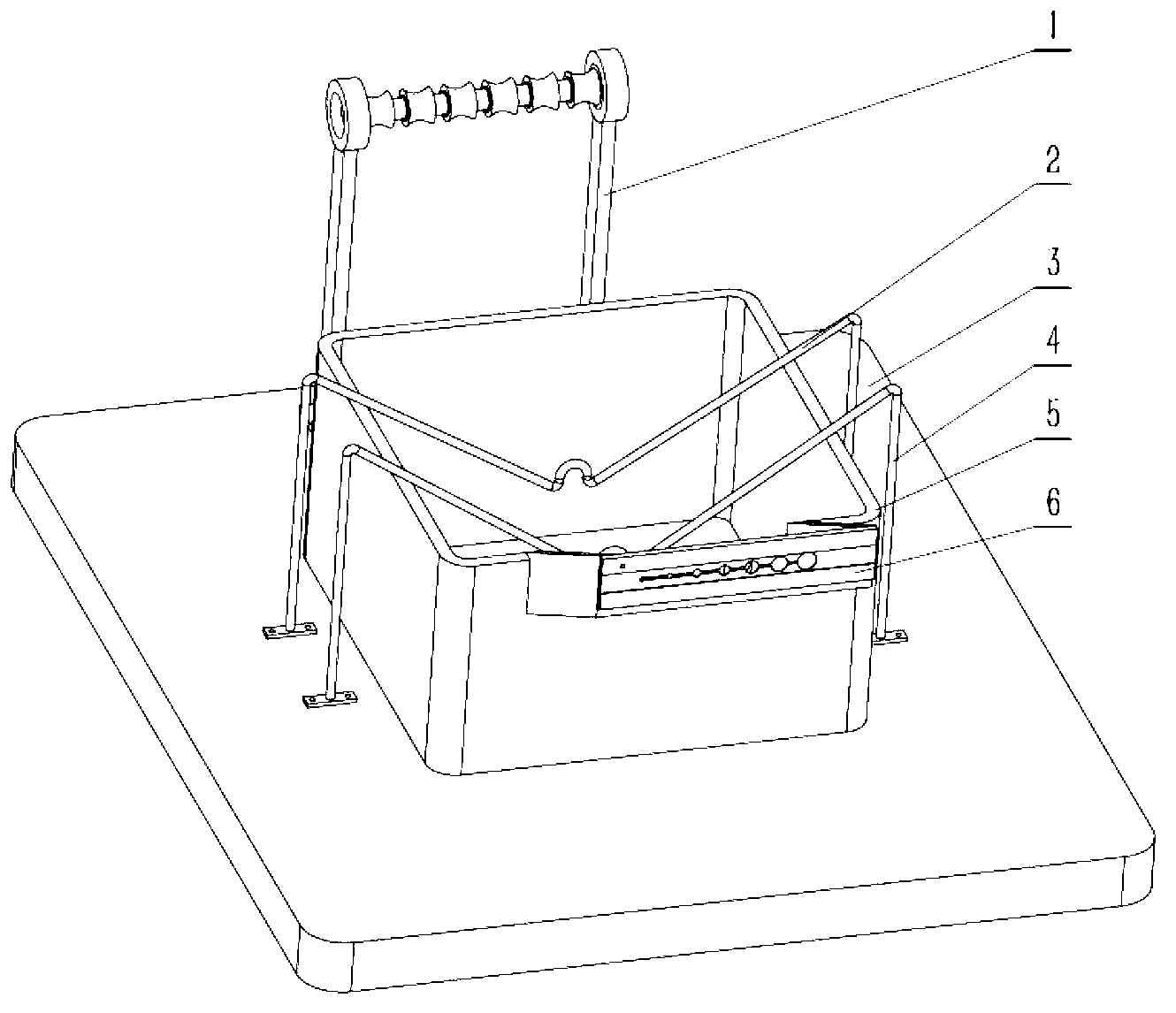

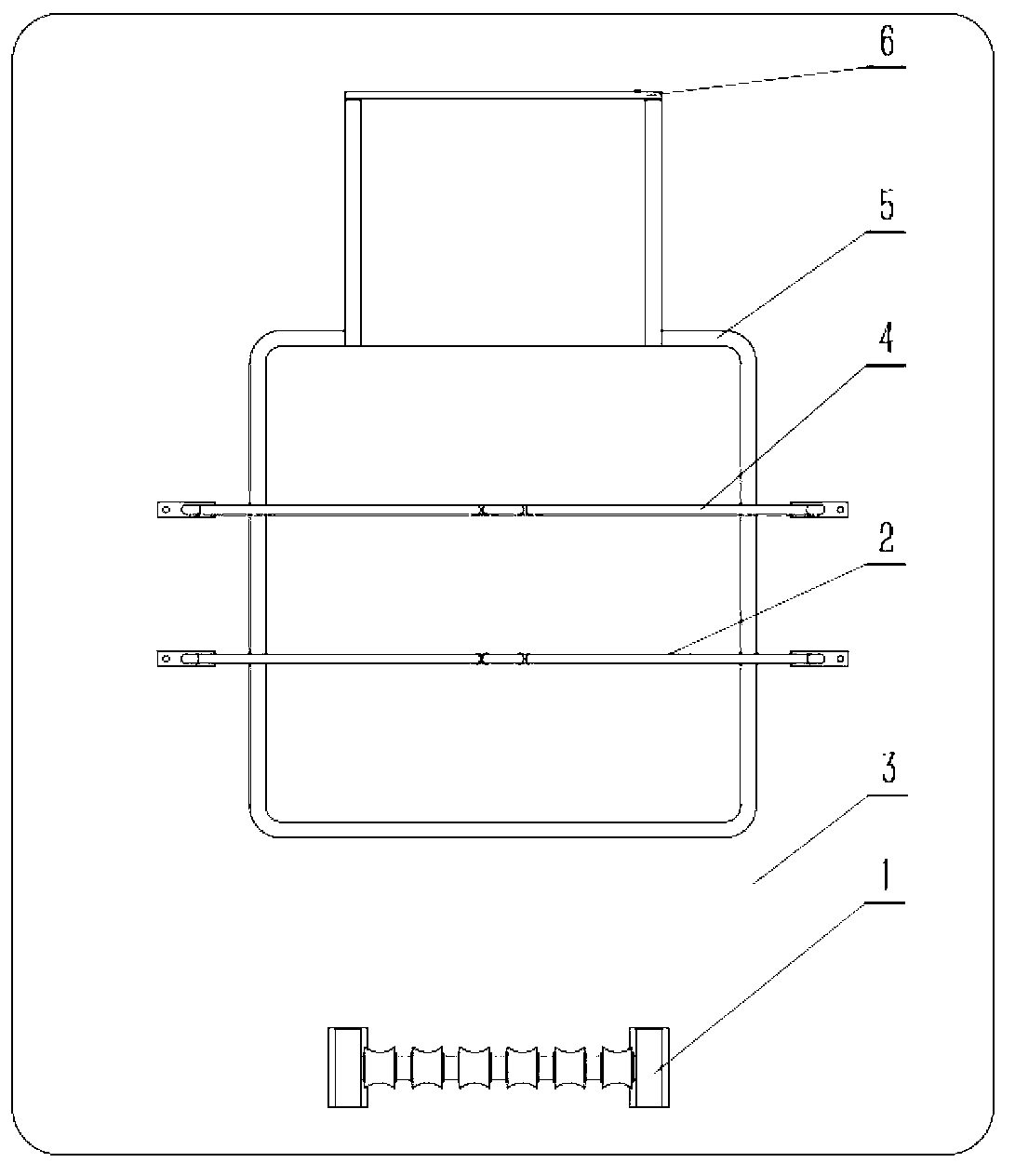

[0018] Refer to attached figure 1 , The dipping device with variable fiber body fraction in this embodiment is composed of a support base plate 3 , a fiber collection device, a dipping tank 5 , a dipping device 4 and a scraping device 6 .

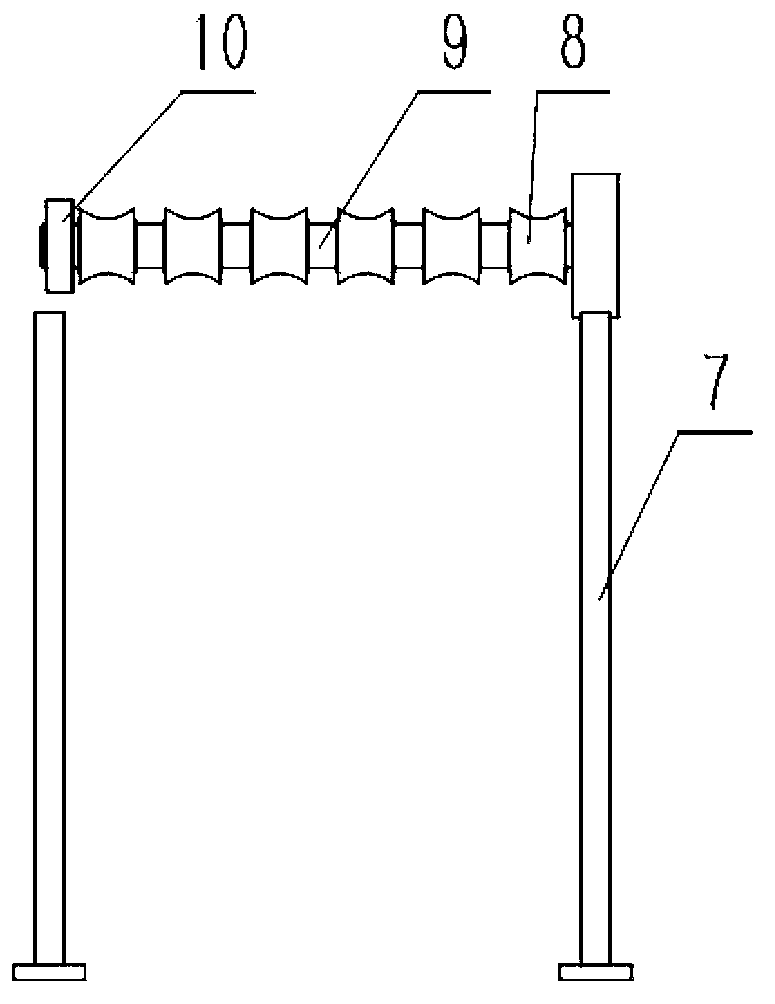

[0019] The fiber collecting device consists of an adjustable delivery hub 1 and a fiber collecting device 2 . Refer to attached image 3 , the adjustable delivery hub is composed of a bracket 7, a hub 8, and a sleeve 9, the two ends of the sleeve are connected to the bracket through bearings 10, several hubs are sleeved on the sleeve, and the hub and the sleeve are fixedly matched, and the bracket is fixed on the support On the bottom plate, the hub rotates with the bearing when the fiber is delivered to reduce the friction between the fiber and the hub. During use, the number of hubs can be increased or decreased according to the number of fiber bundl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com