Protective film and method for producing the same

A technology of protective film and bottom film, applied in chemical instruments and methods, film/sheet adhesives, layered products, etc., can solve problems such as affecting imaging quality and contaminating lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

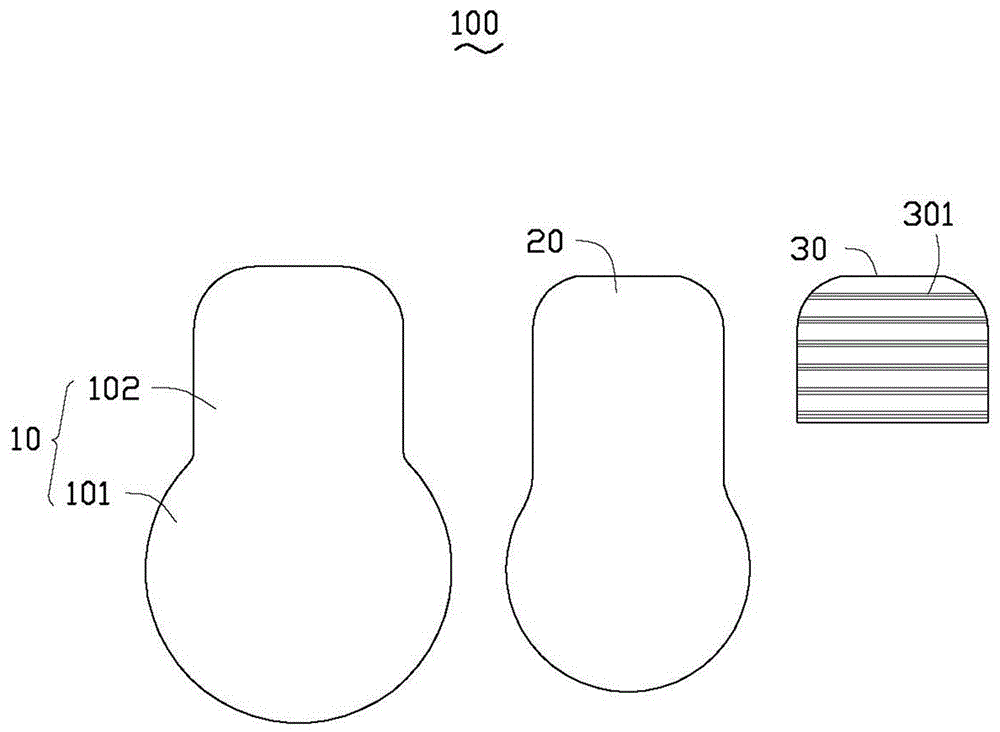

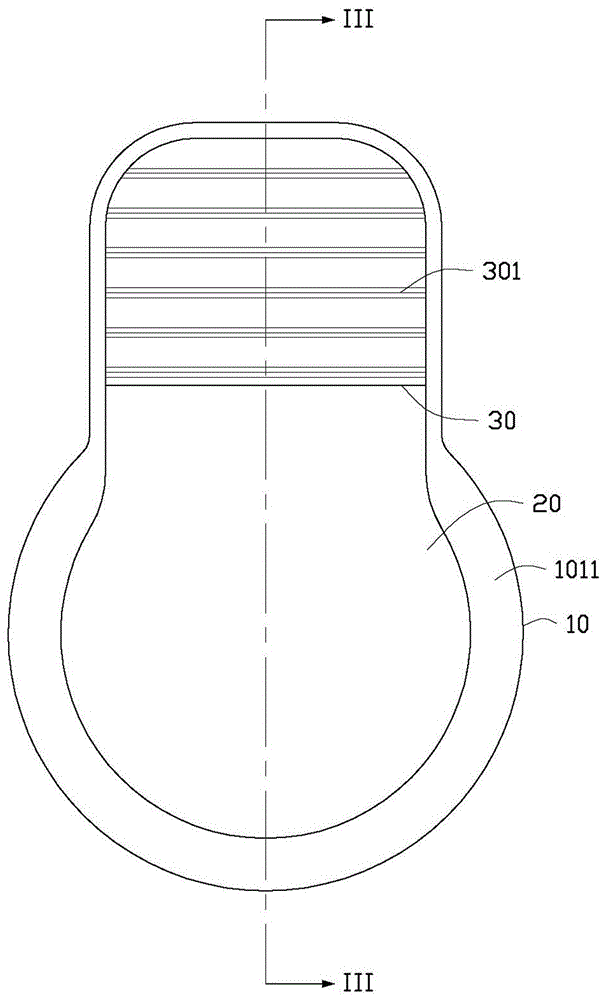

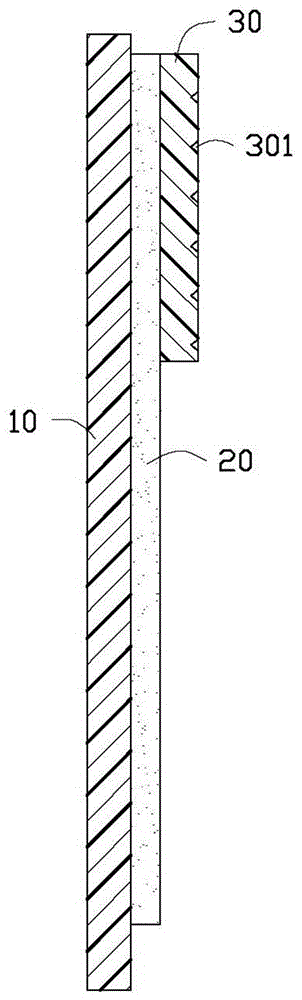

[0020] see Figure 1 to Figure 3 , shows a protective film 100 provided by an embodiment of the present invention, which is used to stick to a lens (not shown) to protect the lens. The protective film 100 includes a base film 10 , an adhesive layer 20 and an isolation film 30 .

[0021] The bottom film 10 is made of electrostatic adsorption materials such as polyethylene (Polyethylene, PE) and polyethylene terephthalate (Polyethylene terephthalate, PET). In this embodiment, the base film 10 is a transparent film made of PET and includes a cover part 101 and a handle part 102 connected to the cover part 101 . The shape of the cover part 101 roughly corresponds to that of the lens and is roughly circular. The handle portion 102 is roughly square.

[0022] The adhesive layer 20 is evenly coated on one surface of the base film 10 . The adhesive layer 20 is continuously coated on the covering part 101 and the handle part 102 . In this embodiment, the adhesive layer 20 is an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com