A kind of preparation method of high-temperature oxidation-resistant and wear-resistant composite coating on the surface of titanium alloy

A technology of anti-oxidation and composite coating at high temperature, which is applied in the coating process of metal materials, coating, and plating of superimposed layers. Limited performance, etc., to solve the problem of poor high temperature oxidation resistance, improve high temperature oxidation resistance and wear resistance, and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

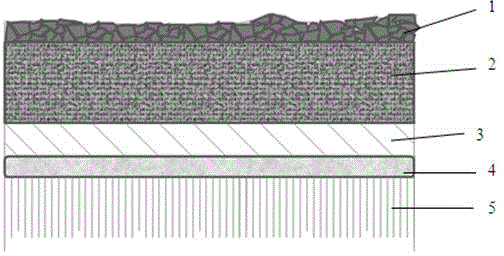

Image

Examples

Embodiment 1

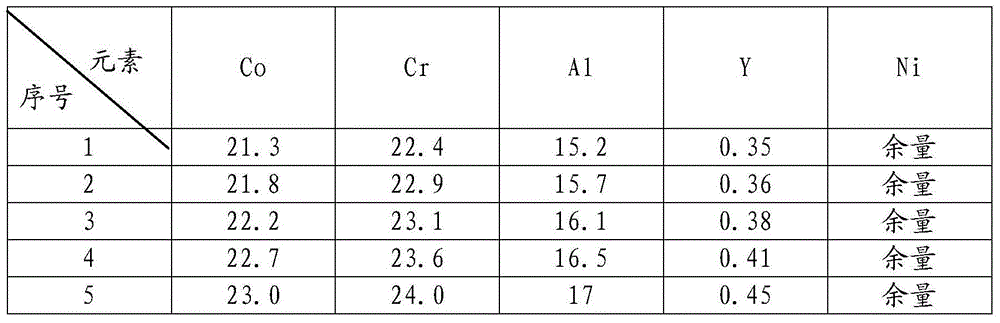

[0053] The NiCoCrAlY alloy target and penetration agent used in the process of preparing the coating on the surface of TiAl alloy, by weight percentage: NiCoCrAlY alloy target, its composition ratio is Co accounted for 21-23wt%, Cr accounted for 22-24wt%, Al It accounts for 15-17wt%, Y accounts for 0.35-0.45wt%, and the balance is Ni; in the solid powder embedding aluminizing process, the components of the infiltration agent formula and the proportions of each component are: pure aluminum powder 20-40wt%, alumina 50 -70wt%, ammonium chloride 2-5wt%, and cerium oxide 0.5-1.5wt%.

[0054] Following table 1-2 provides some preferred embodiments of each component mass percentage of the present invention, but the content of each component of the present invention is not limited to the numerical value listed in this table, for those skilled in the art, fully Reasonable generalizations and inferences can be made on the basis of the numerical ranges listed in the tables.

[0055] Tab...

Embodiment 2

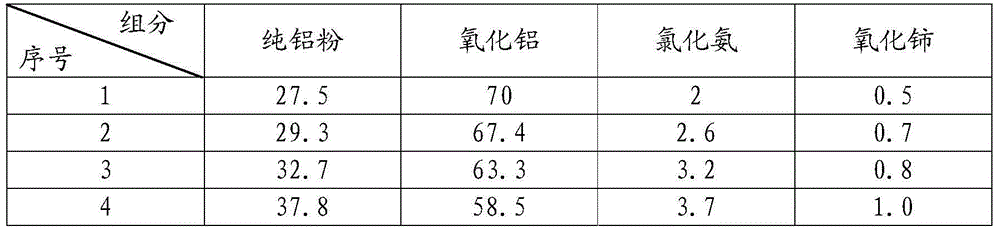

[0084] The NiCoCrAlY alloy target and penetration agent used in the coating process on the surface of TC4 alloy, by weight percentage: NiCoCrAlY alloy target, its composition ratio is 21-22wt% for Co, 22-23wt% for Cr, Al It accounts for 16-17wt%, Y accounts for 0.35-0.45wt%, and the balance is Ni; in the solid powder embedding aluminizing process, the components of the infiltration agent formula and the proportions of each component are: pure aluminum powder 30-40wt%, alumina 54 -70wt%, ammonium chloride 2-4wt%, and cerium oxide 0.5-1.5wt%.

[0085] In conjunction with Table 4-5, provide some preferred embodiments of the mass percentages of each component of the present invention, but the content of each component of the present invention is not limited to the numerical value listed in this table, for those skilled in the art, can fully Make reasonable generalizations and inferences based on the range of values listed in the table.

[0086] Table 4: The mass percentage cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com