Control method of monitored parameters under working condition of high-backpressure heating

A control method and high back pressure technology, which are applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of low energy saving and economic benefits, cumbersome operation steps, and high implementation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

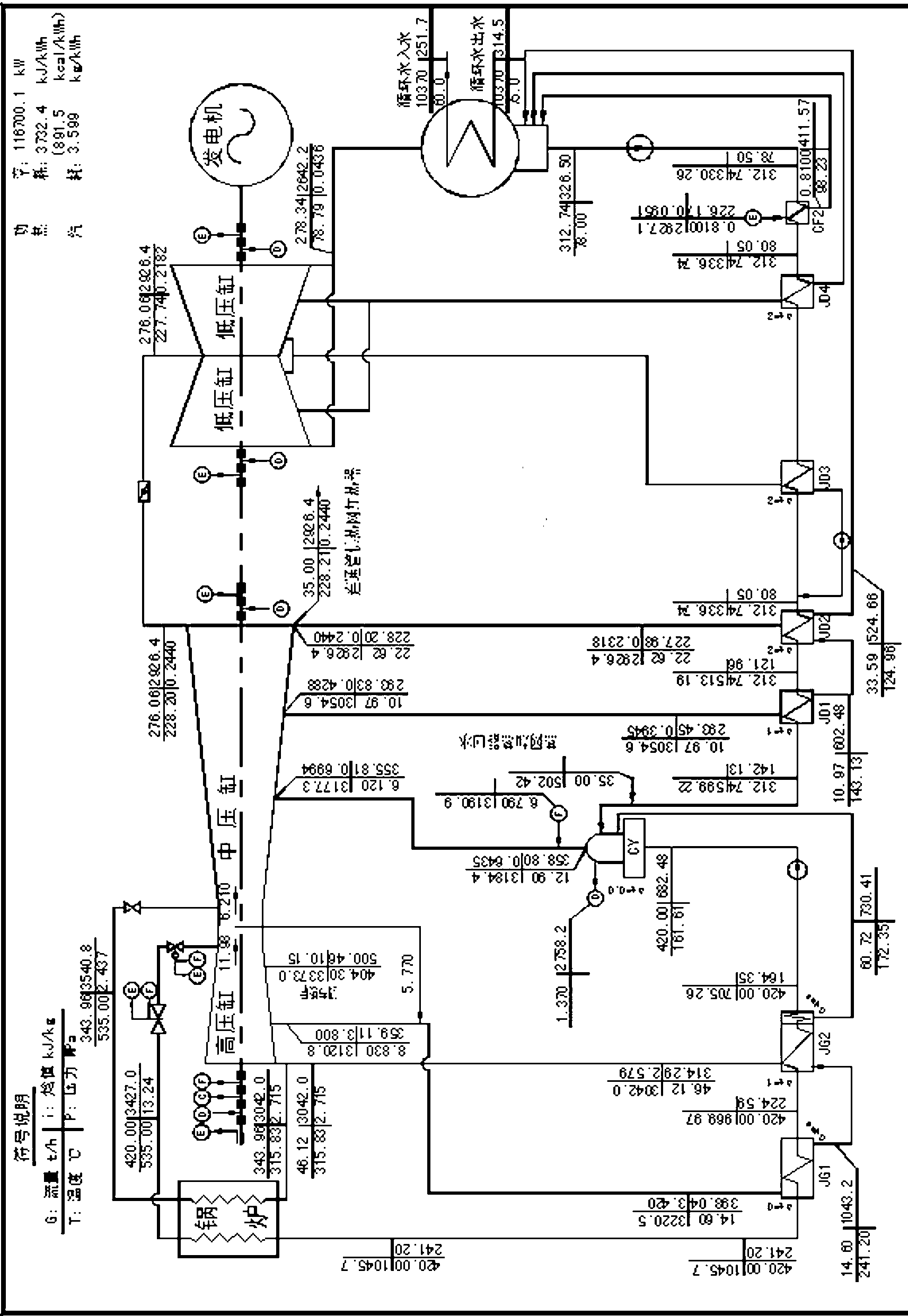

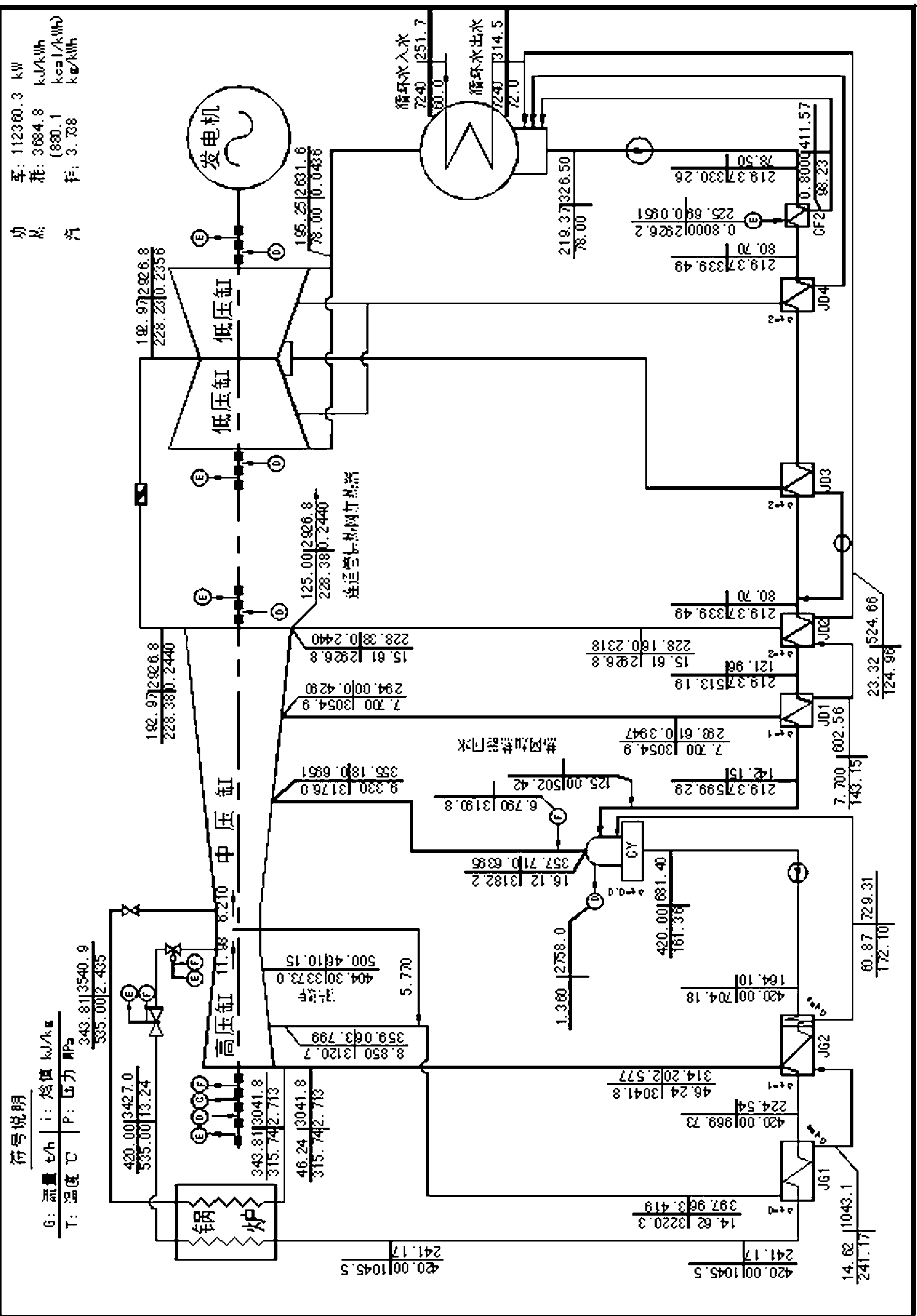

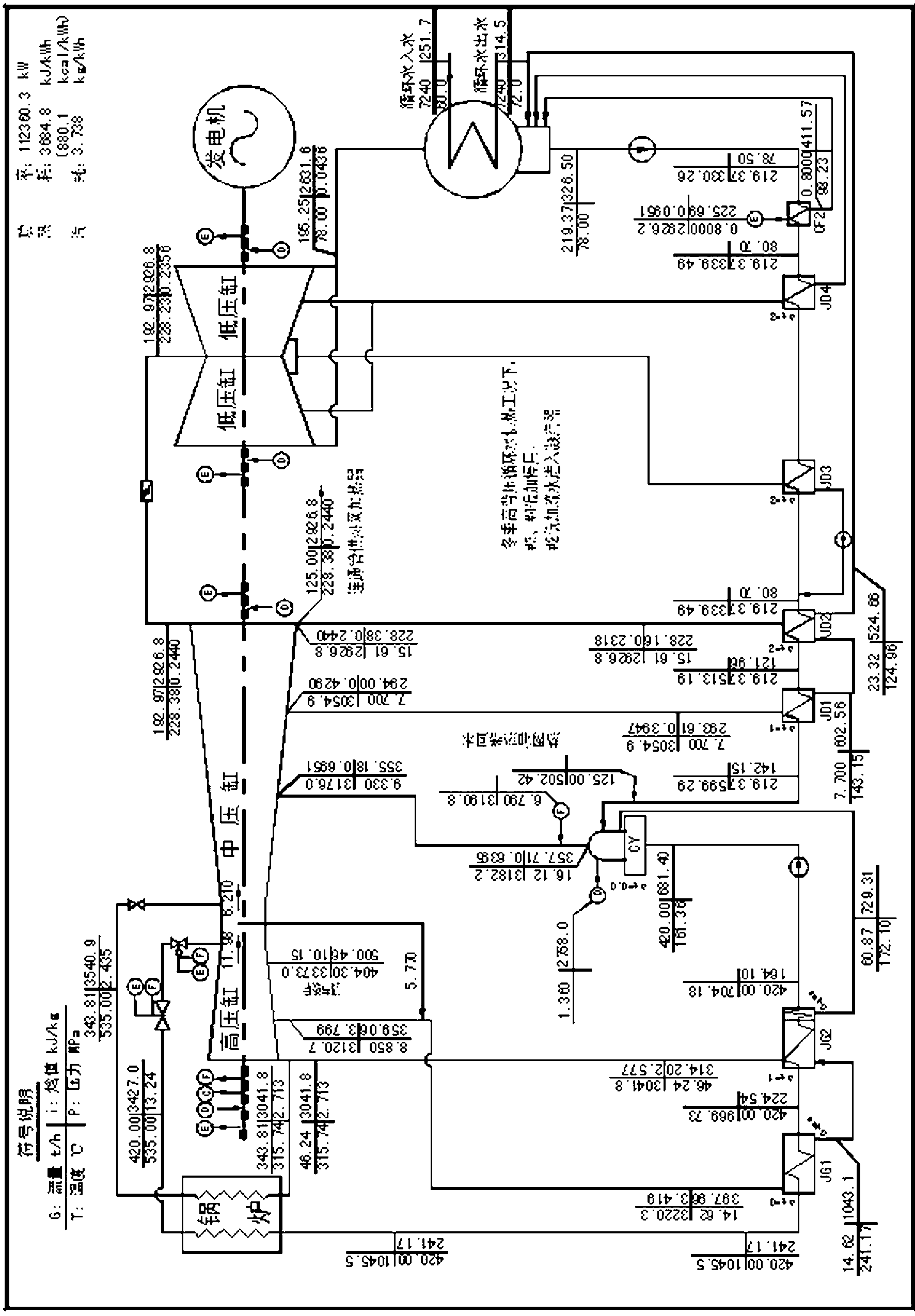

[0032]The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. The correspondence between constituent elements in the claims and specific examples in the embodiments can be exemplified as follows. The description herein is intended to confirm that specific examples used to support the subject matter stated in the claims are described in the embodiments, and since an example is described in the embodiments, it does not mean that the specific examples do not represent constituent elements. Conversely, even if a specific example is included here as an element characteristic corresponding to one constituent element, it does not mean that the specific example does not represent any other constituent element.

[0033] Furthermore, the description herein does not imply that all subject matter corresponding to specific examples set forth in the embodiments are recited in the claims. In other words, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com