Cold volume governing system for regionally concentrated cold supply second-stage cold volume exchange station

A technology for centralized cooling and regulating systems, applied in heating and ventilation control systems, heating and ventilation safety systems, household heating, etc. Low-level problems, to achieve the effect of reducing latent heat load cooling capacity consumption, reducing indoor water loss, and avoiding low ambient humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

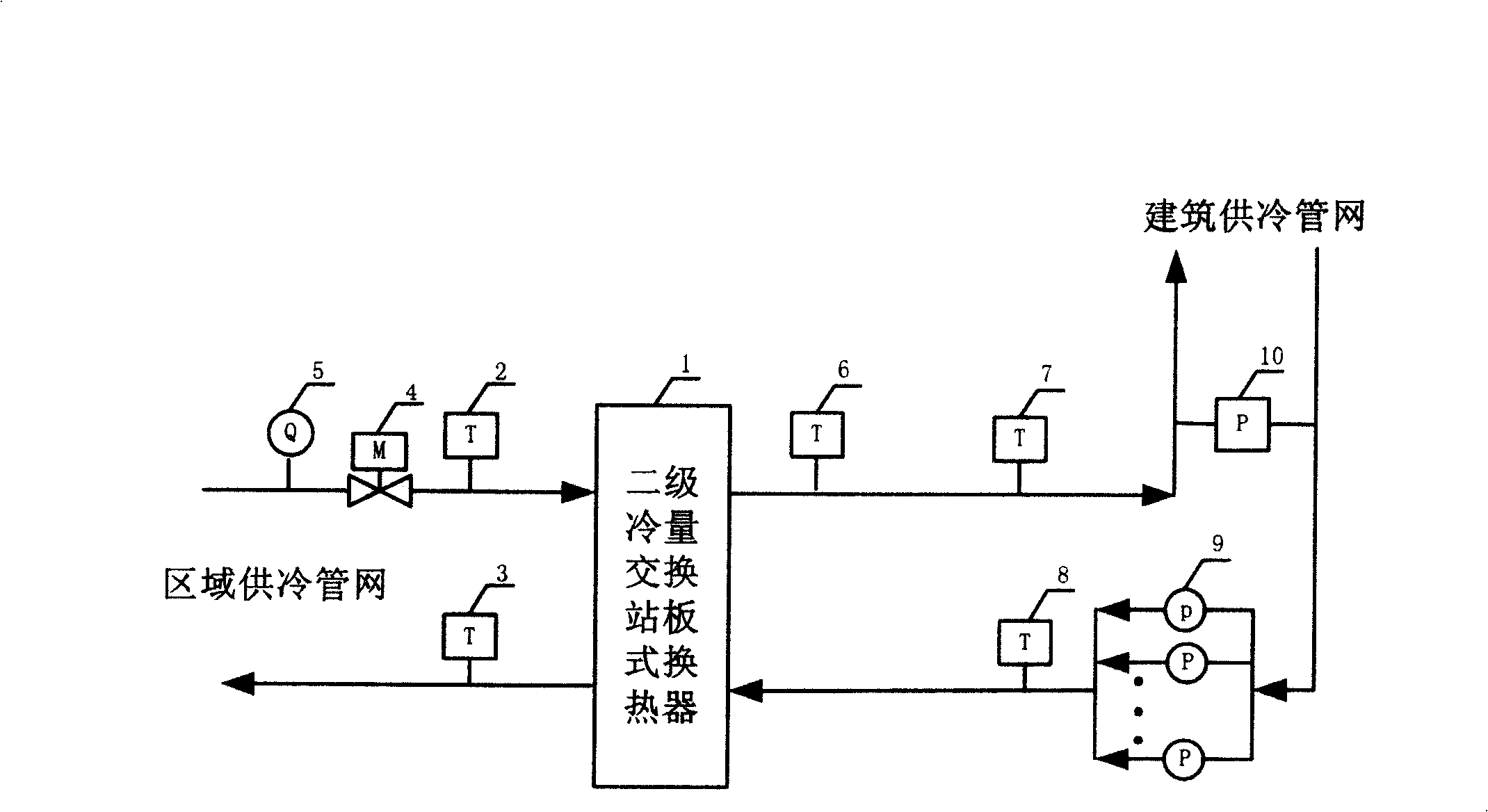

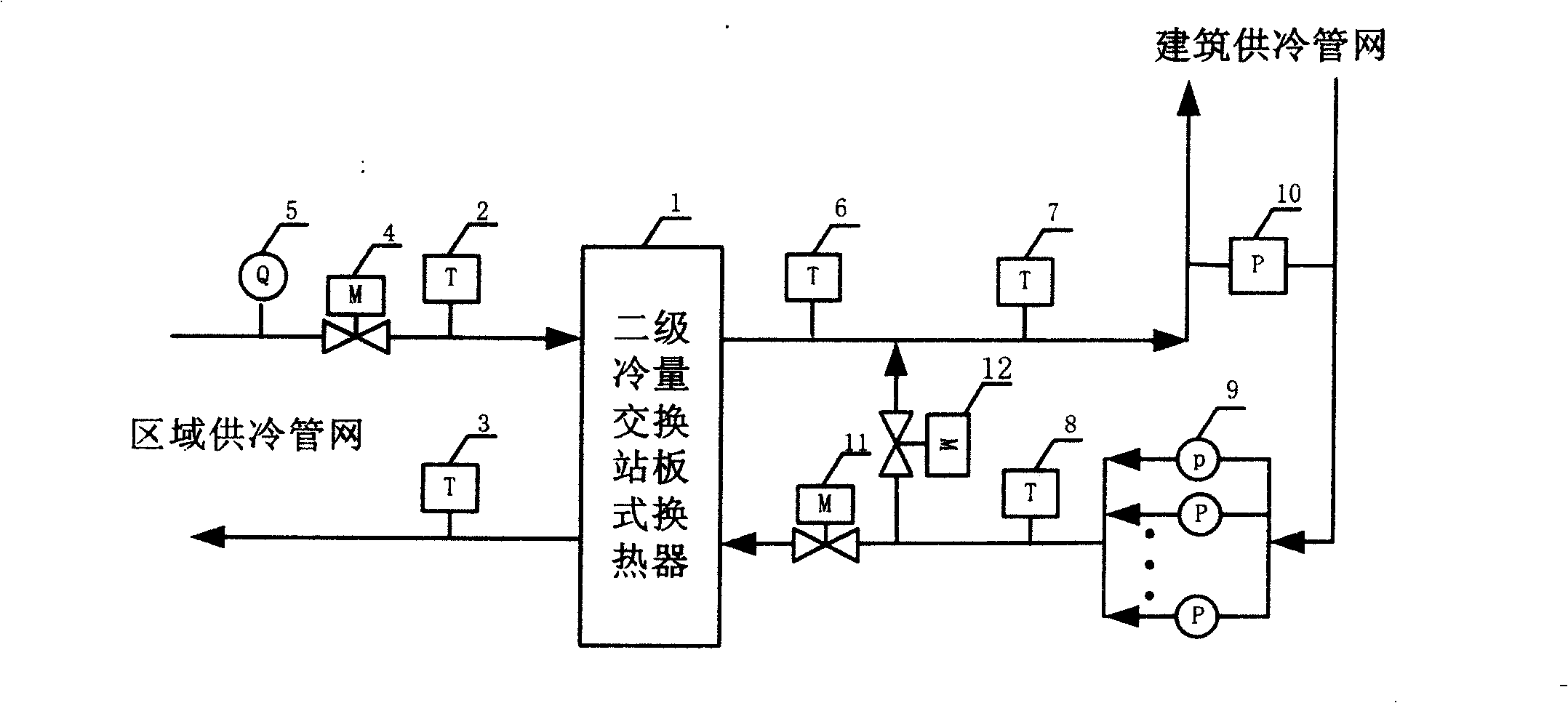

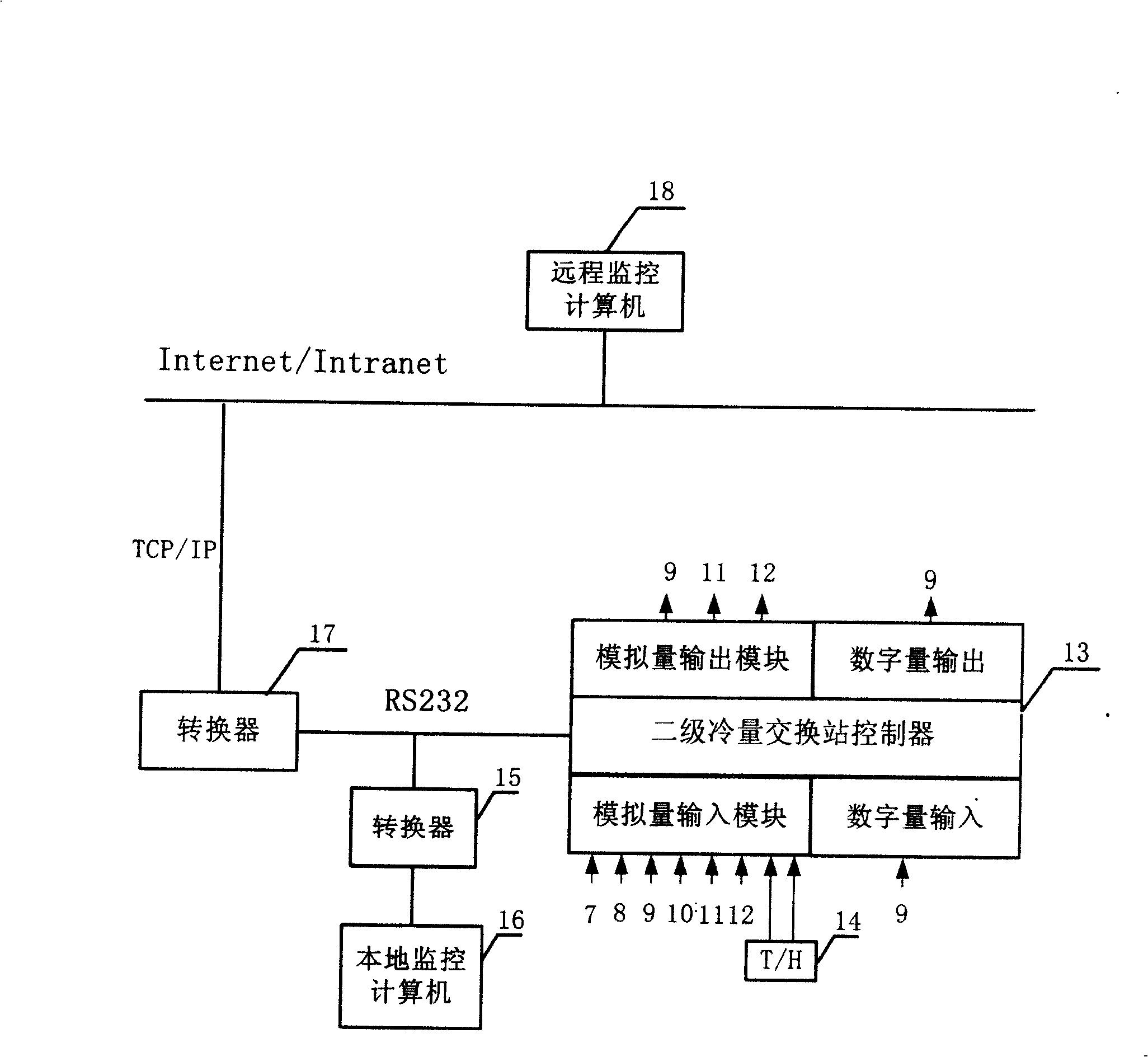

[0027] Such as figure 1 As shown, the traditional regional centralized cooling secondary cooling capacity exchange station consists of the secondary cooling capacity exchange station plate heat exchanger 1, the secondary cooling capacity exchange station plate heat exchanger primary side water supply temperature sensor 2, the secondary cooling capacity exchange Primary side outlet water temperature sensor of station plate heat exchanger 3, primary side water supply flow regulating valve of secondary cooling capacity exchange station plate heat exchanger 4, primary side water supply flowmeter of secondary cooling capacity exchange station plate heat exchanger 5, secondary cooling Water outlet temperature sensor on the secondary side of the plate heat exchanger in the quantity exchange station 6. Water supply temperature sensor for the cooling pipe network of the building with cold storage 7. Return water temperature sensor for the cooling pipe network of the cold building 8. Fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com