A magnetic suspension bearing

A magnetic levitation bearing and magnetic pole technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve problems affecting normal use, equipment overheating damage, rotor overheating, etc., to reduce eddy current loss, heat generation, and work efficiency Improvement, simple structure and easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

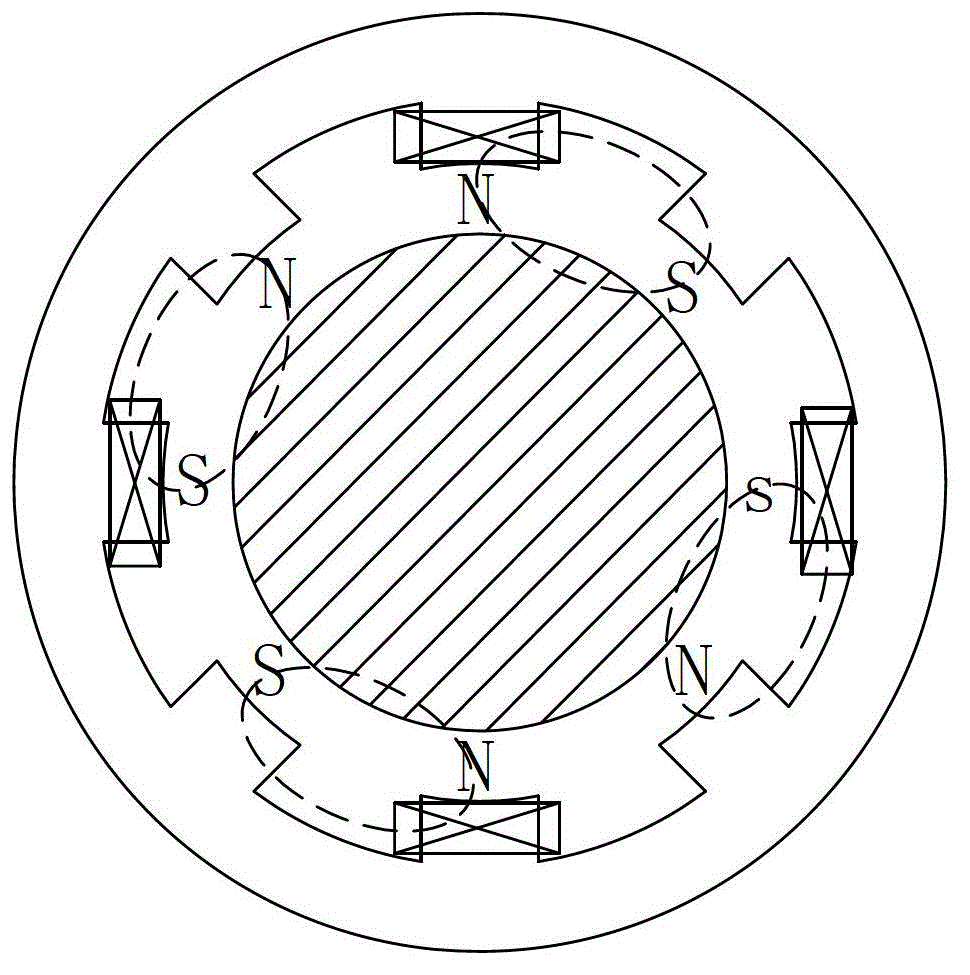

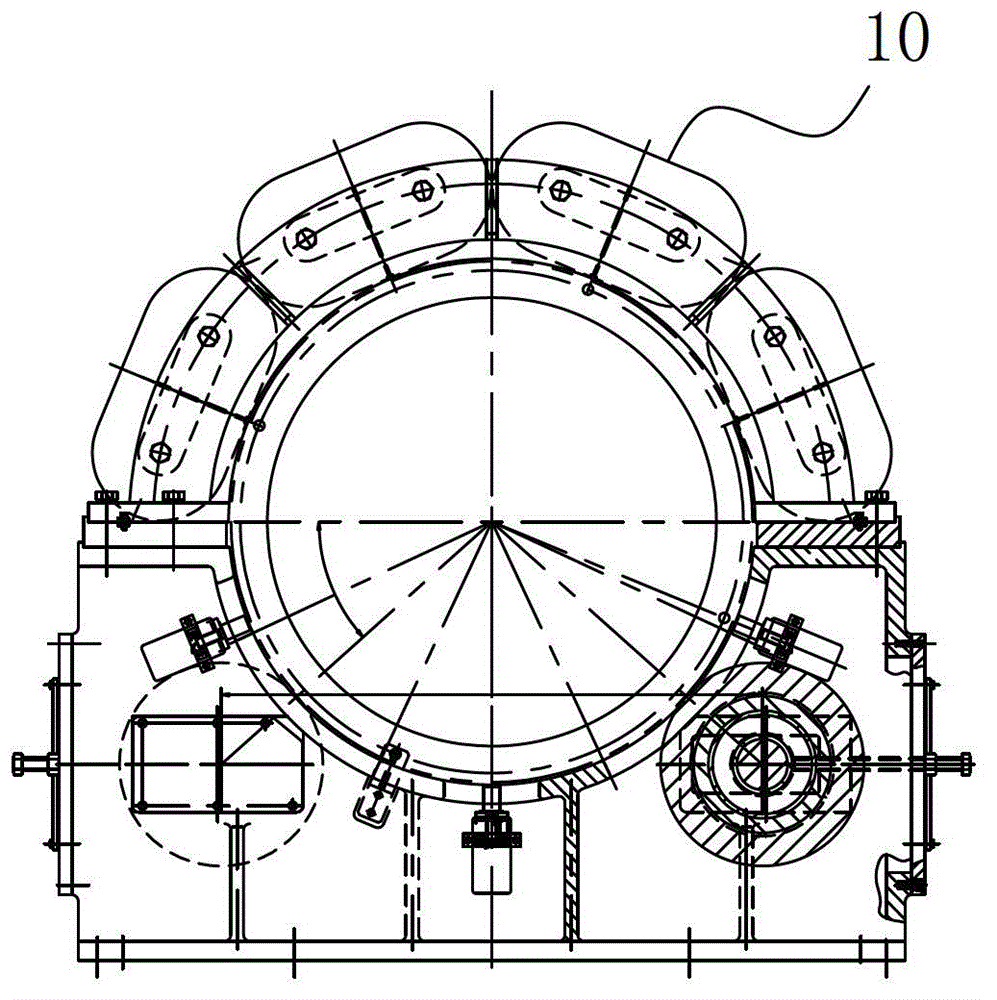

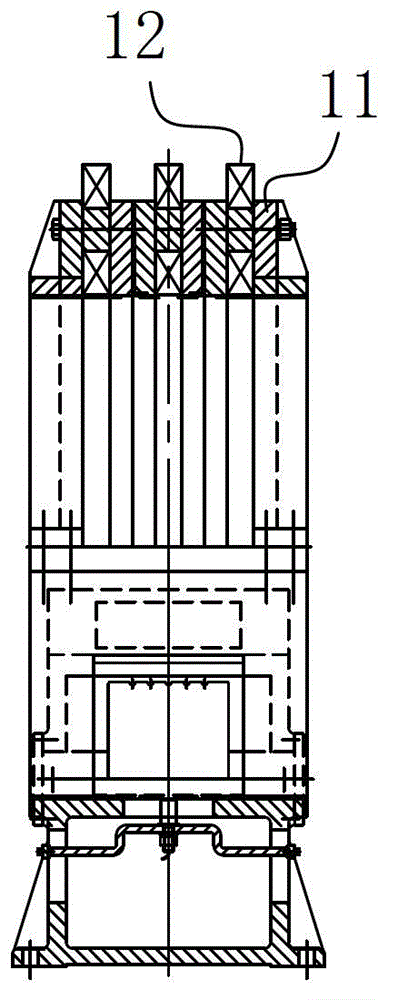

[0012] A magnetic suspension bearing, including a rotor and a stator assembly adapted to it, forming a suspension cooperation relationship between the two; the stator assembly includes a magnetic pole unit 10 on it for forming the rotor suspension power, and the magnetic pole unit 10 The arrangement direction of the N and S poles is set in the same direction as the axial length direction of the stator assembly.

[0013] The actual structure of the present invention is as Figure 2-6 As shown, by abandoning the traditional placement method of arranging the N and S poles of the magnetic pole unit 10 along the radial direction of the stator assembly, it breaks through the abnormal arrangement structure in which the N and S poles are arranged in the same direction as the axial length of the stator assembly , thereby ingeniously playing the unique effect of avoiding the frequent conversion of magnetic poles when the rotor is working; in actual operation, on the one hand, due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com