Throttling type bell-spigot no-pad connecting pipe material

A technology for connecting pipes and pipes, applied in the direction of pipe connection layout, pipe/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of increased use cost, difficult construction, increased transportation cost, etc., to improve work efficiency, connection and installation. Fast and convenient, the effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

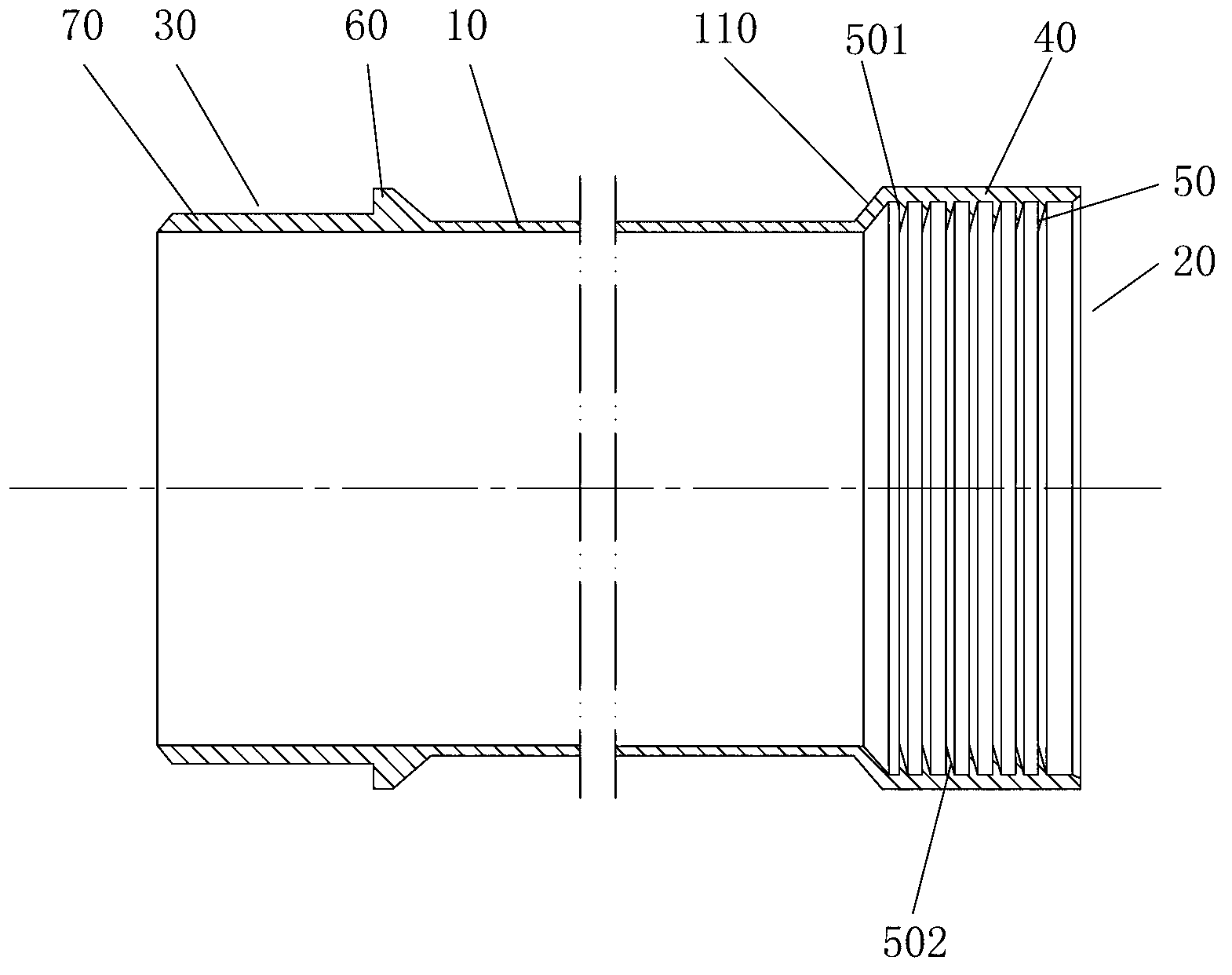

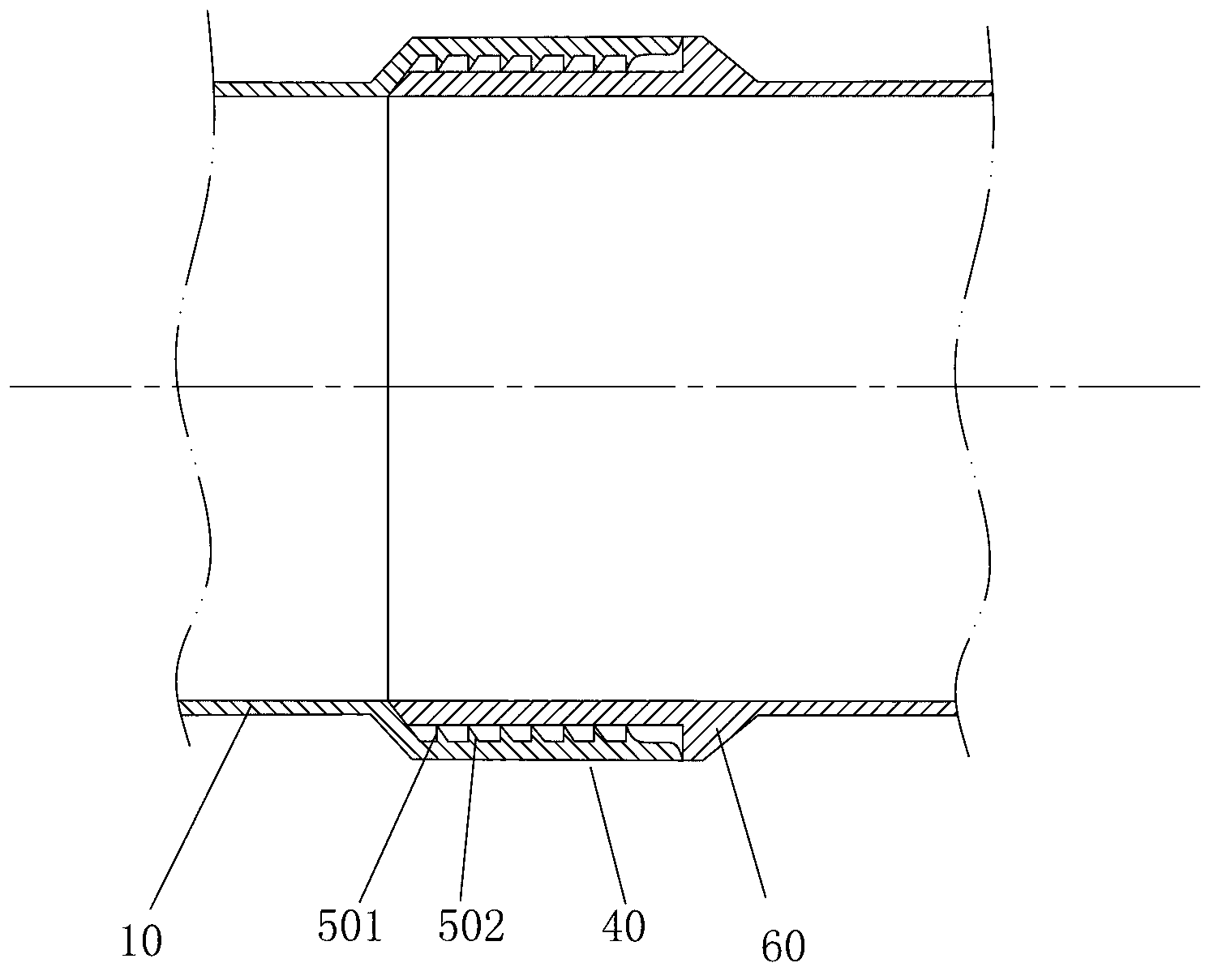

[0027] Embodiment 1: see figure 1 —4:

[0028] A throttling-type socket-and-socket-free connection pipe, in which a socket 20 is provided at one end of the pipe 10, and a socket 30 that can be plugged and connected with the socket 20 is provided at the other end, and the socket 20 is provided at one end of the pipe 10. Reaming part 40, the inner diameter of reaming part 40 is larger than the inner diameter of pipe material 10, on the inner surface of reaming part 40, several independent annular rings 50 are axially spaced, and the socket 30 is at the other end of pipe material 10 The outer surface of the outer surface is provided with an annular convex edge 60 which acts as a limiter. The annular convex edge 60 extends outwards with an insertion part 70. The outer diameter of the insertion part 70 is closely matched with the inner diameter of the independent annular ring 50 on the socket 20. Generally an interference fit.

[0029] The above-mentioned reaming portion 40 and t...

Embodiment 2

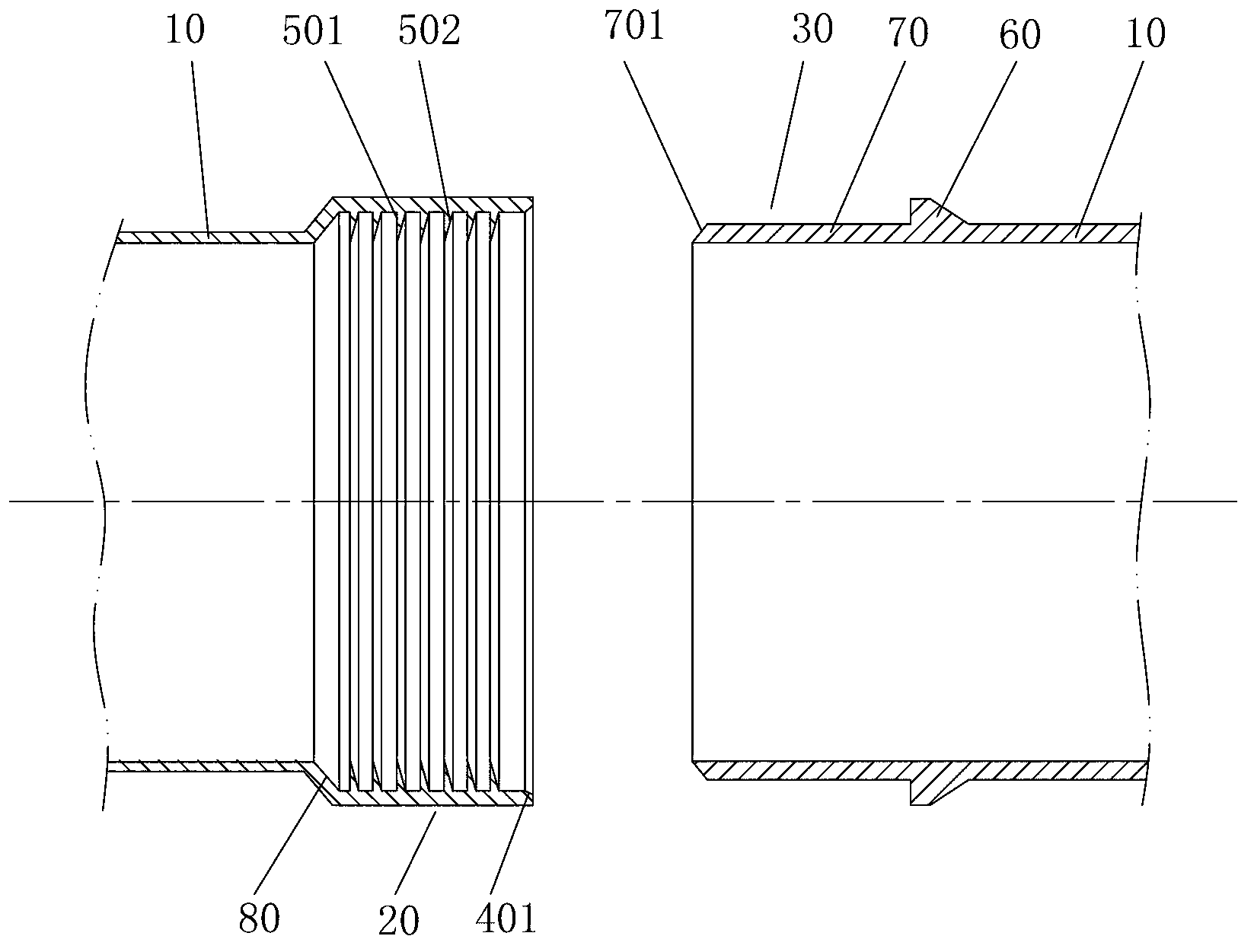

[0041] Example 2: see Figure 5 -7:

[0042] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0043] The socket 21 is: a reaming part 41 is provided at one end of the pipe material 11, and the inner diameter of the reaming part 41 is larger than the inner diameter of the pipe material 11; The annular protruding edge 61 of the position function, the annular protruding edge 61 extends outwards with a plug-in part 71, on the outer cylindrical surface of the plug-in part 71, several independent annular protruding rings 51 are axially spaced, and the independent annular protruding rings 51 The outer diameter is closely matched with the inner diameter of the socket 21, generally an interference fit.

[0044] The cross-section of the independent annular bead 51 is a right triangle or a right trapezoid, its vertical surface 511 faces the pipe 11 , and its conical surface 512 faces the outer end surface of the insertion part 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com