T91-steel ageing ranking method based on transmission electron microscope

An electron microscope and aging test technology, applied in the preparation of test samples, material analysis using wave/particle radiation, instruments, etc., can solve the problems of inaccurate statistical processing, inaccurate statistical results, inaccurate quantitative objects, etc., to achieve Avoid size gaps and evaluate the effect of reasonable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation of the present invention will be described in detail below. The samples mentioned below include the samples to be graded and the original samples.

[0050] The present invention is based on the T91 steel aging rating method of the transmission electron microscope, and its specific implementation is as follows:

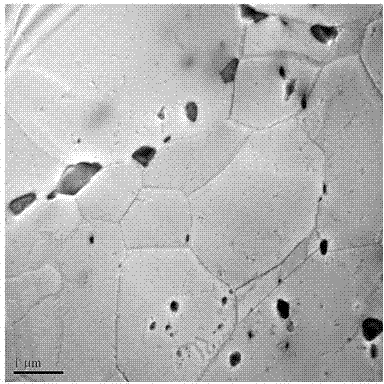

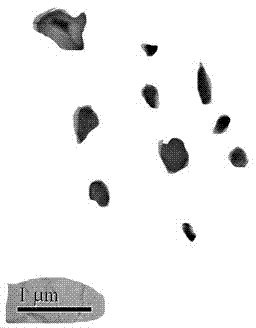

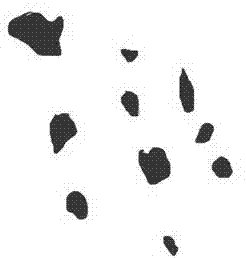

[0051] Step 1. Obtain the transmission electron microscope images of the sample to be rated and the original sample.

[0052] This step in turn includes the following sub-steps:

[0053] 1.1 Obtain the sample

[0054] Samples are taken from different positions of the components to be rated to obtain samples to be rated, and the number of samples to be rated is not less than 2. Obtain original specimens from the same as-delivery product as the specimen material to be graded.

[0055] 1.2 Sample pretreatment

[0056] The samples to be rated and the original samples are pretreated separately, specifically:

[0057] The sample to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com