Contacting and rubbing device of nano-particle air film static-pressure thrust bearing

A technology of nano-particles and thrust bearings, applied in the direction of measuring devices, mechanical devices, instruments, etc., to protect the working surface and avoid severe sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

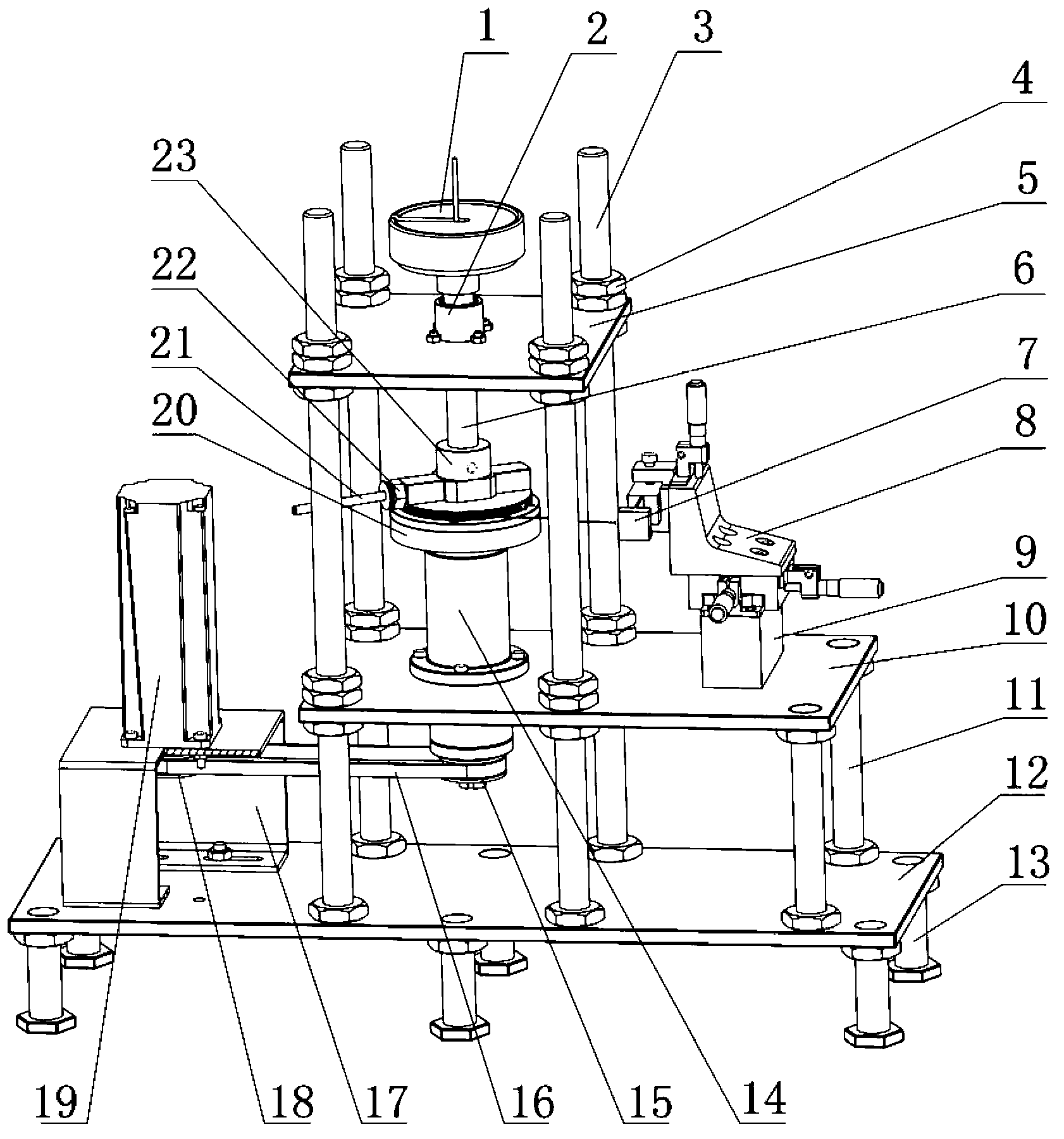

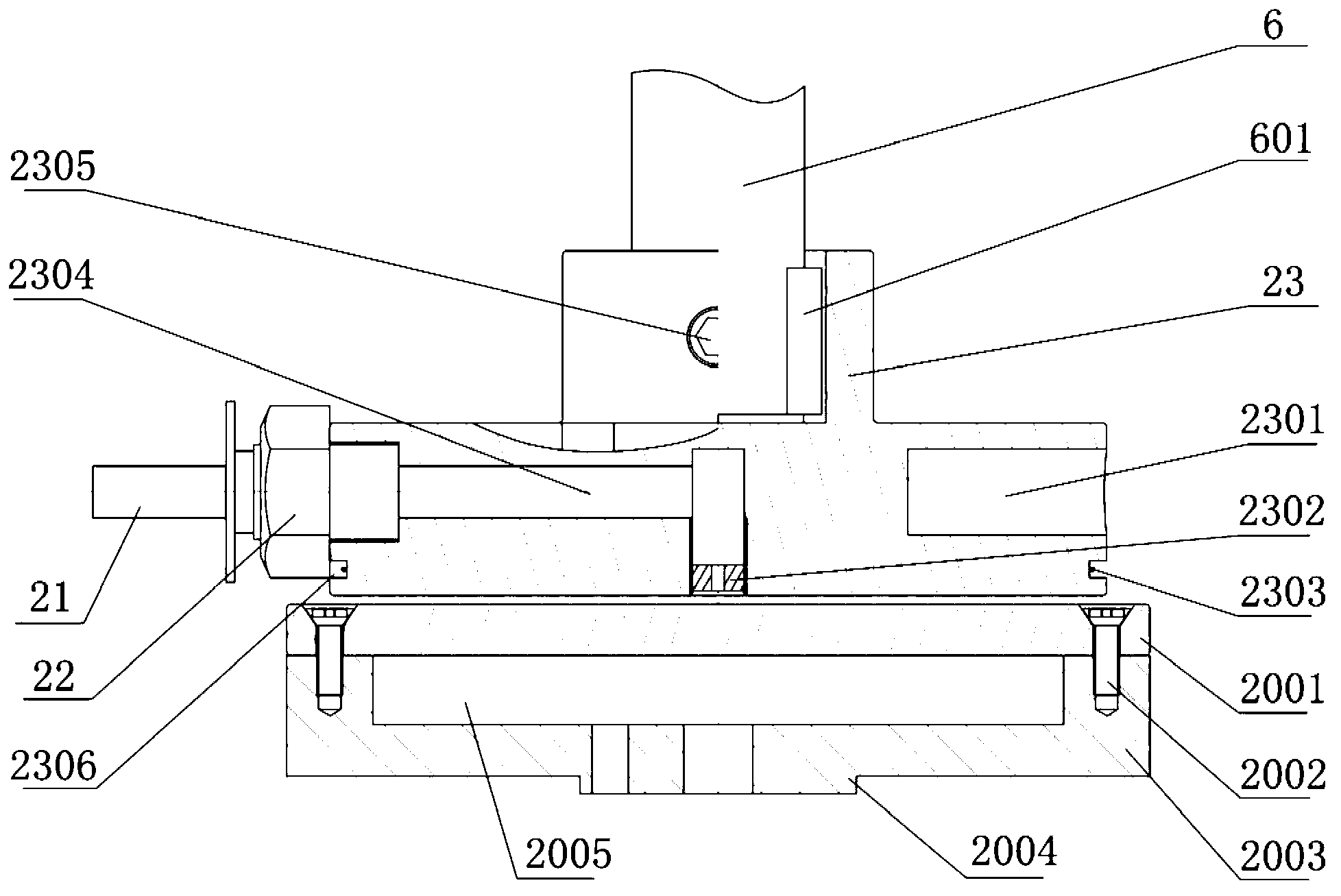

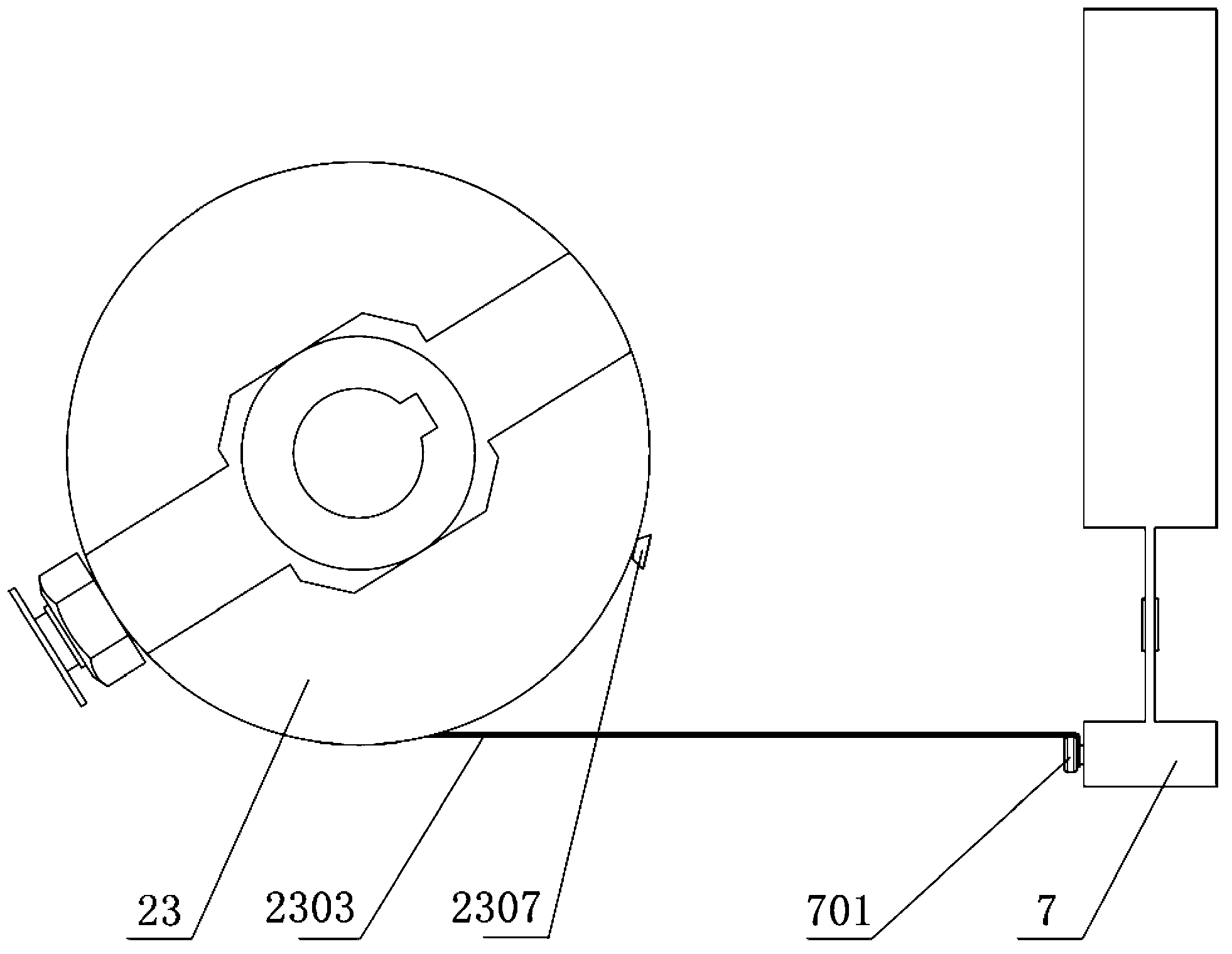

[0036] The nano particle air film static pressure thrust bearing contact friction device provided by the present invention includes a base frame, a bearing part, a loading mechanism 1 and a detection system, wherein the bearing part includes an upper bearing plate 23 and a lower bearing plate 2001, and the gas-nano The mixed air flow of particles enters the inside of the bearing through the upper bearing plate 23, making the upper bearing plate 23 float, and the lower bearing plate 2001 is installed on the high-precision transmission shaft 14, and then connected with the external servo motor 19 through the synchronous toothed belt 16; from the detection The flexible measuring line 2303 drawn from the system is installed on the upper bearing plate 23 . The device can simulate the contact and friction state of the nanoparticle air film static pressure thrust bearing, can change the bearing load and the bearing speed, and can measure the friction coefficient value between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com