Balancing take-up and winding method

A wire receiving and balancing technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of scrapped wires, stoppage of the entire production line, and broken wires, so as to improve the quality of wires and avoid heavy labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

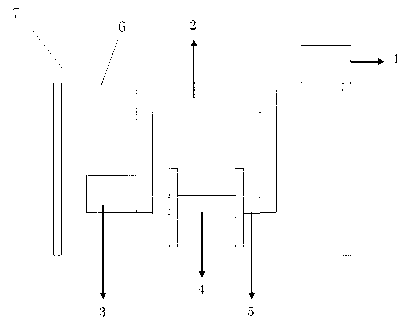

[0015] A kind of balanced take-up method, see figure 1 , the specific steps of the method are as follows:

[0016] 1) Install the wire reel 4 on the wire reel frame 7, the wire reel frame 7 includes the left and right traction motor 1, the slide rail type suspension body 2, the rotating traction motor 3, the rotating shaft 5 and the gantry frame 6, and the left and right traction motors are arranged on the gantry on the frame; the slide rail type suspension body is suspended on the beam of the gantry frame and slides along the beam under the drive of the left and right traction motors; the rotating traction motor is set on the slide rail type suspension body, and the reel 4 is set on the slide rail through the rotating shaft 5 On the type suspension body 2, the rotating shaft that can be adjusted up and down along the slide rail type suspension body is connected to the rotary traction motor; a slide rail is provided at the lower end of the beam of the gantry frame, and a slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com