Method for processing a structured surface of an embossing tool

A kind of embossing tool and structuring technology, which is applied in the field of processing the surface of embossing tools, can solve the problem of high cost of cleaning work, and achieve the effect of improving the appearance impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

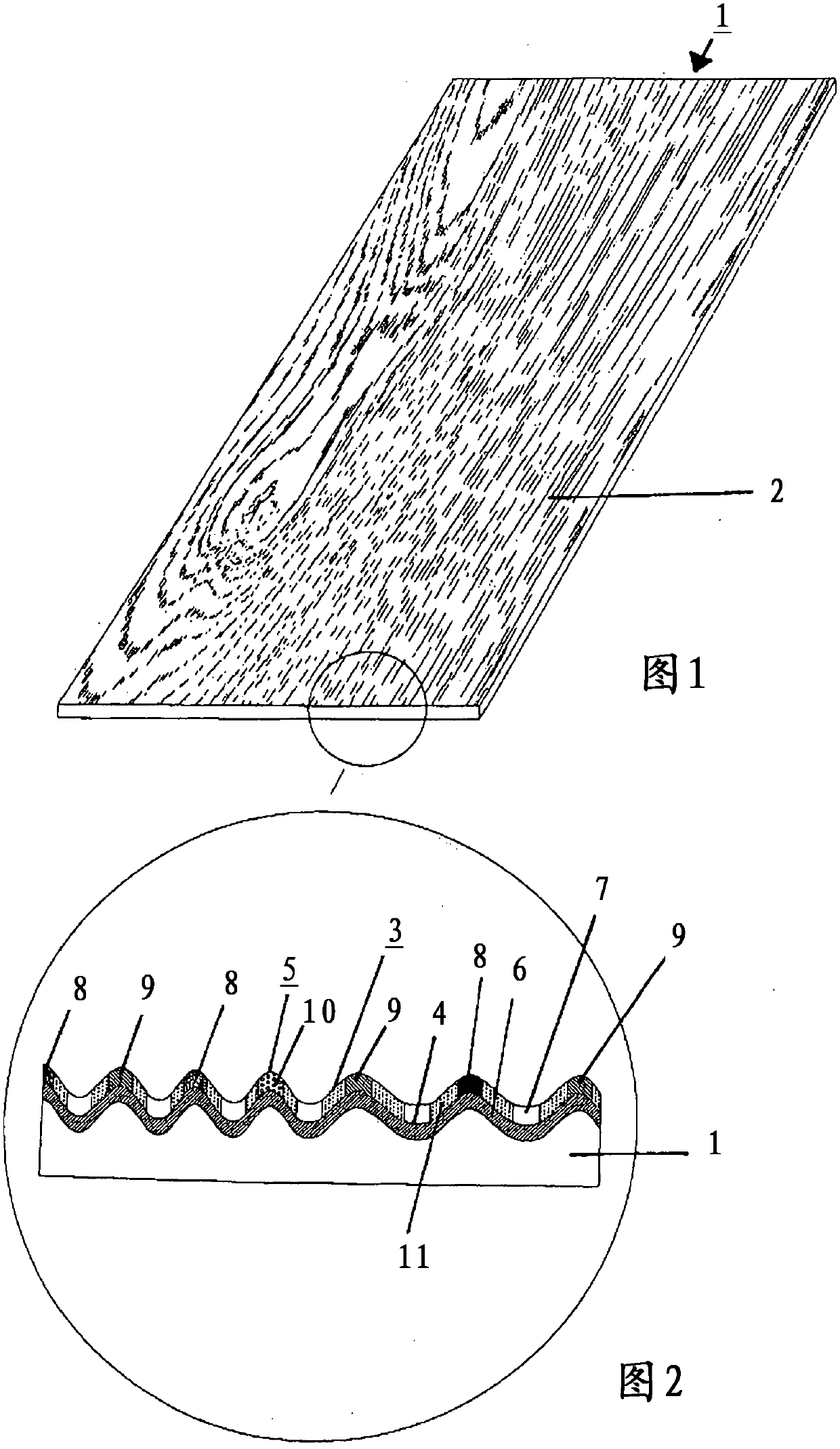

[0155] figure 1 A perspective view of an extruded plate 1 according to the invention is shown, which is designed to be flat in the exemplary embodiment shown. In the case of endless belts, however, the embossing tool can also be curved. The extruded board 1 shows a grain 2 which imitates the shape of a wooden structure. However, it is conceivable to produce other textures or other surface properties in this way by means of the method according to the invention and the etching method required for this.

[0156] figure 2 Shown is an enlarged side view of a part of the front edge region of the extruded plate 1 and a structure 3 lying thereon, which has a mountain-like surface with a plurality of recesses 4 and elevations 5 . In this case, the surface is produced by one or more etching processes, whereby the form is first coated in a standard manner or digitally with printing techniques, the regions that are not to be subjected to the etching process being masked. For example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com