Method for evaluating the installation of blind rivets, method and system for installing blind rivets, method and system for obtaining a pattern, and aircraft

A technology of blind rivets and rivets, which is applied in the aircraft field and can solve problems such as rivet defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

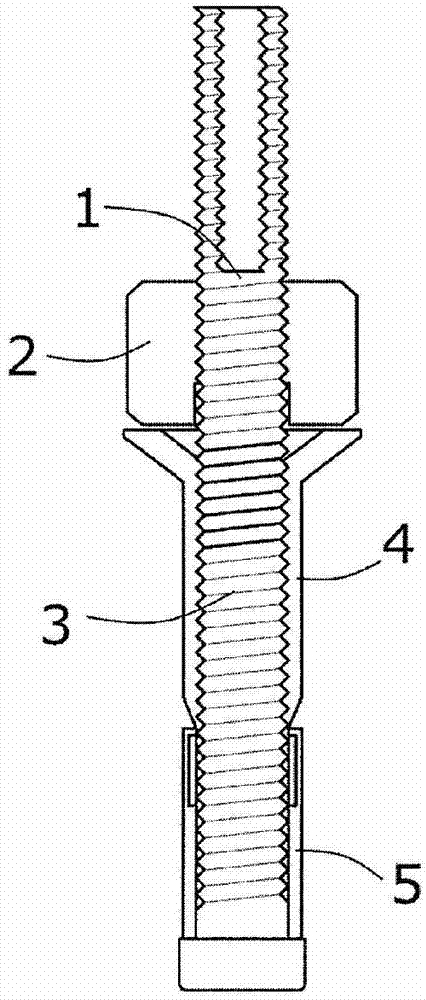

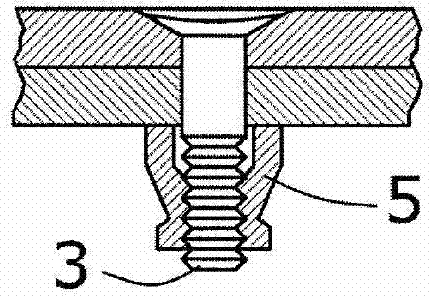

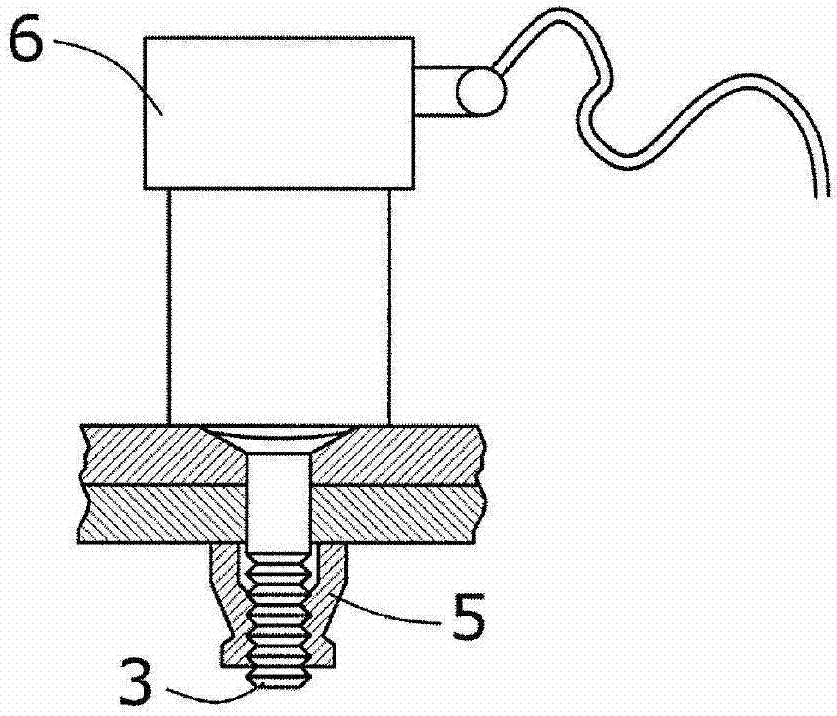

[0069] The present invention relates to a method for assessing the installation of blind rivets for use in joining closed structures or structures for which it is complex and costly to access "unexposed faces" to check that the rivets have been installed correctly. Examples of blind rivets are shown in figure 1 middle. In this figure a blind blind rivet with a countersunk head can be seen. The figure shows the different parts of the rivet: the stem 1 , the mounting nut 2 , the breaking notch 3 , the cut-off point 4 and the bushing 5 . figure 2 shows the installation in a structure of figure 1 rivet, where the bushing 5 is folded and can be seen abutting the structure to prevent the rivet from coming out. The length of the rivet is expressed as less than figure 1 Medium length, because rod 1 breaks.

[0070] A non-invasive method for evaluating the installation of rivets

[0071] In one embodiment, a non-invasive method for evaluating the installation of a blind rivet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com