Safe tool cabinet

A tool cabinet and safety technology, applied in the field of safety tool cabinets with rotating compartments, can solve the problems of screw design, time delay, messy placement of screws, nuts and other small parts, etc., to achieve easy movement and storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

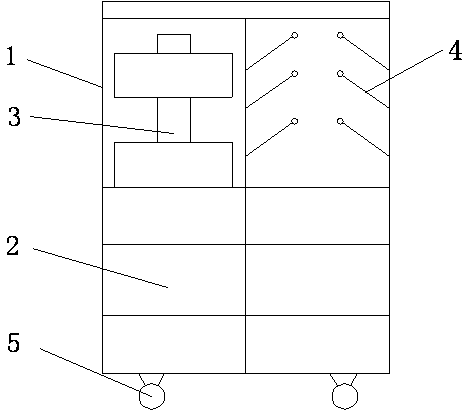

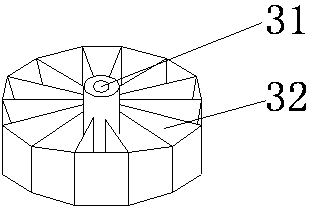

[0013] Such as figure 1 and figure 2 As shown, a safety tool cabinet includes a cabinet body 1, the cabinet body 1 is divided into an upper half and a lower half, the lower half is a multi-layer drawer structure, and a rotating compartment 3 is provided in the cabinet, Described rotating compartment 3 comprises a bottom plate that is fixed in the cabinet, and the middle position of described bottom plate is provided with a rotating shaft 31, and the rotating disk that rotates with this rotating shaft 31 as the center, on the rotating disk, the circumference of this rotating disk is even, spaced apart. A baffle is arranged, which evenly divides the turntable into several independent compartments 32 in the radial direction.

[0014] The upper part of the cabinet body 1 is also provided with a cavity, and at least one bracket is arranged on the left and right side walls of the cavity, and a plurality of hanging rods 4 arranged obliquely are arranged on the bracket.

[0015] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com