Parallel wire extruding auxiliary mould

An auxiliary mold and wire technology, which is applied in the field of parallel wire extrusion auxiliary molds, can solve the problems of easy dislocation of arrangement and irregular product shape, and achieves the effects of simple structure, easy processing and diverse material selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

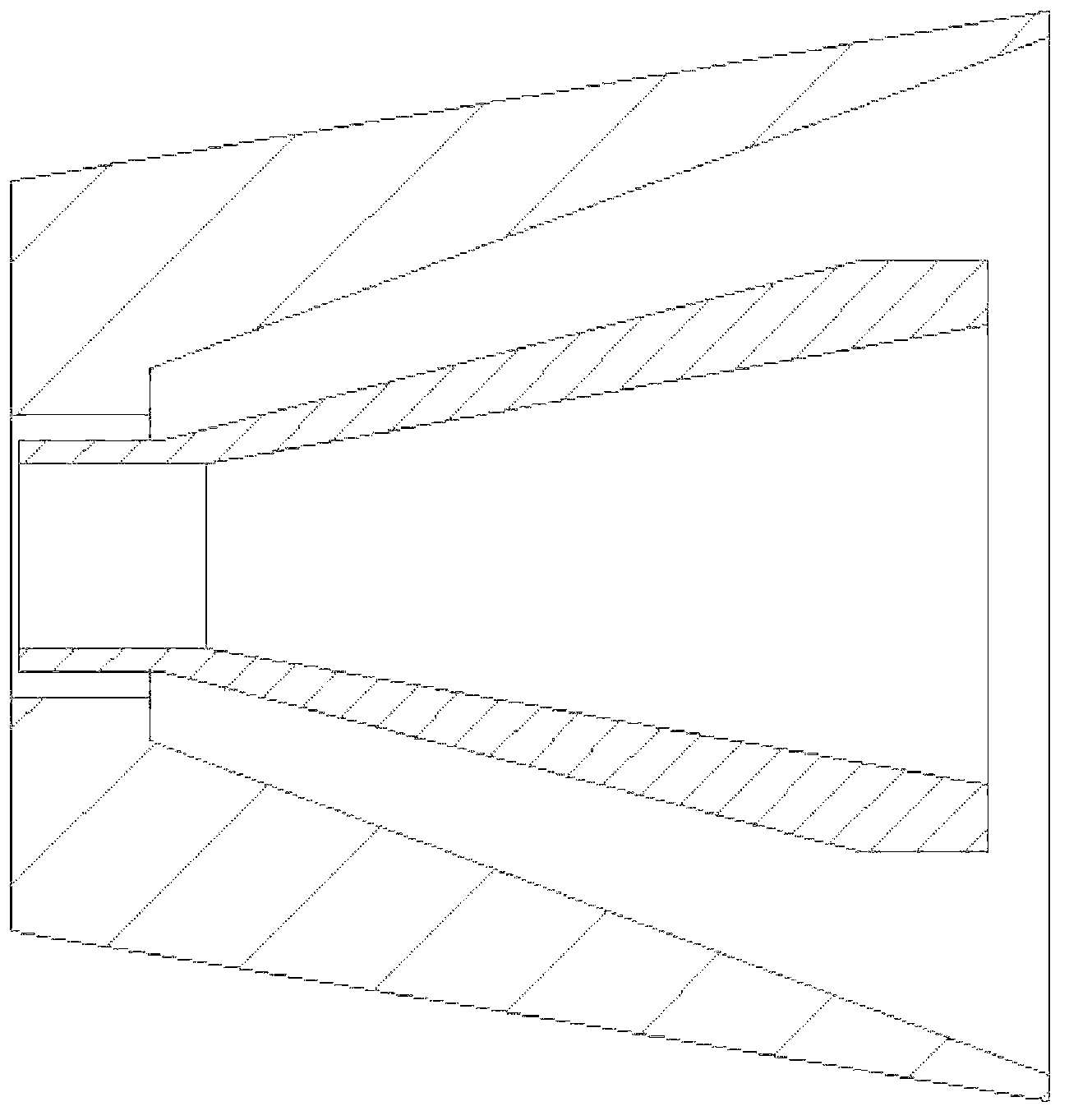

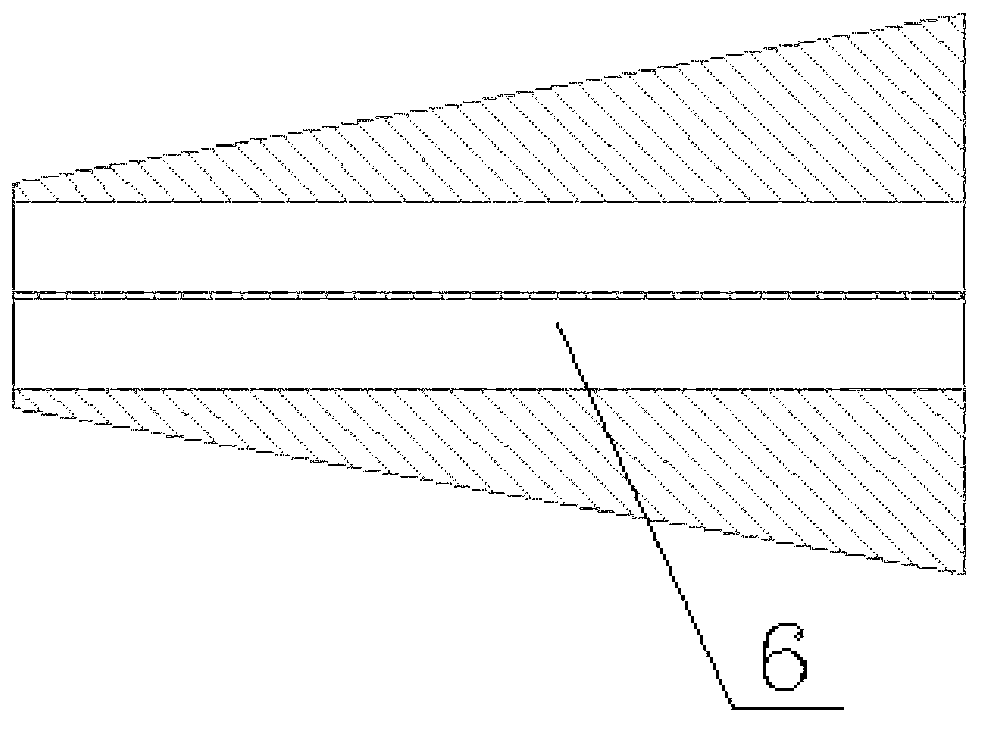

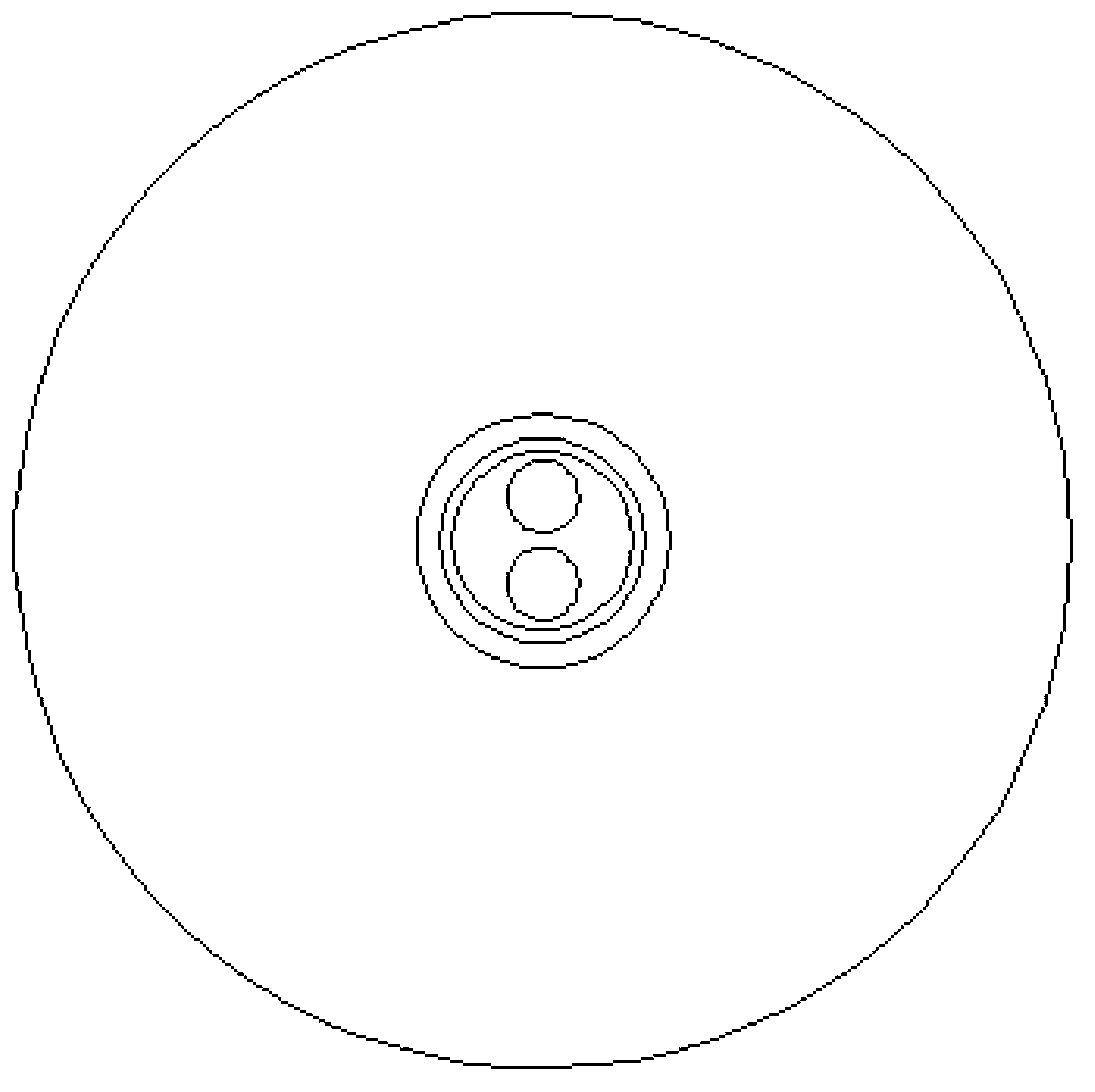

[0017] Such as Figure 2 ~ Figure 4 As shown, a parallel wire extrusion auxiliary mold includes a conventional cable mold cover 2, an auxiliary mold core 3, a conventional cable mold core 5, and a threading hole 6. The inner cavity of the conventional cable mold cover 2 is covered with a conventional Cable mold core 5, an extrusion sheath 1 is also installed on the gap between the conventional cable mold core 5 and the conventional cable mold sleeve 2, the cavity of the conventional cable mold core 5 is a tapered hole, and the tapered hole An auxiliary mold core 3 is set inside, and a plurality of threading holes 6 parallel to each other are evenly opened on the auxiliary mold core 3 .

[0018] The tapered hole of the auxiliary mold core 3 corresponding to the inner cavity of the conventional cable mold core 5 is a cone and the apex of the cone is flattened into a circular surface.

[0019] The described threading hole 6 is used for threading the cable core 4 .

[0020] Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com