Closed-type press clutch gas inlet sealing mechanism

A sealing mechanism and clutch technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as poor sealing effect and poor sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

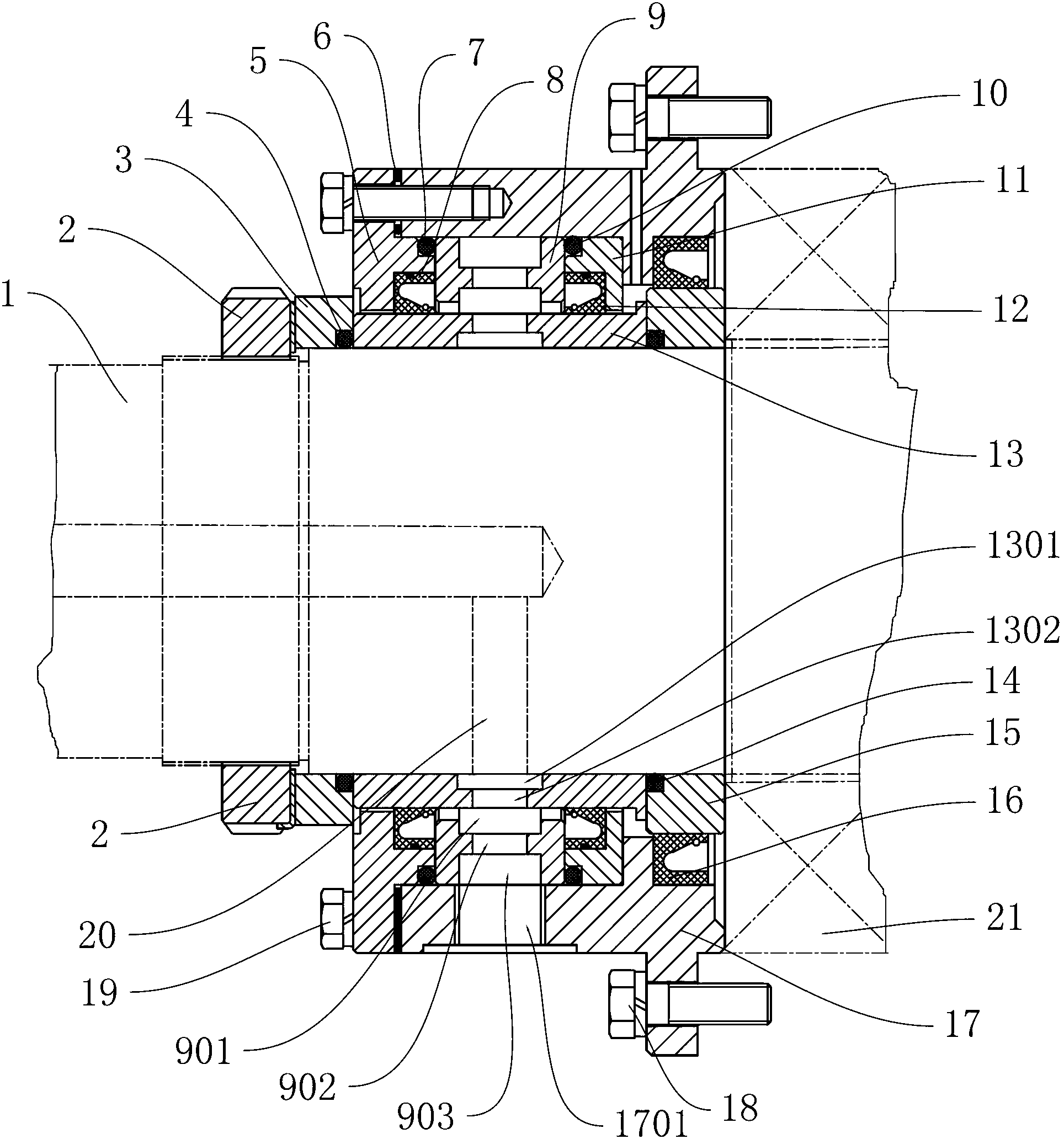

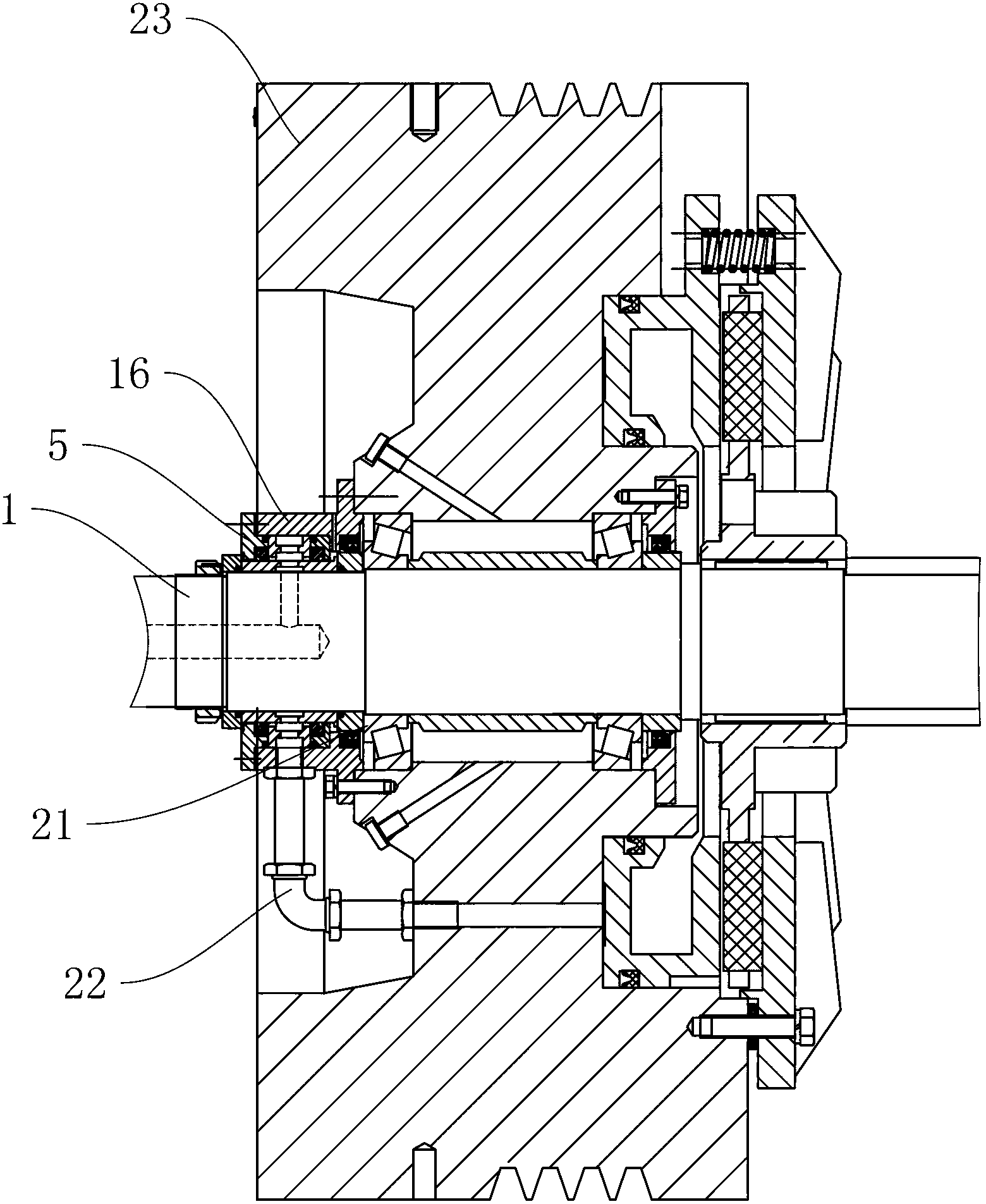

[0024] Such as figure 1 and figure 2 As shown, a closed press clutch air intake sealing mechanism includes a support sleeve 13 installed on the clutch transmission shaft 1, and the support sleeve 13 is provided with a vent hole 20 matched with the clutch transmission shaft 1 in the circumferential direction. The air outlet channel of the support sleeve 13, the first pressure sleeve 15 and the second pressure sleeve 3 are pressed against the two sides of the support sleeve 13 respectively, and the first pressure sleeve 15, the support sleeve 13 and the clutch drive shaft 1 are provided with The first O-shaped sealing ring 14, the second O-shaped sealing ring 4 is arranged between the second pressure sleeve 3, the support sleeve 13 and the clutch transmission shaft 1, through the first O-shaped sealing ring 14 and the second O-shaped sealing ring The ring 4 seals the gap between the clutch transmission shaft 1 and the support sleeve 13 to prevent air leakage from here. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com