Support

A support frame and support part technology, applied in the field of support frames, can solve problems such as space occupation and easy breakage of positioning devices, and achieve the effect of strong support structure, simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

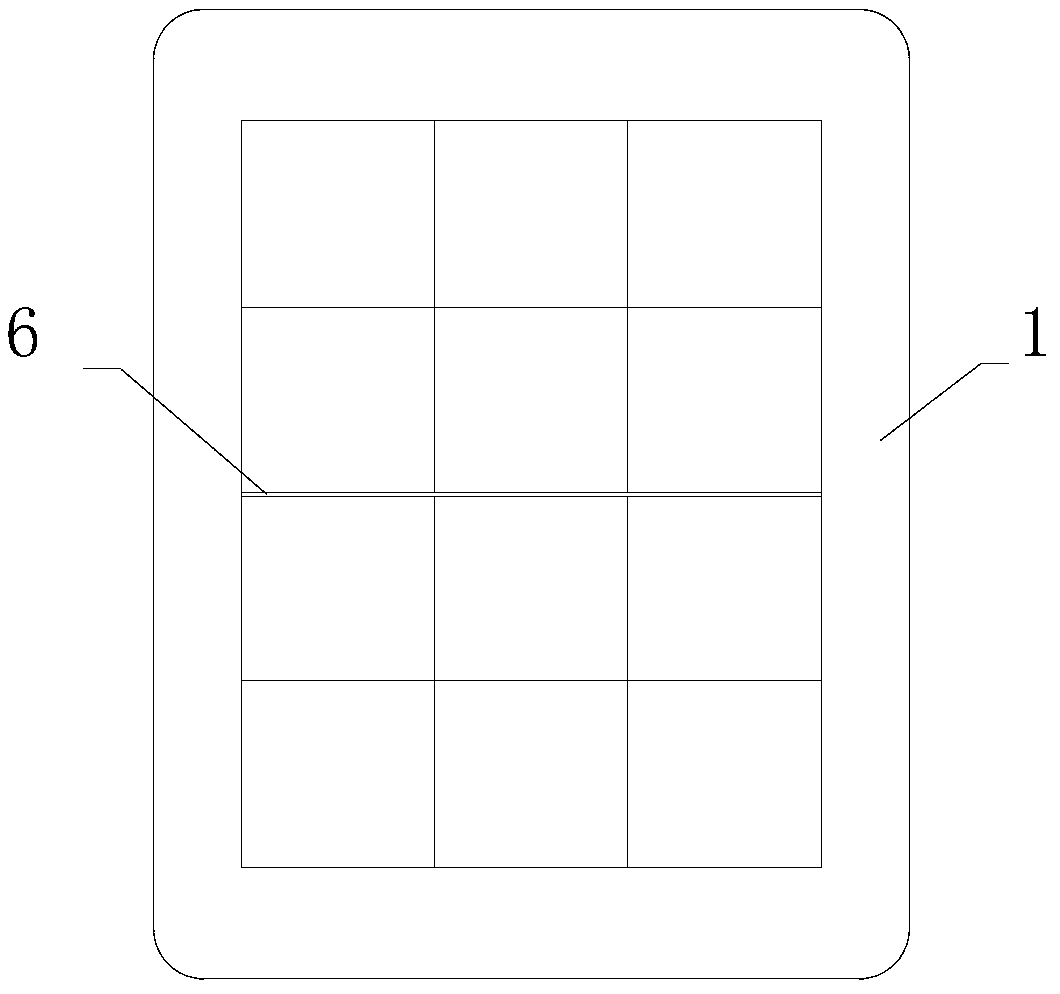

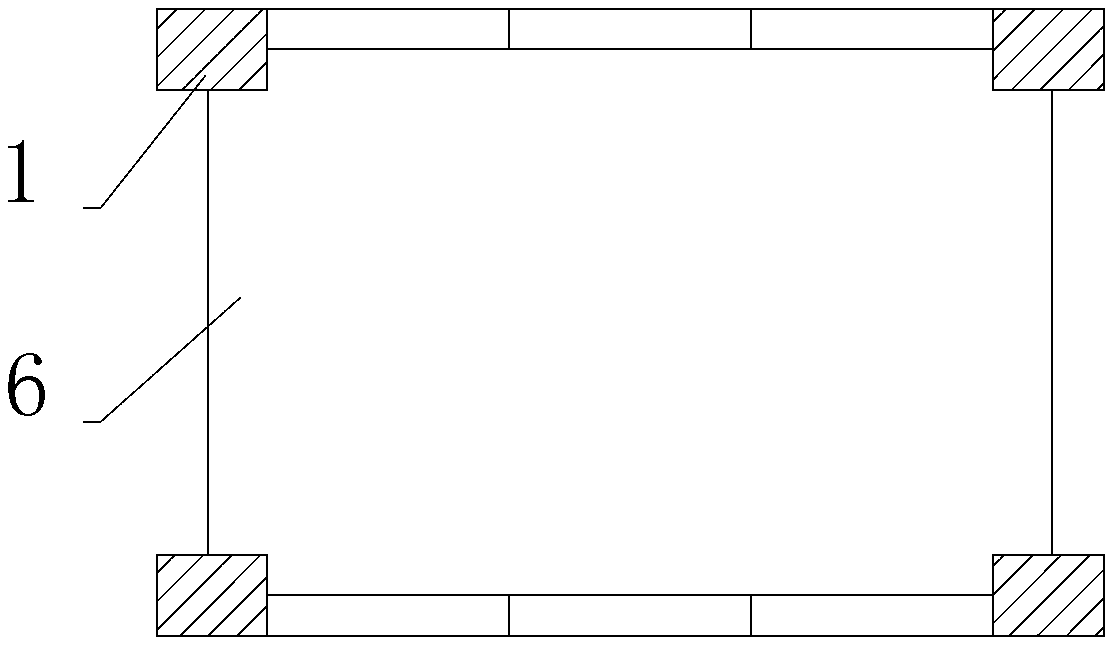

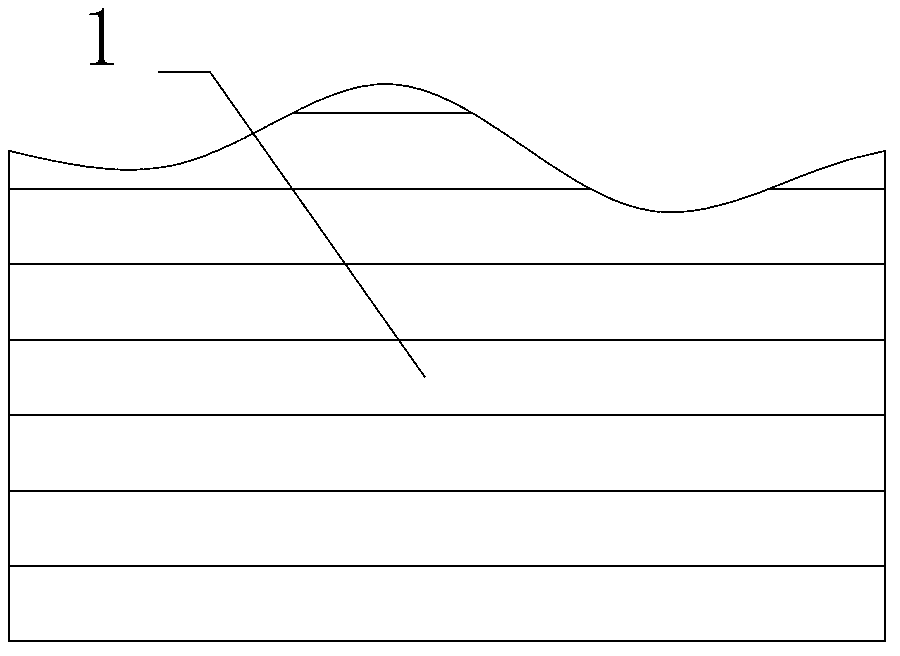

[0021] Such as Figure 4 , 5 Support frame shown is die cut from corrugated cardboard. The supporting frame is provided with a positioning part I2, a wrapping part I3 and a supporting part I4, and the three are connected as a whole and are distinguished by a crease line 5 between the three. The positioning part I2 has a rectangular structure as a whole, and the side lengths of two opposite sides are longer than the side lengths of the other opposite two sides, forming a rectangular shape. The wrapping part I3 is also in the shape of a rectangle, and is distributed on four sides of the positioning part I2. The support part I4 is also rectangular in shape, and the support part I4 is provided with two parallel crease lines 5, so that the support part I4 has a three-stage structure, and the support part I4 is also distributed on four sides of the positioning part support part I4. On either side of the positioning part I2, the crease line 5 between the wrapping part I3 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com