Plow discharger

A plough unloader and plough share technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as defects in details, and achieve the effect of changing the direction of unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

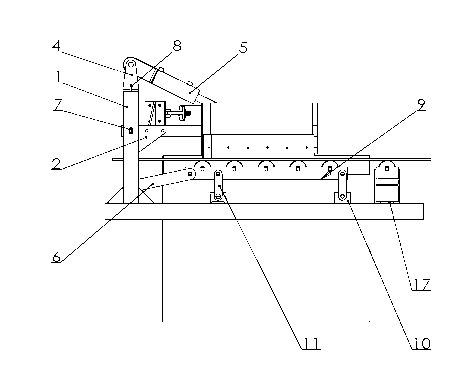

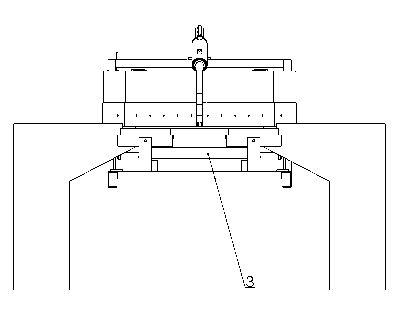

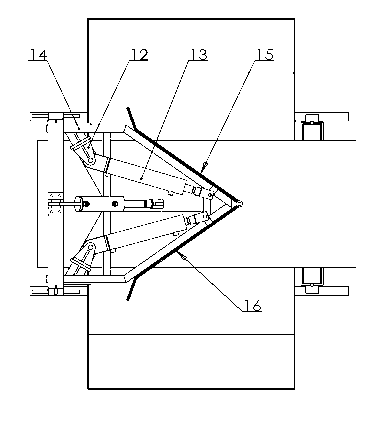

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0013] Such as figure 1 , 2 As shown in and 3, a plow type unloader includes a door frame 1, a large connecting rod 2, a round connecting rod 3, a lifting cylinder seat 4, a lifting cylinder 5, a long connecting rod 6, a bearing pin 7, a boom 8, Roller frame 9, lower bracket 10, short connecting rod 11, rotary cylinder seat 12, rotary cylinder 13, plowshare 14, left plowshare plate 15, right plowshare plate 16, adjustable idler roller frame 17, the idler roller The frame 9 is connected with the door frame 1 through the long connecting rod 6, the round connecting rod 3, the large connecting rod 2, the pin shaft 7, and the suspender 8, and the roller frame 9 is connected with the lower bracket 10 through the short connecting rod 11. The lift cylinder seat 4 is bolted to the mast 1, the rotary cylinder seat 12 is welded to the plow share 14, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com