a vane pump

A technology of vane pumps and vanes, which is applied to pumps, pump controls, pump components, etc., can solve the problems of impermissible vane reversal, complex structure of vane pumps, and impact on service life, so as to facilitate processing, prevent excessive reversal, Effect of reducing noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

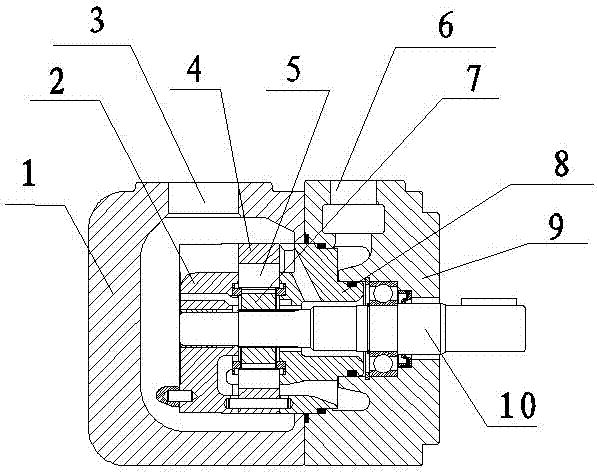

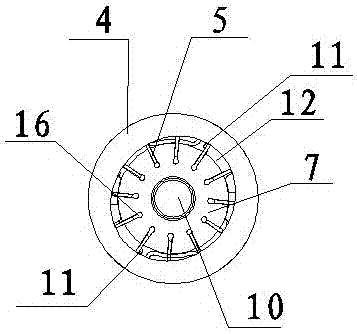

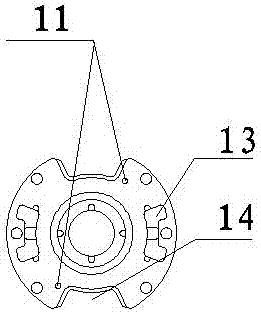

[0021] Such as figure 1 with 2 As shown, a vane pump includes a pump body, a pump core and a transmission shaft 10 located in the pump body. The pump body includes a front housing 1 and a rear housing 9 located on the left and right sides, the front housing 1 is provided with an oil suction port 3 , and the rear housing 9 is provided with an oil pressure port 6 . The pump core includes a rotor 7 which is located on the transmission shaft 10 and rotates synchronously with the transmission shaft 10. A vane groove 16 is opened on the rotor 7, and a vane 5 is inserted in the vane groove 16. A The stator 4 has an oval hole in the center of the stator 4, the stator 4 and the rotor 7 rotate coaxially, and there is a gap between the stator 4 and the rotor 7. When the vane pump works normally, one end of the vane 5 is always close to the stator 4 under the centrifugal force of the rotor 7 . An oil suction distribution plate 2 and a pressure oil distribution plate 8 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com