One-way clutch rubbing type IC engine

A one-way clutch, internal combustion engine technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of poor mechanical stability, high noise, increased contact gap, etc., to improve mechanical efficiency and reduce hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

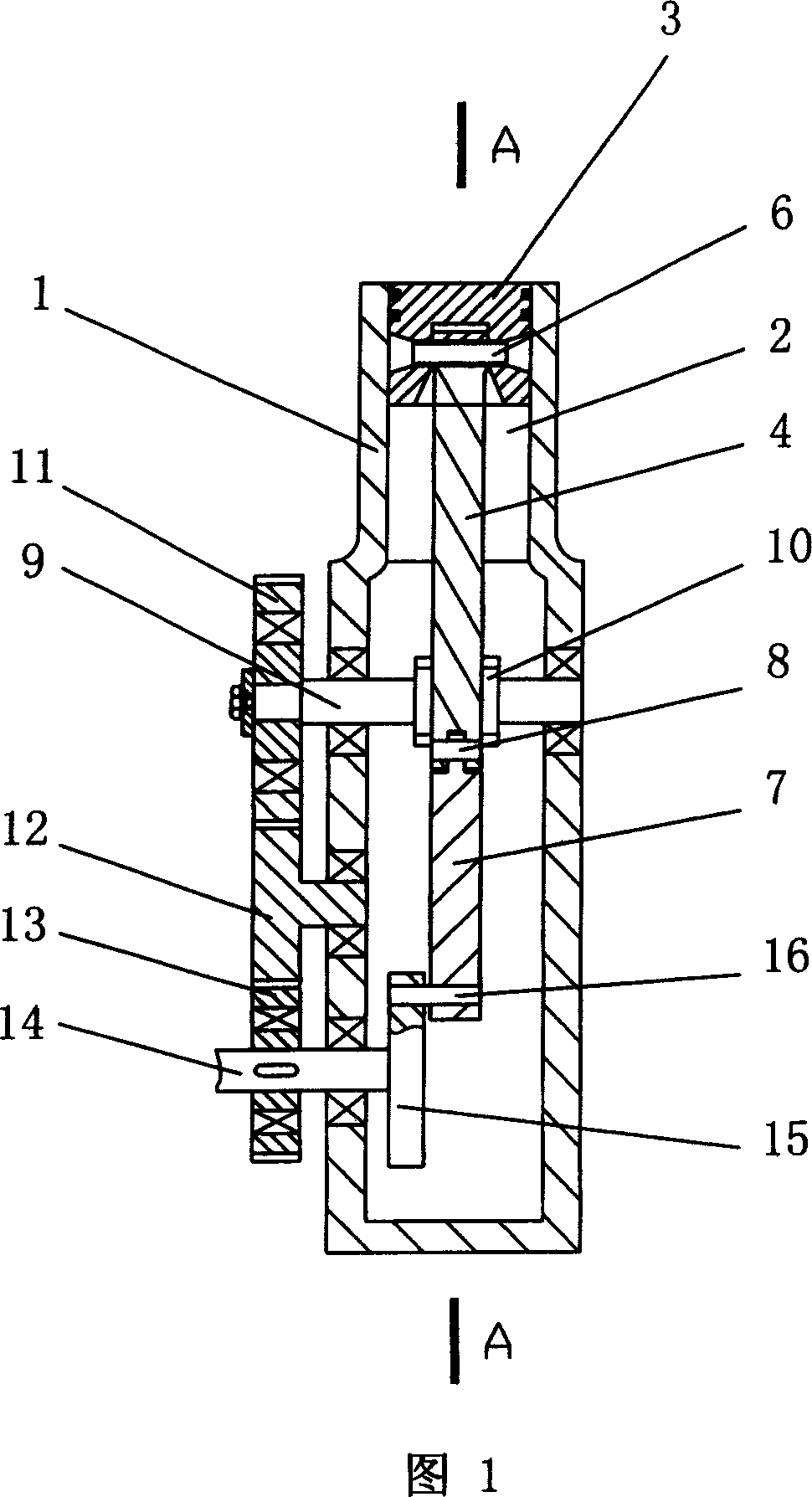

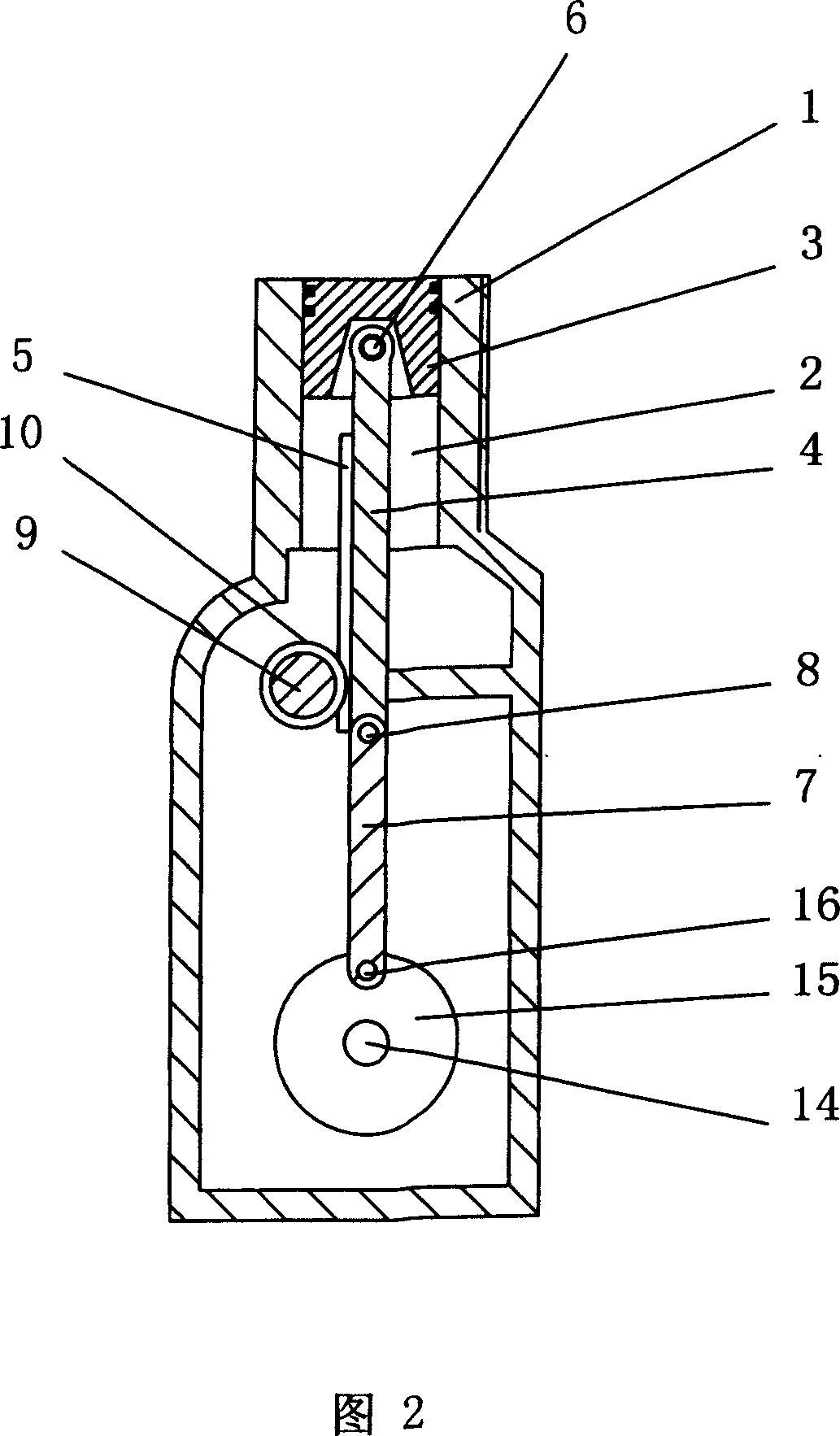

[0014] Referring to Figures 1 and 2, a one-way clutch rubbing internal combustion engine includes a cylinder body 1 and a piston push rod force transmission mechanism, a force unloading mechanism, a gas distribution mechanism, a fuel supply system, a lubrication system, Cooling system, a cylinder 2 is arranged in the upper part of the cylinder body 1, and a piston 3 is arranged in the cylinder 2. The piston 3 is connected with the push rod 4 through the piston pin 6. The inside of the push rod 4 is provided with a rack 5, and the lower end of the push rod 4 A connecting rod 7 is provided, and the rack 5 meshes with the tooth 10 on the middle part of the ratchet shaft 9 located in the middle of the cylinder body 1. The two ends of the ratchet shaft 9 are connected to the cylinder body 1 through bearings. One end of the gear shaft 9 is provided with a power transmission ratchet 11, which meshes with the center gear 12 arranged on the cylinder body 1, and the upper end of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com