Large gear two-side bearing withdrawing machine

A large gear and unloading machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to keep the large gear stationary, and achieve the effect of filling the gaps in technology and the market, and the structure is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

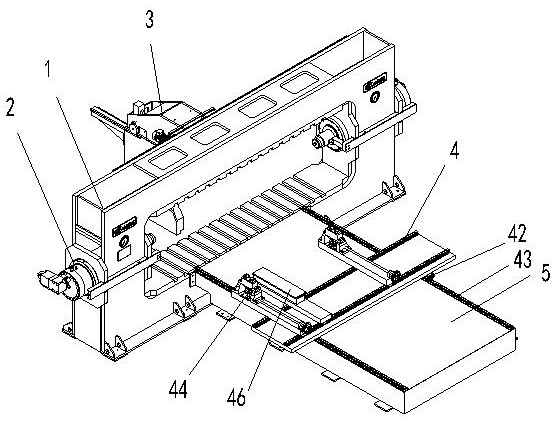

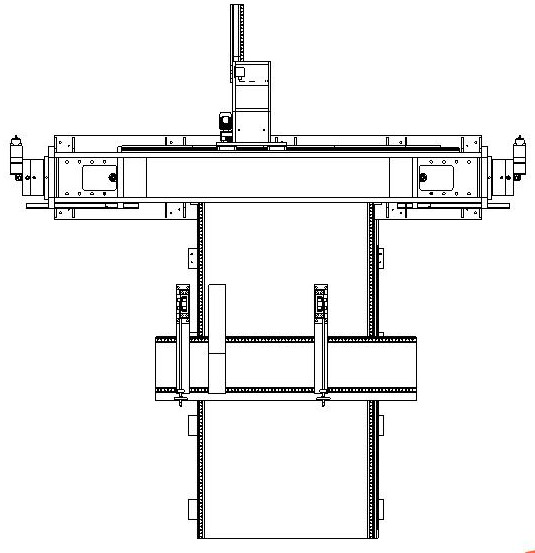

[0036] Such as Figure 1 to Figure 9 As shown, the present invention discloses a bearing unloading machine on both sides of a large gear, including a frame 1, an oil cylinder device 2, an unloading device 3, a supporting trolley 4, a supporting trolley chassis 5, and a transition tool 6;

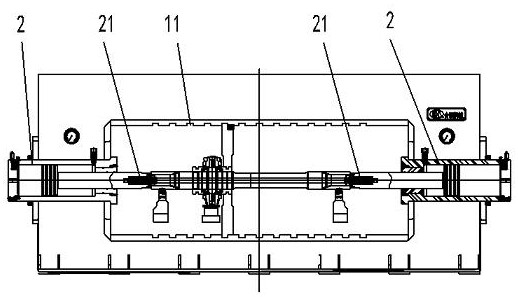

[0037] The frame 1 is in the shape of a back, and the upper and lower beams of the frame are correspondingly provided with slots 11 for inserting plates;

[0038] The oil cylinder device 2 is symmetrically arranged at both ends of the frame in the center of the coaxial line, and the oil cylinder device has a top mechanism 21;

[0039] The unloading device 3 is arranged on one side of the frame, and it h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com