Winding device

A winding device and package technology, applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve the problems of deterioration of spinning quality, difficult lifting mechanism, and large operating cost burden, so as to prevent further Contact, simple structure, anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

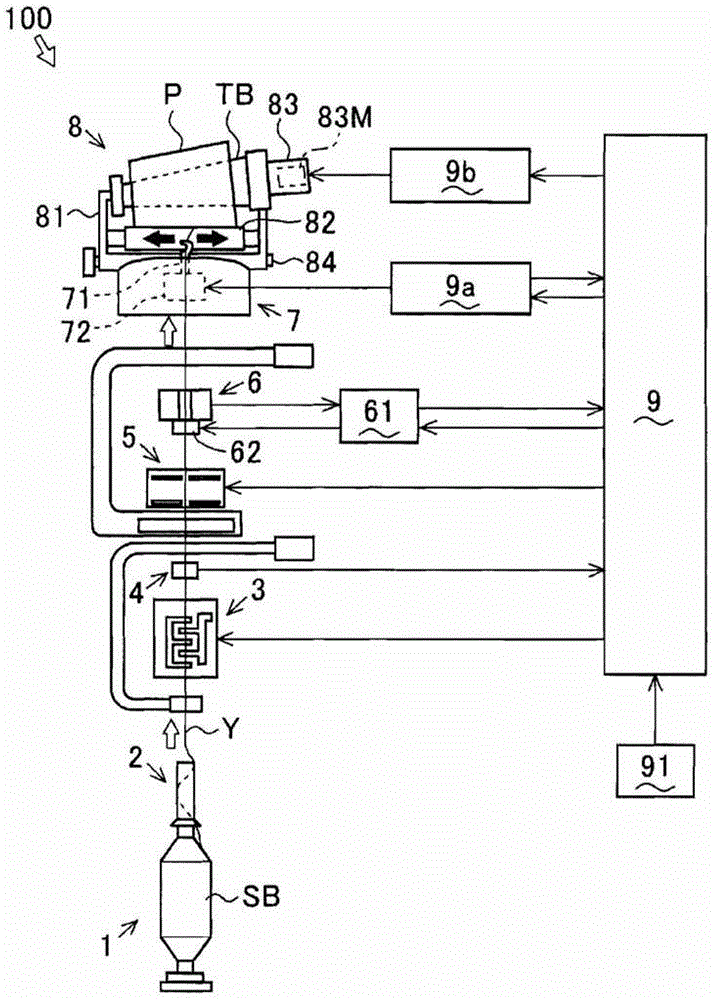

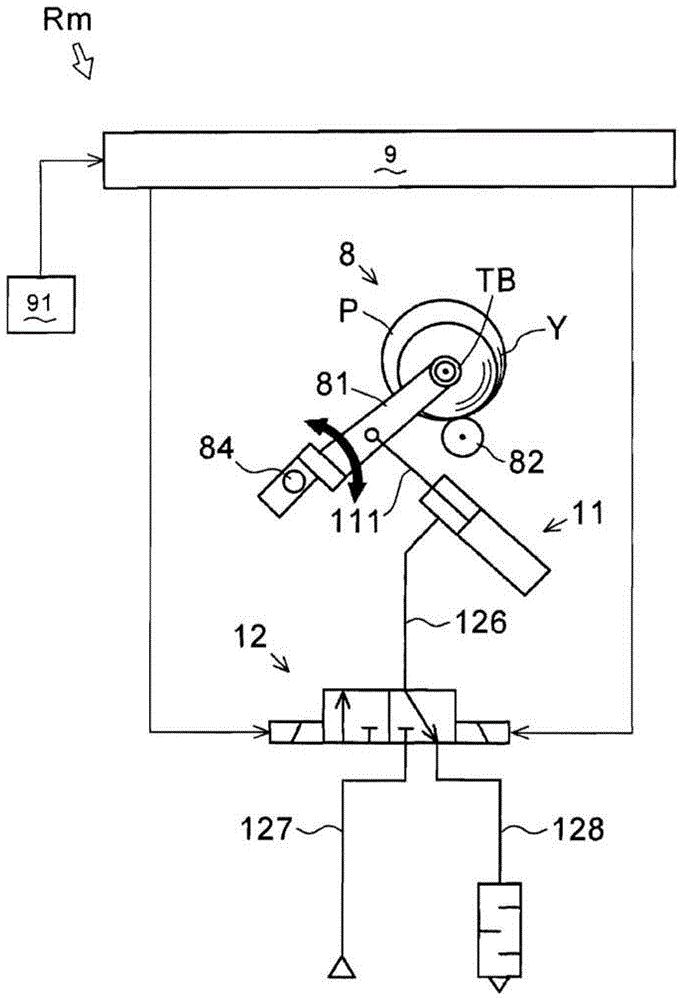

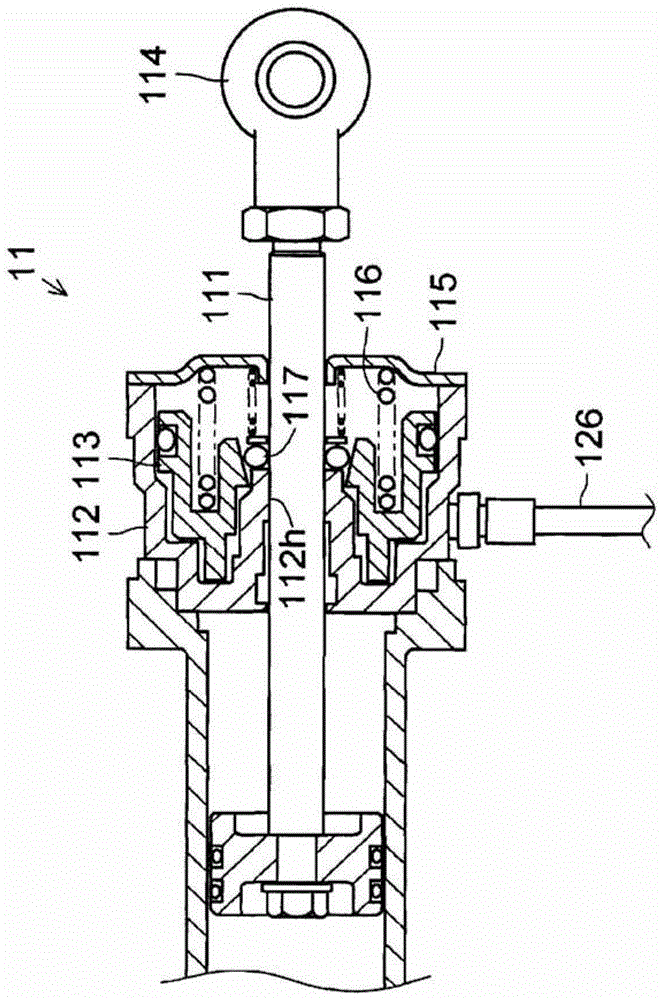

[0034] First, a winding device 100 according to an embodiment of the present invention will be described.

[0035] figure 1 It is a figure which shows the whole structure of the winding apparatus 100. The hollow arrow in the figure indicates the conveying direction of the spun yarn Y. In addition, arrows filled in black in the figure indicate the movable direction of a member (the traverse guide 71 ) constituting the winding device 100 .

[0036] The winding device 100 includes a yarn supplying unit 1 . The yarn supplying bobbin SB on which the spun yarn (yarn) Y is wound is mounted in the yarn supplying section 1 . The winding device 100 includes a yarn unwinding auxiliary section 2, a tension applying section 3, a tension detecting section 4, a splicing section 5, and a defect detecting section 6 along the conveying direction of the spun yarn Y unwound from the yarn supplying bobbin SB. , Traversing portion 7 and winding portion 8 . Furthermore, the winding device 100 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com