A self-elevating tower crane with a wall frame structure

A wall-attached, self-elevating technology, applied to cranes and other directions, can solve the problems of increased cost, large wall-attached struts, and increased construction difficulty, so as to save costs, reduce construction difficulty, and improve strength and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

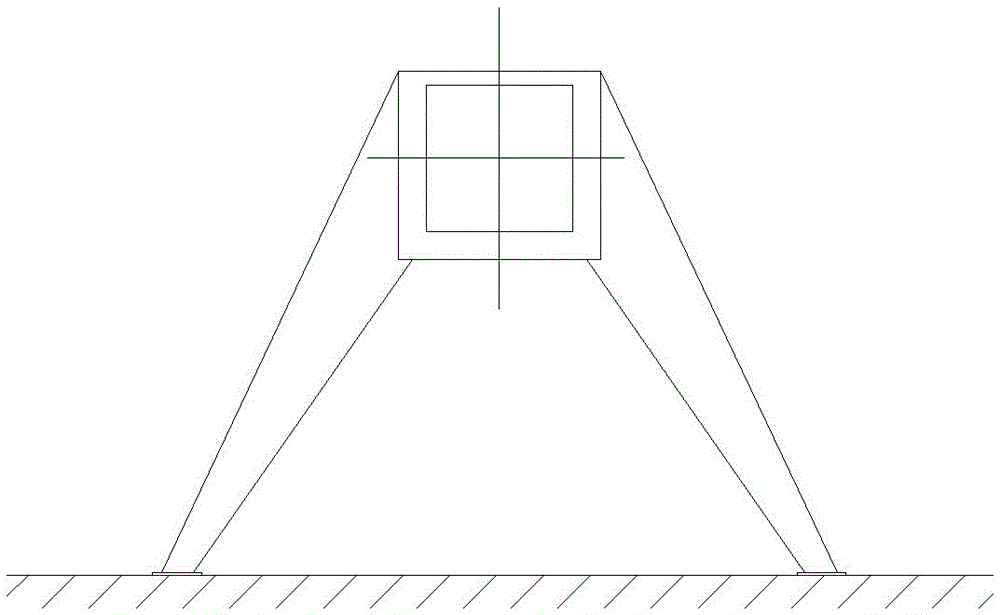

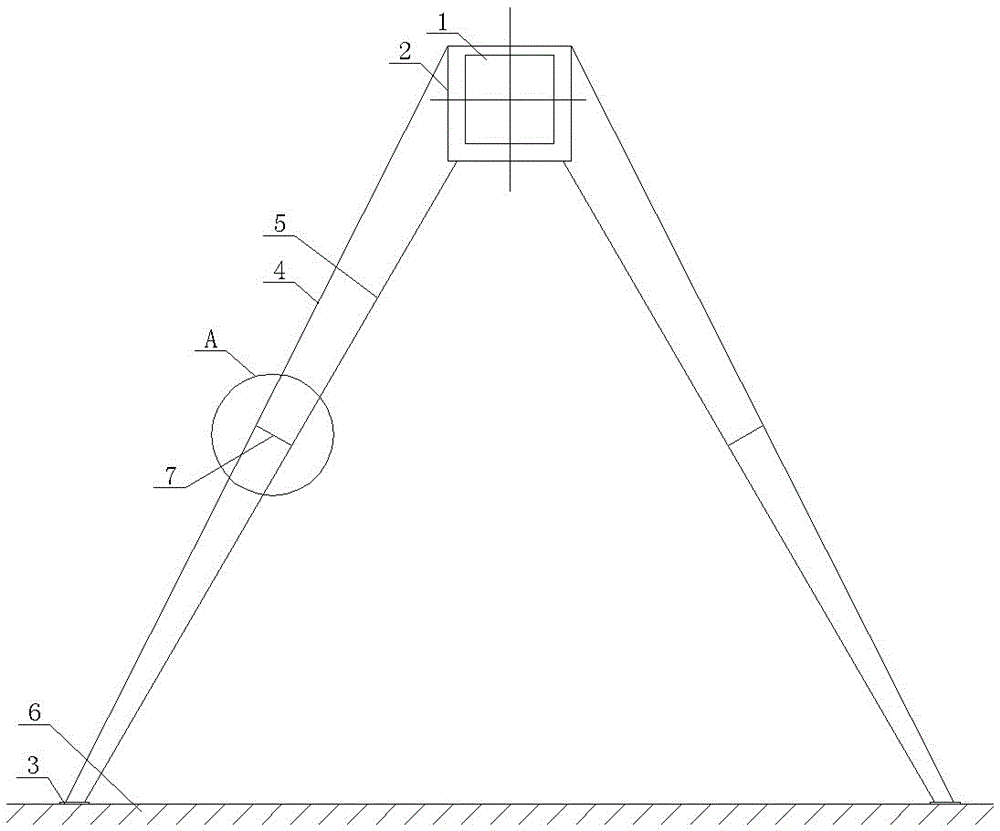

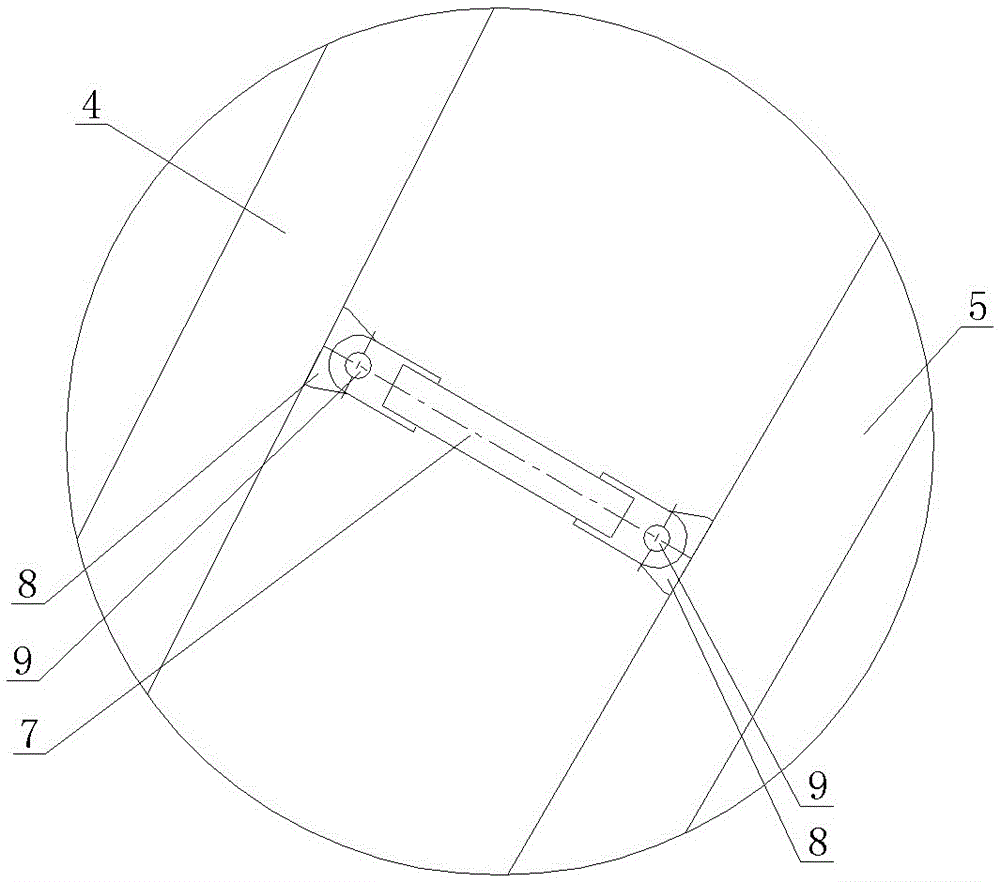

[0011] See figure 2 , image 3 , which includes a tower body 1, a wall-attached frame 2, struts, and a support 3. The struts include an outer strut 4 and an inner strut 5. The support 3 is supported on a building 6. The tower body 1 is provided with an attached wall The frame 2, the wall-attached frame 2 and each corresponding support 3 are provided with an outer strut 4 and an inner strut 5, and the middle position of the outer strut 4 and the inner strut 5 corresponding to each support 3 They are connected by a connecting rod 7, and the specific connection structure is as follows: the opposite sides of the corresponding middle positions of the outer strut 4 and the inner strut 5 corresponding to each support 3 are respectively welded with ear plates 8, and the connecting rods 7 are welded to each other. The two ends are respectively fastened to the lug plates 8 of the corresponding outer struts 4 and inner struts 5 through pin shafts 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com