Shower head and vapor deposition equipment

A shower head, gas technology, applied in the direction of gaseous chemical plating, chemical reactive gas, crystal growth, etc., can solve the problems of shower head formation defects, and achieve the effect of avoiding deposition in the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

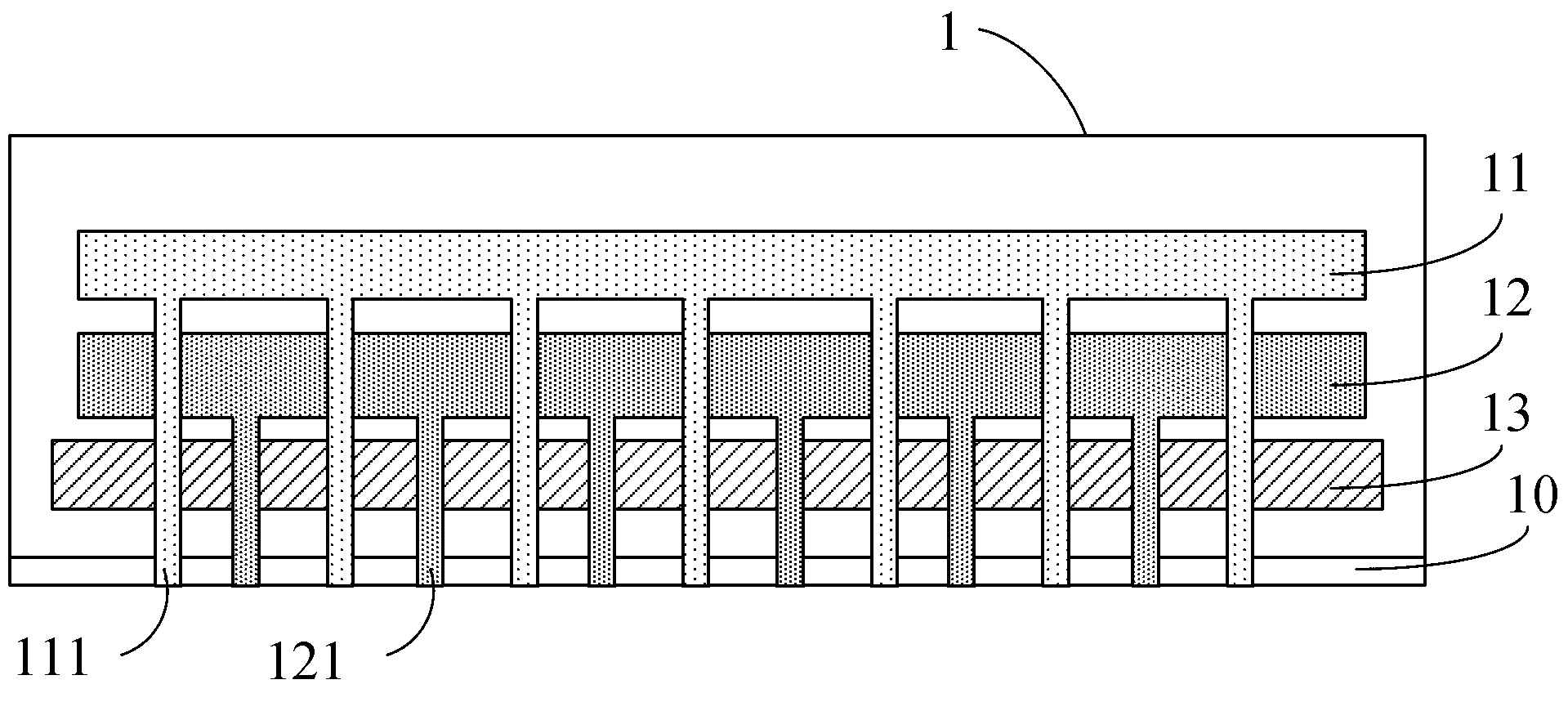

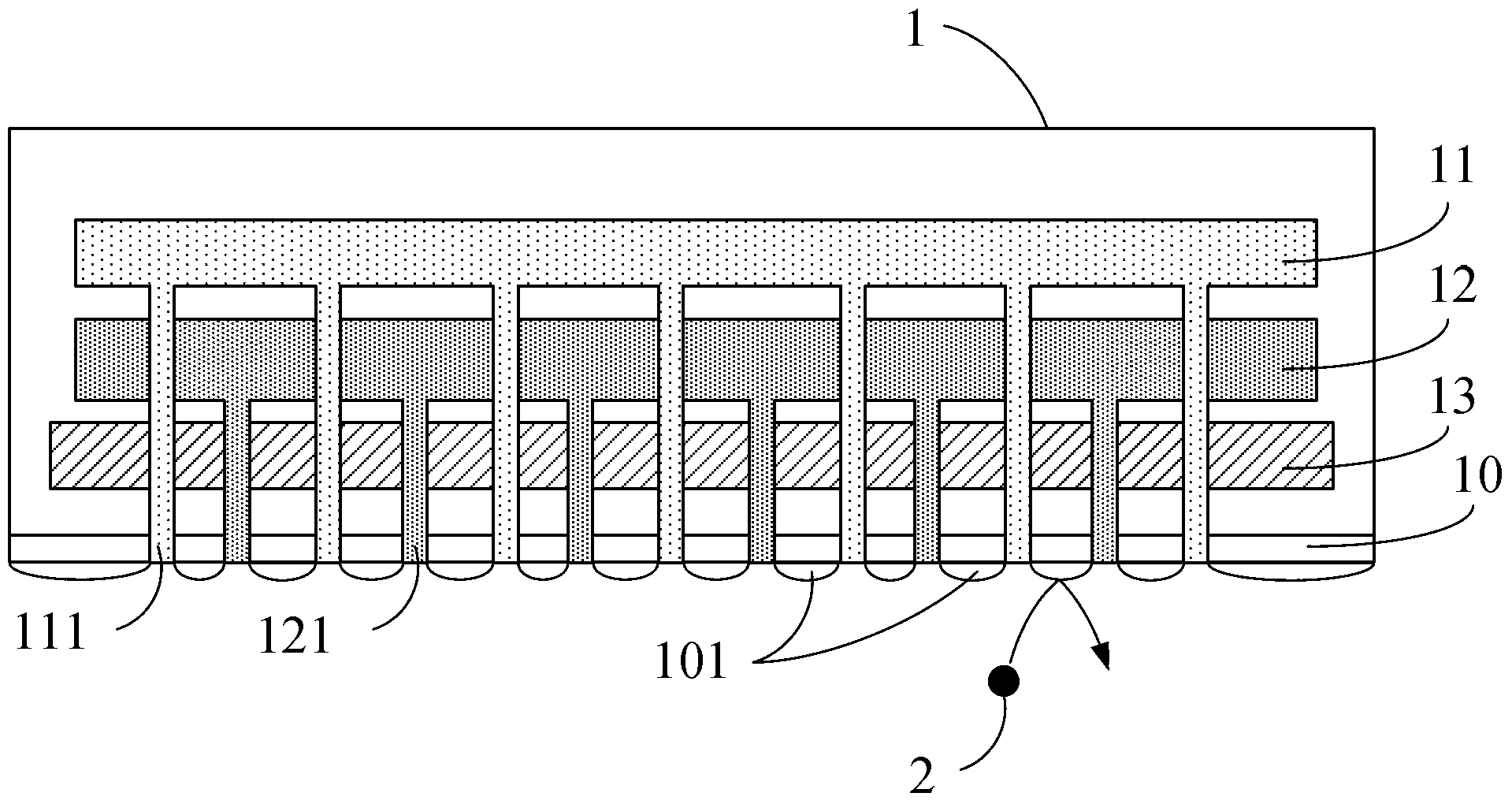

[0012] The shower head and vapor deposition equipment provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form, and are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0013] It can be seen from the content described in the background art that the shower head of the prior art is easy to form impurity residues on the substrate. The inventors of the present invention have found in research that if a material layer is arranged on the lower surface of the shower head to absorb the gas that does not react in the MOCVD process, so that a layer of gas layer is formed on the lower surface of the shower head ; The gas layer constitutes a protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com