Plasma processing equipment and method and method for washing chamber

A plasma and processing equipment technology, applied in the field of plasma, can solve the problems of shortening the normal service life of equipment, reducing production efficiency of cleaning time, affecting the adsorption effect of coatings, etc., so as to avoid equipment loss, improve cleaning effect and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

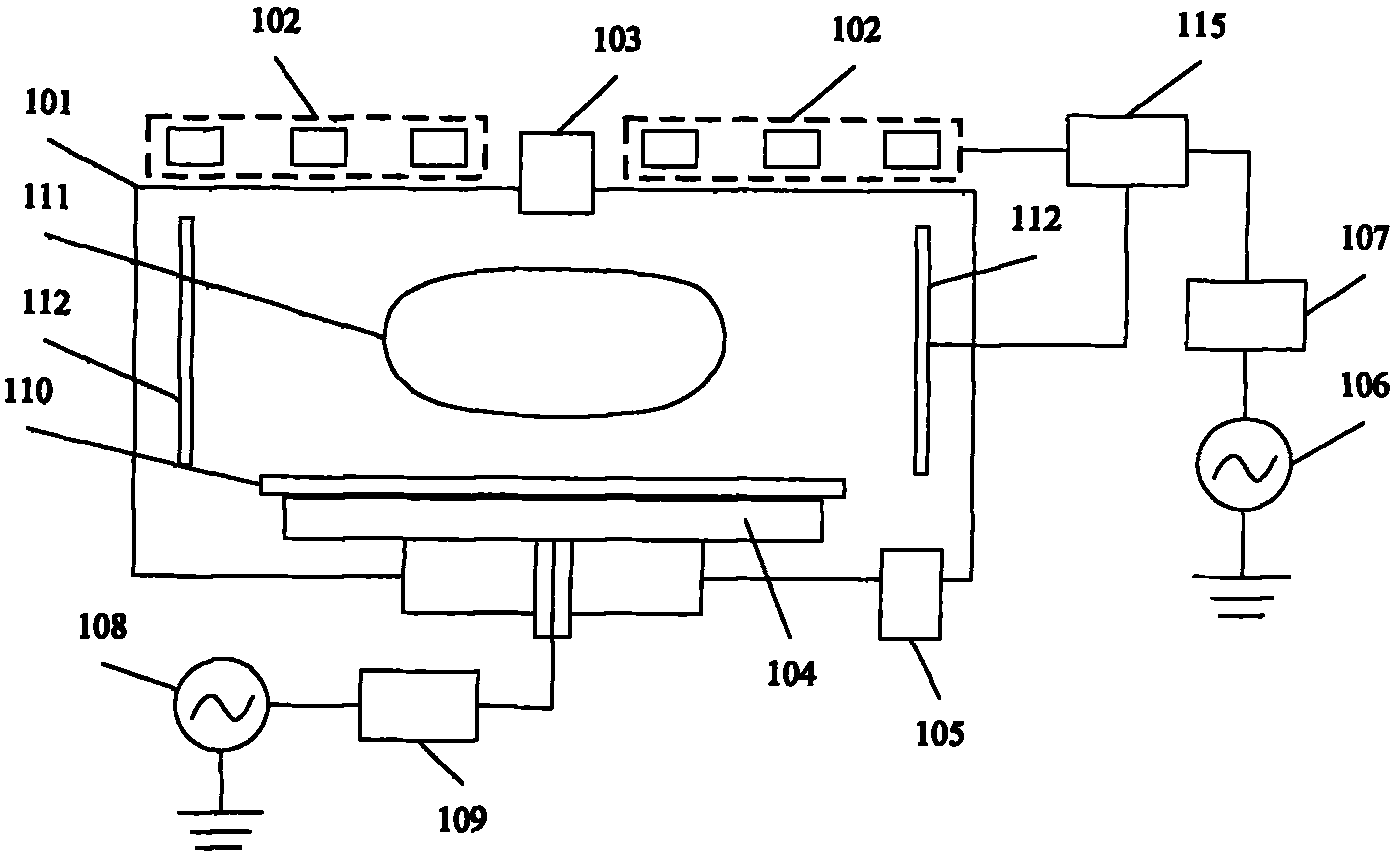

[0042] see below Figure 4 , the third embodiment of the plasma processing equipment provided by the present invention, and image 3 The illustrated embodiment is similar. In this embodiment, the lower electrode radio frequency power supply 108 is used as the lining radio frequency power supply, that is: the lower electrode power distributor 116 is set between the lower electrode radio frequency power supply 108 and the lower electrode 104, and the lower electrode power distributor 116 is connected with the inner lining 112 are connected to provide part of the RF power of the lower electrode RF power supply 108 to the inner liner 112 . In this embodiment, the lower electrode matching device 109 is arranged between the lower electrode RF power supply 108 and the lower electrode power distributor 116, so that the lower electrode matching device 109 can simultaneously connect the lower electrode 104 and the lining 112 to the lower electrode RF power supply 108 It is not limited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com