Cable fixing clamp for high-speed railway system

A technology of cable fixing clamps and clamps, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as cable short circuit, cable clamp damage, and increased costs, so as to improve reliability and fix reliability , the effect of strengthening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

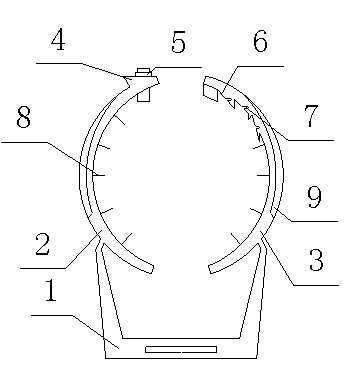

[0013] Example: such as figure 1 As shown, the present invention includes a base 1, and the base 1 is respectively elastically connected with the first hoop piece 2 and the second hoop piece 3 which are arc-shaped and oppositely arranged, and the end of the first hoop piece 2 There is a buckle 4 on the part, and a fixing hole is opened on the buckle 4, and a fixing bolt 5 is arranged in the fixing hole, and several slots 6 corresponding to the buckle 4 are arranged on the second clamp piece 3, And the positions corresponding to the fixing holes on each clamping groove 6 are provided with bolt holes 7 matching the fixing bolts 5, and several pieces are arranged on the opposite inner side of the first clamp piece 2 and the second clamp piece 3. positioning piece 8; and the outer edges of the first clamp piece 2 and the second clamp piece 3 are all provided with reinforcing ribs 9; the surfaces of the base 1, the first clamp piece 2 and the second clamp piece 3 are all covered T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap