Wide-angle LED (light-emitting diode) lamp

A wide-angle LED lamp technology, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of unguaranteed life, complex process, poor heat dissipation, etc., to avoid heat accumulation and save the volume of the whole lamp , good light distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

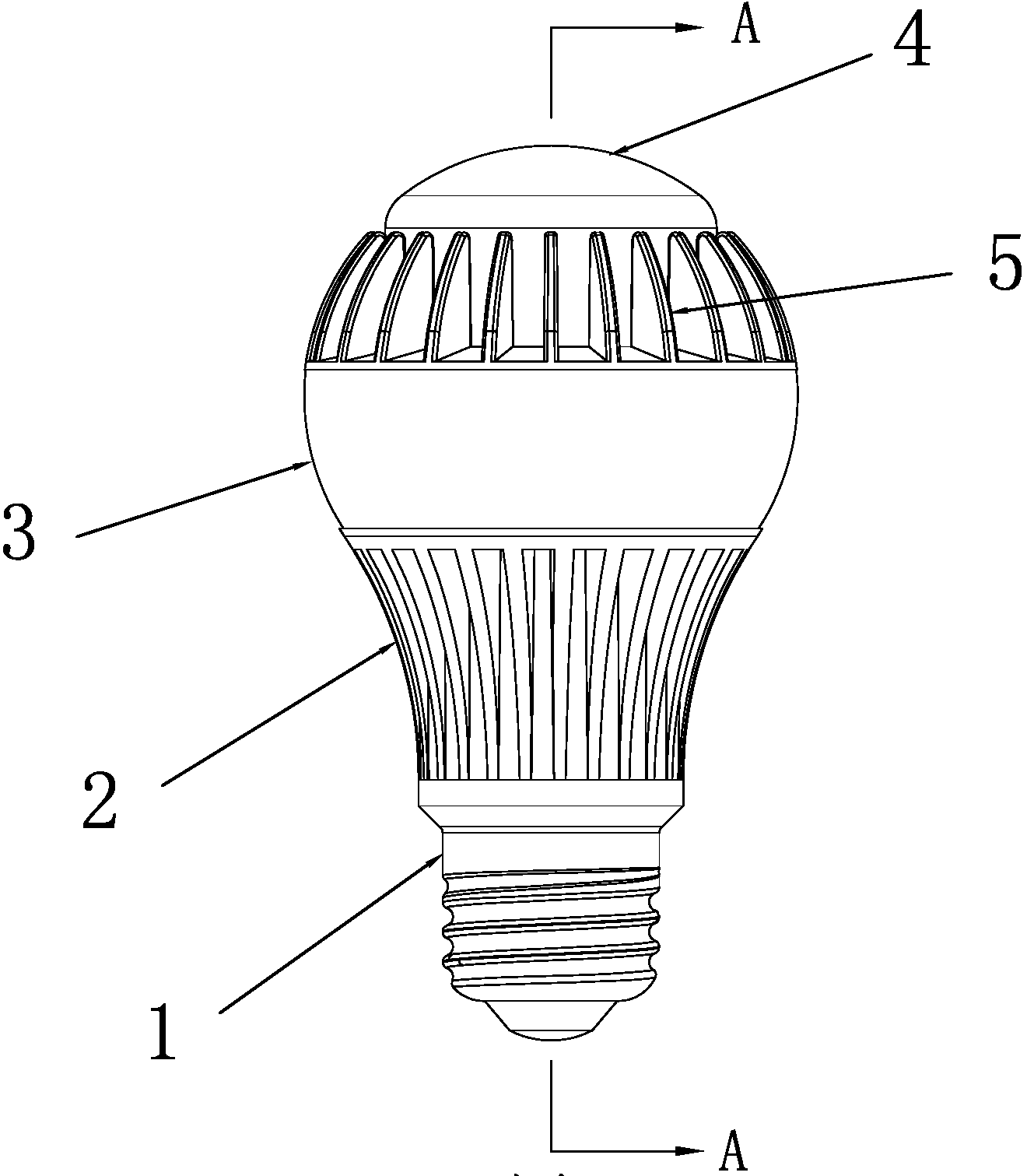

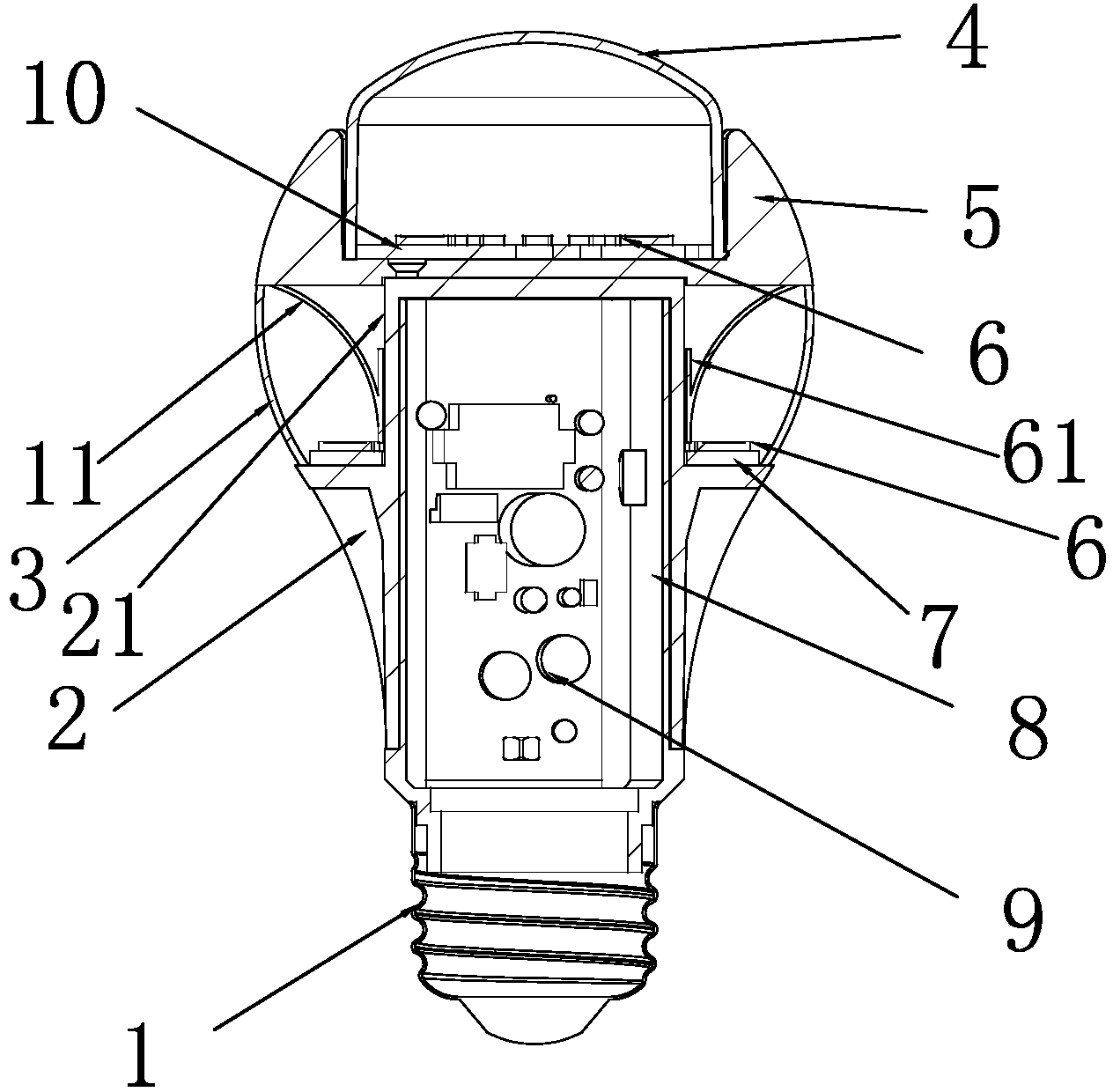

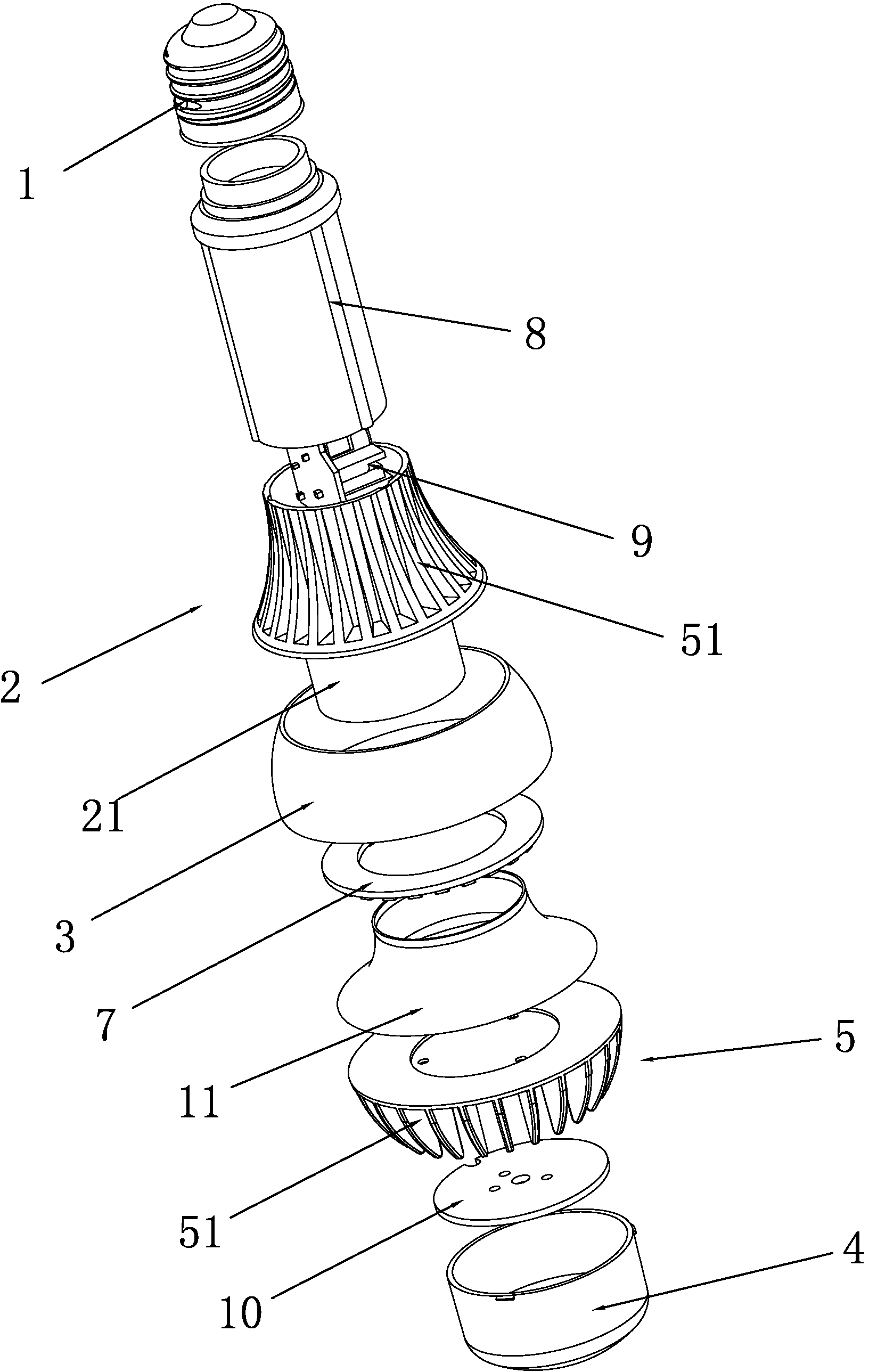

[0027] Example: such as Figure 1-4 As shown, the wide-angle LED lamp of the present invention includes a lamp base 1, a driving power supply 9 electrically connected to the lamp base, a first lamp body 2, a first bulb 3, a second bulb 4, a second lamp body 5, a first The lamp board 7 , the second lamp board 10 , the power supply housing 8 and the reflective cup 11 . The first lamp body 2 and the second lamp body 5 are aluminum radiators or radiators made of other materials such as heat-conducting plastics and ceramics, and the outer surfaces of the first lamp body 2 and the second lamp body 5 are A plurality of longitudinally arranged cooling fins 51 are uniformly distributed along the circumferential direction. The inside of the first lamp body 2 is a hollow structure, the first lamp body 2 and the power supply housing 8 are socketed together, the driving power supply 9 is arranged in the power supply housing 8, and the power supply housing 8 is made of heat-conducting plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com