Horizontal agricultural special hot air environmental protection boiler

A hot air and agricultural technology, applied in the field of horizontal agricultural special hot air environmental protection boilers, can solve the problems of unfavorable material cost saving, unreasonable structure, large steel consumption, etc., to save material cost, facilitate processing and production, and reduce steel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

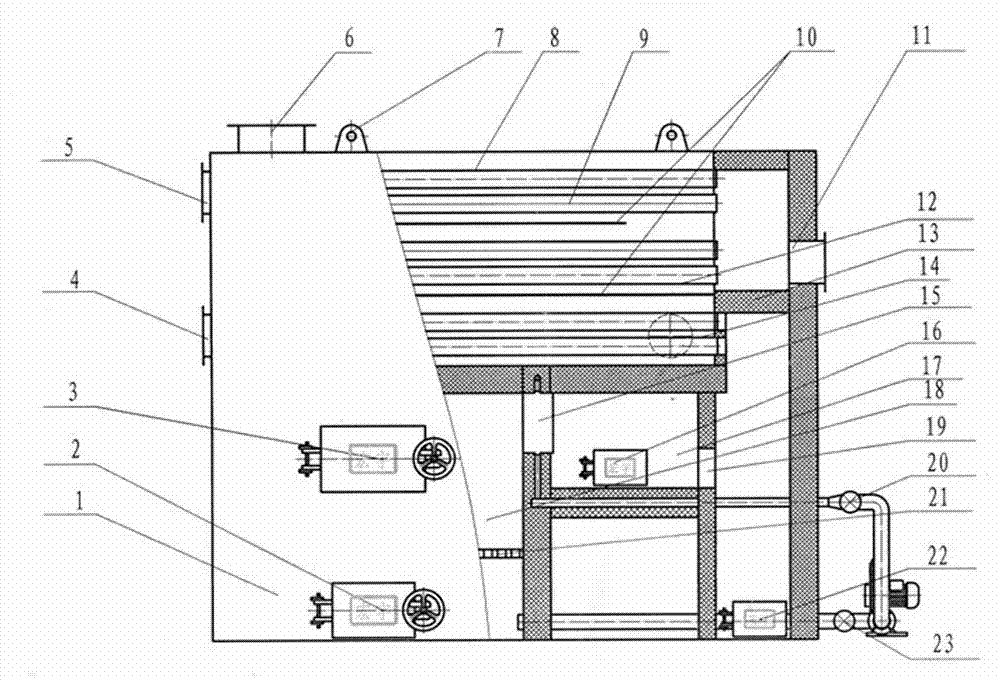

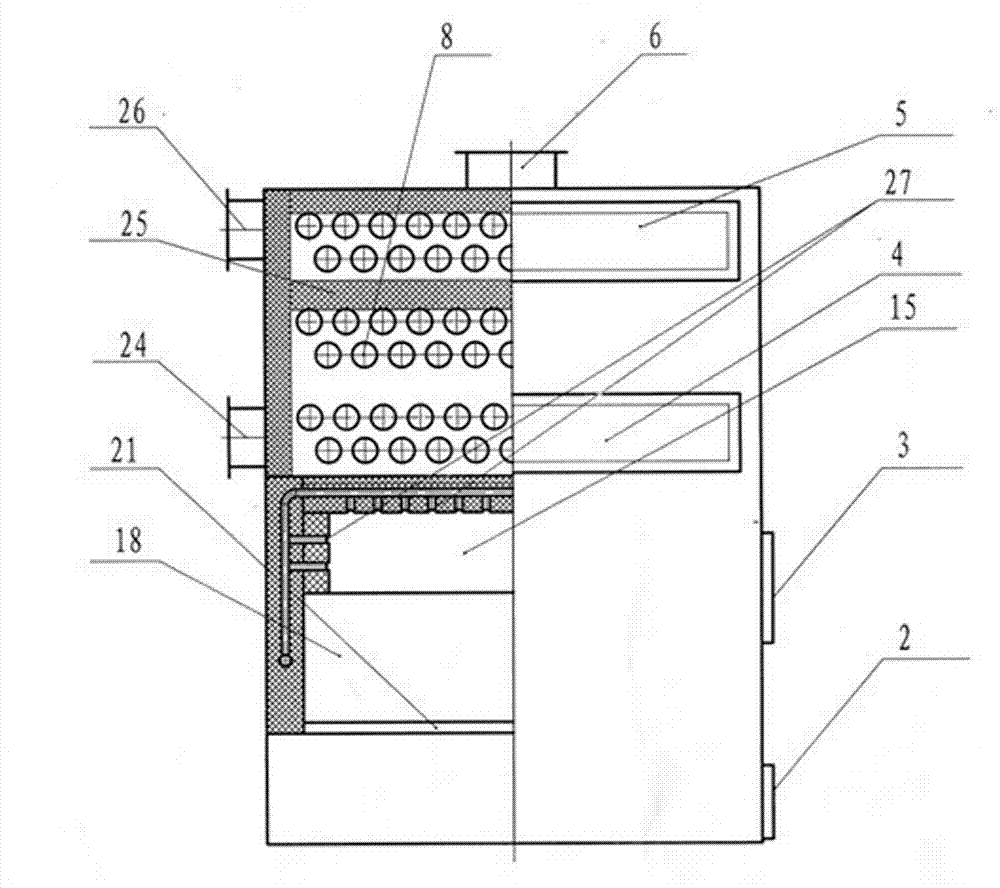

[0015] The horizontal hot air environment-friendly boiler for agriculture includes a furnace body 1, a coal inlet door 3 at the lower part of the furnace body, a return exhaust smoke heating tube bundle 8, a combustion chamber 18 and a fixed fire grate 21. The inner lower part of the furnace body 1 is provided with an independent refractory pouring and a combustion chamber 18 equipped with a fixed fire grate 21. The inner upper part of the furnace body 1 is not directly heated with the combustion chamber, and three continuous return smoke exhaust heating tube bundles 8 hearths. The right side of the combustion chamber 18 is provided with a high-temperature smoke elimination furnace 17, and on the left side wall of the high temperature smoke elimination furnace 17, that is, the right side wall of the combustion chamber, a plurality of heightened radiation flower hole-type upper smoke elimination chambers are provided to block the smoke from being discharged from the furnace. Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com