Lengthways outer wing type heat exchange tube

A heat exchange tube, vertical technology, applied in the field of heat exchange tubes, to achieve the effect of simple integrated structure, good quality and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

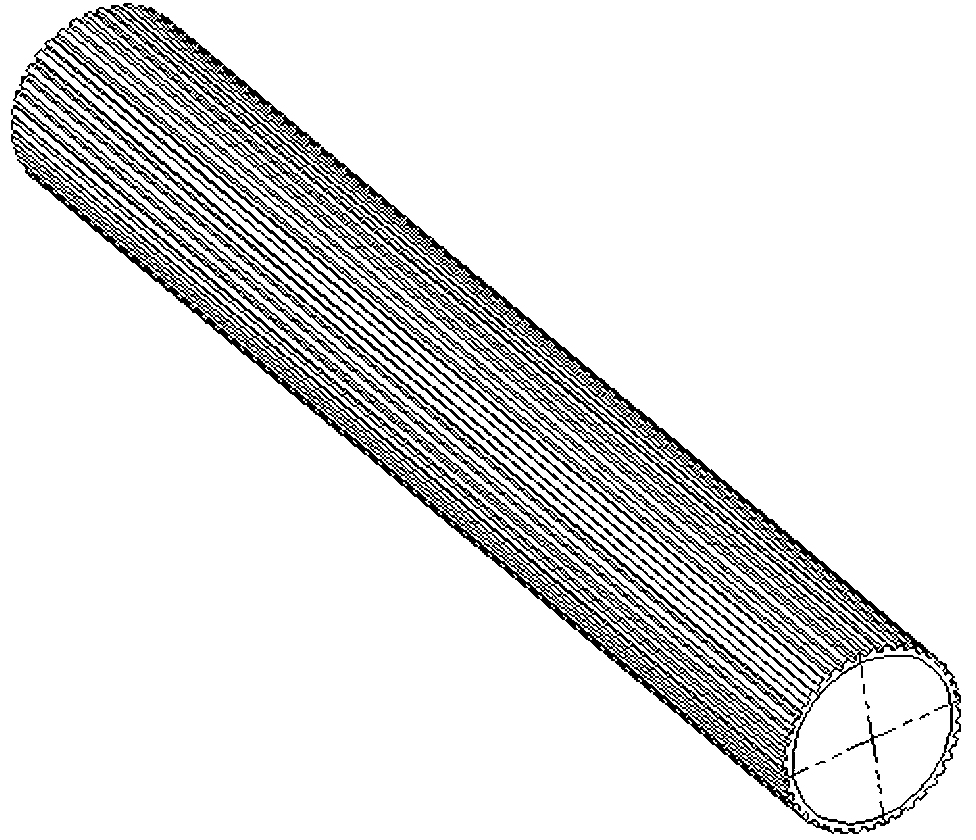

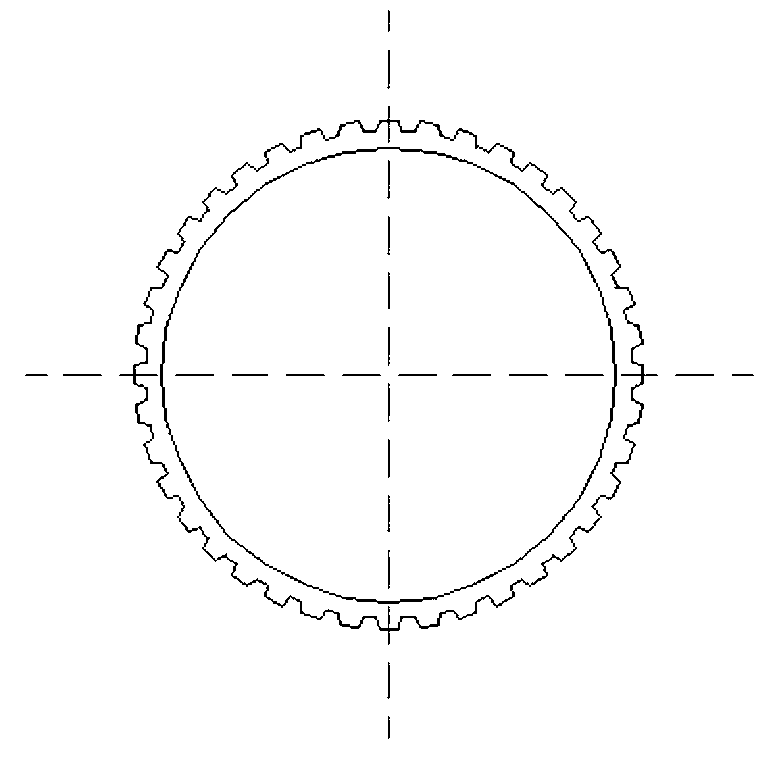

[0021] figure 1 The longitudinal outer-finned heat exchange tube shown is integrally composed of a tube body and protruding fins. The tube body is a round tube, and longitudinal fins are evenly distributed on the circumference of the outer wall, and the integrated fins are equal in length and homogeneous to the tube body. This example figure 2 As shown, the diameter of the circular tube is 12mm, and the longitudinal fins are evenly distributed on the circumference of the outer wall, the distance between adjacent fins is 2.0mm, the transverse section of the fins is trapezoidal, and the height of the fins is 0.5mm. In the present invention, the longitudinal fins and the tube body are integrally drawn, and the protruding longitudinal fins are evenly distributed on the outer wall of the tube. In addition to significantly increasing the heat exchange area, the biggest positive effect is that the longitudinal fins and the evaporating liquid flow direction Consistent, there is no ...

Embodiment 2

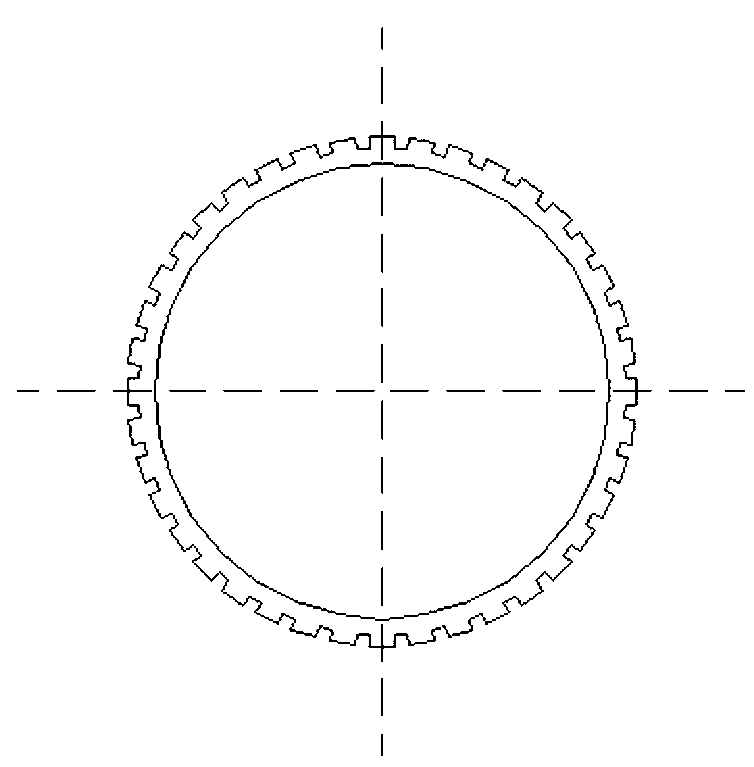

[0023] The three-dimensional structure of this embodiment is the same as that of Embodiment 1, only the cross-section of the longitudinal fins and the diameter of the pipe body are different. In this embodiment, the diameter of the pipe body is 22 mm. Due to the large diameter of the pipe body and the large amount of heat exchange, it is evenly distributed on the circumference of the outer wall of the pipe like image 3 For the rectangular longitudinal fins shown, the distance between adjacent fins is 0.4mm, the height of the fins is 0.8mm, and the transverse section of the fins is rectangular. The positive effect after application is similar to that of Example 1, although the shape of the transverse cross-section of the longitudinal fins is different.

[0024] The invention achieves an integrated structure by uniformly distributing longitudinal fins on the outer wall of the tube, which greatly facilitates installation in the manufacturing process, and improves heat exchange e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com