Shell cleaning device for air conditioner compressor production

A technology for air-conditioning compressors and cleaning devices, which is applied in the direction of cleaning methods using liquids, dry gas arrangements, cleaning methods using tools, etc., and can solve problems such as cumbersome operations, insufficient surface cleaning, and no flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

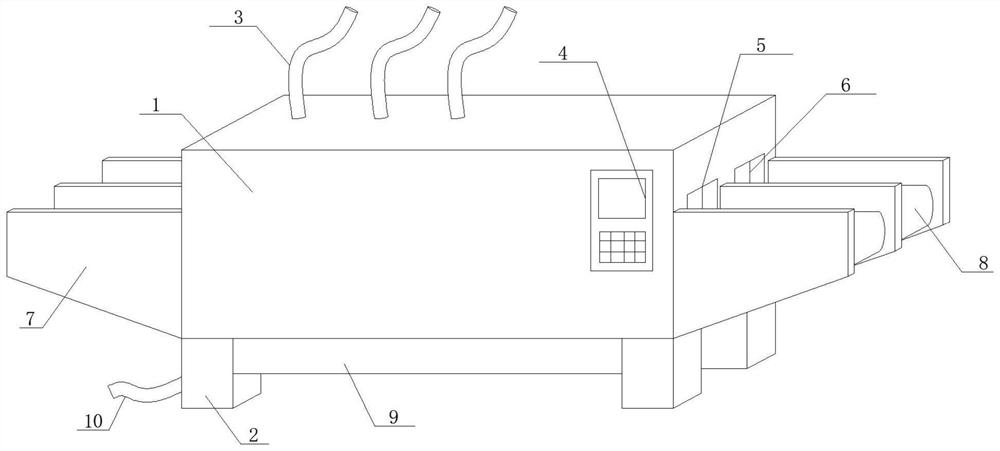

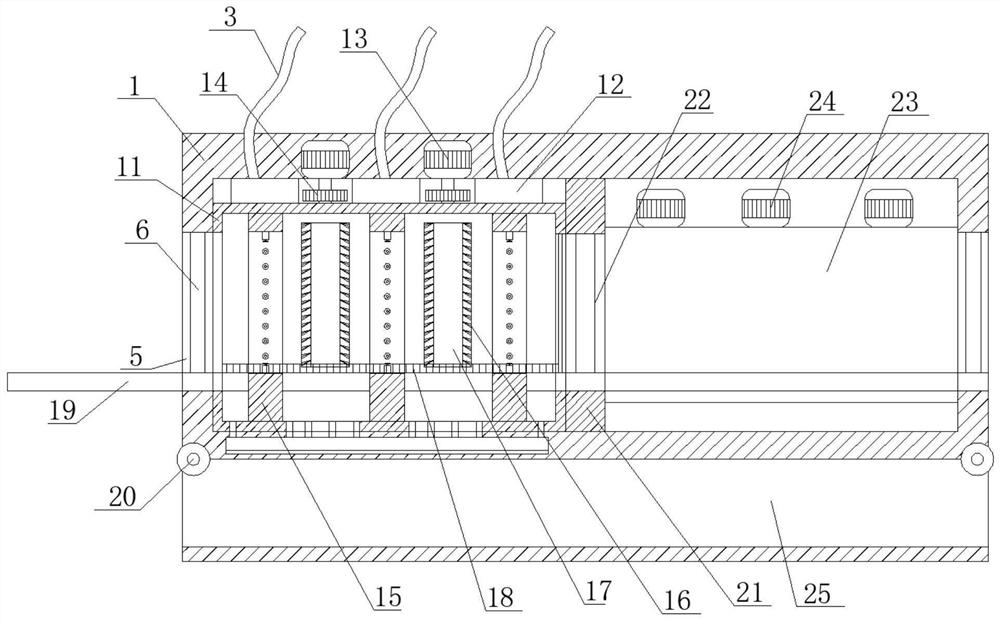

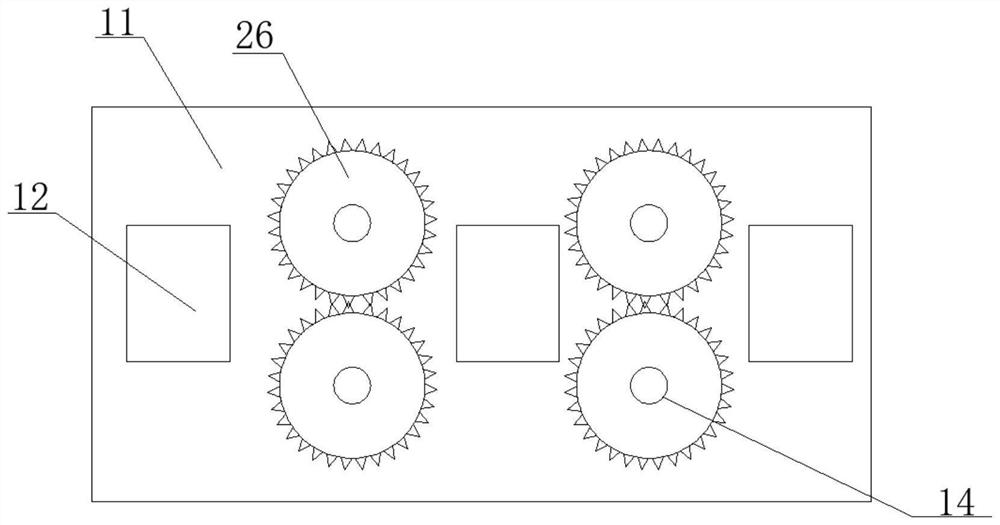

[0027] see Figure 1-2, in an embodiment of the present invention, a shell cleaning device for air-conditioning compressor production includes a processing main box 1, the bottom surface of the processing main box 1 is welded with a support pole 2 vertically downward, and the top surface of the processing main box 1 is plugged There are feed pipes 3, and the number of supporting vertical rods 2 is four, and the four supporting vertical rods 2 are arranged parallel to each other, and the tops of the four supporting vertical rods 2 are fixed vertically upward on the four sides of the bottom surface of the processing main box 1 Angle position, the number of feed pipes 3 is multiple, and one end of multiple feed pipes 3 runs through the top surface of the processing main box 1 and extends to the inside, and the extension end is plugged into the inner side of the pump body box 12 to maintain communication. One side of the processing main box 1 is inlaid with a control board 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com