Patents

Literature

39results about How to "Simple design and integrated structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

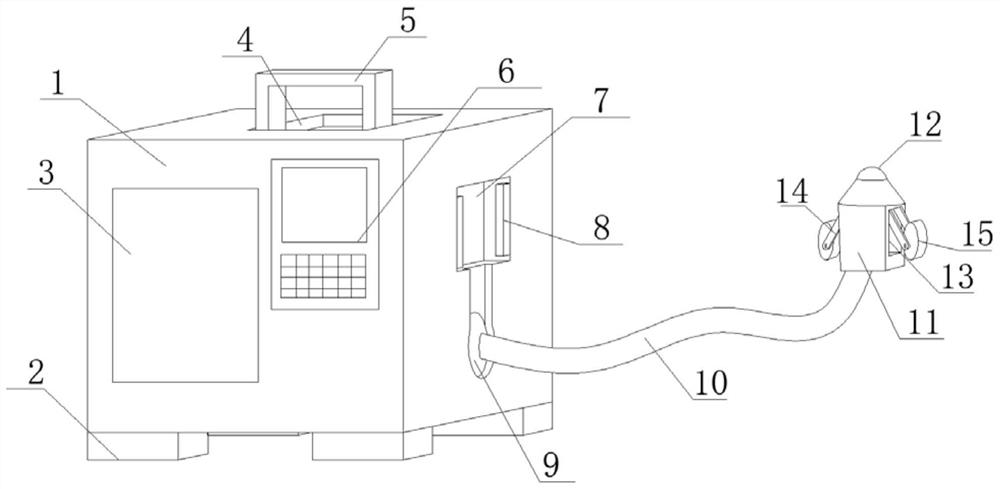

Spraying equipment for socket type large-diameter plastic-coated steel pipe

InactiveCN113351410AEasy to operate and intelligentSimple design and integrated structureHollow article cleaningPretreated surfacesMachiningMaterials science

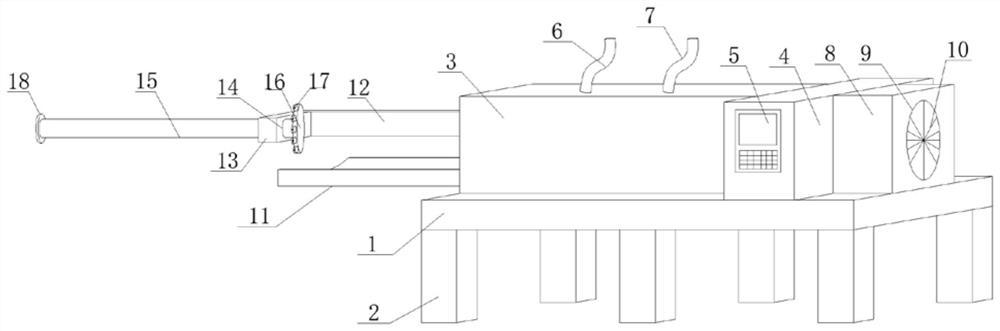

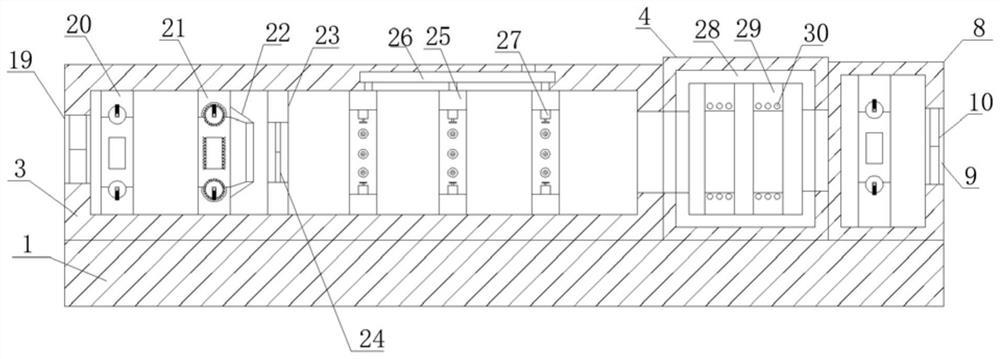

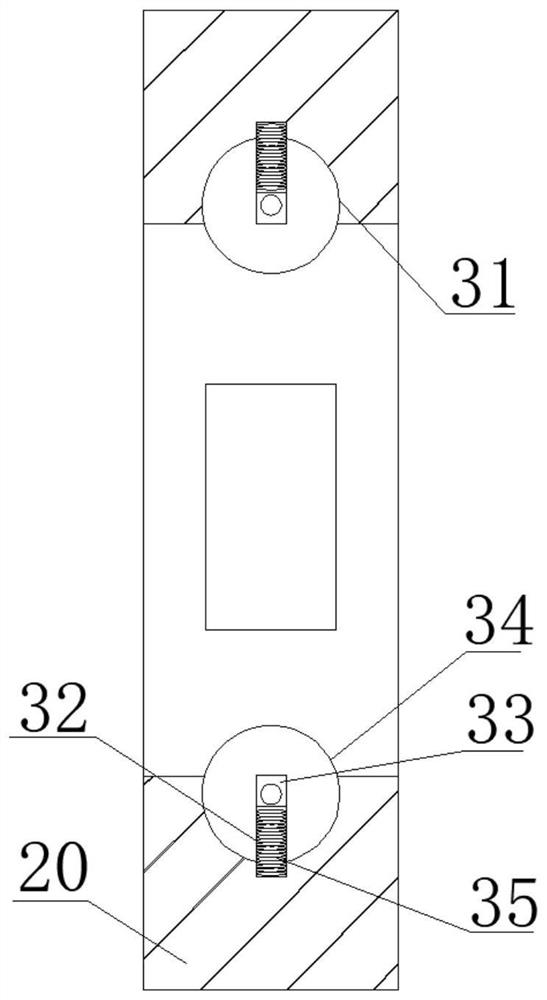

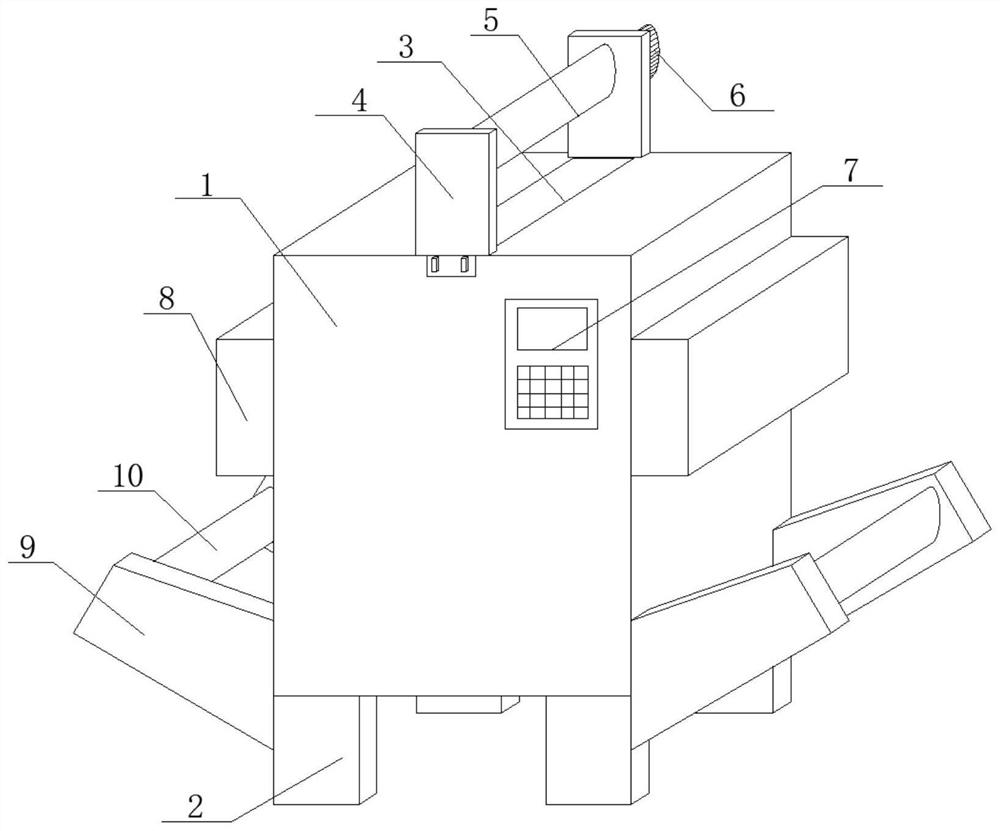

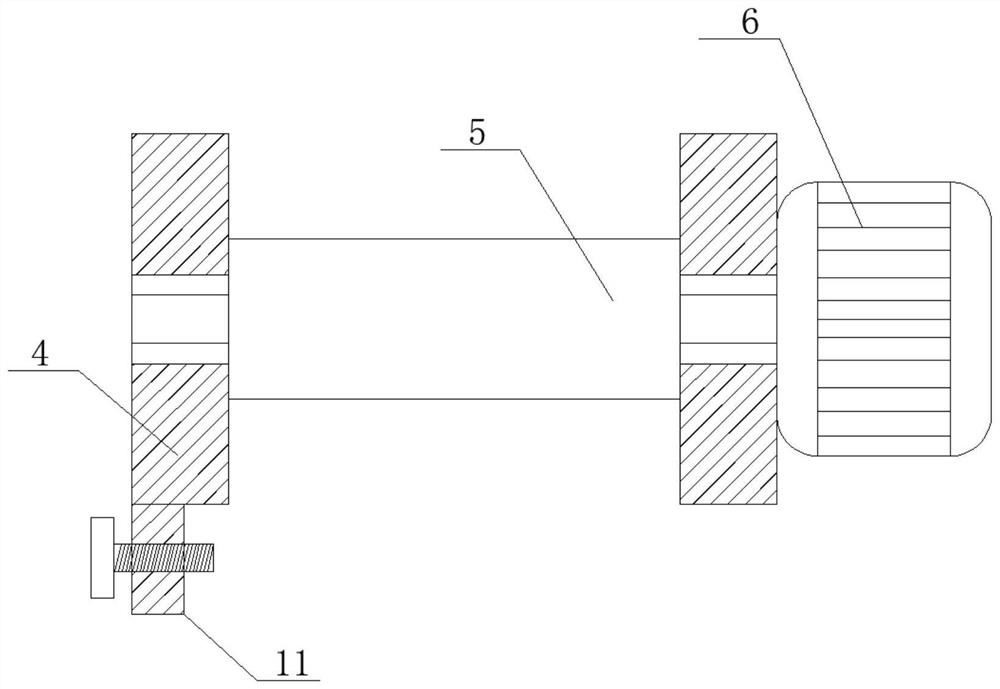

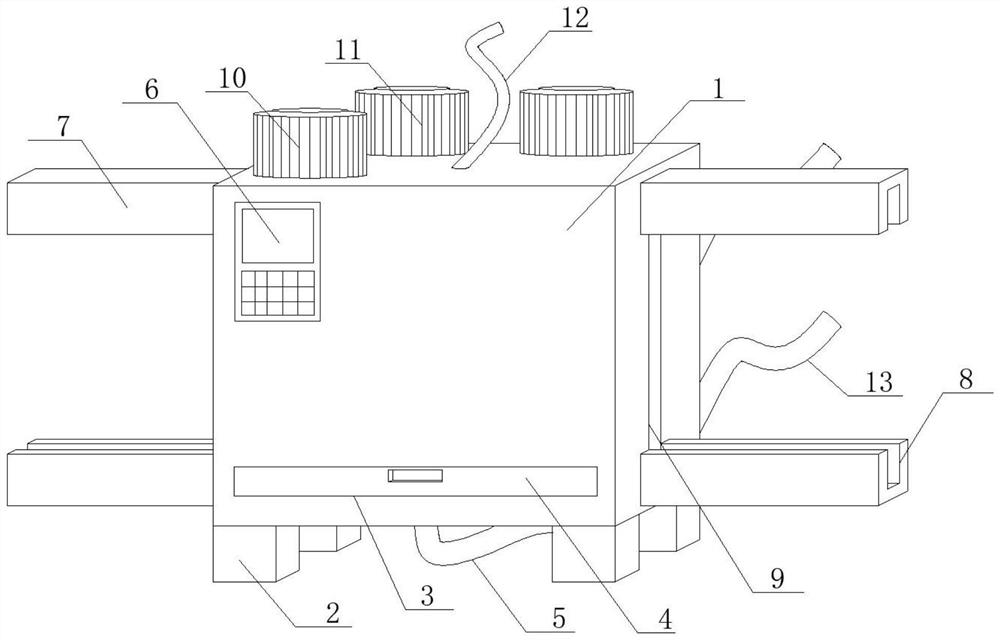

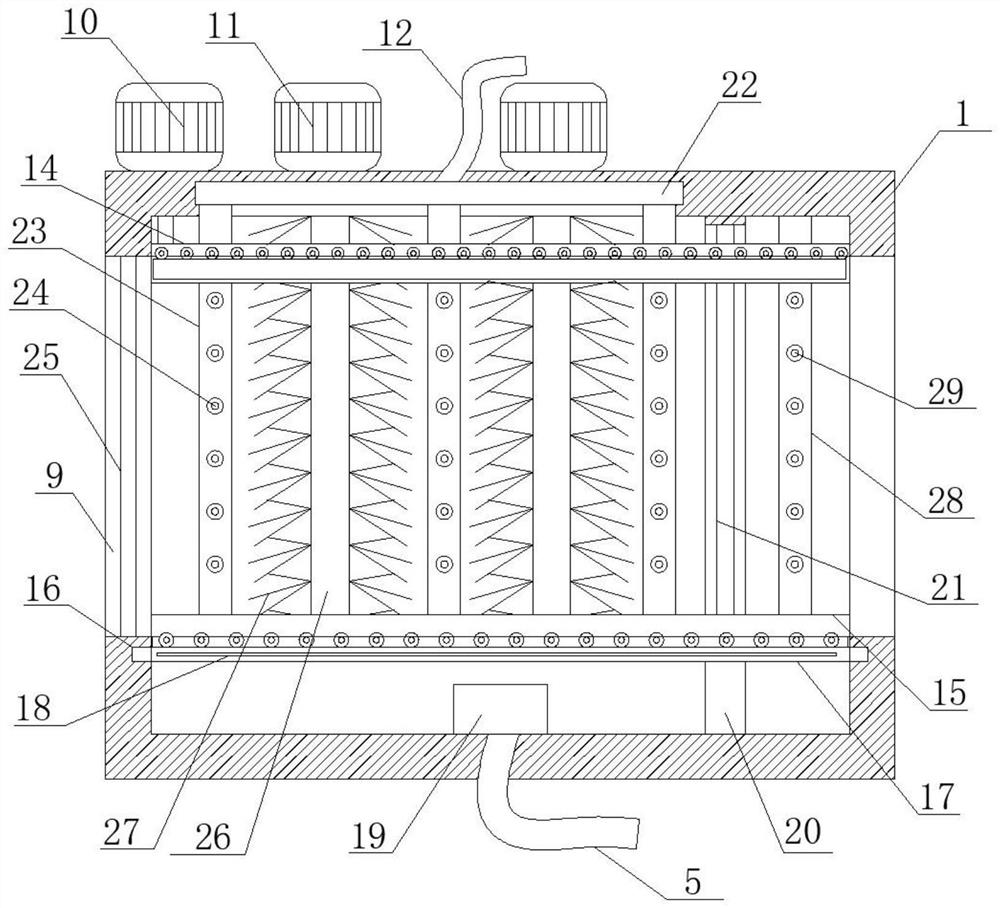

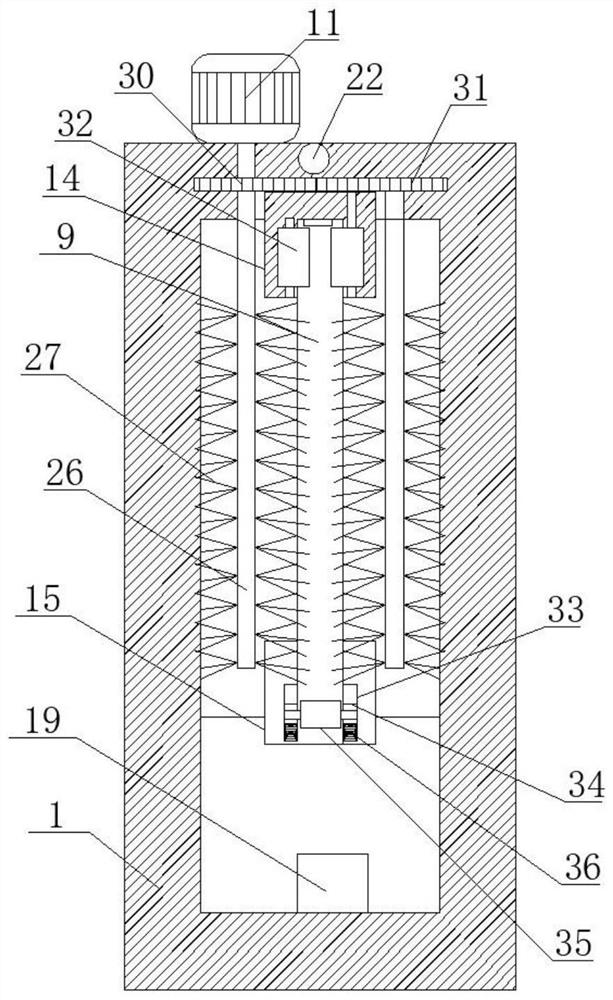

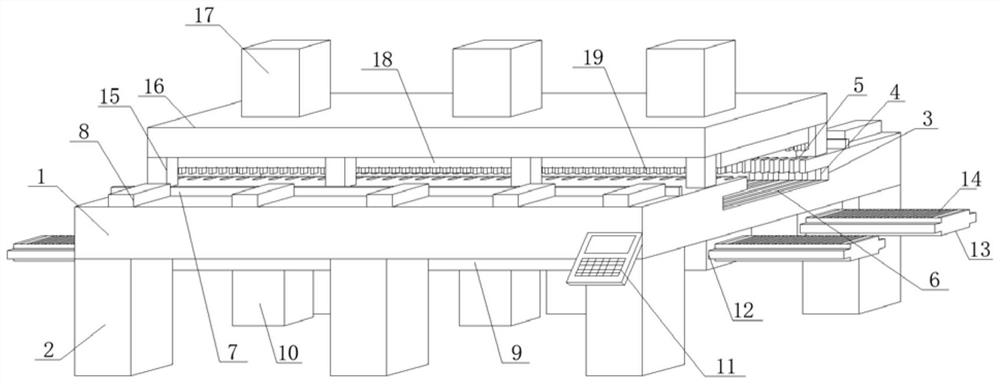

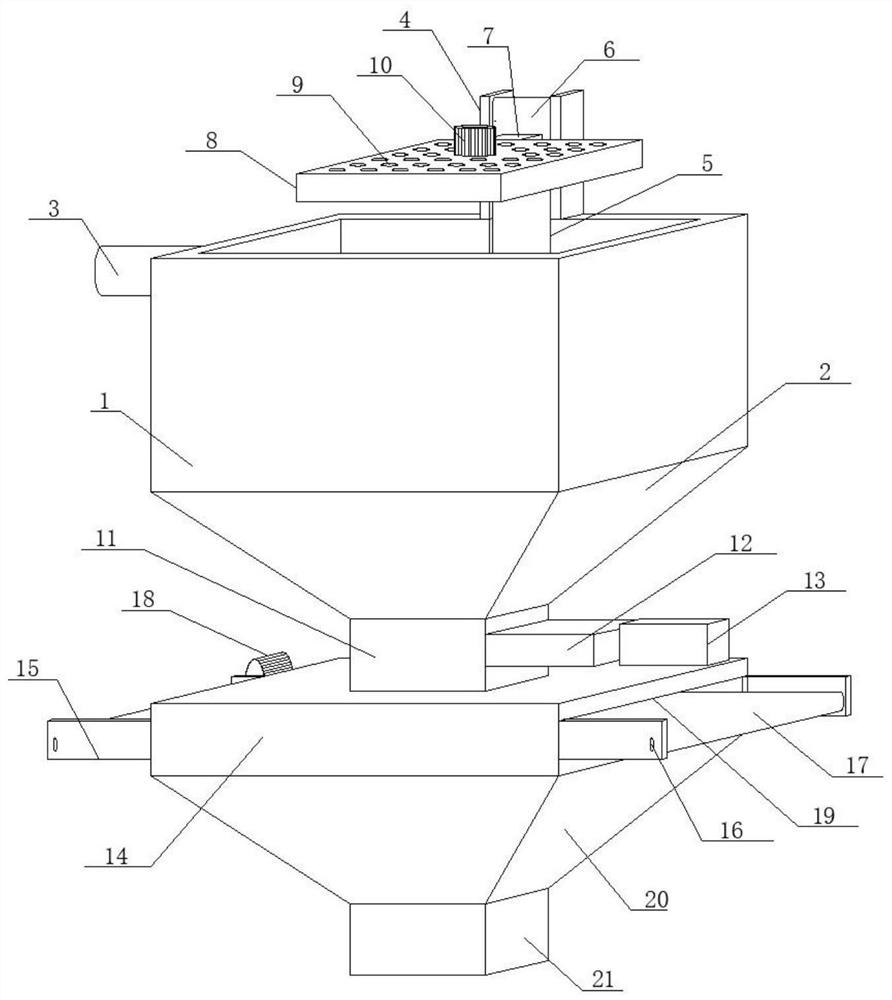

The invention discloses spraying equipment for a socket type large-diameter plastic-coated steel pipe, and relates to the field of plastic-coated steel pipes. The spraying equipment comprises a fixed bottom plate, wherein a supporting vertical rod is vertically and downwards welded on the bottom surface of the fixed bottom plate; the top surface of the fixed bottom plate is in bolted connection with a spraying main box, and the top surface of the fixed bottom plate is in bolted connection with a baking main box; a control panel is embedded in one side edge of the baking main box; a dust suction pipe is inserted into the top surface of the spraying main box, and a feeding pipe is inserted into the top surface of the spraying main box; the end, away from the spraying main box, of the top surface of the fixed bottom plate is in bolted connection with an end conveying box, and discharging holes are symmetrically formed in the two side edges of the end conveying box; and sealing rubber blocks are fixedly clamped to the inner side edges of the discharging holes. The equipment is designed to be integrated, the structure is simple, and operation is easy and convenient. Spraying is faster and more efficient by adopting the structure that the inner wall and the outer wall of a pipe body are sprayed at the same time, and meanwhile the machining and production efficiency is greatly improved through the spraying and baking integrated design.

Owner:杭州中橙科技有限公司

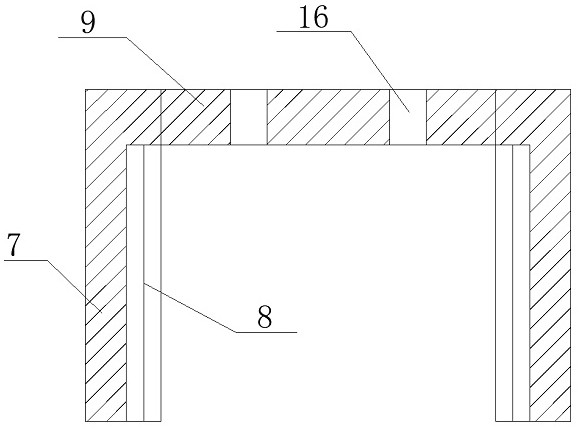

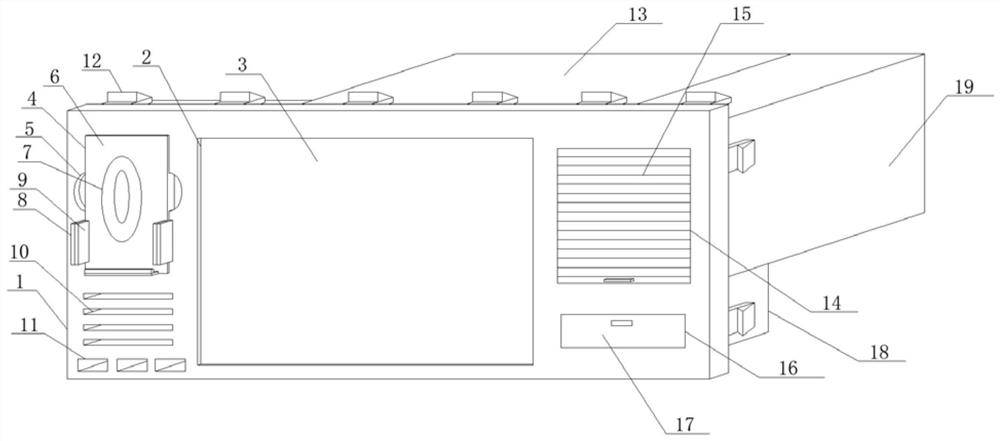

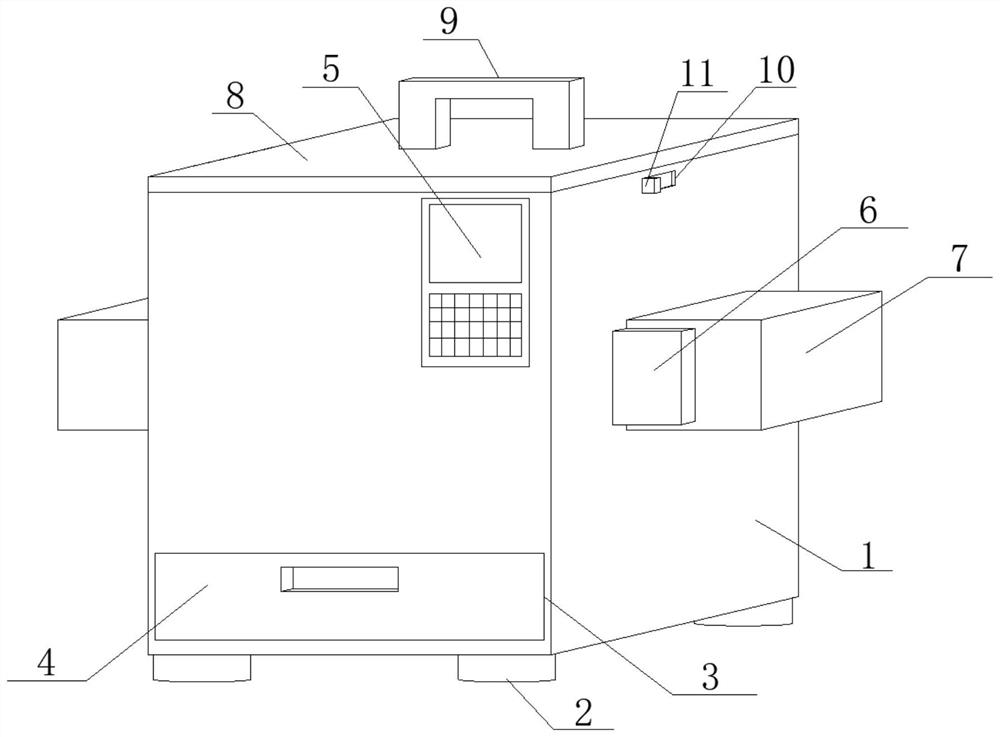

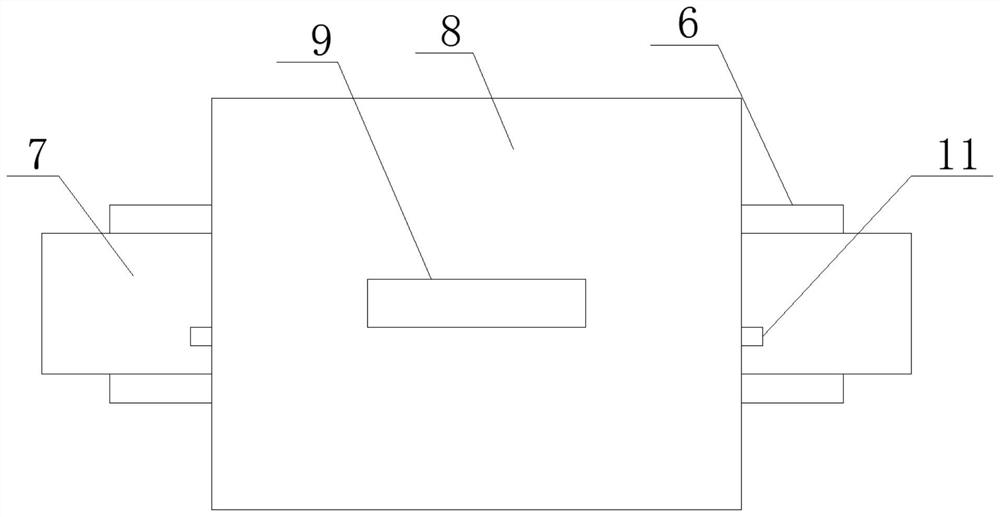

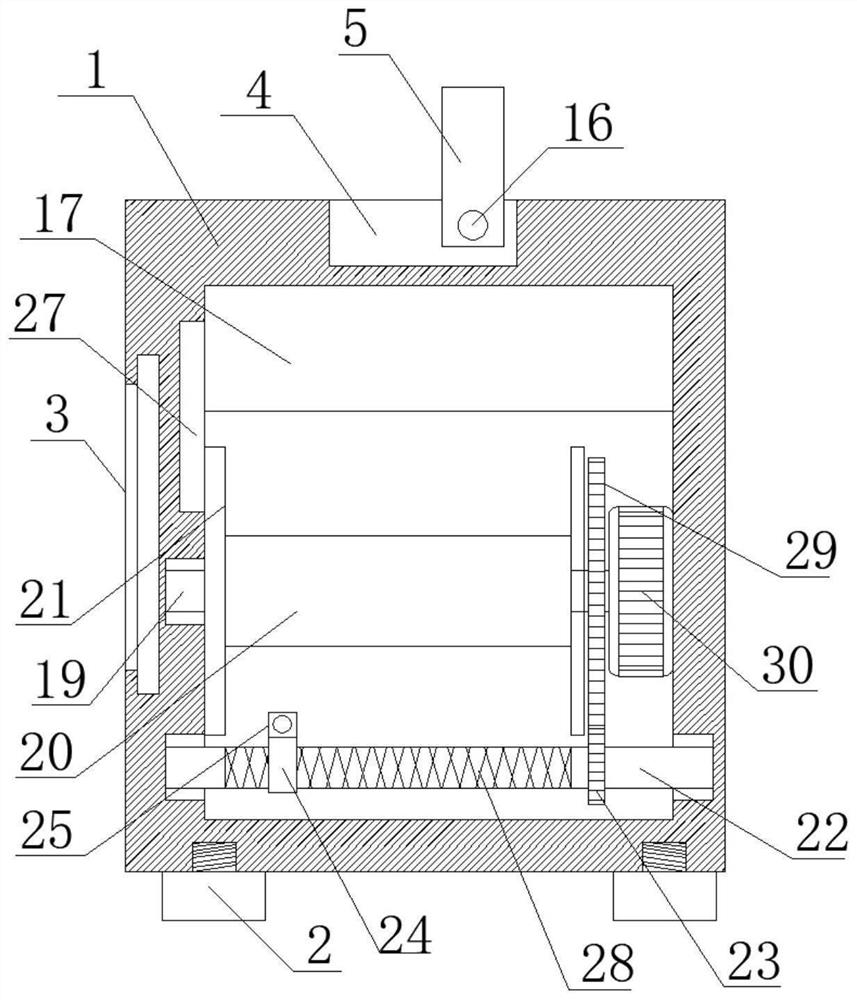

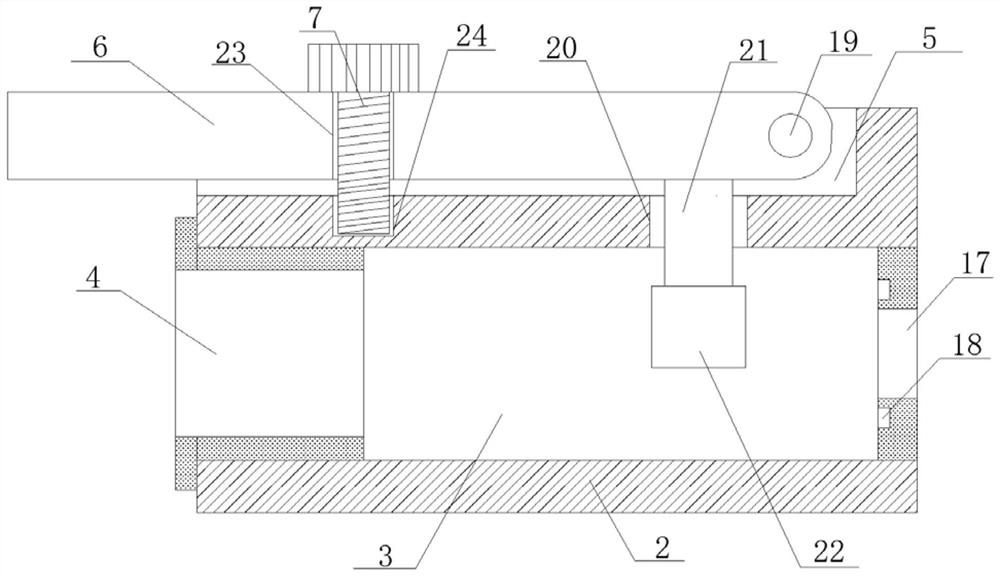

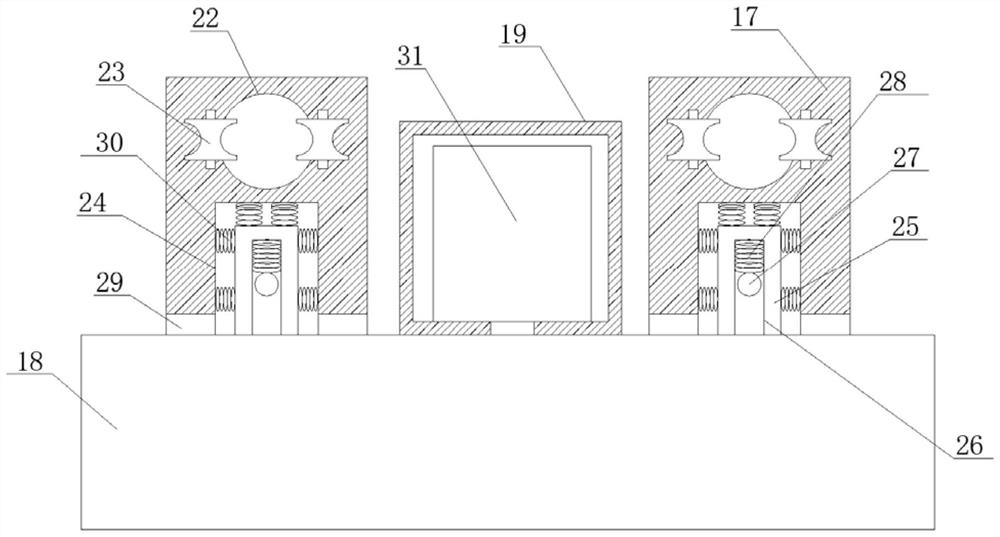

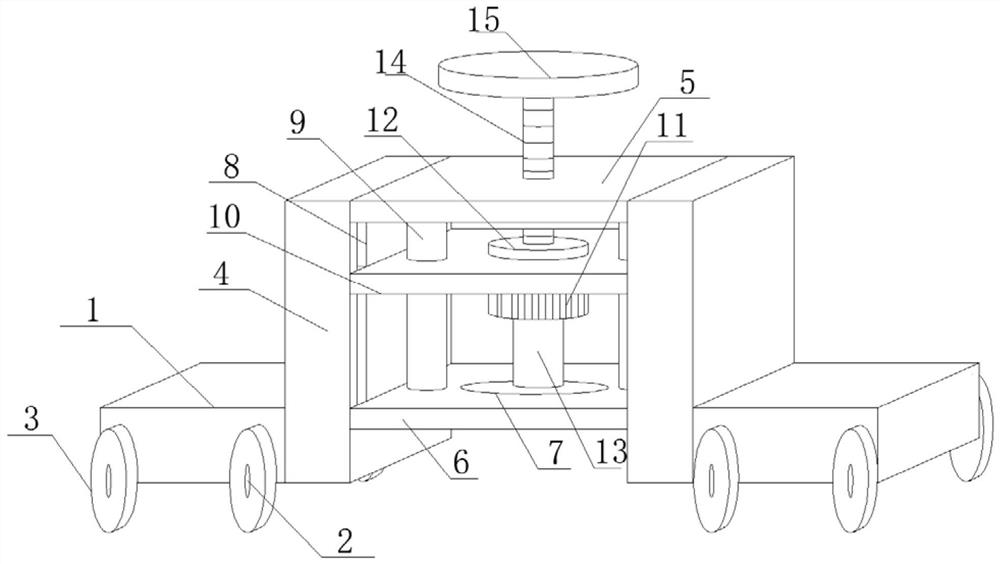

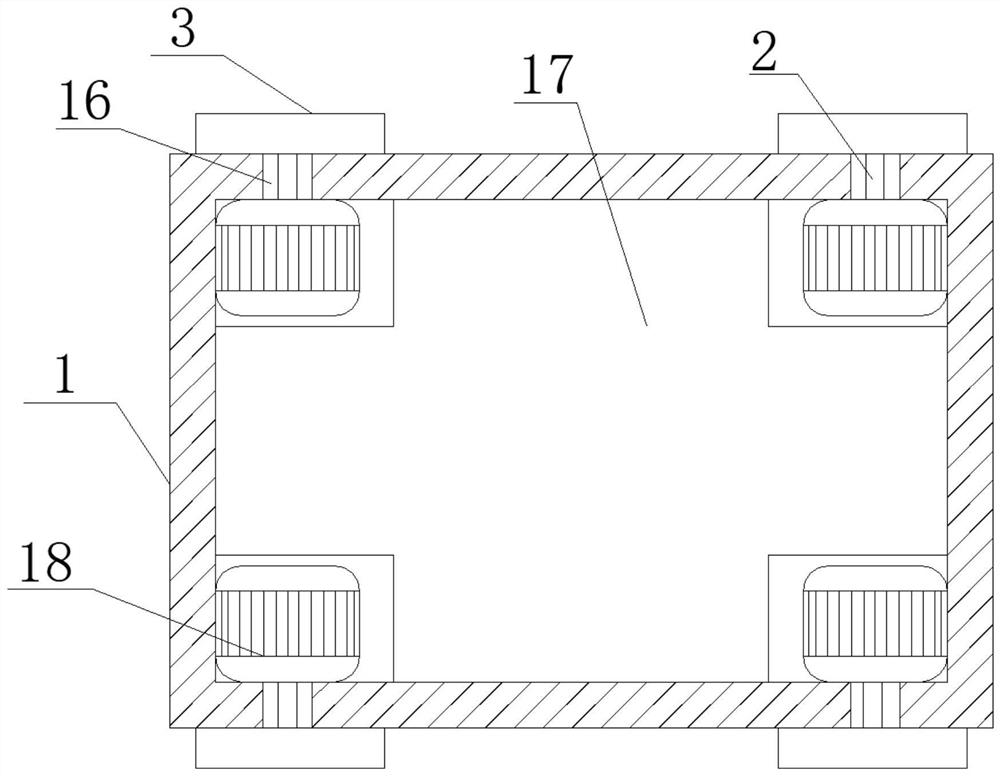

Stainless steel tableware polishing device

ActiveCN112192431AEasy and quick installationSimple structureEdge grinding machinesPolishing machinesStructural engineeringMechanical engineering

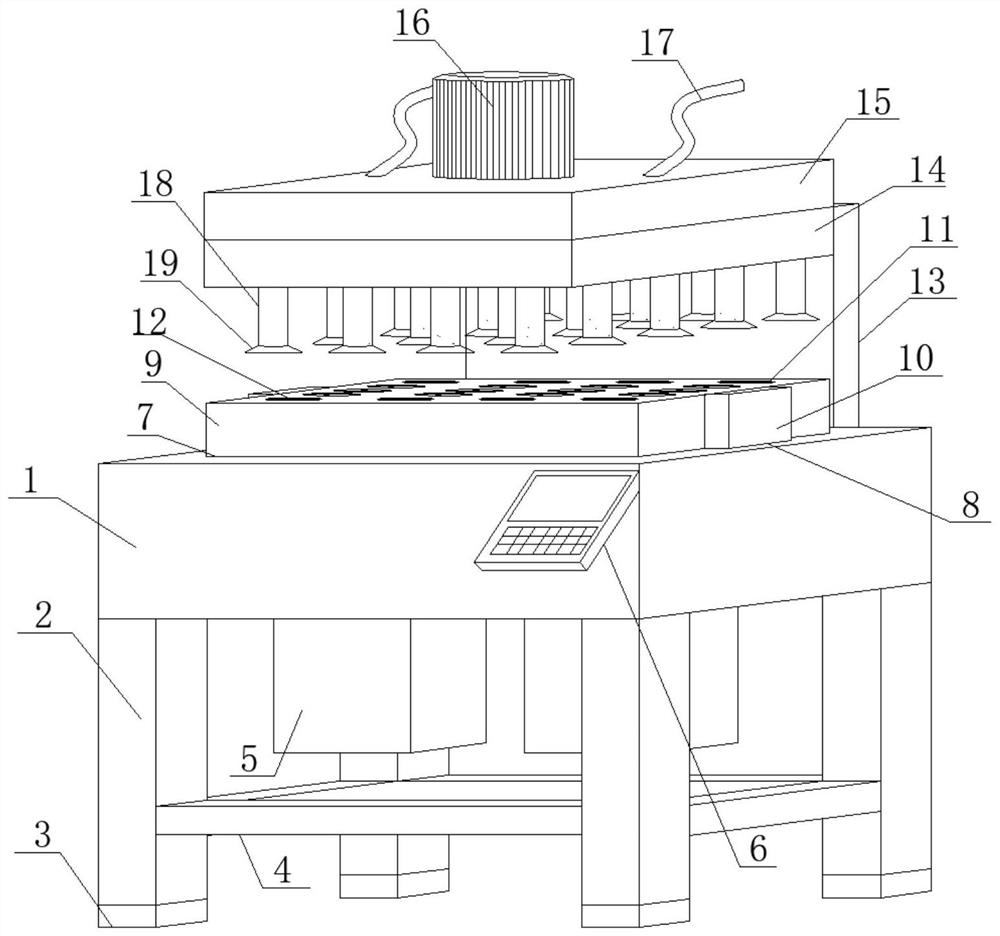

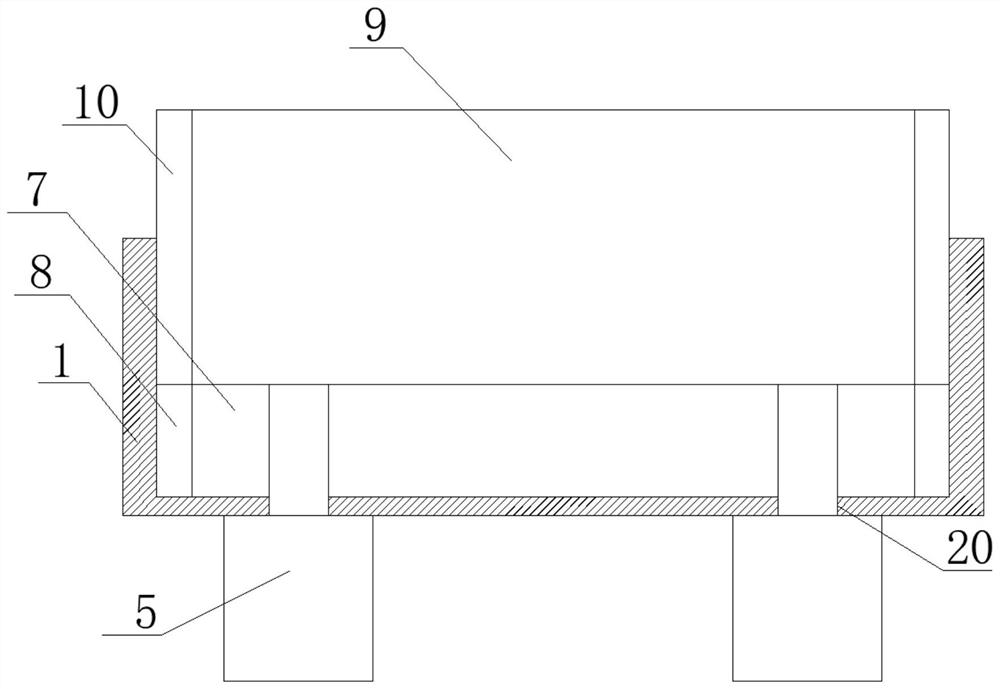

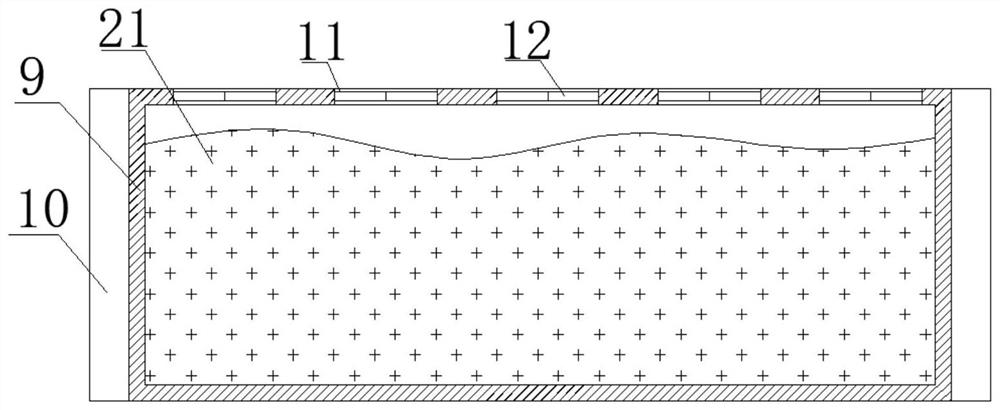

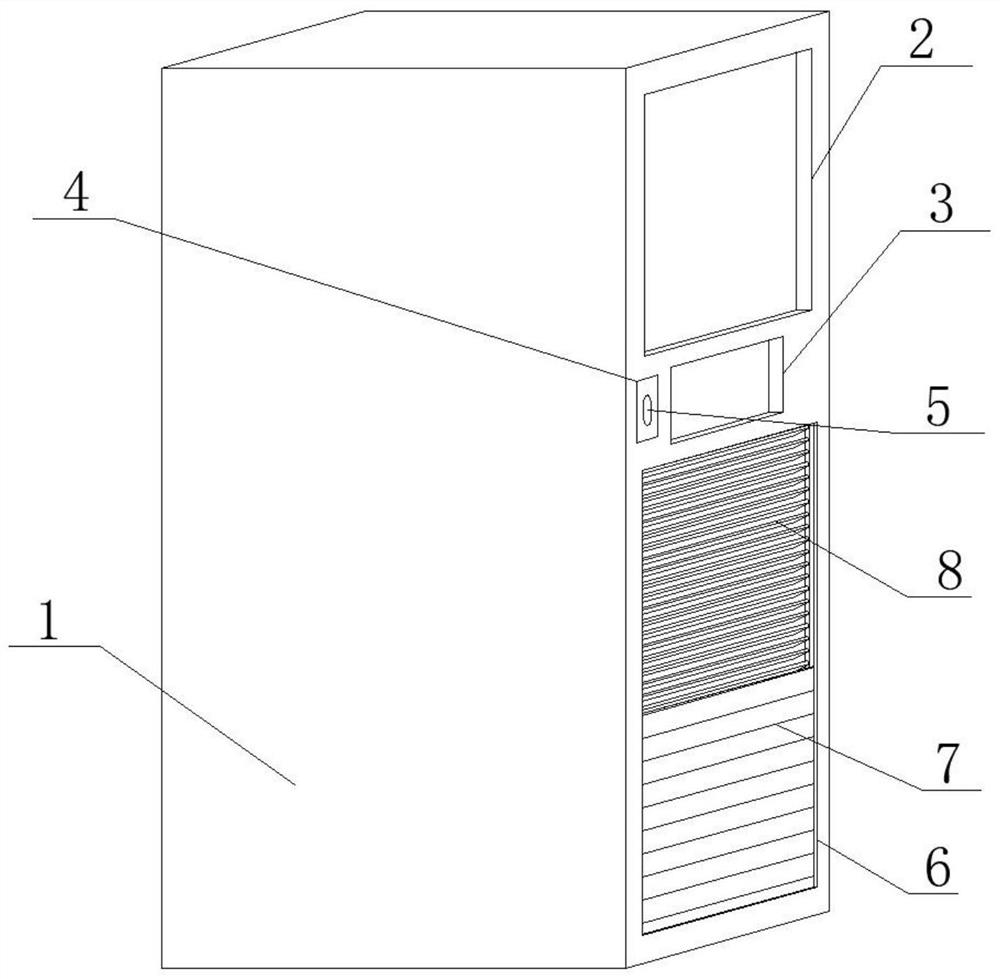

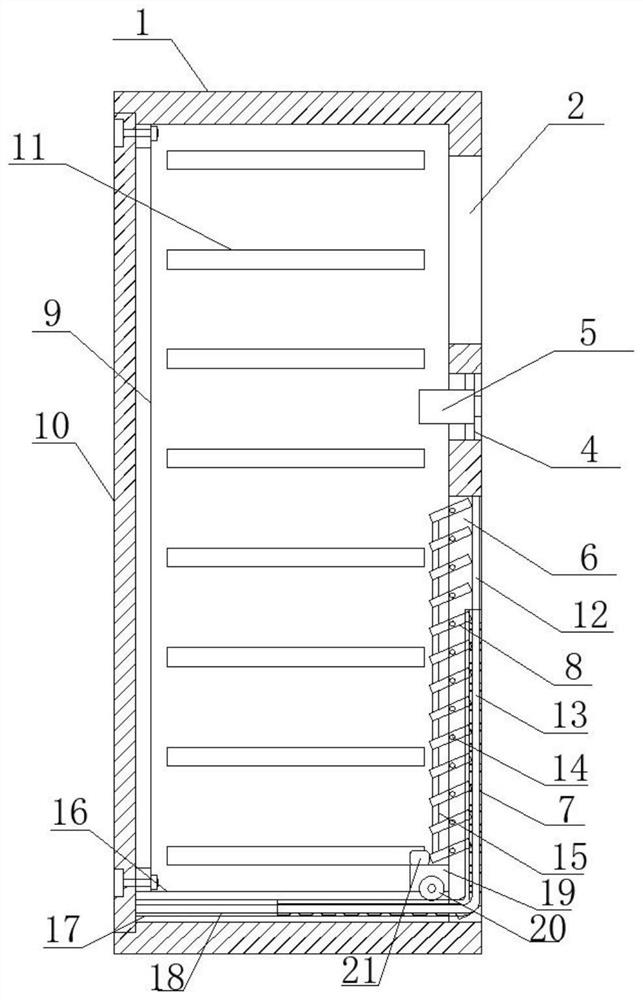

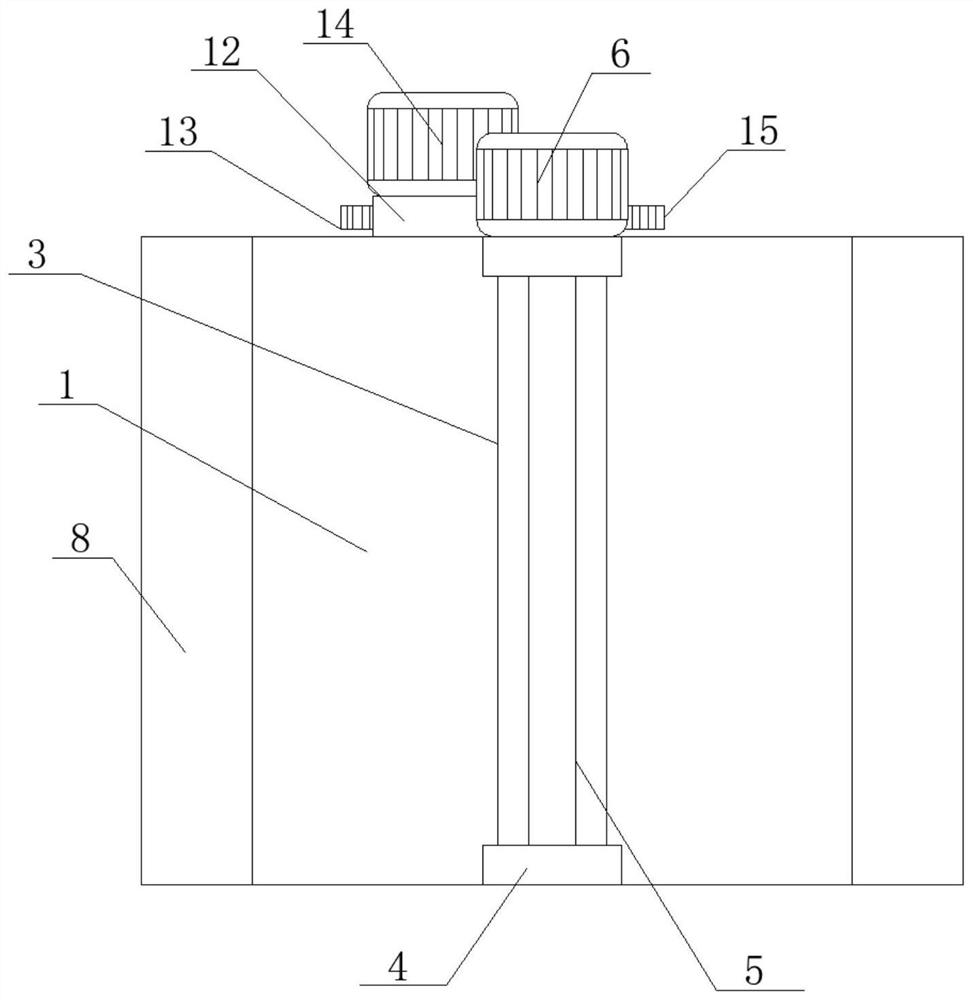

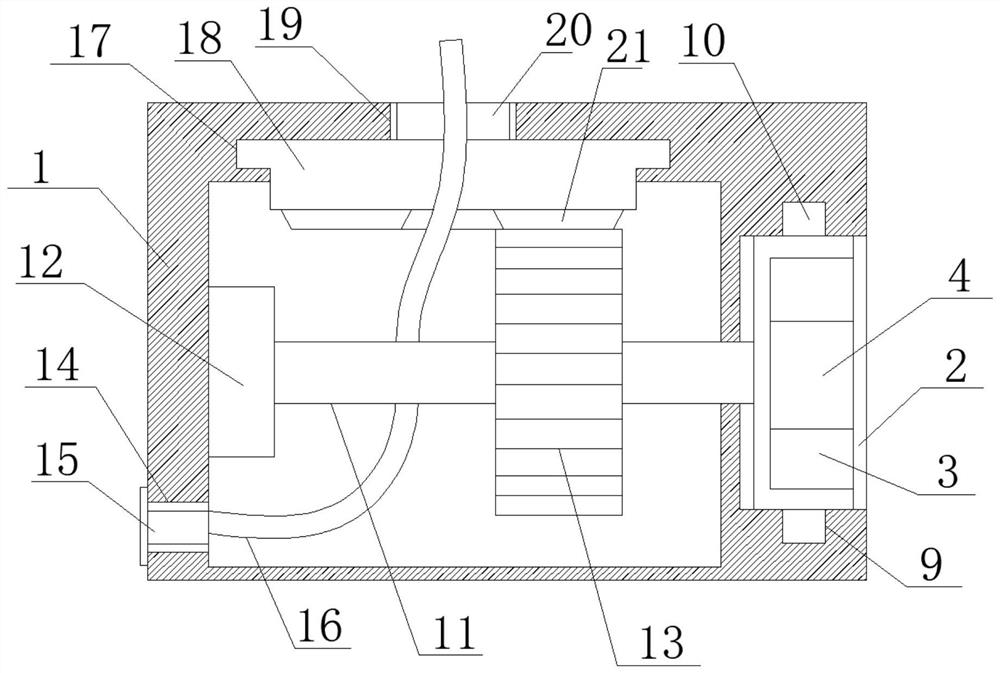

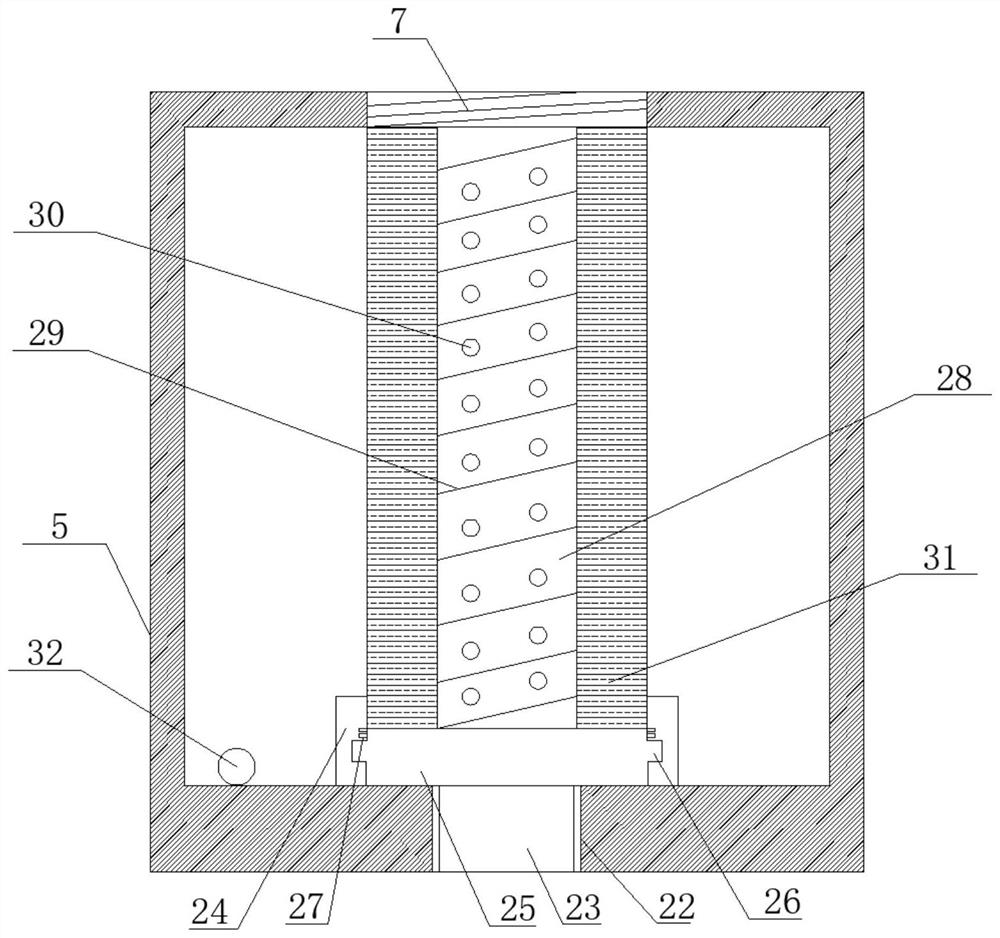

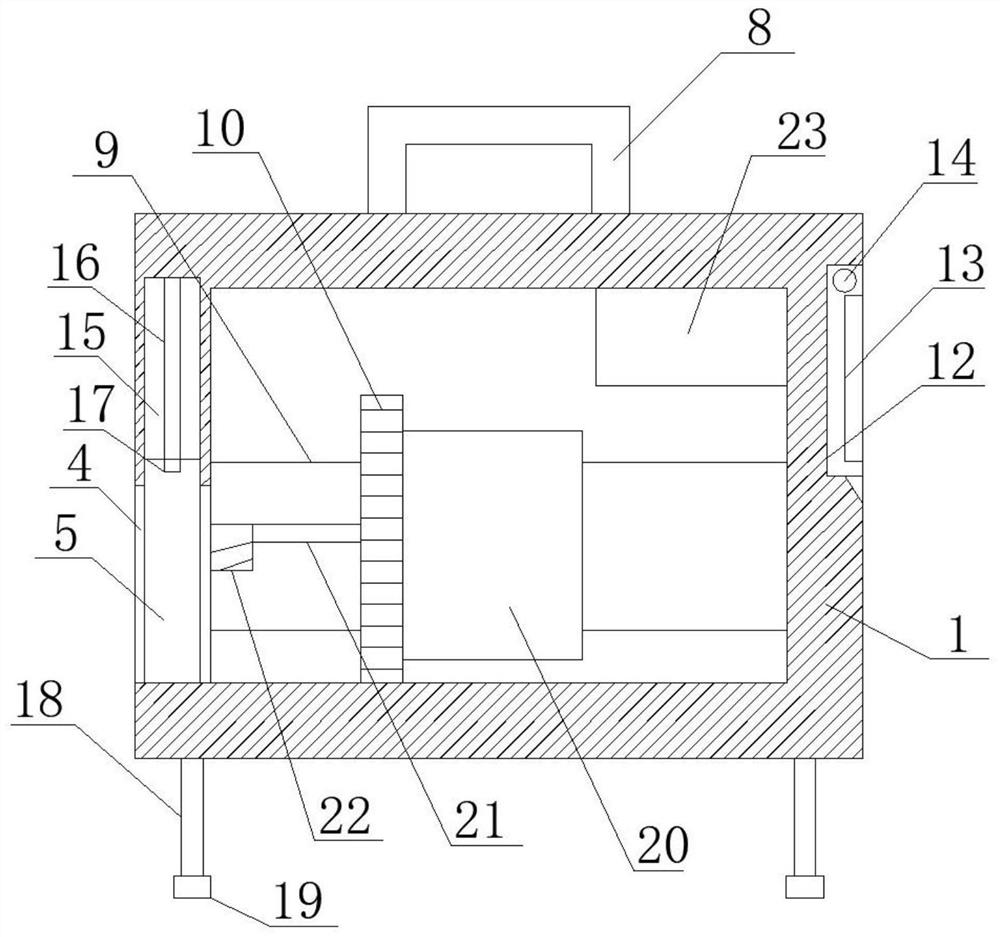

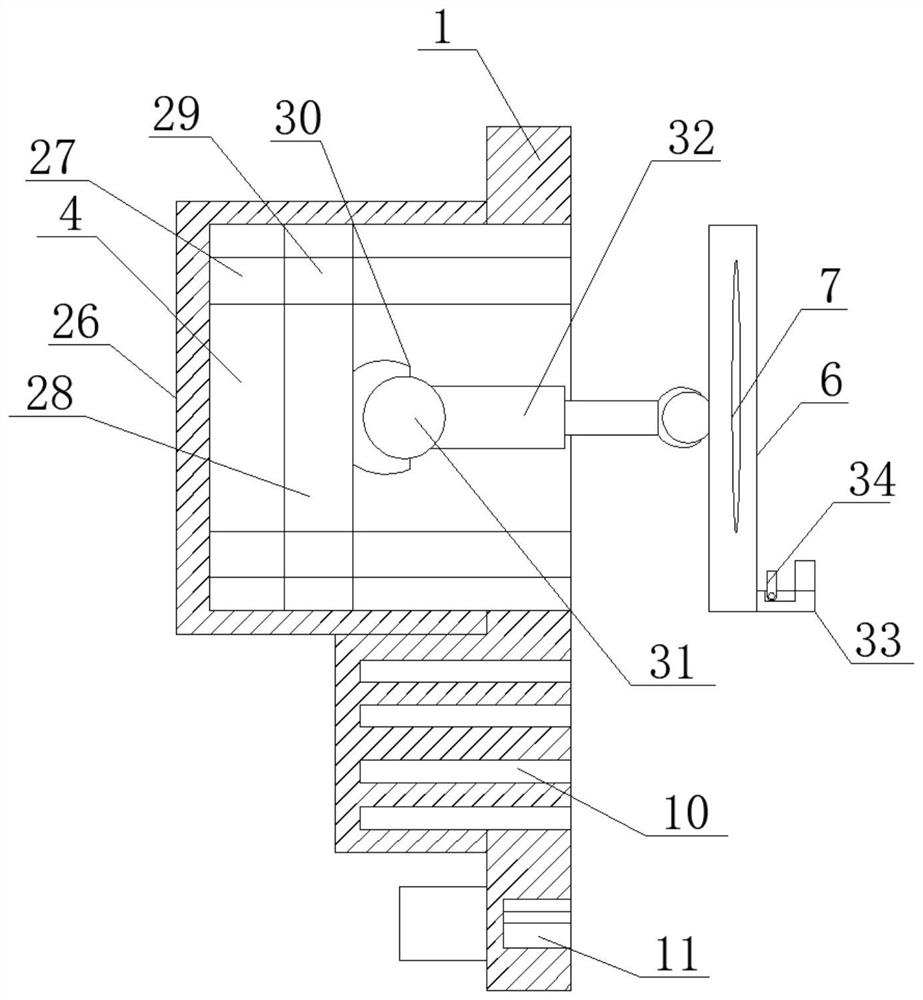

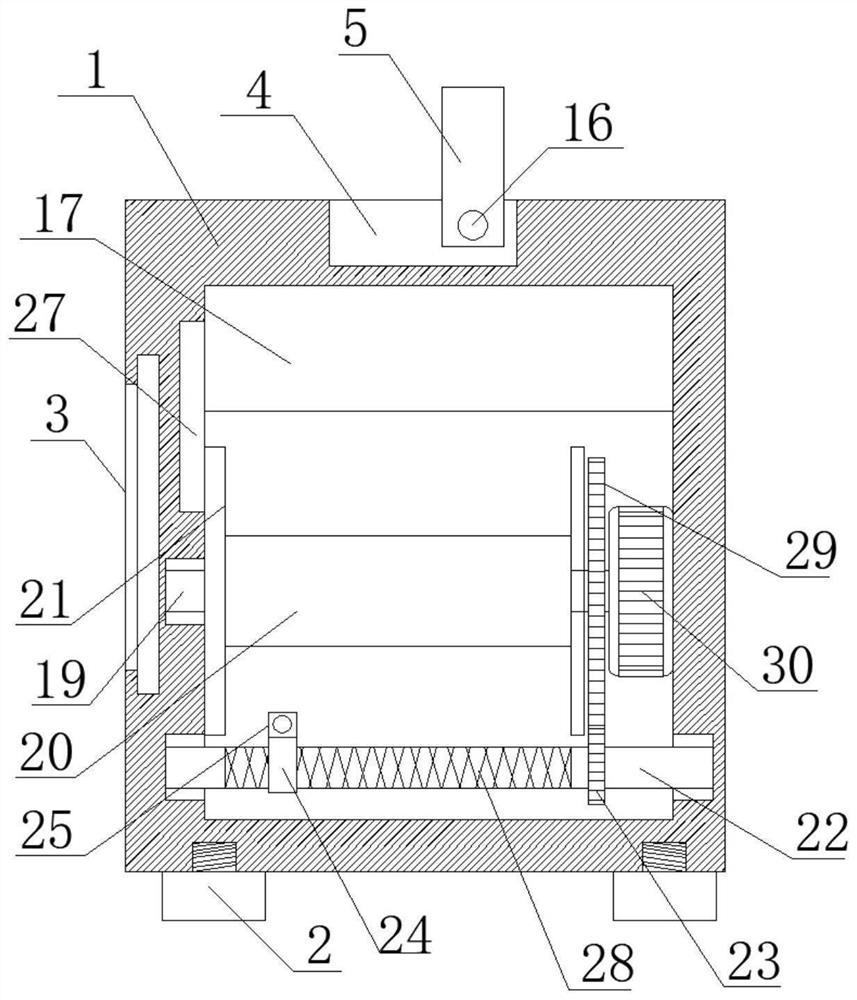

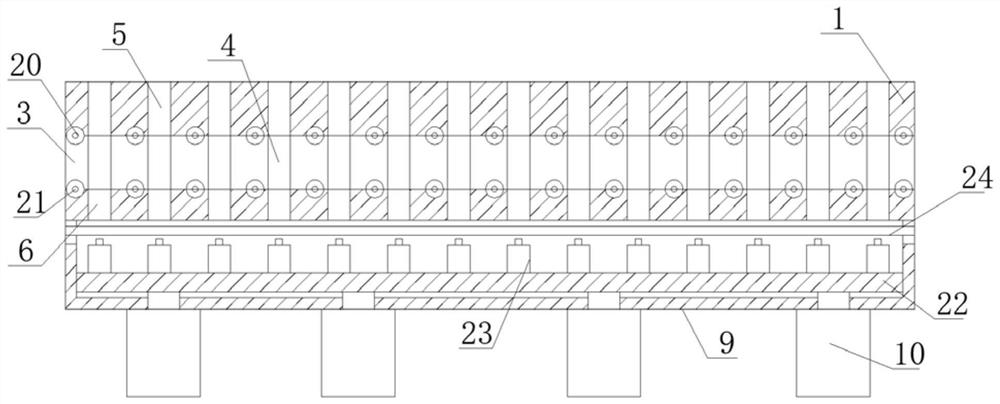

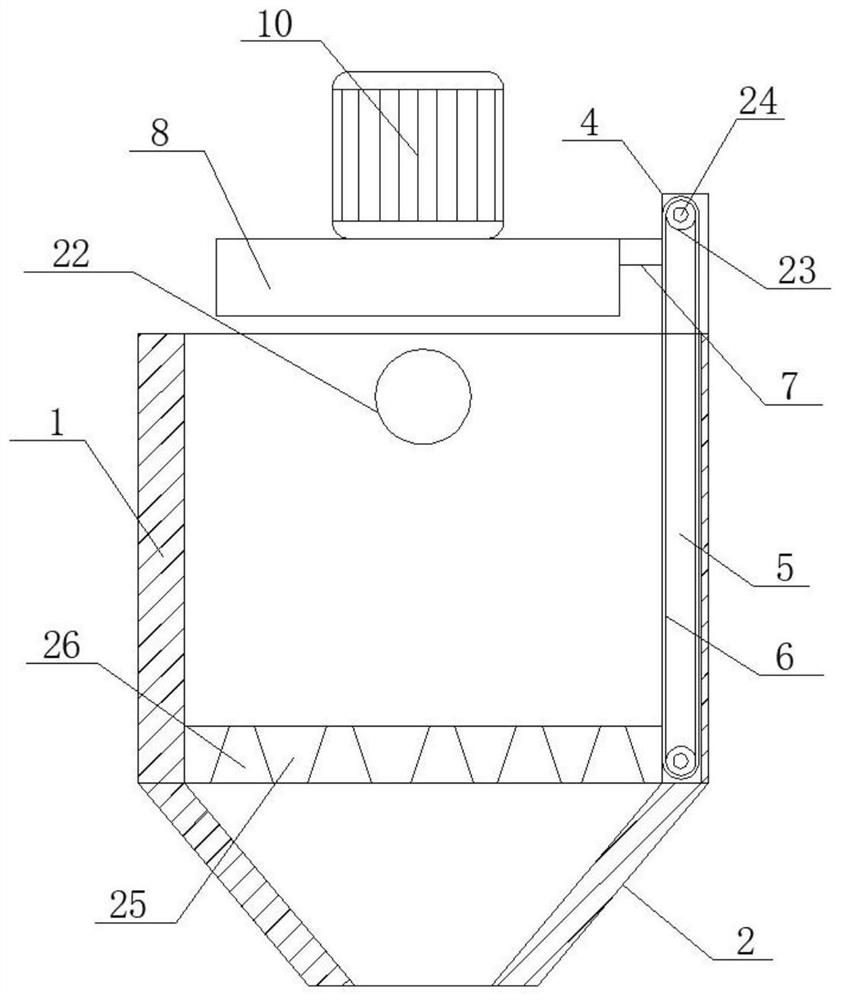

The invention discloses a stainless steel tableware polishing device, and relates to the field of tableware polishing. The stainless steel tableware polishing device comprises a fixed box body, wherein a supporting vertical rod is vertically welded downwards on the bottom surface of the fixed box body; a bottom rubber cushion block is fixedly clamped at the bottom end of the supporting vertical rod; a fixed cross rod is horizontally welded on the side edge of the supporting vertical rod; a bottom air cylinder is connected to the bottom surface of the fixed box body through a vertical bolt; a control panel is obliquely welded on one side edge of the fixed box body; a movable groove is horizontally formed in the top surface of the fixed box body; limiting grooves are vertically and symmetrically formed in the two side edges of the movable groove; a processing box body is clamped on the inner side edge of the movable groove; and limiting parts are vertically and symmetrically welded on the two side edges of the processing box body. The stainless steel tableware polishing device is simple in design integrated structure and convenient to operate, the surface of tableware is polished inan all-around and dead-angle-free mode by adopting a sand grain polishing mode, the stainless steel tableware polishing device is more reasonable and efficient, meanwhile, the batch polishing effect can be achieved, and the polishing working efficiency is greatly improved.

Owner:揭阳市东拓家居实业有限公司

Air conditioner shell facilitating air conditioner air inlet area adjustment

InactiveCN112628866AEasy to installEasy to moveLighting and heating apparatusNoise suppressionEngineeringBolt connection

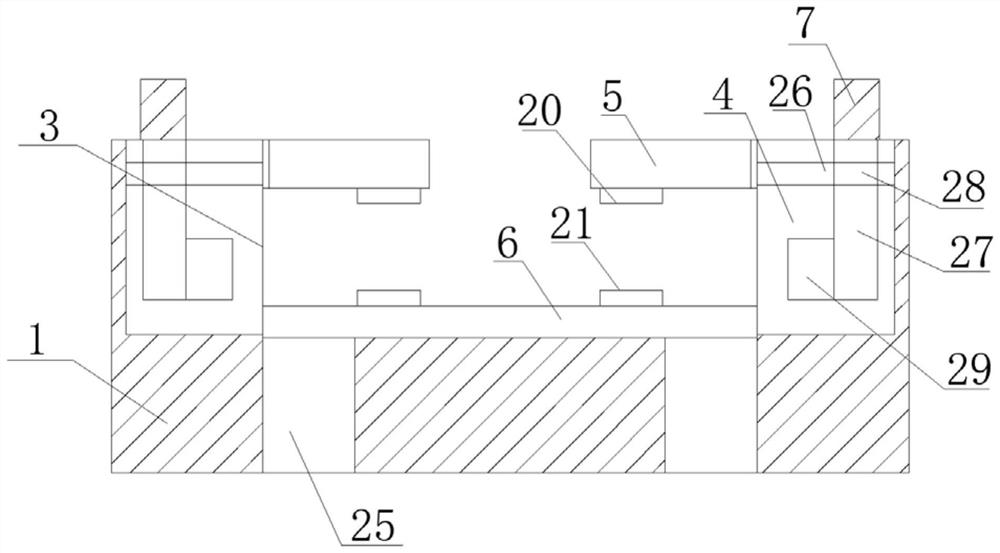

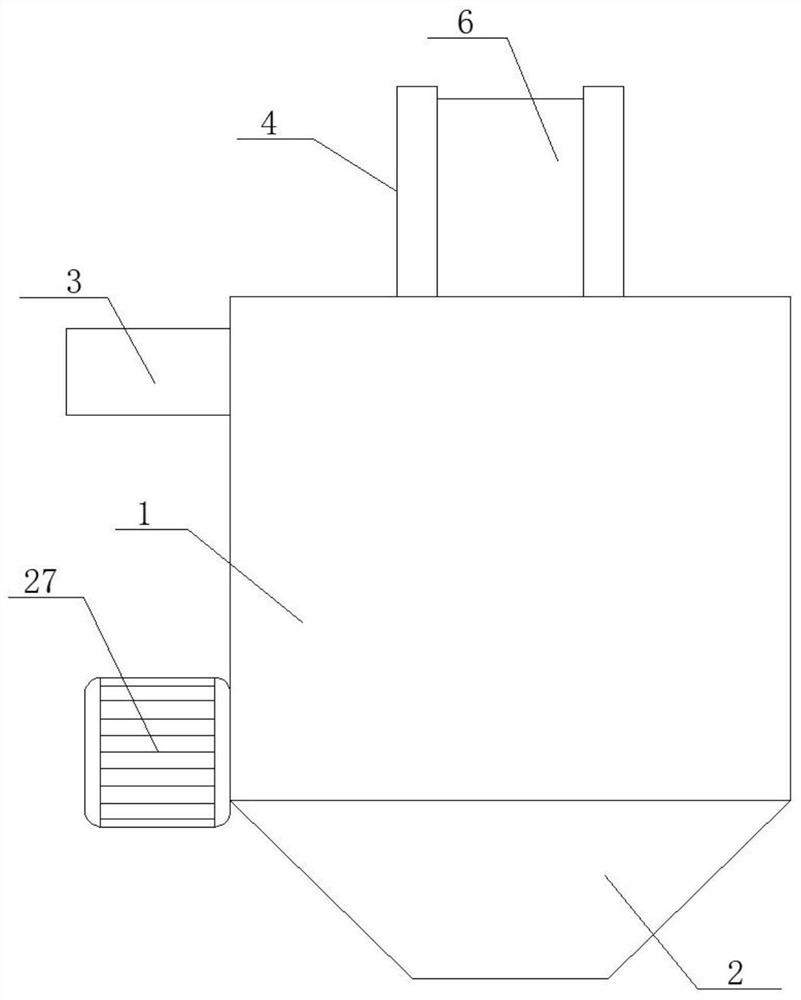

The invention discloses an air conditioner shell facilitating air conditioner air inlet area adjustment, and relates to the field of air conditioner shells. The air conditioner shell comprises a main outer shell, an air outlet groove channel is formed in one side edge of the main outer shell, a control plate groove hole is horizontally formed in one side edge of the main outer shell, a clamping hole plate is connected to one side edge of the main outer shell in a clamped mode, a temperature sensing probe is inserted into one side edge of the clamping hole plate, an air inlet channel is vertically formed in one side edge of the main outer shell, a movable sealing plate is clamped to the inner side edge of the air inlet channel, an adjusting guide plate is horizontally arranged on the inner side edge of the air inlet channel, a rear frame body is fixedly welded to the side, away from the air inlet channel, of the main outer shell, and a sealing rear plate is connected to the side, away from the air inlet channel, of the main outer shell through bolts. The device is integrated in design, simple in structure and convenient to operate, more humanization is achieved through the intelligent centralized control design, and control over the air inlet area is more accurate and efficient through the dual regulation and control structure.

Owner:CHUZHOU UNIV

Intelligent omnibearing anti-theft monitoring platform and processing system

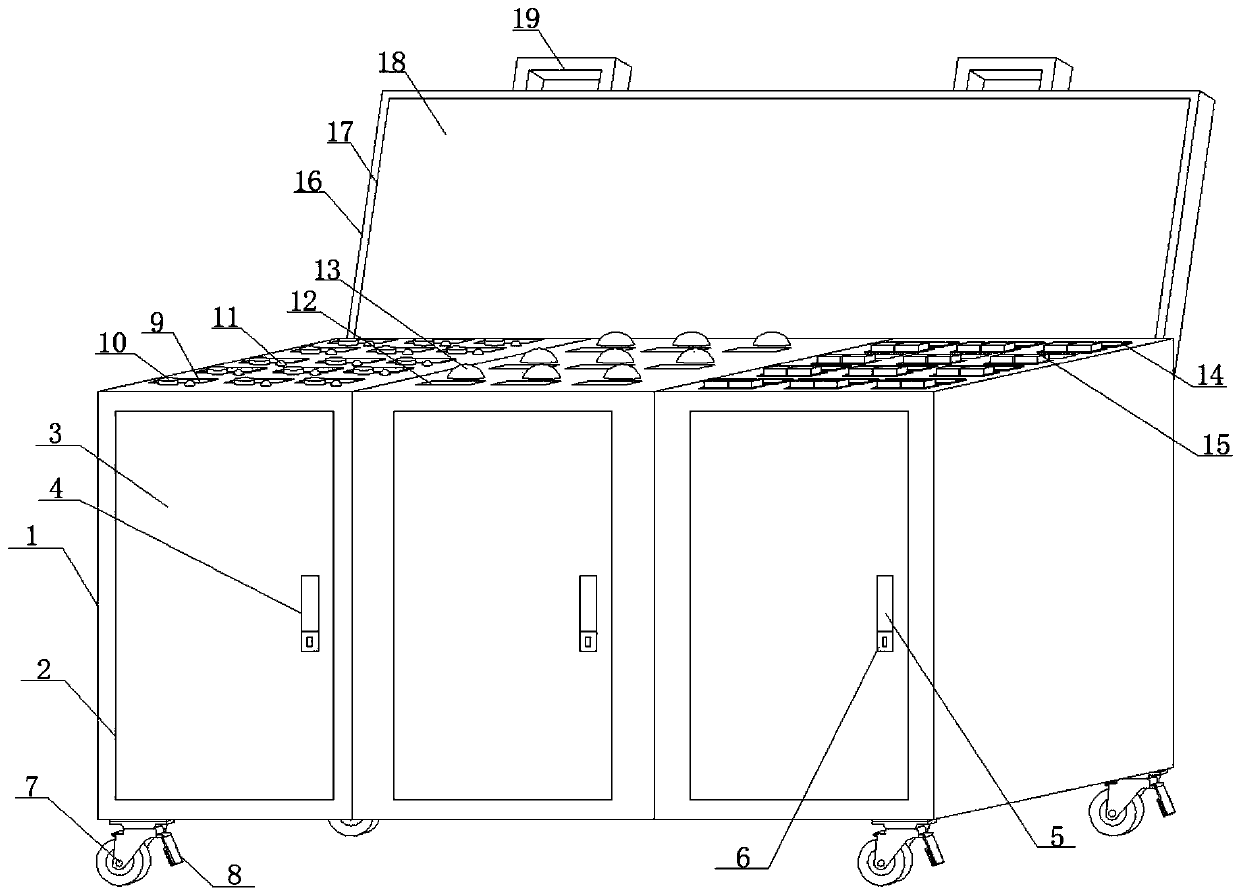

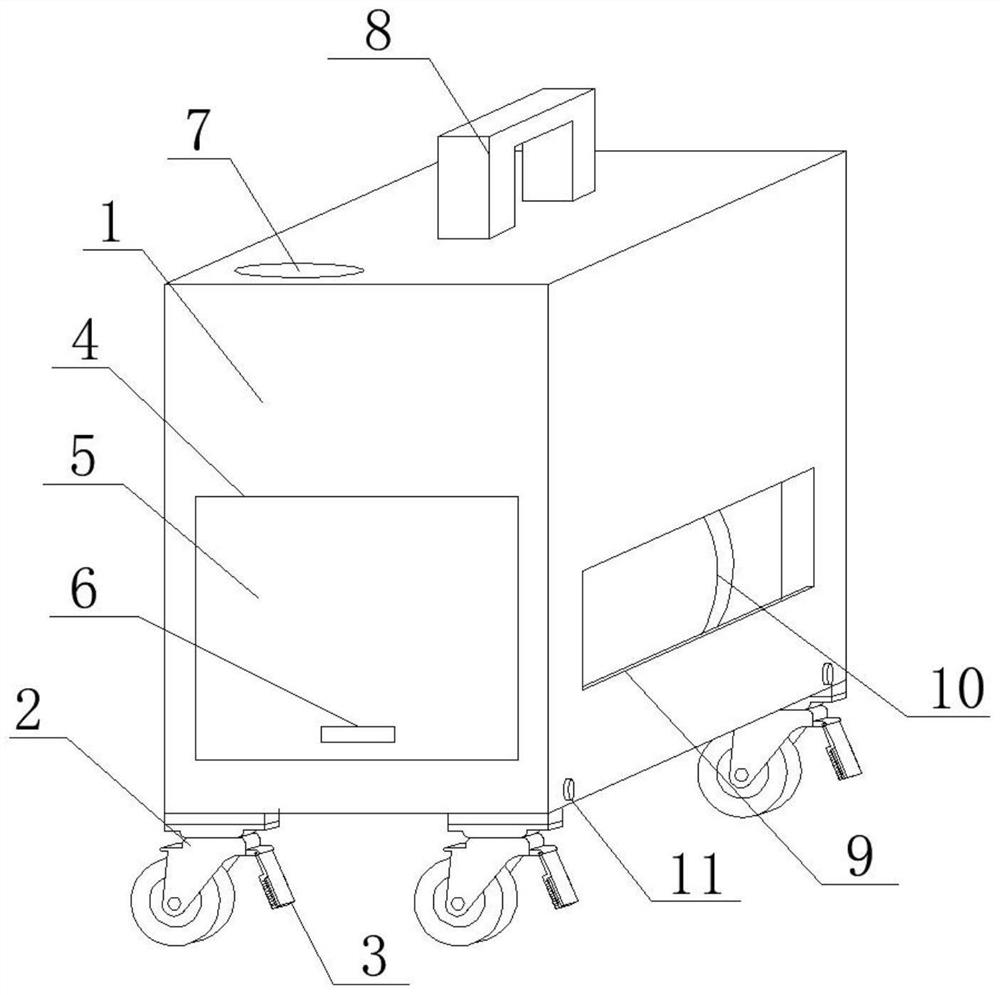

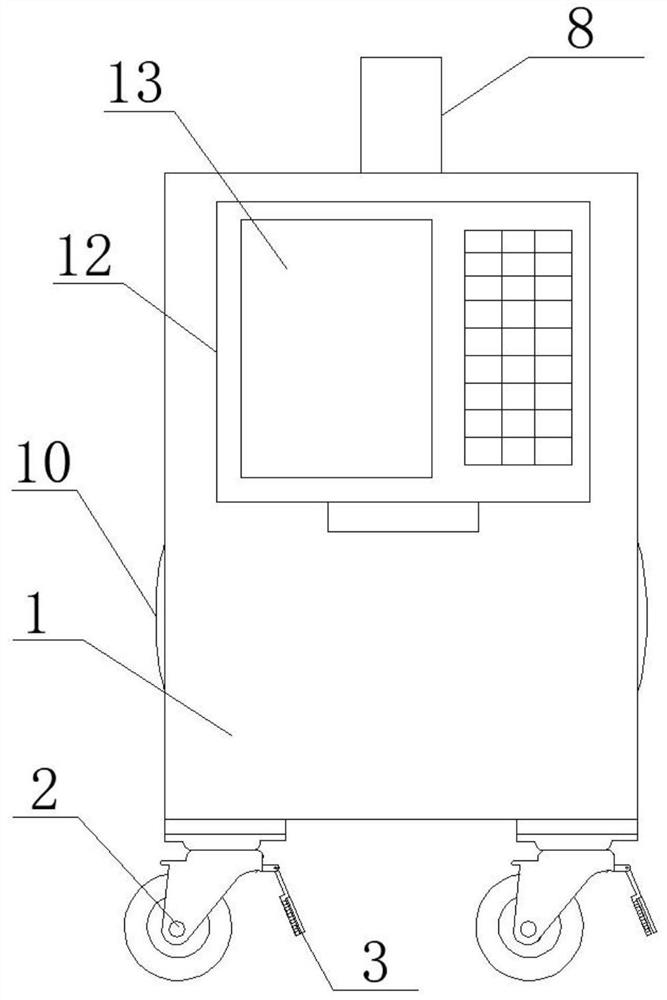

ActiveCN111565526AReduce wasteQuick and efficient installationTelevision system detailsCasings with display/control unitsBrakeHandling system

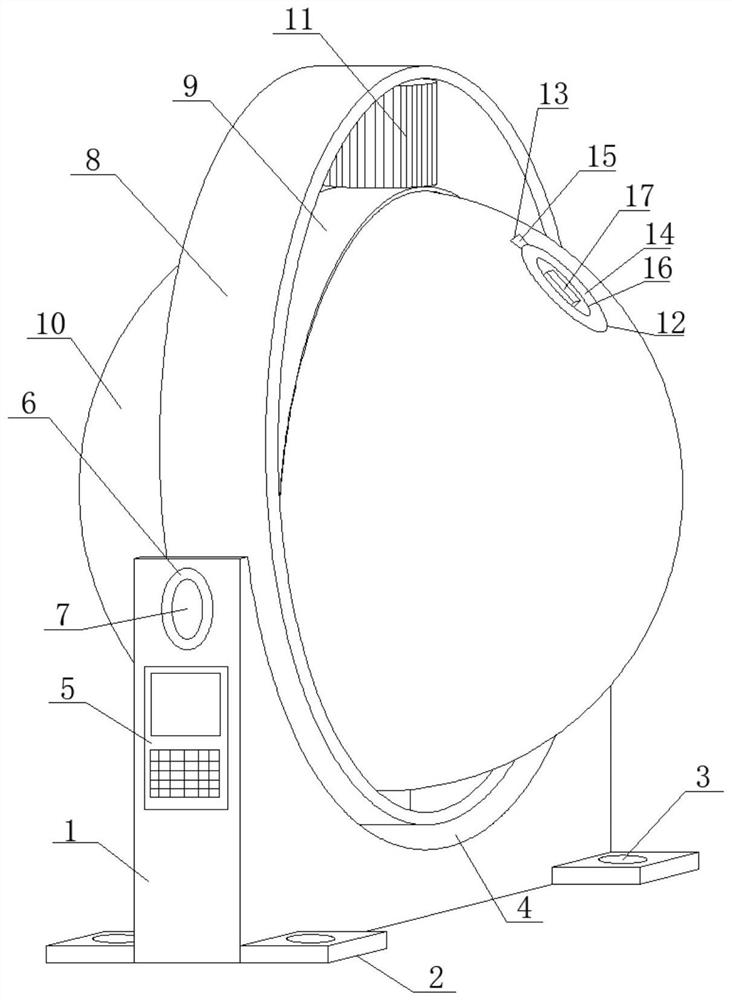

The invention discloses an intelligent omnibearing anti-theft monitoring platform and a processing system, and relates to the field of antitheft monitoring platforms, the system comprises an infraredbox body, a monitoring box body and an access control box body, each of the infrared box body, monitoring box body and access control box body comprises a supporting box body, a sealing notch is formed in one side edge of the supporting box body; the inner side edge of the sealing notch is vertically connected with a door plate in a clamped mode. A movable groove is vertically formed in one side edge of the door plate; a handle is clamped to the inner side edge of the movable groove. A locking block is connected to the inner side edge of the movable groove in a clamping manner; the bottom surface of the supporting box body is in bolted connection with moving rollers; and brake plates are inserted into the side edges of the moving rollers. The system is integrated in design, simple in structure and convenient and fast to operate, centralized control is adopted, running of personnel can be reduced for control, the workload of the personnel is greatly reduced, meanwhile, monitoring is more efficient and comprehensive, and the system is convenient to carry and move and suitable for large-scale application and popularization.

Owner:浙江众诚智能信息有限公司

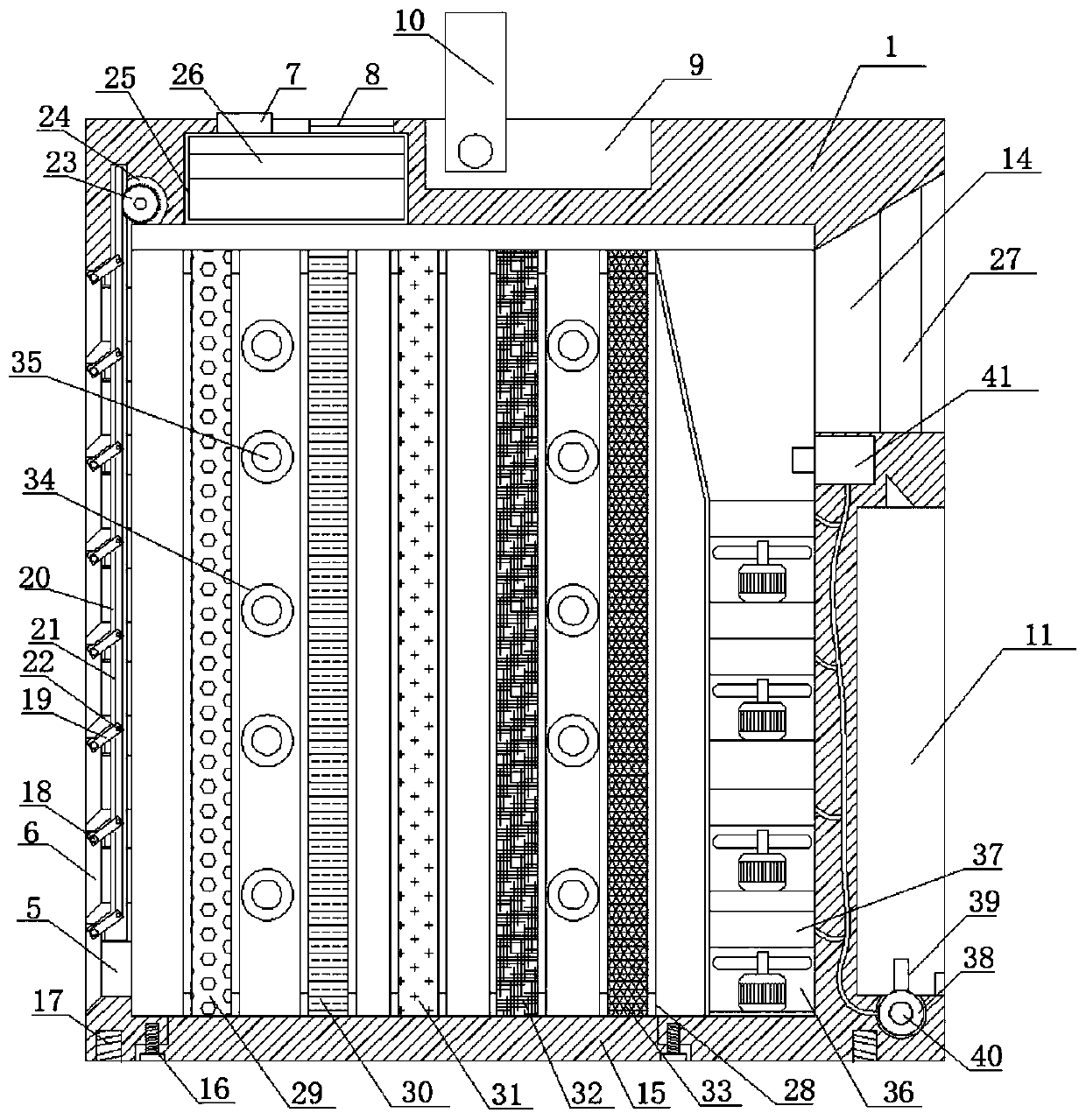

Anti-static textile fabric cleaning and flattening device

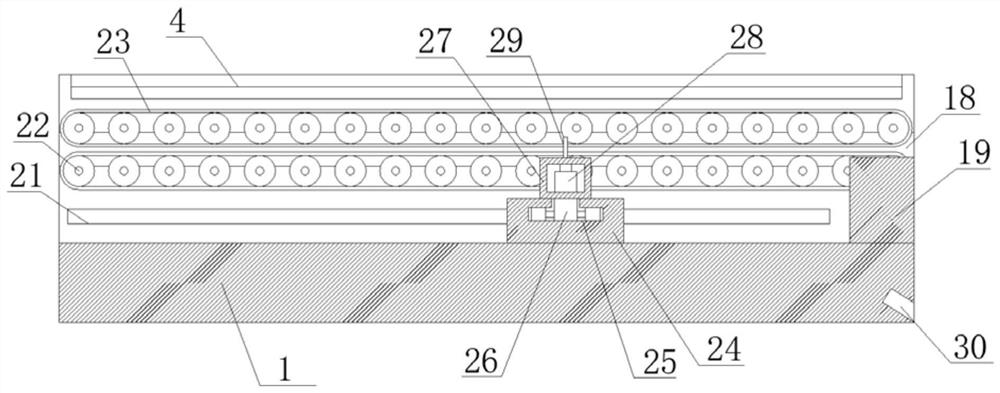

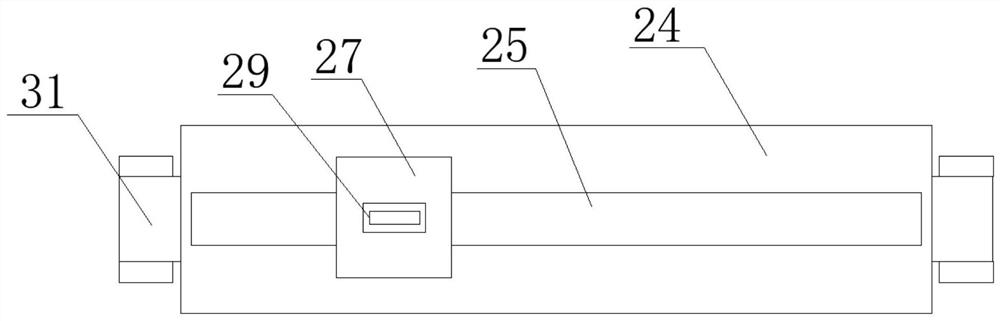

InactiveCN114197139AEasy to handlePrevent static electricityMechanical cleaningPressure cleaningElectric machineryStructural engineering

The invention discloses an anti-static textile fabric cleaning and flattening device, and relates to the field of textile fabrics, the anti-static textile fabric cleaning and flattening device comprises a main treatment box, a supporting vertical rod is vertically and downwards welded to the bottom surface of the main treatment box, a feeding top groove is formed in the top surface of the main treatment box, and a supporting side plate is vertically arranged on the top surface of the main treatment box; a main material shaft rod is inserted into the side edge between the supporting side plates, a rotating motor is connected to one side edge of one supporting side plate through a bolt, a control panel is embedded into one side edge of the main treatment box, fixed side boxes are welded to the two side edges of the main treatment box, and extending side plates are obliquely welded to the two side edges of the main treatment box; according to the device, the integrated structure is designed, operation is easy and convenient, sweeping is more thorough by adopting a rolling type washing and brushing structure, meanwhile, the external pollution situation cannot be caused, and cloth is safer and more reliable after being collected by adopting multiple static electricity removing measures.

Owner:吕智

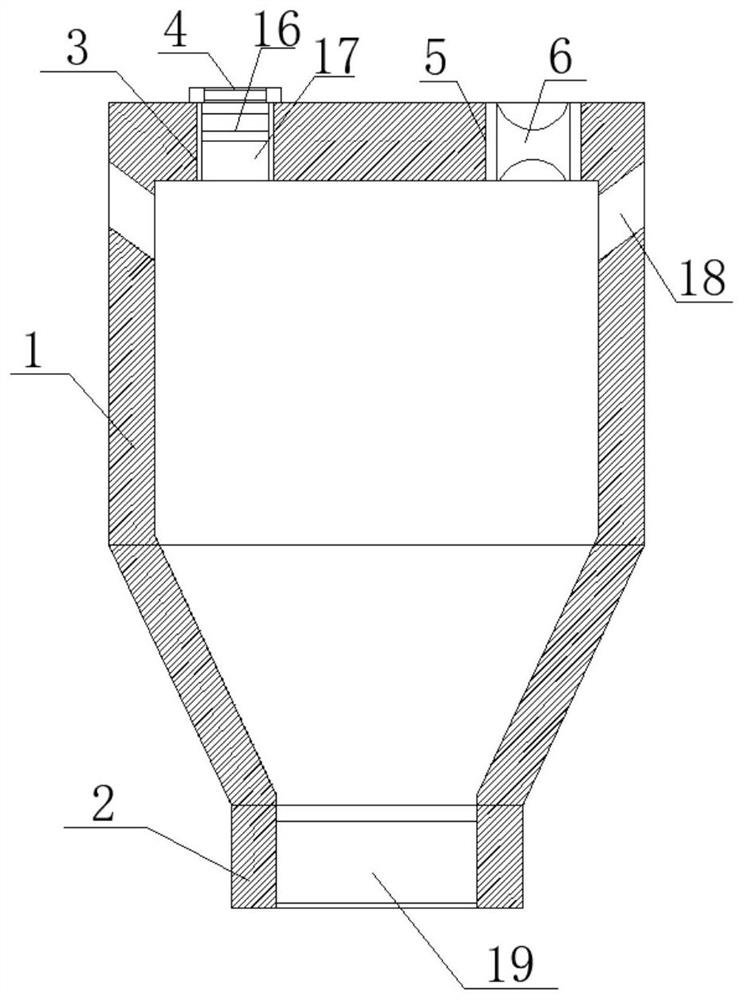

Rotatable filter element connecting base

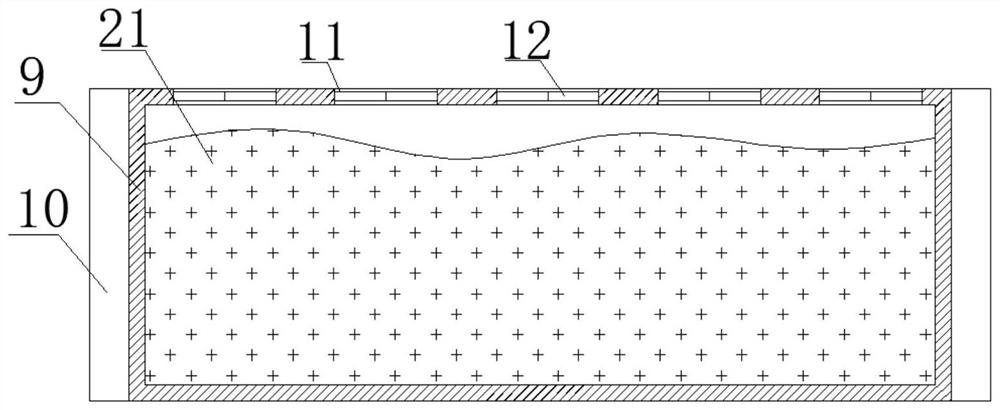

ActiveCN112275008ASimple and fast operationEasy replacementStationary filtering element filtersEngineeringScrew thread

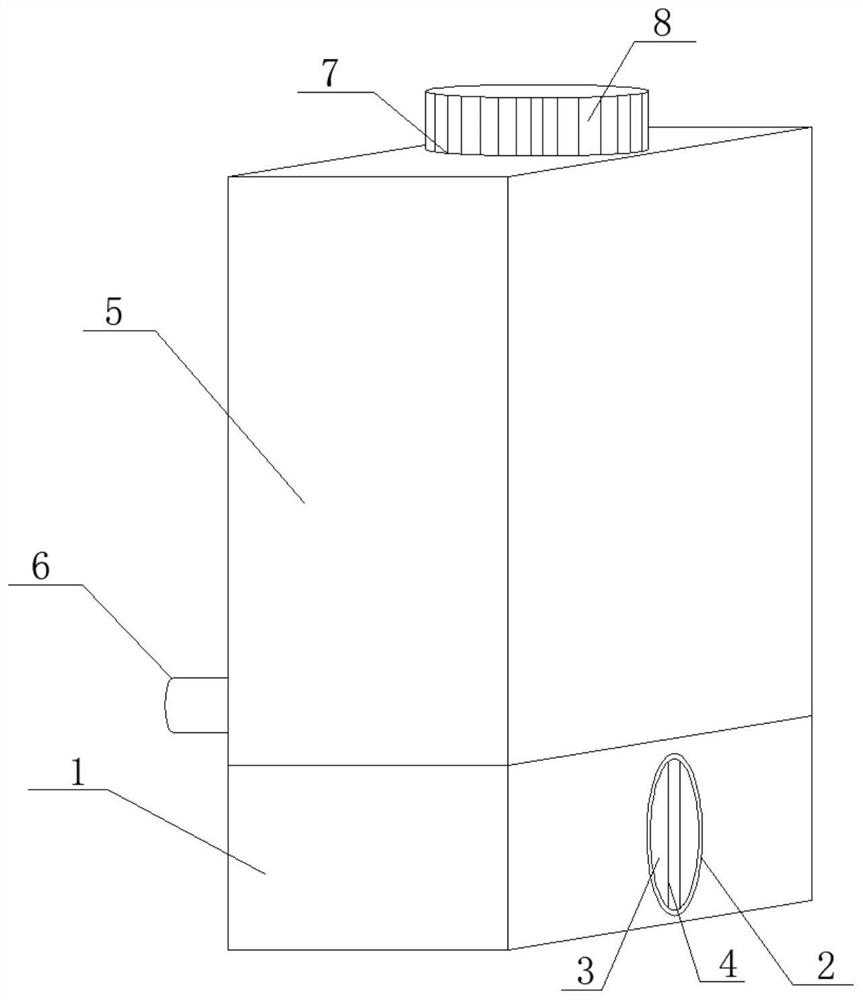

The invention relates to the field of filter element connecting bases and discloses a rotatable filter element connecting base. The rotatable filter element connecting base comprises a bottom fixing plate, wherein a rotating groove hole is formed in one side edge of the bottom fixing plate, the inner side edge of the rotating groove hole is sleeved with a rotating block, a shifting plate is horizontally and fixedly arranged on the inner side edge of the rotating block, a filtering main box is fixedly bonded to the top surface of the bottom fixing plate, a water outlet pipeline is horizontallyinserted into one side edge of the filtering main box, a top screw hole is formed in the top surface of the filtering main box, a sealing cover plate is in threaded connection with the inner side edgeof the top screw hole, a limiting ring groove is formed in the inner side edge of the rotating groove hole, a limiting ring is clamped to the inner side edge of the limiting ring groove, and a shaftrod is horizontally and fixedly inserted into one side edge of the rotating block. The rotatable filter element connecting base is integrated in design, simple in structure and convenient to operate;replacement is simpler, more convenient and more efficient by adopting a rotary structure; and connection is stable, and the situation that water is not filtered thoroughly due to gaps is avoided.

Owner:佛山市芯耀环保科技有限公司

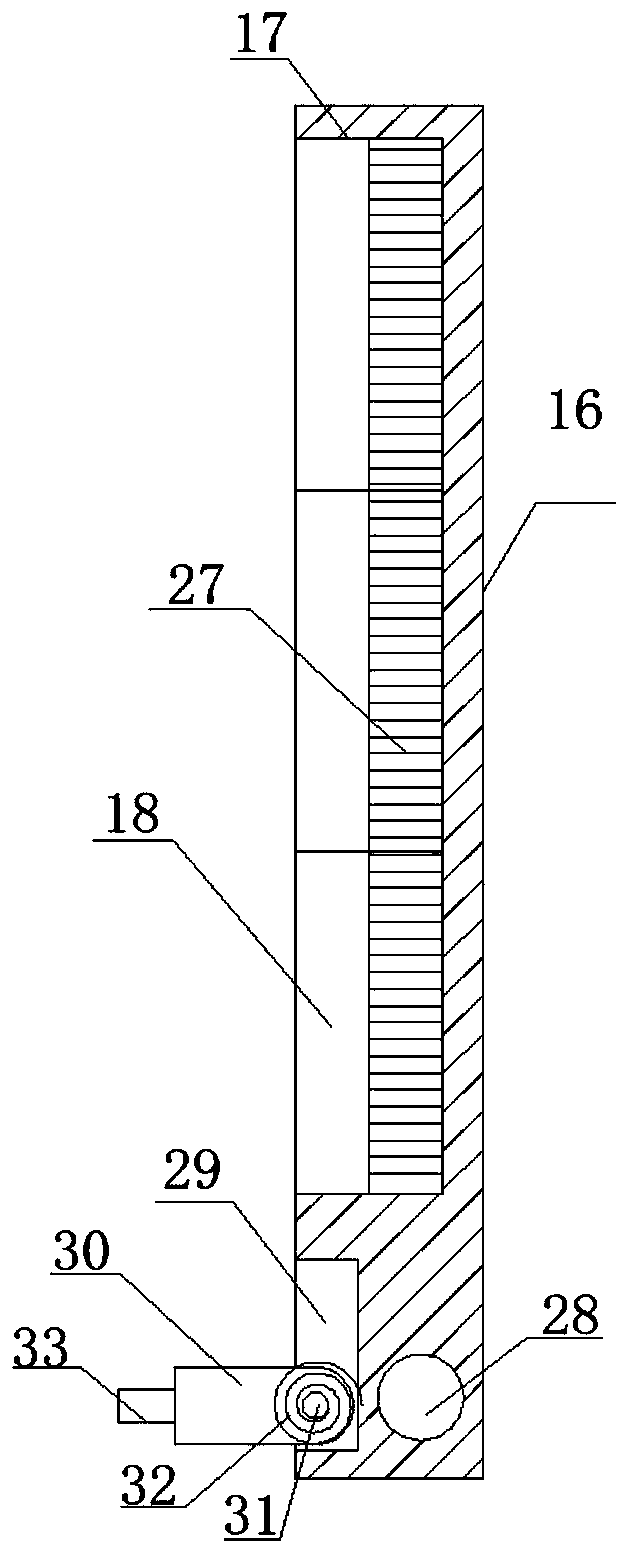

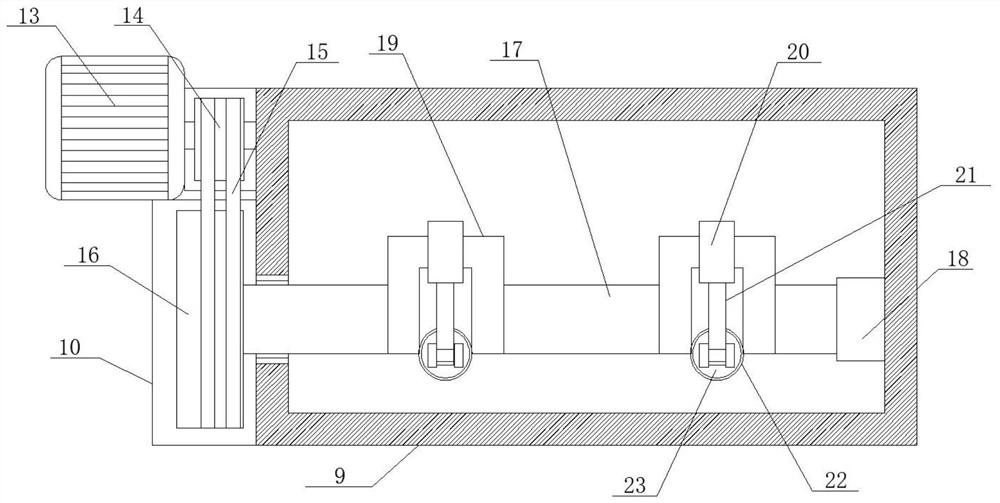

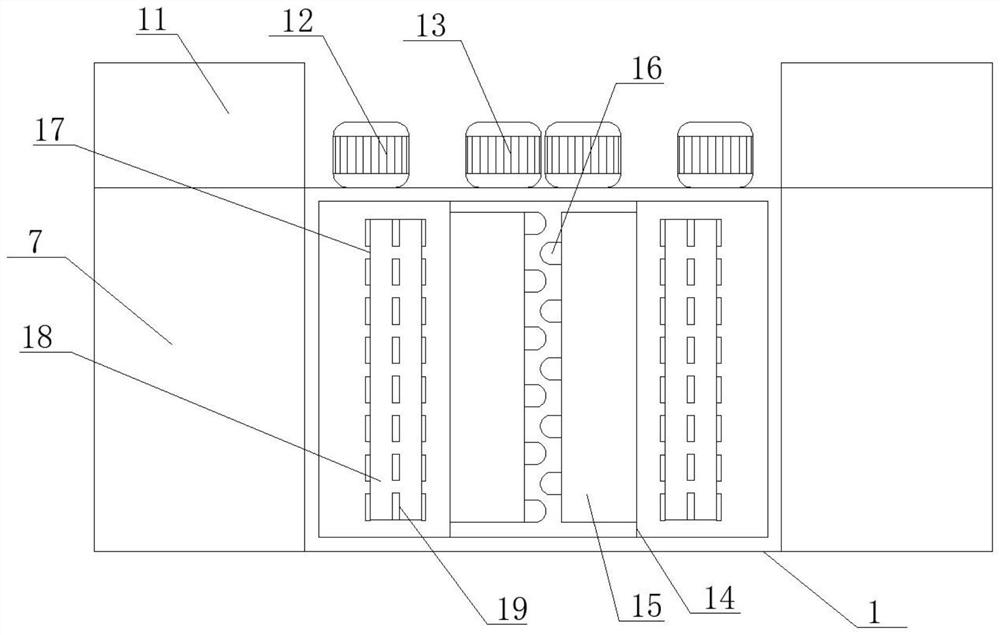

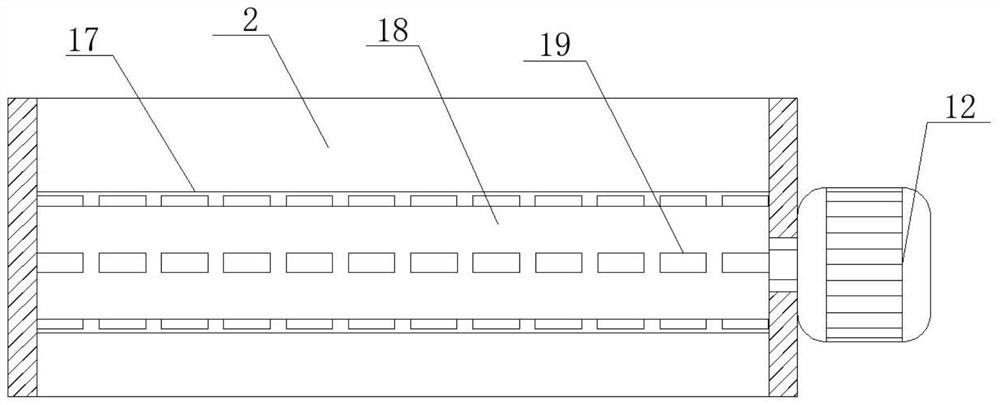

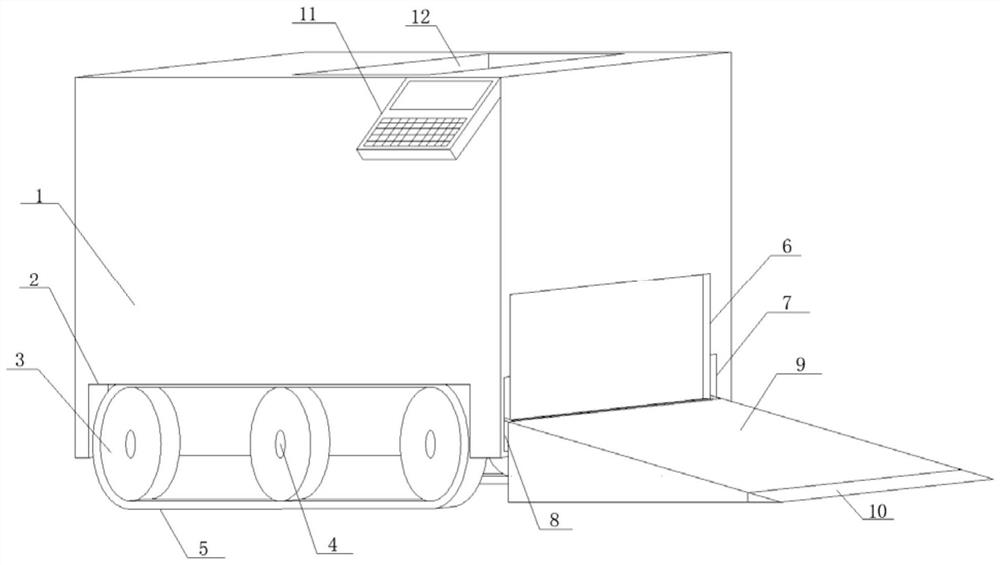

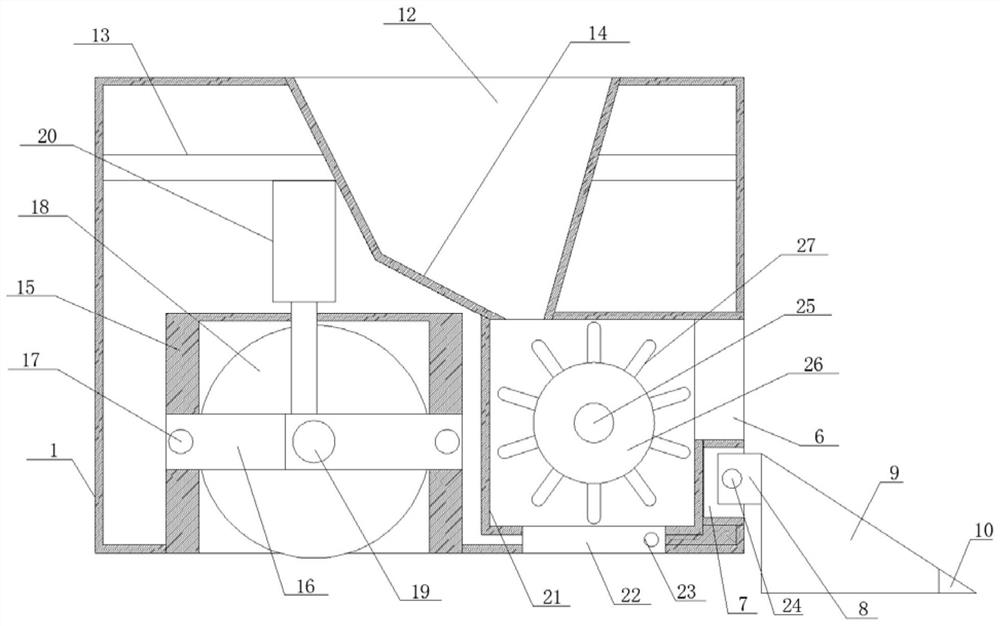

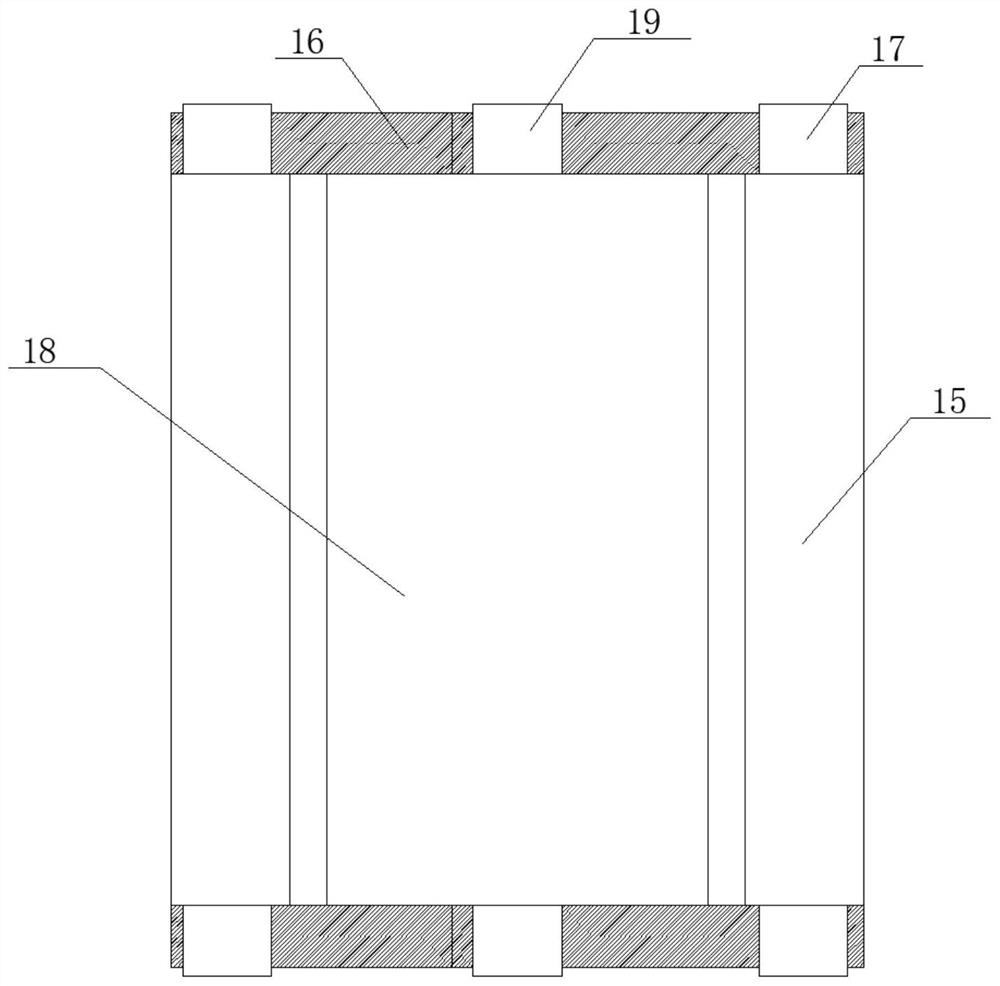

Induction curing heating equipment

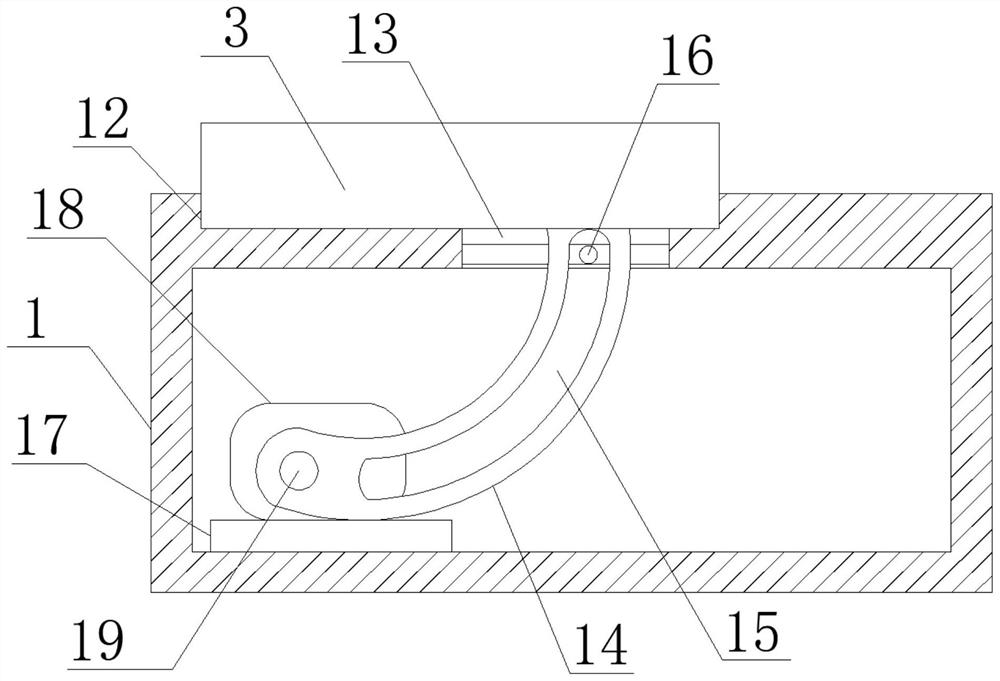

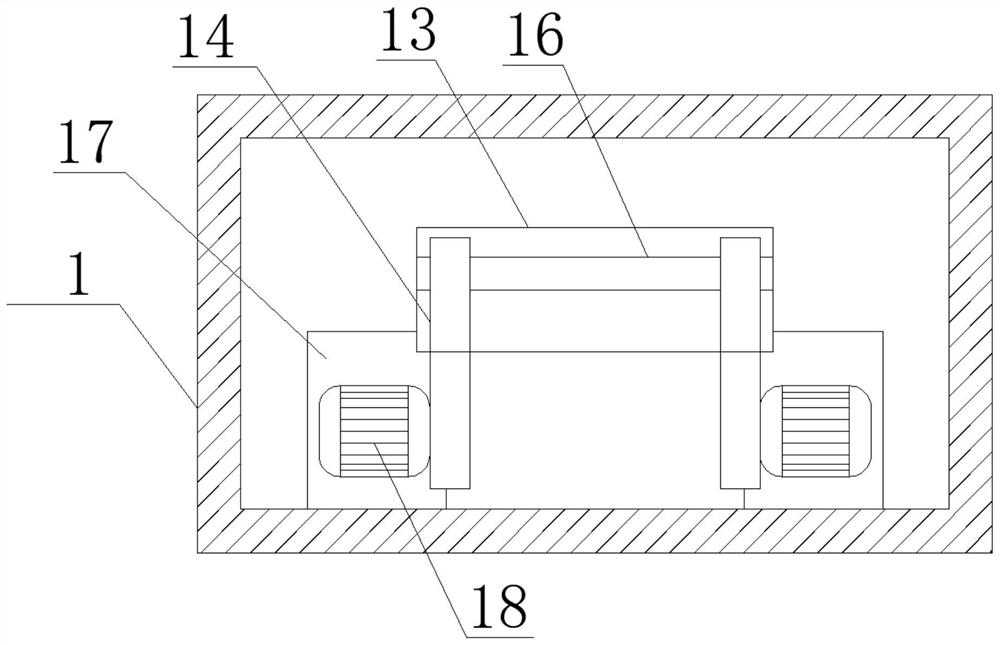

The invention discloses induction curing heating equipment, and relates to the field of heating equipment. The induction curing heating equipment comprises a main outer box body, rolling wheels are connected to the bottom face of the main outer box body through bolts, brake plates are arranged on the side edges of the rolling wheels, an extending through groove is formed in one side edge of the main outer box body, and a sealing cover plate is clamped to the top face of the inner side of the extending through groove; a buckling groove is horizontally formed in the side edge of the sealing cover plate, a gradienter is horizontally embedded in the top face of the main outer box body, a handle rod is connected to the top face of the main outer box body through bolts, side through grooves are symmetrically formed in the two side edges of the main outer box body, and a shifting rotary disc is arranged on the inner side edge of the main outer box body; and adjusting pressing blocks are symmetrically connected to the two side edges of the main outer box body in a clamped mode. According to the device, the integrated structure is designed, operation is easy and convenient, the equipment height and the heating angle can be adjusted at will under the condition that an adjustable structure is adopted, and meanwhile the conditions of collision damage and accidental injury are avoided due to the adoption of a storage structure.

Owner:江文坚

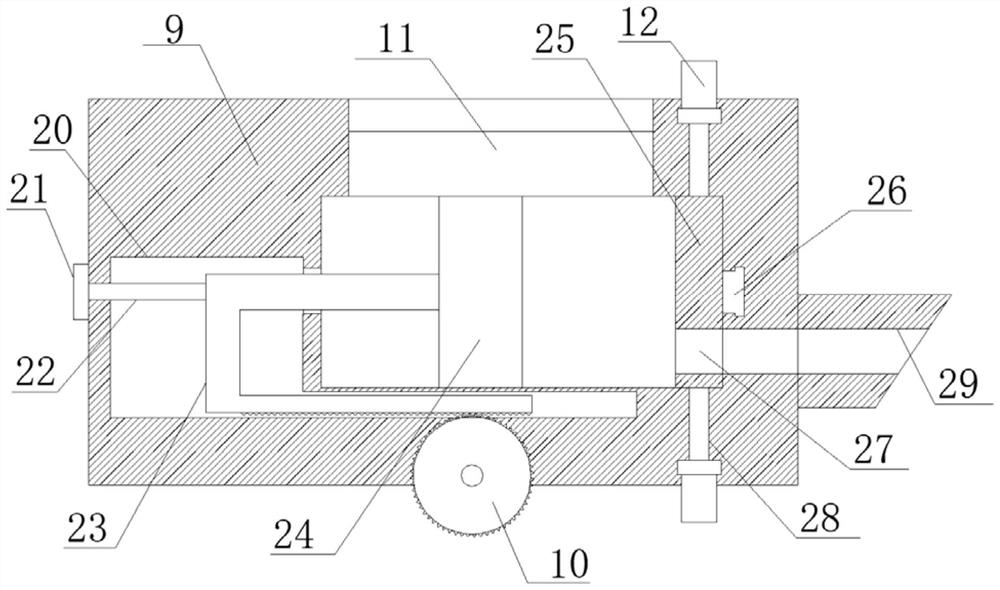

Metal material machining device

InactiveCN113182606ASatisfy fixationReduce investmentMetal sawing devicesMeasurement/indication equipmentsMetallic materialsMaterials processing

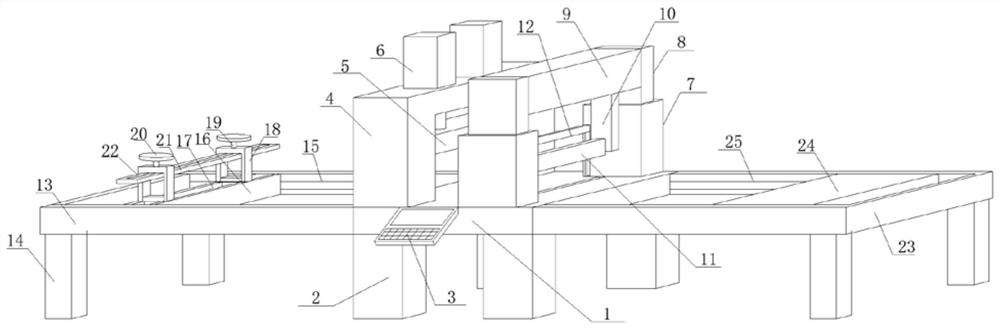

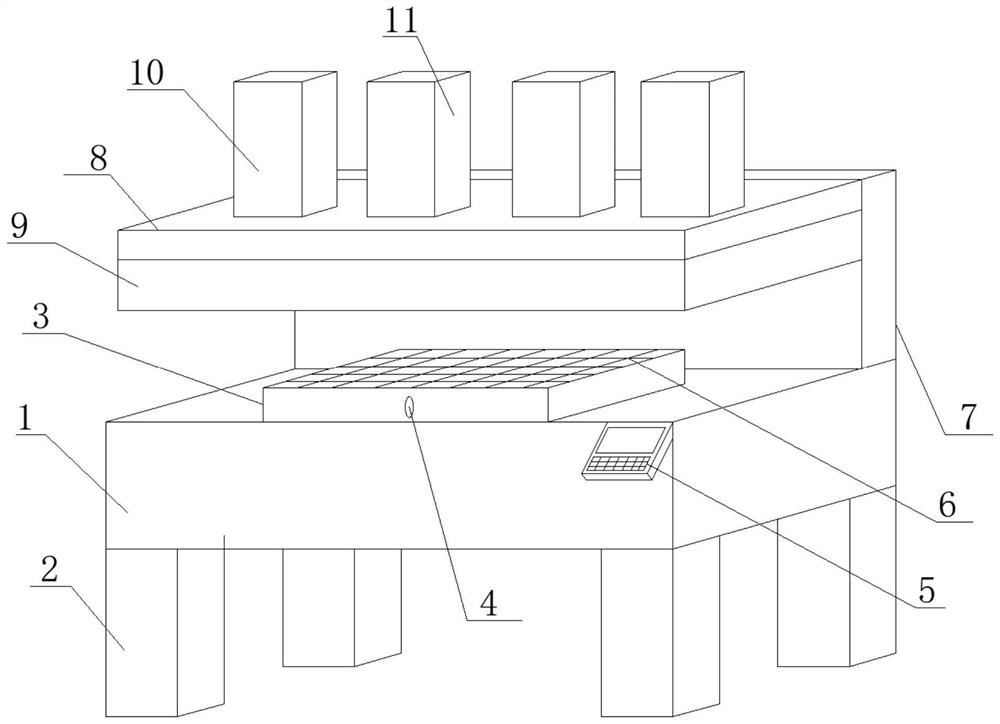

The invention discloses a metal material machining device, and relates to the field of metal materials. The metal material machining device comprises a fixed bottom plate, wherein supporting vertical rods are vertically and downwards welded to the bottom face of the fixed bottom plate; a control panel is obliquely welded to one side edge of the fixed bottom plate; a fixed top block is welded to the top face of the fixed bottom plate; an extrusion plate is horizontally arranged on the inner side edge of the fixed top block; a pushing and pressing air cylinder is connected to the top face of the fixed top block through a bolt; bottom sleeve rods are vertically and upwards welded to the top face of the fixed bottom plate; extending vertical rods are vertically and upwards inserted into the top ends of the bottom sleeve rods; a top box body is horizontally welded to the side edge between the extending vertical rods; and extending side rods are vertically and downwards welded on the bottom surface of the top box body. According to the device provided by the invention, the design is integrated, the structure is simple, operation is convenient, product discharging is faster and more efficient by adopting the intelligent automatic measuring and cutting procedure, meanwhile, labor input is greatly reduced in a more time-saving and labor-saving mode, and the requirement for market development is met.

Owner:宿迁小鲤工业设计有限公司

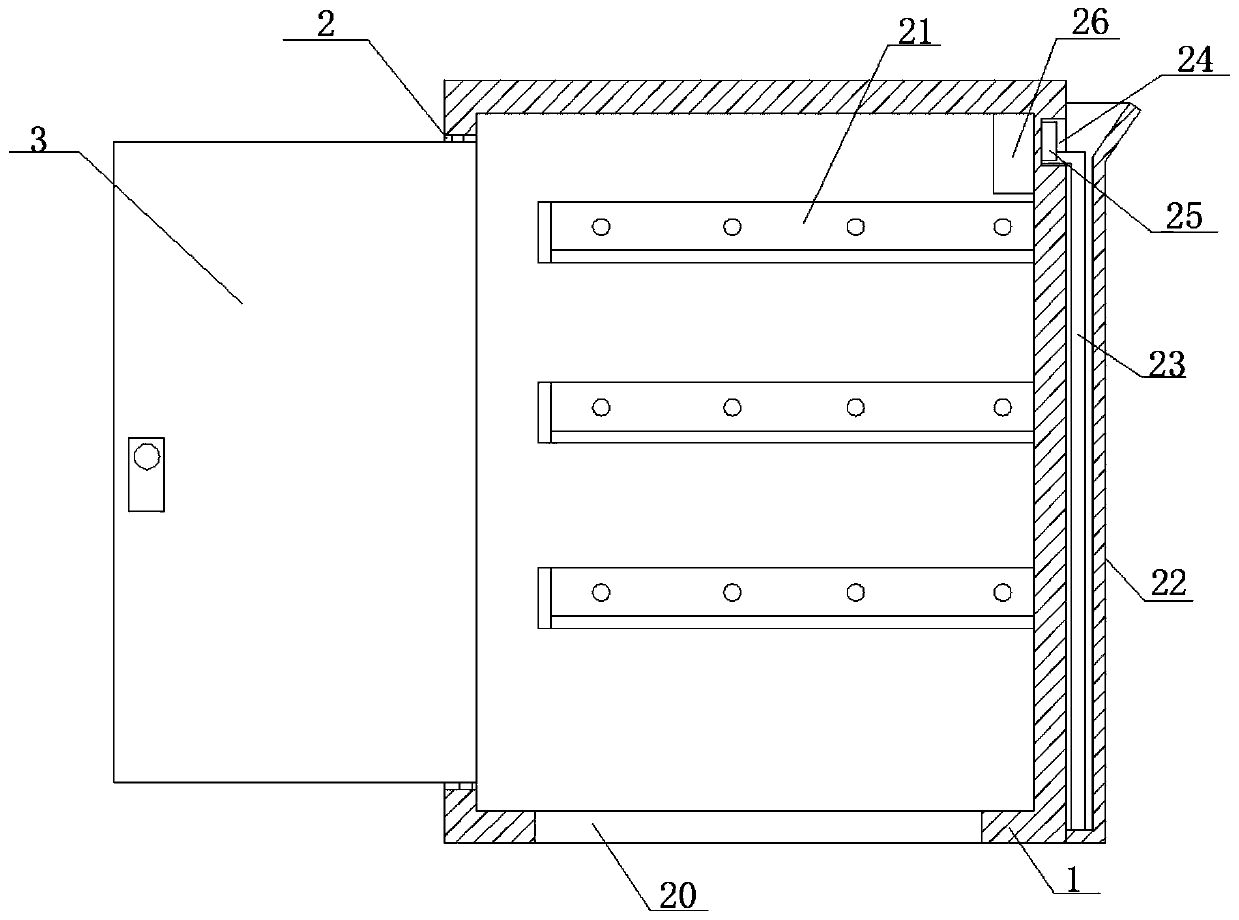

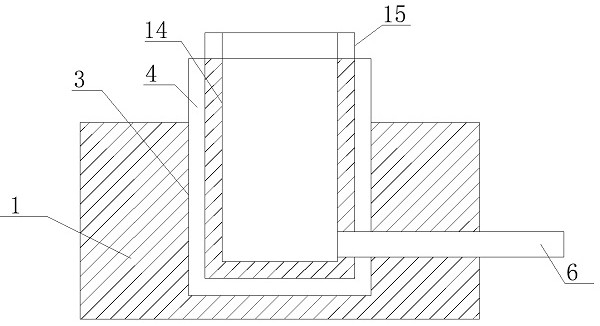

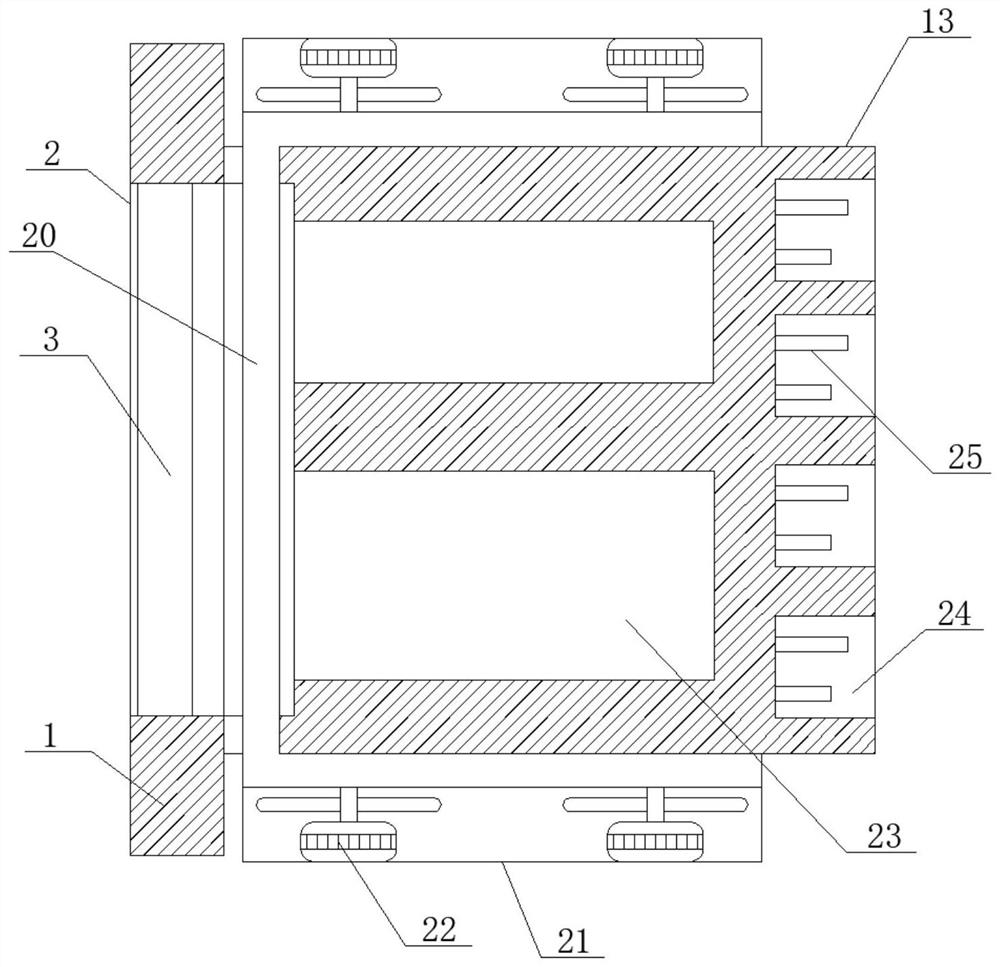

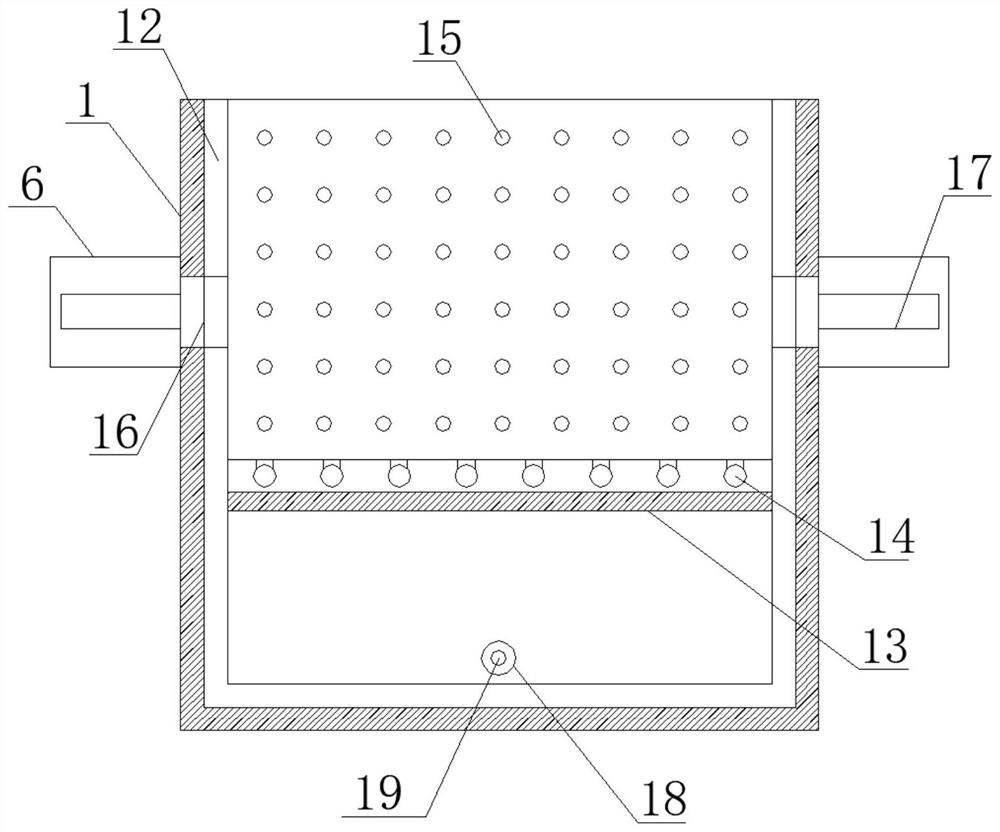

High-pressure steam sterilization device for cell culture

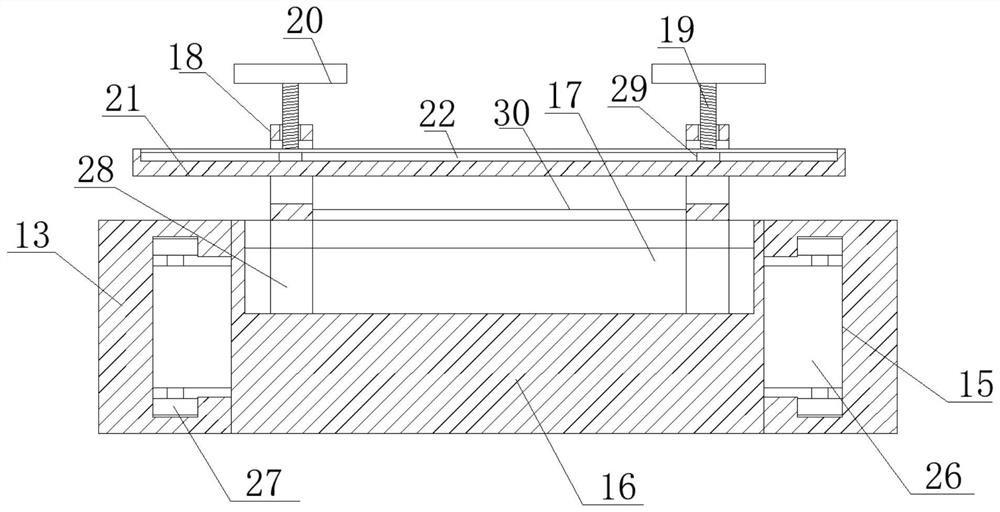

InactiveCN113717835ASmooth slidingFixed tightlyApparatus sterilizationTissue/virus culture apparatusEngineeringMechanical engineering

The invention discloses a high-pressure steam sterilization device for cell culture and relates to the field of cell culture. The high-pressure steam sterilization device comprises a bottom supporting plate, wherein a supporting base plate is horizontally welded to the bottom face of the bottom supporting plate, a top sleeving groove is vertically formed in the top face of the bottom supporting plate, the inner side edge of the top sleeving groove is vertical and fixed sleeve connection with a main treatment tank, one side edge of the bottom supporting plate is in threaded connection with a high-pressure valve, a steam pipeline is horizontally connected to one side edge of the bottom supporting plate in an inserted mode, fixed side plates are vertically and upwards welded to the top face of the bottom supporting plate, a clamping side groove is vertically formed in the side edge between the fixed side plates, and a fixed top plate is horizontally welded to the side edge between the fixed side plates. The device is designed to be integrated, the structure is simple, operation is easy and convenient, high-pressure treatment is safer by adopting automatic operation, meanwhile, internal cells can directly make contact with high-pressure steam through a permeable culture box body, and efficient sterilization operation is conducted on the cells.

Owner:肖财根

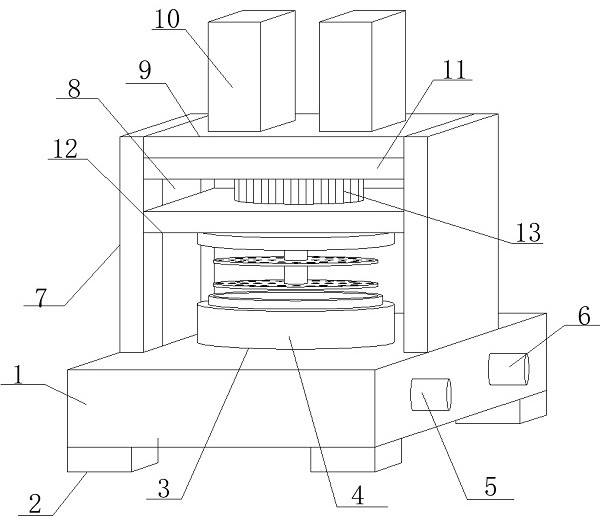

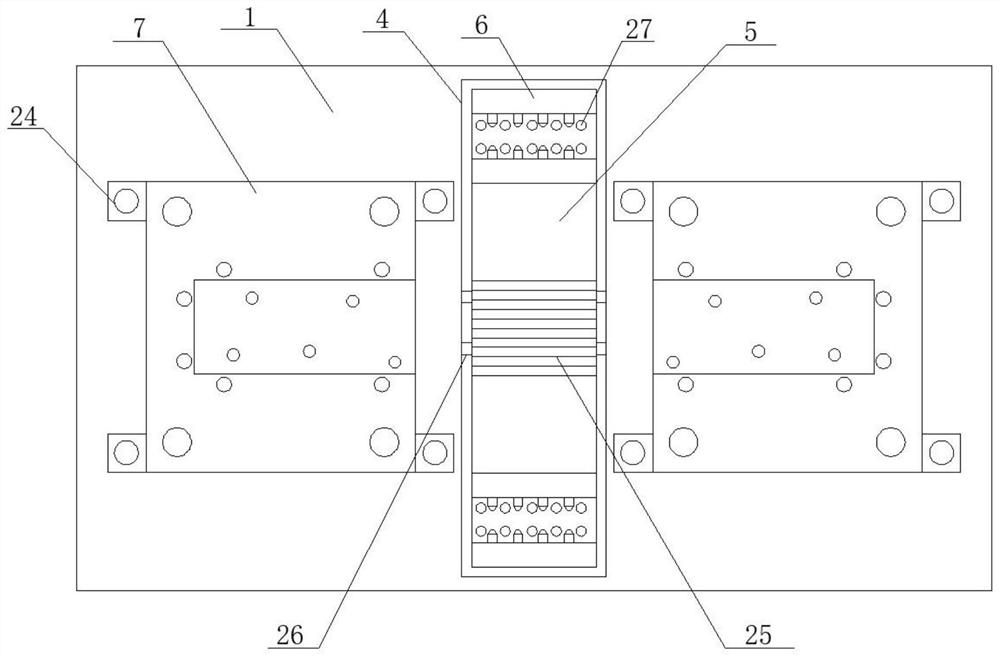

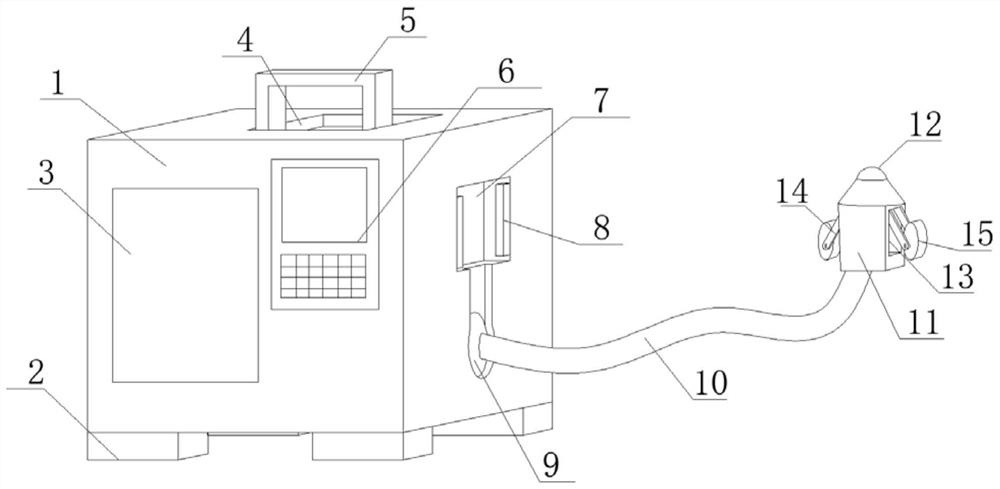

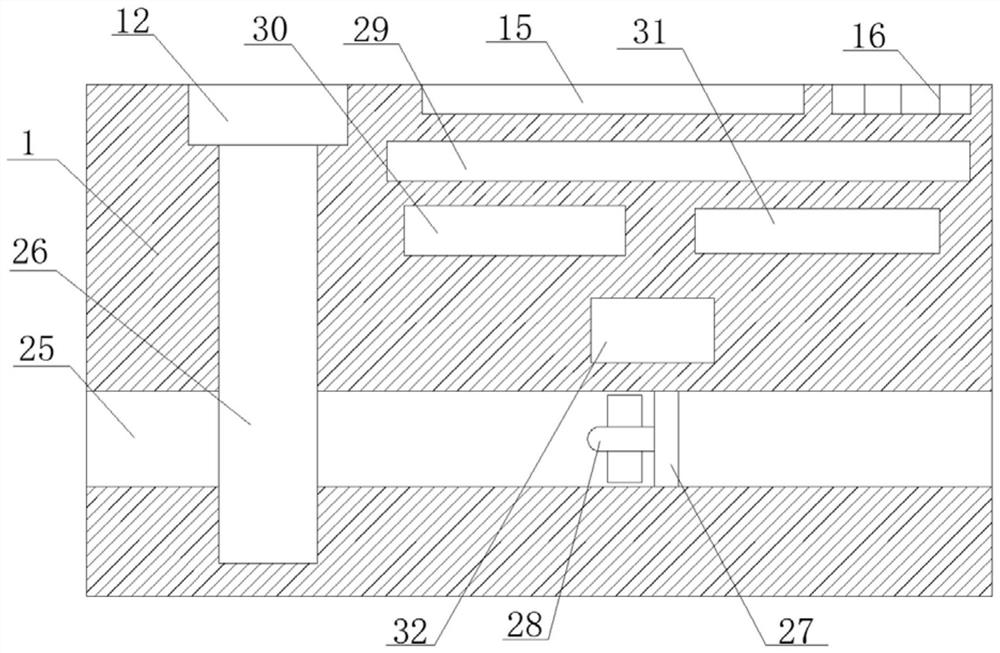

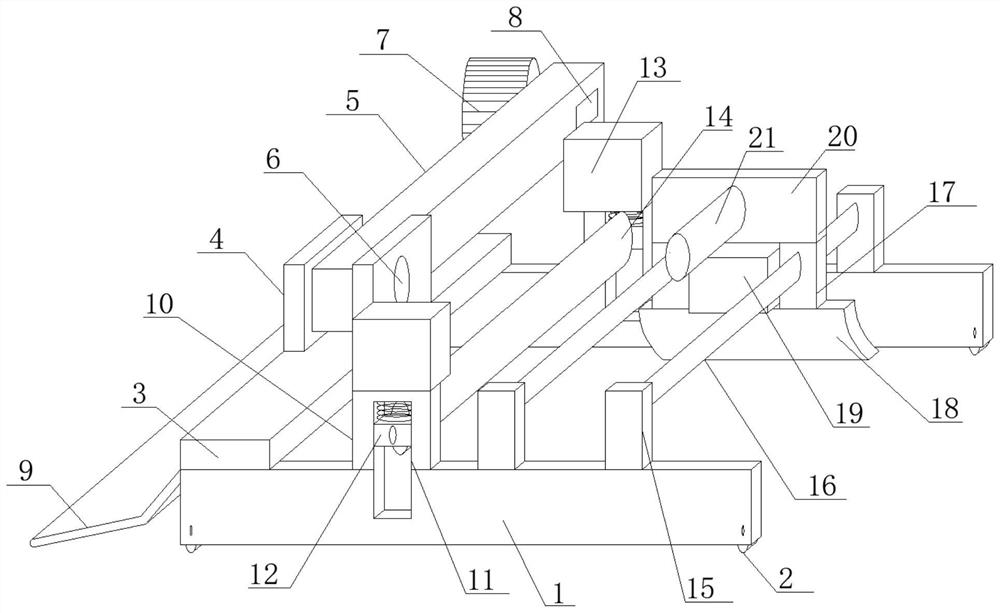

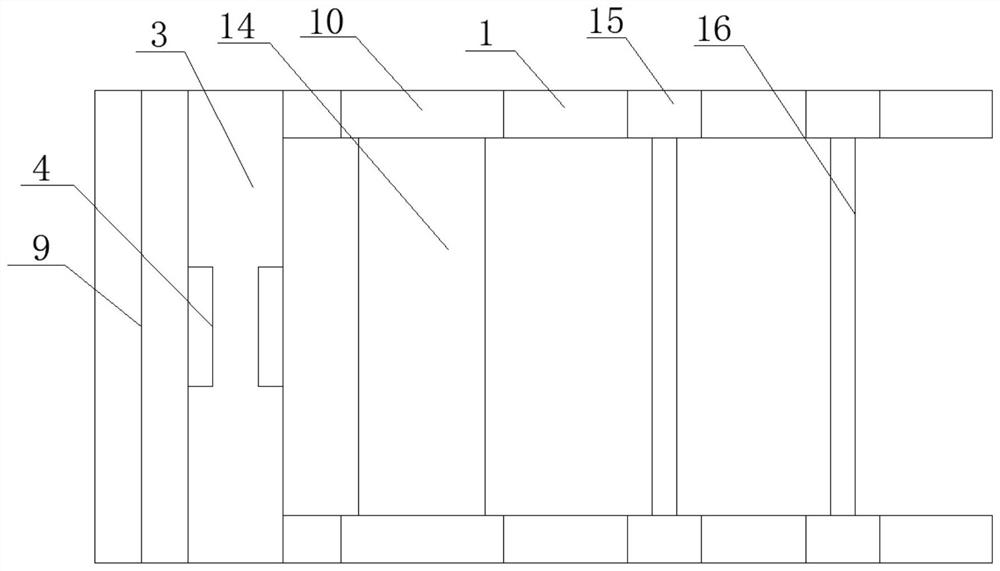

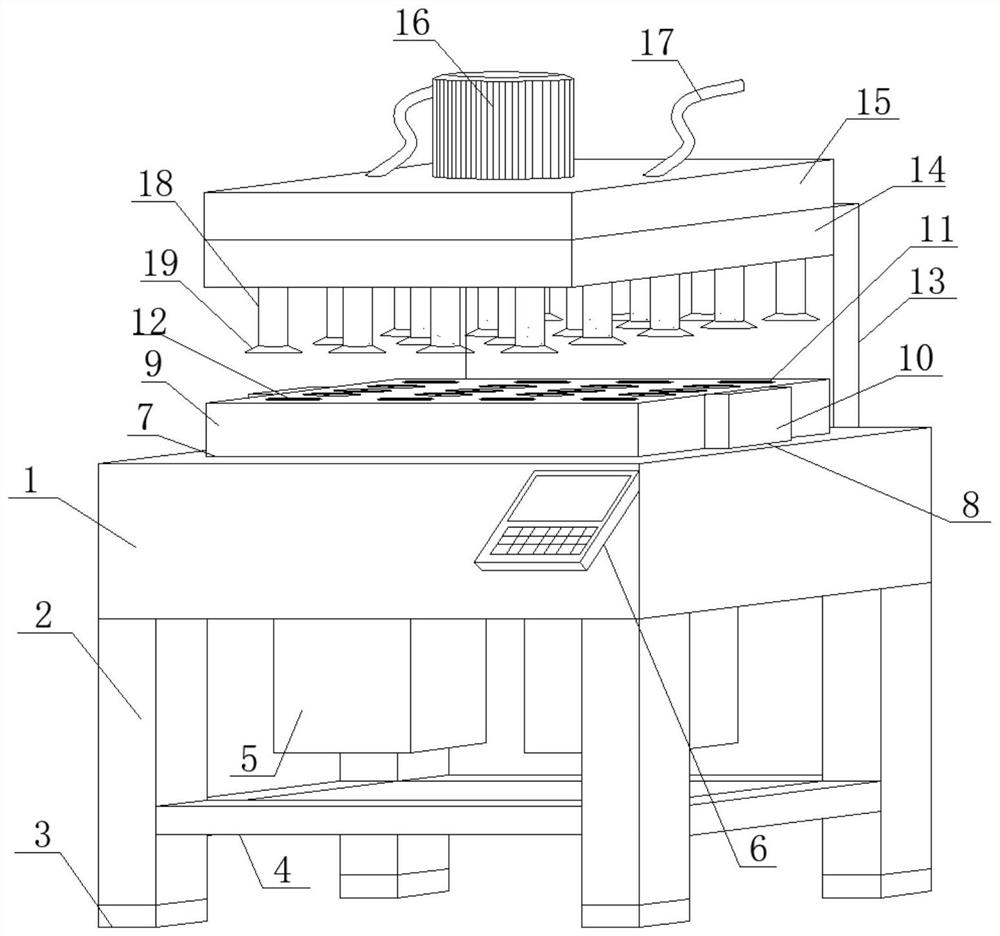

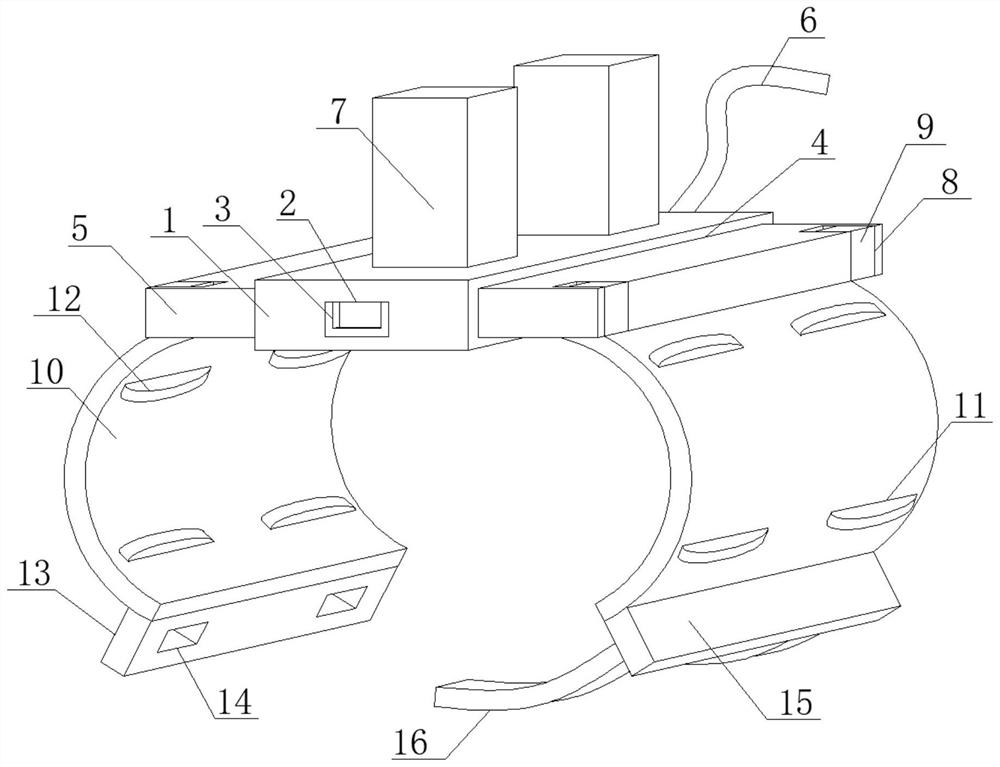

An integrated equipment for processing complex-shaped high-current contact brackets

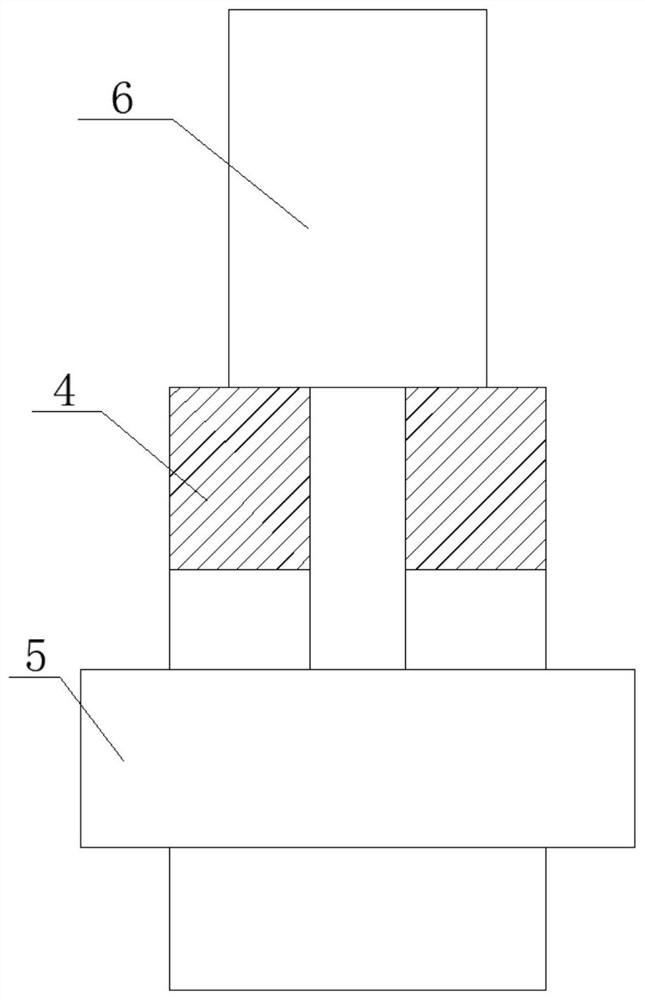

ActiveCN111715782BEasy to useIncrease productivityShaping toolsPerforating toolsIndustrial engineeringBolt connection

The invention discloses an integrated equipment for processing high-current contact brackets with complex shapes, which relates to the field of current contact brackets, and includes a support bottom box, the bottom surface of the support bottom box is fixedly welded with a support pad, and one side A control panel is welded on the side obliquely, and the top surface of the supporting bottom box is longitudinally provided with a turning card slot, and the inner side of the turning card slot is horizontally connected with a turning lever, and the top surface of the turning lever is vertically upwardly connected with a bolt. The vertical plate is fixed, and the top surface bolts of the supporting bottom box are connected with a stamping bottom mold; the stamping bottom mold includes a fixed supporting plate, and the top surface of the fixed supporting plate is connected with a fixed sleeve plate, and the top surface of the fixed sleeve plate The butt has a stabilizing plate. The integrated structure of the device of the present invention is simple and easy to operate, and the stamping, bending and welding are used in one body to make the working efficiency higher, and the specification and size are more standardized under the action of stamping, which can meet the needs of large-scale production.

Owner:温州立高智能科技有限公司

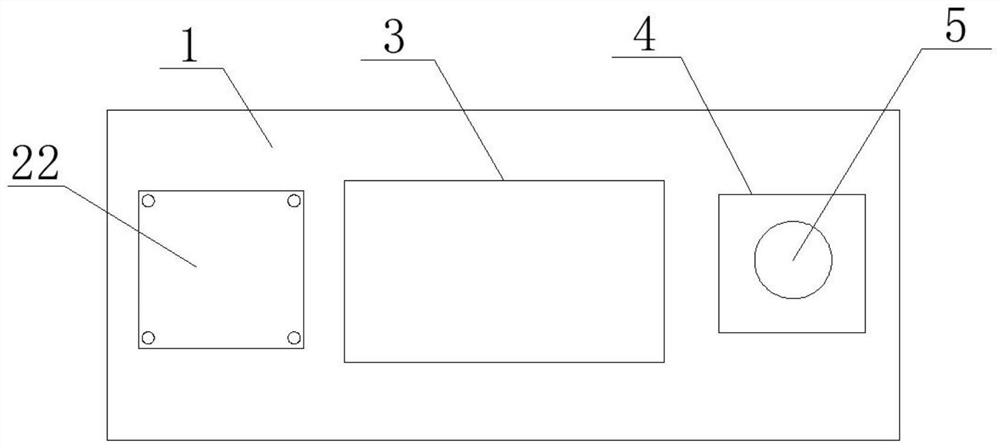

Multifunctional intelligent Internet of Vehicles terminal device

ActiveCN111769846AEasy accessEasy and efficient installationTransmissionTerminal equipmentEngineering

The invention discloses a multifunctional intelligent Internet of Vehicles terminal device and relates to the field of intelligent vehicle connection. The device includes a fixed panel, and a clampinggroove is vertically formed in one side edge of the fixed panel; a display screen is clamped on the inner side edge of the clamping groove; a storage groove is vertically formed in one side edge of the fixed panel; expansion grooves are symmetrically formed in the two side edges of the storage groove. A bottom supporting plate is vertically connected to the inner side edge of the storage groove in a clamped mode. A wireless charging disc is embedded in the inner side edge of the bottom supporting plate; the two side edges of the bottom supporting plate are in butt joint with fixed side plates. An isolation film is fixedly adhered to the side edge of the fixed side plate; card inserting grooves are uniformly formed in one side edge of the fixed panel; the device disclosed by the inventionis integrated in design, simple in structure and convenient to operate; the installation is simple and convenient due to adoption of buckle type installation design, and the later use is more convenient and efficient due to the integration of multiple functions.

Owner:地上铁租车(深圳)有限公司

Efficient punching equipment for PE leakage pipe

PendingCN113715093AEasy to fixProduction needs to be goodMetal working apparatusPunchingStructural engineering

The invention discloses efficient punching equipment for a PE leakage pipe, and relates to the field of PE leakage pipes. The efficient punching equipment comprises a main supporting plate, supporting vertical rods are vertically and downwards welded to the bottom surface of the main supporting plate, a control panel is obliquely welded to one side edge of the main supporting plate, a display screen is embedded in the top surface of the control panel, and a setting plate is embedded in the top surface of the control panel; and a sliding transverse groove is horizontally formed in the top face of the main supporting plate, a movable vertical plate is vertically arranged on the top face of the main supporting plate, an extending top plate is horizontally welded to one side edge of the movable vertical plate, sleeving rods are symmetrically welded to the two side edges of the extending top plate, and extending rods are horizontally inserted into the ends, away from the extending top plate, of the sleeving rods. According to the efficient punching equipment, the design is integrated, the structure is simple, operation is convenient, fixing arrangement is more stable and saves more labor by adopting an electric clamping mode, and meanwhile, multi-direction intelligent drilling treatment can be achieved, so that the drilling efficiency is greatly improved.

Owner:钟通

Semiconductor coating equipment convenient to clean

InactiveCN113707531AEasy to placeUniform coatingElectric discharge tubesVacuum evaporation coatingStructural engineeringMechanical engineering

The invention discloses semiconductor coating equipment convenient to clean, and belongs to the field of semiconductor coating. The semiconductor coating equipment convenient to clean comprises a main treatment box, a bottom cushion block is fixedly adhered to the bottom surface of the main treatment box, a drawer groove is horizontally formed in one side edge of the main treatment box, a storage box body is inserted into the inner side edge of the drawer groove, a control panel is embedded in one side edge of the main treatment box, fixed side plates are symmetrically connected to the two side edges of the main treatment box through bolts, a movable outer cover is in butt joint with the side edges between the fixed side plates, a sealing top plate is horizontally in butt joint with the top face of the main treatment box, and a lifting handle is connected to the top face of the sealing top plate through bolts, stirring grooves are symmetrically formed in the two side edges of the main treatment box, and stirring blocks are connected to the inner side edges of the stirring grooves in a clamped mode. According to the equipment, the equipment is designed to be integrated, the structure of the equipment is simple, the operation of the equipment is convenient; a rolling type film coating mode is adopted so that film material attachment can be more uniform and efficient, and meanwhile direct cleaning treatment can be conveniently conducted after the equipment is detached through a buckle type connecting mode.

Owner:杭州很美网络科技有限公司

Threading guiding device for electrical engineering

ActiveCN113471880ANo messSimple design and integrated structureApparatus for laying cablesMechanical engineeringBolted joint

The invention discloses a threading guiding device for electrical engineering, and relates to the field of electrical engineering. The threading guiding device comprises a main processing box, the bottom surface of the main processing box is in bolted connection with a bottom cushion block, one side edge of the main processing box is embedded with a display screen, and the top surface of the main processing box is horizontally provided with a storage top groove; a handle block is clamped to the inner side edge of the storage top groove, a control panel is embedded in one side edge of the main treatment box, a side storage groove is vertically formed in one side edge of the main processing box, a clamping strip is fixedly clamped to the inner side edge of the side storage groove, and a clamping disc is fixedly clamped to the inner side edge of the side storage groove; and an extension pipe is inserted into the inner side edge of the clamping disc, and the end, away from the clamping disc, of the extension pipe is in butt joint with a moving block. The device is designed to be integrated, the structure is simple, operation is convenient, threading is faster and more efficient by adopting an electric driving structure, and meanwhile, adjustment can be performed according to the internal situation of a pipeline through a camera shooting structure so that threading is convenient.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

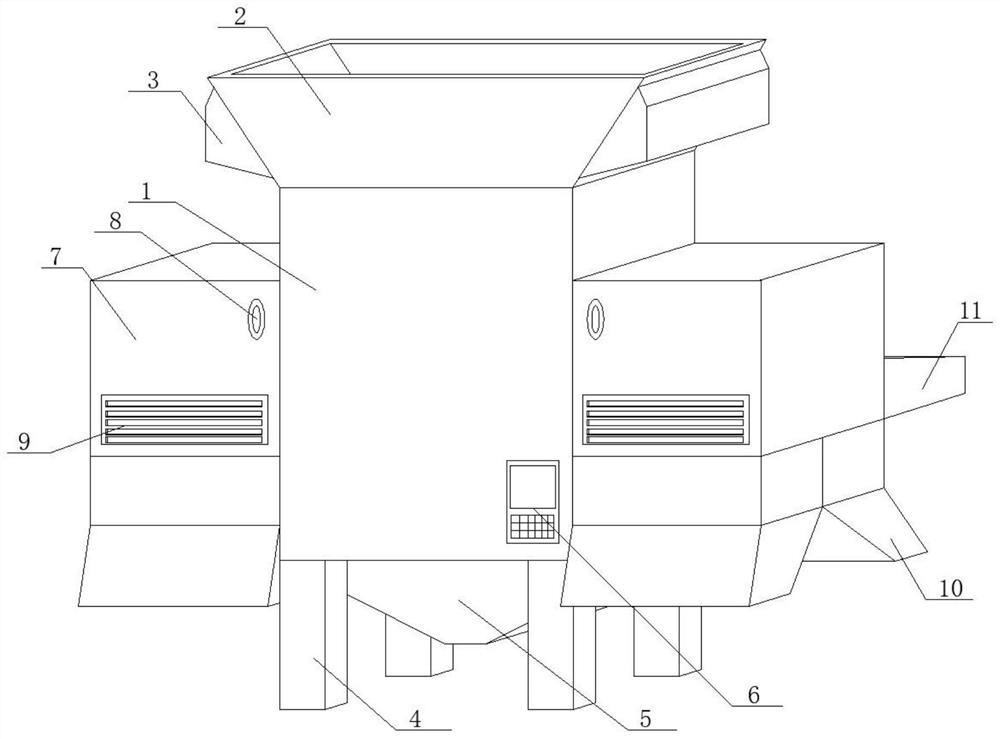

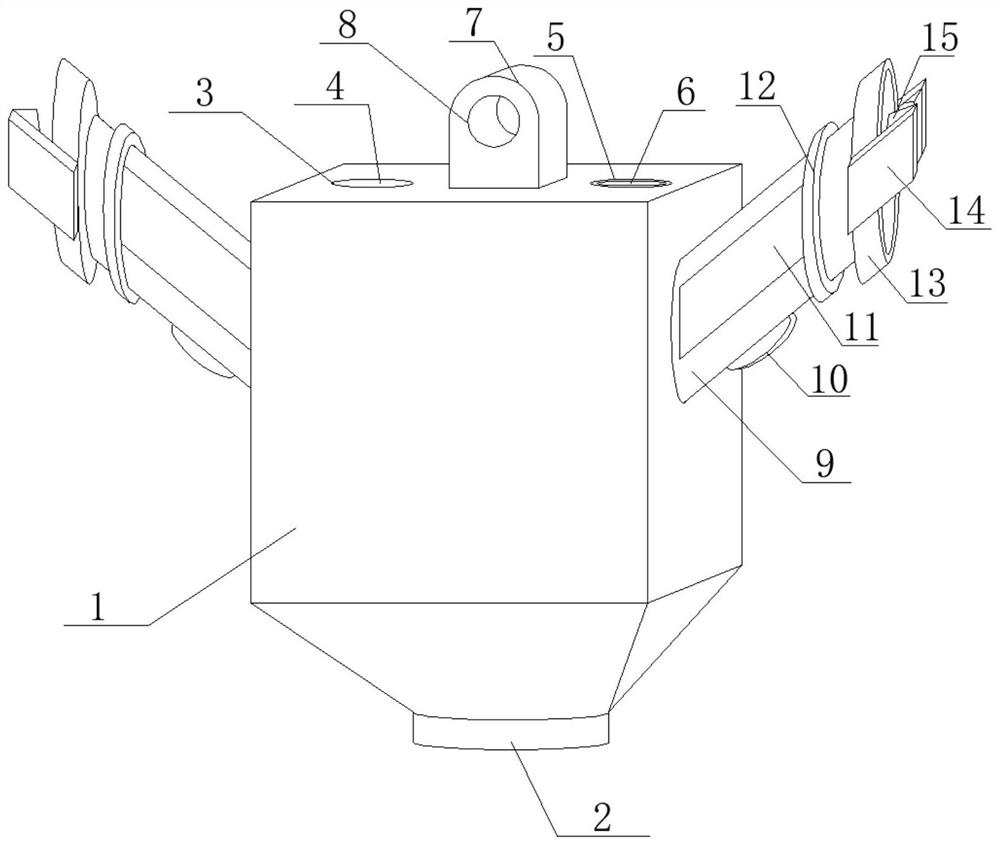

Construction waste cyclic crushing device

InactiveCN112892702ANo cloggingSmash thoroughlyGas current separationGrain treatmentsArchitectural engineeringStructural engineering

The invention discloses a construction waste cyclic crushing device, and relates to the field of construction waste treatment. The construction waste cyclic crushing device comprises a treatment main box, a falling hopper is horizontally welded to the top surface of the treatment main box, outer cover bodies are symmetrically welded to the two side edges of the falling hopper, and a supporting vertical rod is vertically and downwards welded to the bottom surface of the treatment main box; and a discharging bottom hopper is horizontally welded to the bottom face of the treatment main box, a control panel is embedded at one side edge of the treatment main box, treatment side boxes are symmetrically connected to the two side edges of the treatment main box through bolts, outer conveying rollers are horizontally inserted into the inner side edges of the treatment side boxes, and ventilation grooves are horizontally and evenly formed at one side edge of each treatment side box. A guide hopper is welded on the bottom surface of each treatment side box. According to the device, the design is integrated, the structure is simple, operation is easy and convenient, the crushing and screening integrated design is adopted, so that construction waste treatment is faster and more efficient, meanwhile, the abrasion condition can be controlled through classification treatment, and the device can circularly work for a long time.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

An integrated device for asphalt collection, treatment and harmless utilization

ActiveCN111560819BSimple and fast operationStorage is complete and thoroughRoads maintainenceDrive wheelStructural engineering

The invention discloses an integrated device for asphalt collection, treatment and harmless utilization, which relates to the field of asphalt treatment and includes a main moving box. The two sides of the main moving box are symmetrically and horizontally provided with locking grooves. The inner side of the groove is evenly provided with a driving wheel, the center of the driving wheel is plugged with a plug-in fixing rod, the outer side of the driving wheel is sleeved with a moving track, and one side of the main moving box The side is horizontally provided with a recovery groove, and the two ends of the recovery groove are symmetrically and vertically provided with an overturning groove, and the inner side of the overturning groove is inserted with a supporting overturning lever, and the supporting overturning lever is far away from the overturning One end of the groove is horizontally welded with a shovel connecting inclined block. The integrated structure of the device of the present invention is simple and easy to operate. It adopts multiple functions in one body to make the asphalt collection and treatment more rapid and efficient, and at the same time adopts the eradication method to make the asphalt collection more complete and thorough.

Owner:萍乡新越沥青有限公司

A concentration-adjusting anesthesia device for anesthesiology

ActiveCN113134127BQuick feedingPrecise drawingFiltering accessoriesFlow controlAnesthetic departmentEngineering

The invention discloses a concentration-adjusting anesthesia device for anesthesiology, which relates to the field of anesthesiology. , the inner side of the ventilation hole is clamped with a sealing plug, the top surface of the main drip tank is provided with a feed hole horizontally, and the inner side of the feed hole is fixedly clamped with a colloid block, the main drip tank is The top surface of the tank is fused vertically upward with an extension hanging rod, the side of the extension hanging rod is provided with a through hole, the side of the main drip tank is obliquely welded with a feeding inclined pipe, and the side of the feeding inclined pipe is clamped. There is a toggle gear, and the outer side of the feeding inclined tube is fixedly inlaid with a transparent target plate. The device of the present invention has a simple and integrated structure in design and is easy to operate. The drip bottle structure is adopted to make it more convenient, intuitive, and convenient for subsequent infusion, and the extraction structure is adopted to make the adjustment faster and more efficient.

Owner:辽宁省肿瘤医院

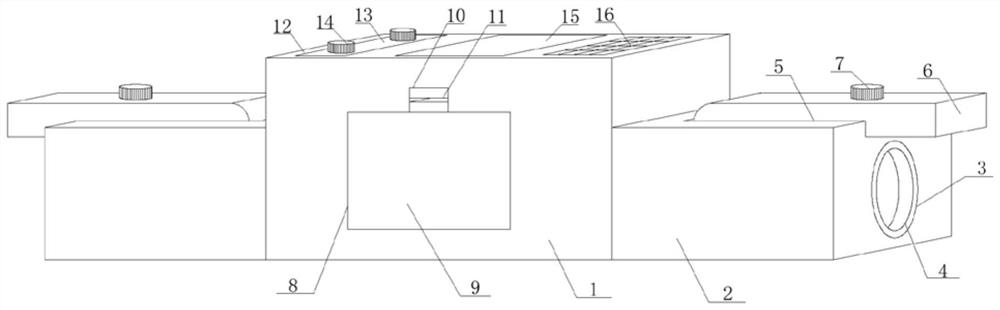

An easy-to-install smart water meter

ActiveCN111457981BPrevent rolloverHigh degree of intelligenceVolume indication and recording devicesSmart waterControl theory

The invention discloses an easy-to-install smart water meter, which relates to the field of water meters, and includes a supporting main board, two sides of the supporting main board are horizontally welded with extended counter-boards, and one end of the extended counter-board is horizontally provided with a plug-in connection hole, so The plug-in connection hole is fixedly connected with a port ring at the end far away from the supporting main board, and the top surface of the extending opposite board is horizontally provided with a movable card slot, and the inner side of the movable card slot is horizontally connected with a flip lever. The top surface of the turning rod is vertically inserted with a fixed screw. The integrated structure of the device design of the present invention is simple and convenient to operate. The data can be transmitted to the client in real time to facilitate observation and monitoring. At the same time, it can also filter the water body for later use, which greatly improves the intelligence of the water meter and is conducive to the development needs of the current society.

Owner:宁夏隆基宁光仪表股份有限公司

A guide threading device for electrical engineering

ActiveCN113471880BNo messSimple design and integrated structureApparatus for laying cablesEngineeringBolt connection

The invention discloses a guiding threading device for electrical engineering, which relates to the field of electrical engineering. , the top surface of the main processing box is horizontally provided with a receiving top groove, the inner side of the receiving top groove is clamped with a handle block, one side of the main processing box is inlaid with a control panel, and the main processing box is A side storage slot is vertically opened on one side of the side storage slot, the inner side of the side storage slot is fixedly clamped with a clamping strip, the inner side of the side storage slot is fixedly clamped with a clamping plate, and the clamping plate An extension tube is inserted into the inner side of the extension tube, and a moving block is butted on the end of the extension tube away from the clamping plate. The device of the present invention has a simple and integrated structure in design and is easy to operate. The motorized drive structure is adopted to make threading more efficient and efficient. At the same time, the camera structure enables adjustment according to the internal conditions of the pipeline to facilitate threading.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

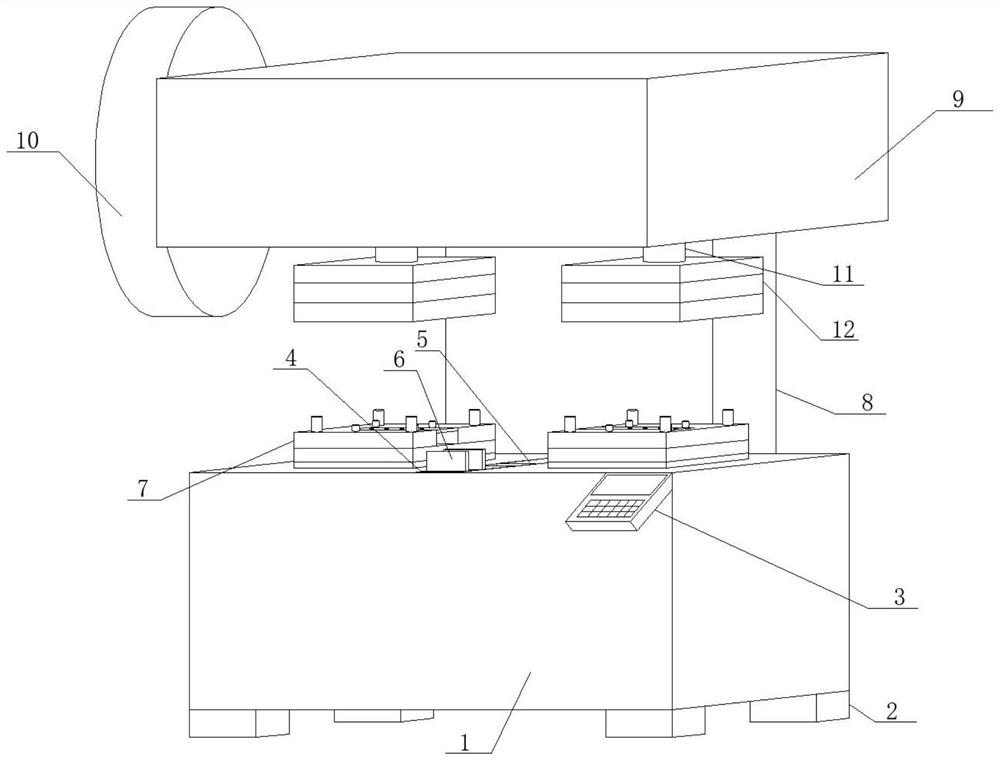

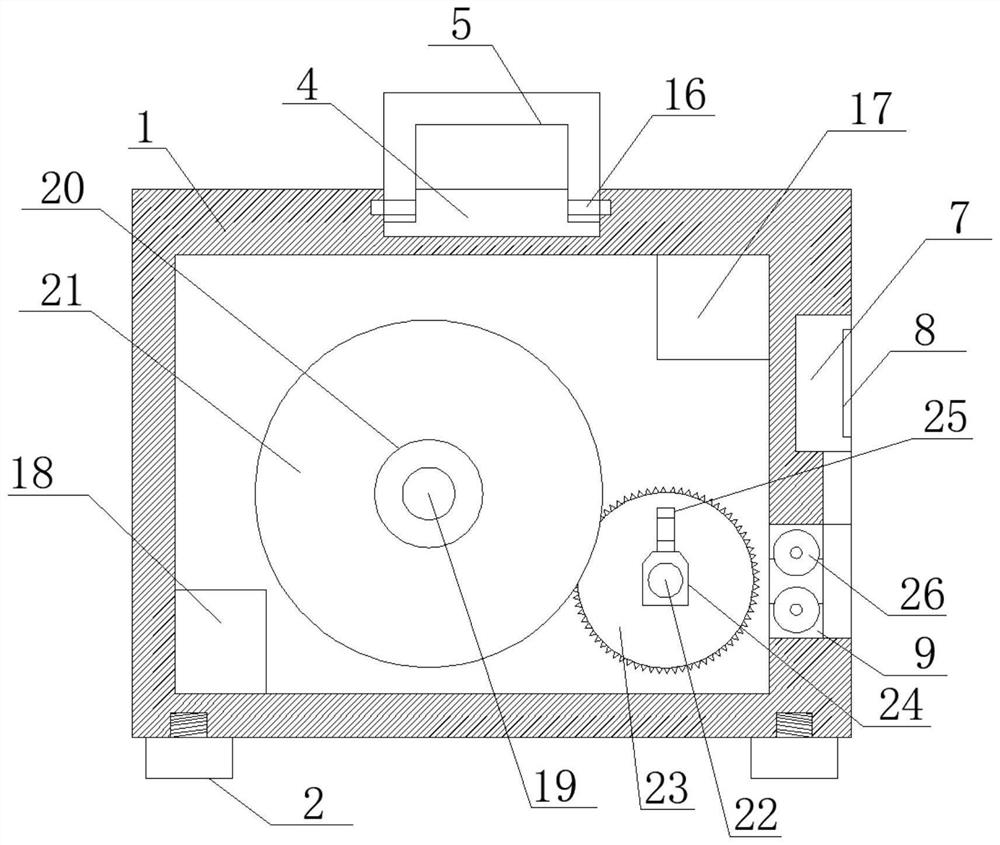

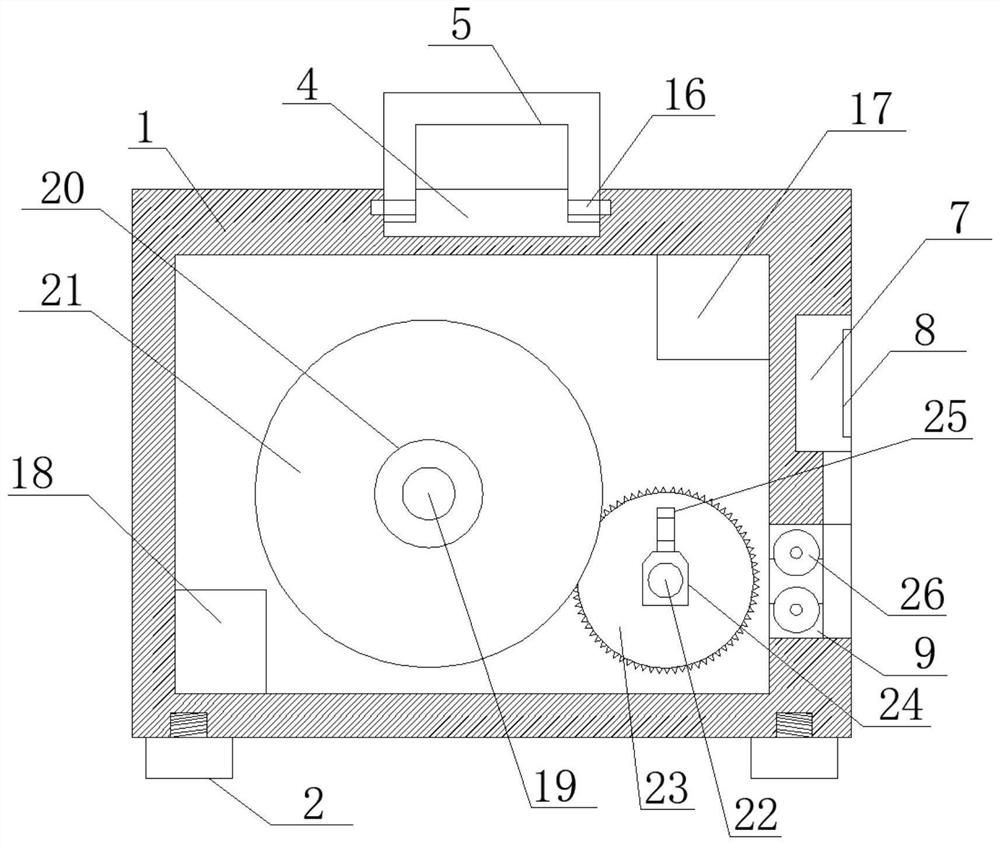

Sample grinder for preparing steel material spectrum detection samples

InactiveCN113664681AFlip reliableSimple loadingGrinding drivesPreparing sample for investigationEngineeringStructural engineering

The invention discloses a sample grinder for preparing steel material spectrum detection samples, and relates to the field of sample grinders. The sample grinder comprises a fixed bottom plate, wherein supporting vertical rods are vertically downwards welded to the bottom surface of the fixed bottom plate, a bottom magnetic plate body is horizontally clamped to the top surface of the fixed bottom plate, a magnetic attraction switch is arranged on one side edge of the bottom magnetic plate body, a control panel is obliquely welded to one side edge of the fixed bottom plate, crossed channels are horizontally formed in the top surface of the bottom magnetic plate body, a supporting side plate is vertically upwards welded to the top surface of the fixed bottom plate, a fixed top plate is horizontally welded to one side edge of the supporting side plate, a movable pressing plate is horizontally in butt joint with the bottom surface of the fixed top plate, and pushing and pressing air cylinders are in bolted connection with the top surface of the fixed top plate. According to the device, through the design integration, the structure is simple, and operation is convenient; more time and labor are saved during feeding due to the adoption of an overturning structure; and meanwhile higher accuracy and higher efficiency are achieved due to the adoption of an intelligent detection and grinding structure.

Owner:杨晓明

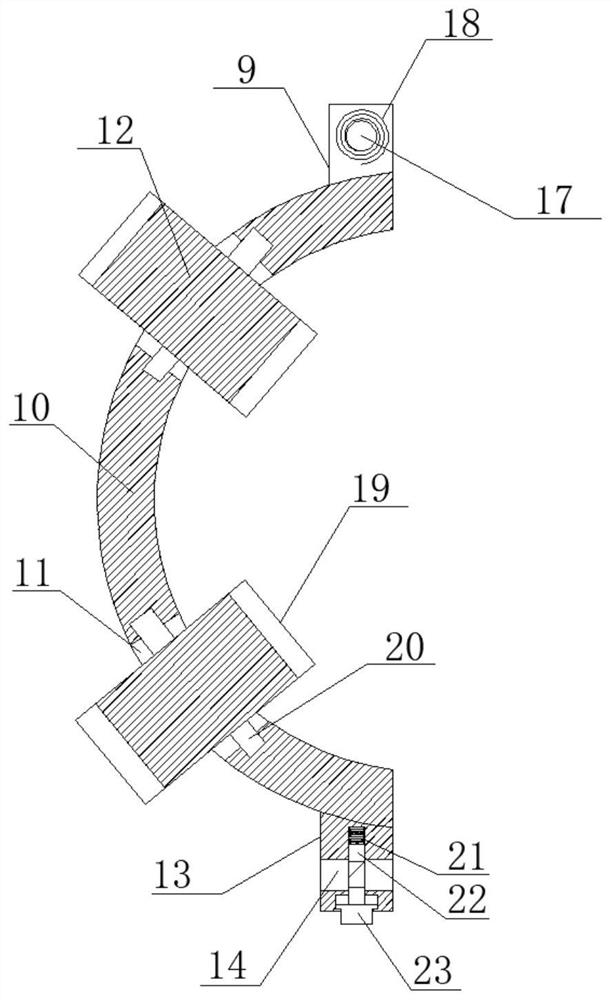

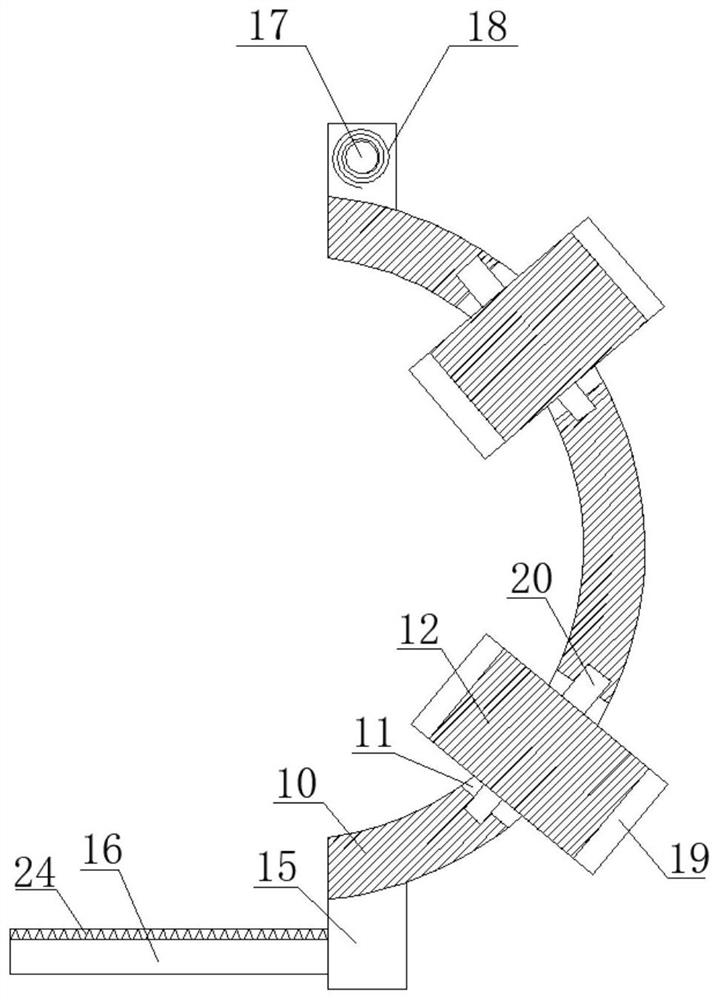

River channel slope protection laying device for water conservancy project

InactiveCN114382053AMove quicklySimple design and integrated structureCoastlines protectionRiver routingAgricultural engineering

The invention discloses a river channel slope protection laying device for water conservancy projects, and relates to the field of water conservancy projects, the river channel slope protection laying device comprises a supporting side plate, rolling wheels are clamped on the bottom surface of the supporting side plate, a connecting transverse plate is connected to the top surface of the supporting side plate through bolts, and a fixed top block is vertically and upwards welded to the top surface of the connecting transverse plate; an extending turning rod is horizontally inserted into the side edge between the fixed top blocks, a connecting insertion rod is horizontally inserted into the side edge of each fixed top block, the side edge of the end, away from the corresponding fixed top block, of each extending turning rod is in butt joint with a turning motor, and the output end of each turning motor is horizontally and fixedly sleeved with a turning block; a tail troweling plate is horizontally welded to one end of the supporting side plate, and a top side plate is vertically and upwards welded to the top face of the supporting side plate. The device is designed to be integrated, the structure is simple, operation is easy and convenient, laying is more attractive and stable under the condition that multiple vibration screeding structures are adopted, and meanwhile laying is more rapid and efficient under the movable construction mode.

Owner:曾秀云

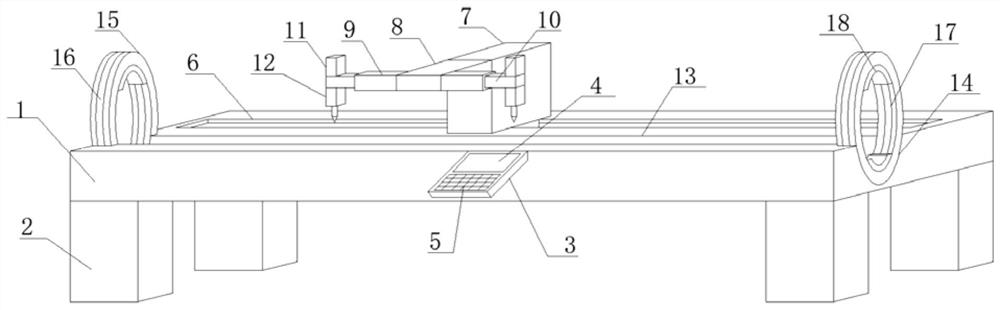

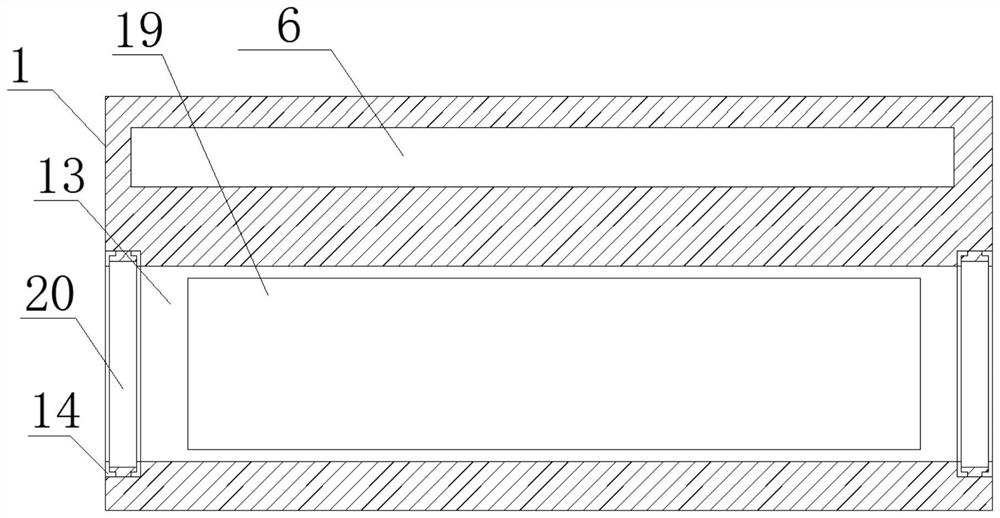

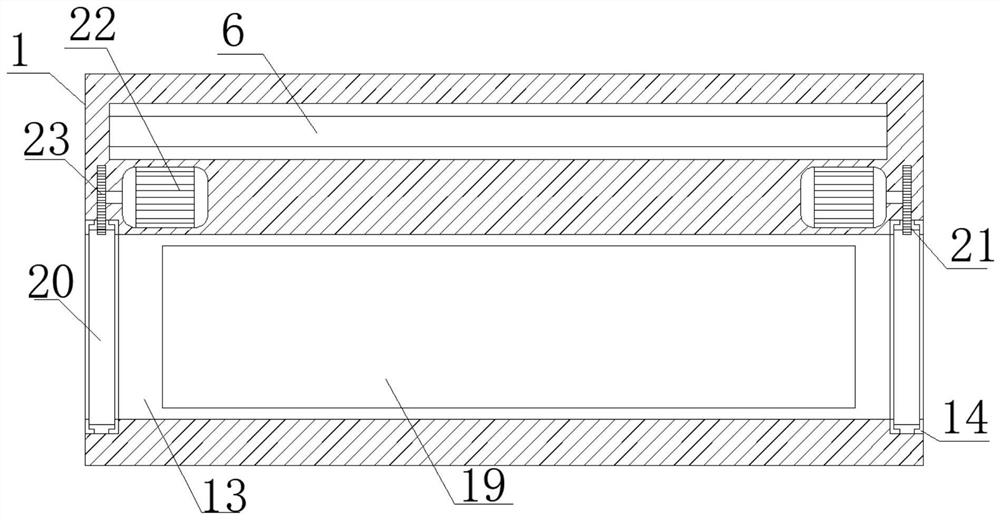

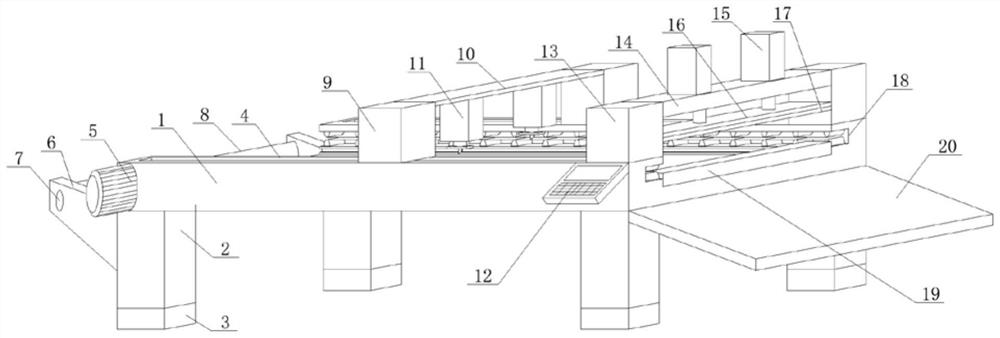

Full-automatic cutting processing equipment for tarpaulin production

InactiveCN113373677AEasy to installFast and efficient vertical crop processingSevering textilesElectric machineryStructural engineering

The invention discloses full-automatic cutting processing equipment for tarpaulin production, and relates to the field of tarpaulin production. The full-automatic cutting processing equipment comprises a main supporting plate, supporting vertical rods are perpendicularly and downwards welded to the bottom face of the main supporting plate, bottom cushion blocks are fixedly bonded to the bottom ends of the supporting vertical rods, and transverse channels are horizontally and symmetrically formed in the top face of the main supporting plate; conveying motors are connected to the two side edges of the main supporting plate through bolts, supporting inclined plates are obliquely welded to the side edges of the supporting vertical rods, inserting shaft rods are horizontally inserted into the side edges between the supporting inclined plates, and a material rolling shaft is horizontally arranged at the end between the inserting shaft rods; and moving rods are in butt joint with the top face of the main supporting plate in the vertical direction, a fixed transverse rod is horizontally welded to the side edge between the movable rods, and the bottom face of the fixed transverse rod is in butt joint with a top air cylinder in the vertical direction. According to the full-automatic cutting processing equipment for the tarpaulin production, the design is integrated, the structure is simple, operation is convenient, cutting work of various specifications and sizes can be met by adopting multi-direction cutting combination, and meanwhile, more rapidness and convenience are achieved through intelligent integrated control.

Owner:杭州罗松贸易有限公司

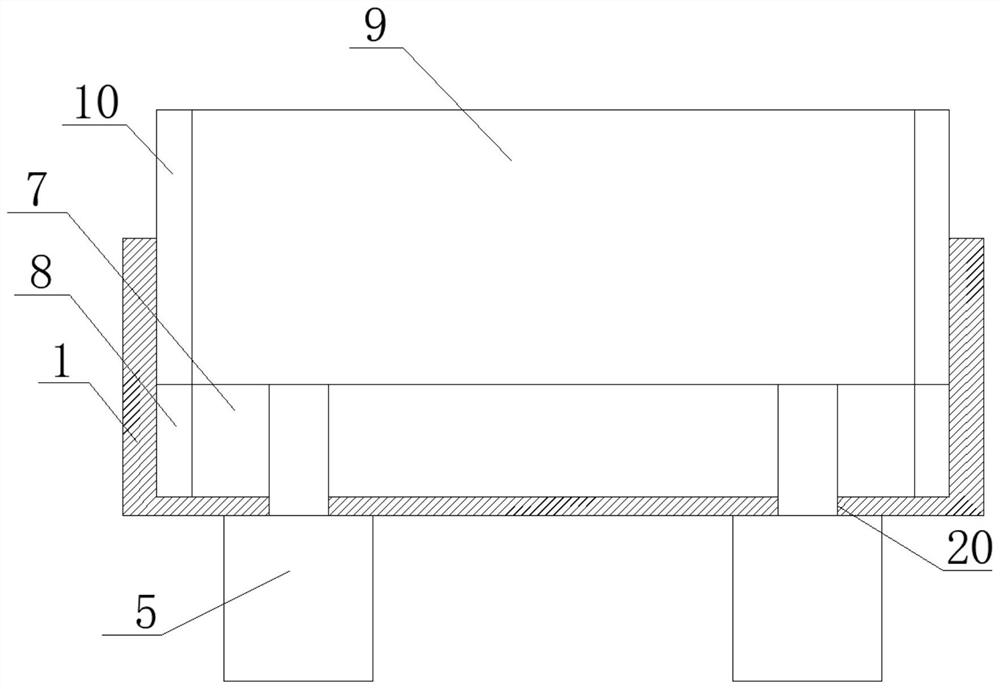

Coring drill and coring machine suitable for asphalt pavement

InactiveCN113640048ASports reliableReduce resistanceWithdrawing sample devicesStructural engineeringIntegrated design

The invention discloses a coring drill and a coring machine suitable for an asphalt pavement, and relates to the field of coring drills, the coring drill comprises a fixed bottom box, transmission shaft rods are symmetrically inserted into the two side edges of the fixed bottom box, rolling wheel bodies fixedly sleeve the outer side edges of the transmission shaft rods, and supporting side plates are vertically welded to the side edges of the fixed bottom box; a fixed top plate is horizontally welded to the side edges between the supporting side plates, a fixed bottom plate is horizontally welded to the side edges between the supporting side plates, an extending through hole is horizontally formed in the top face of the fixed bottom plate, side limiting grooves are symmetrically formed in the side edges between the supporting side plates, a guide column body is vertically and downwards welded to the bottom face of the fixed top plate, and a movable flat plate is horizontally arranged on the side edge between the supporting side plates. The machine is designed to be of an integrated structure, the structure is simple, operation is convenient, the balance weight and movement integrated design is adopted, so that the device is more stable, reliable and convenient to carry, and meanwhile, a detachable connecting structure is adopted, so that maintenance is more convenient.

Owner:苏俊

Cleaning device for magnesium alloy material surface treatment

InactiveCN114558829AEasy feedingEasy dischargeDrying gas arrangementsCleaning using toolsBolt connectionMagnesium alloy

The invention discloses a cleaning device for magnesium alloy material surface treatment, and relates to the field of magnesium alloy materials, the cleaning device comprises a cleaning main box, a supporting bottom block is welded to the bottom surface of the cleaning main box, a clamping groove is horizontally formed in one side edge of the cleaning main box, and a sealing panel is horizontally clamped to the inner side edge of the clamping groove; a blow-off pipe is connected to the bottom face of the cleaning main box in an inserted mode, a control panel is embedded in one side edge of the cleaning main box, extending material rods are symmetrically welded to the two side edges of the cleaning main box, material clamping grooves are horizontally formed in the side edges between the extending material rods, communicating groove channels are symmetrically formed in the two side edges of the cleaning main box, and the connecting grooves are communicated with the communicating groove channels. The top face of the cleaning main box is in bolted connection with a conveying motor, and the top face of the cleaning main box is in bolted connection with a sweeping motor. The device is designed to be integrated, the structure is simple, operation is easy and convenient, flushing and brush body structure cleaning are adopted, cleaning is faster and more efficient, meanwhile, water stain treatment is more thorough, and the magnesium alloy plate body cleaning effect is better.

Owner:TONGLING UNIV

Zipper tooth clamping device for zipper production

PendingCN113925263AIncrease productivitySimple design and integrated structureSlide fastenersButt jointEngineering

The invention discloses a zipper tooth clamping device for zipper production, and relates to the field of zipper production, the zipper tooth clamping device comprises a bottom supporting plate, a supporting vertical rod is vertically and downwards welded to the bottom surface of the bottom supporting plate, a top conveying groove is horizontally formed in the top surface of the bottom supporting plate, and a through groove hole is formed in the inner side edge of the top conveying groove, matched top grooves are evenly formed in the top face of the bottom supporting plate, bottom through grooves are horizontally and evenly formed in the bottom face of the inner side of the top conveying groove, a pushing and pressing transverse plate is in butt joint with the top face of the bottom supporting plate, a pushing and pressing air cylinder is horizontally connected to the top face of the bottom supporting plate through bolts, and a bottom sleeving box is horizontally welded to the bottom face of the bottom supporting plate, and the bottom surface of the bottom sleeving box is in bolted connection with a top connection air cylinder. According to the device, the integrated structure is designed, the structure is simple, operation is convenient, machining is faster and more efficient by adopting a double material conveying structure, meanwhile, batch clamping treatment can be conducted at a time through machining integration, and the zipper production efficiency is greatly improved.

Owner:杭州罗松贸易有限公司

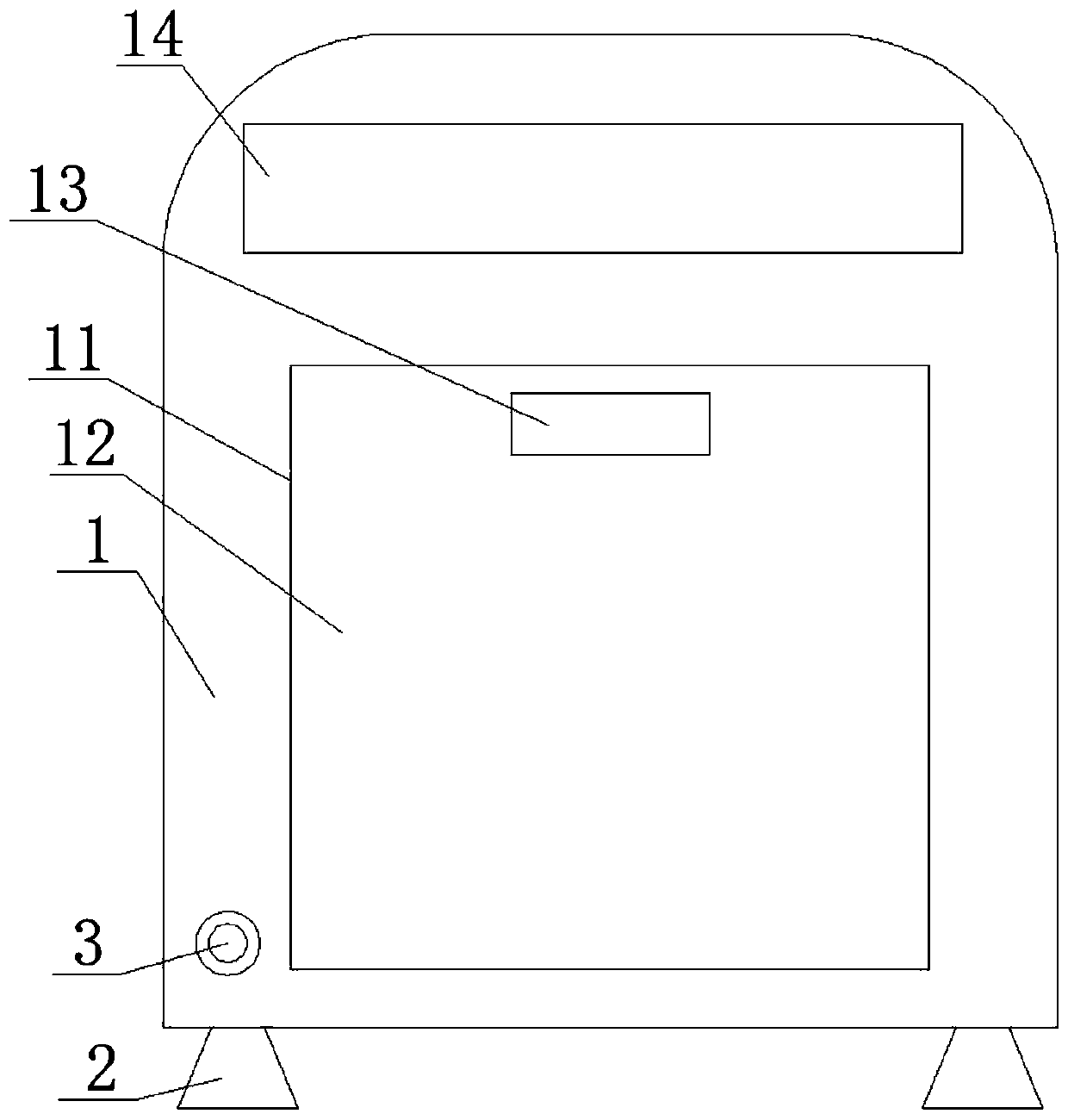

Air purifier

InactiveCN111550885AEasy to carryEasy to moveMechanical apparatusLighting and heating apparatusAir purifiersStructural engineering

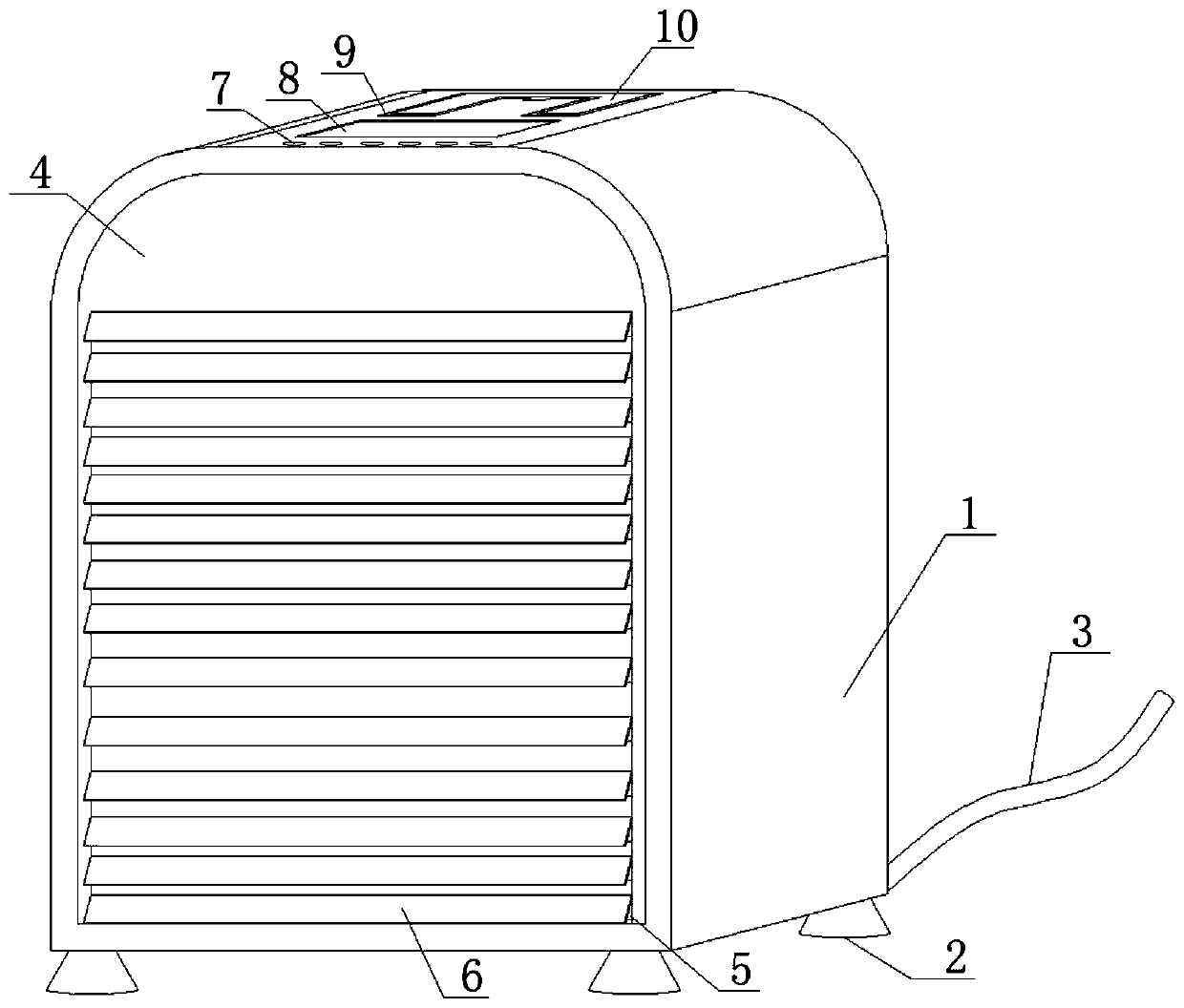

The invention discloses an air purifier, and relates to the field of air purification. The air purifier comprises a support shell, wherein bottom cushion blocks are in threaded connection with the bottom surface of the support shell; a power wire is inserted into one side edge of the support shell; a sealing panel is fixedly clamped and connected to one side edge, away from the power wire, of thesupport shell; ventilation channels are horizontally and uniformly formed in one side edge of the sealing panel; an overturning partition plate is horizontally clamped and connected to the inner sideedge of each ventilation channel; setting keys are embedded in the top surface of the support shell; a display screen is embedded in the top surface of the support shell; a containing groove is horizontally formed in the top surface of the support shell; and an overturning handle is clamped and connected to the inner side edge of the containing groove. According to the air purifier, the design isintegrated, the structure is simple, the operation is convenient, multiple filtering structures are adopted to make the air purification more thorough, filter screens in the interior of the air purifier are convenient to replace due to the detachable structure, and the air purifier is better to use with the sterilization and humidification effects.

Owner:徐明生

A stainless steel tableware grinding device

ActiveCN112192431BQuick installationImprove work efficiencyEdge grinding machinesPolishing machinesCutleryStructural engineering

The invention discloses a stainless steel tableware grinding device, which relates to the field of tableware grinding, and comprises a fixed box body, the bottom surface of the fixed box body is welded vertically downward with a support pole, and the bottom end of the support pole is fixedly clamped with a Bottom rubber block, the side of the support pole is horizontally welded with a fixed cross bar, the bottom surface of the fixed box is vertically connected to the bottom cylinder with bolts, and the side of the fixed box is obliquely welded with a control panel , the top surface of the fixed box is horizontally provided with movable slots, the two sides of the movable slot are vertically and symmetrically provided with limiting slots, the inner side of the movable slot is clamped with a processing box, and the processing The two sides of the box body are vertically symmetrically welded with limited positions. The integrated structure of the device design of the present invention is simple and easy to operate, and the grinding method of sand grains is used to make the surface of the tableware be polished in all directions without dead ends, which is more reasonable and efficient, and at the same time, it can be polished in batches, which greatly improves the grinding work. efficiency.

Owner:揭阳市东拓家居实业有限公司

Electric power system maintenance device

InactiveCN113394736AEasy to installPrevent slippingOverhead installationElectric power systemElectric cables

The invention discloses an electric power system maintenance device, and relates to the field of electric power system maintenance, the electric power system maintenance device comprises a fixed transverse plate, one end of the fixed transverse plate is provided with an end sleeve groove, the inner side edge of the end sleeve groove is provided with an overturning buckle, and the two side edges of the fixed transverse plate are symmetrically provided with side sleeve connection grooves; an extending side plate is horizontally inserted into the inner side edge of the side sleeving groove, a main power line is inserted into the end, away from the end sleeving groove, of the fixing transverse plate, a top fixing box is connected to the top face of the fixing transverse plate through a bolt, a side overturning groove is formed in the side edge, away from the fixing transverse plate, of the extending side plate, an overturning block is clamped to the inner side edge of the side overturning groove, an arc-shaped turning plate is horizontally welded to one end of the turning block. The device is integrally designed, is simple in structure, is convenient to operate, is simpler and more convenient by adopting a buckling surrounding mode, can be suitable for cables of various specifications, is quicker and more efficient by adopting a hammering mode to break ice, and is safer during operation.

Owner:杭州迦北科技有限公司

Environment-friendly catering oil-water separation equipment

InactiveCN112520928AEfficient separationReduce internal temperatureFatty/oily/floating substances removal devicesTreatment involving filtrationStructural engineeringOil water

The invention discloses environment-friendly catering oil-water separation equipment, and relates to the field of catering oil-water treatment. The environment-friendly catering oil-water separation equipment comprises a main standing box, a standing funnel is vertically and downwards welded to the bottom surface of the main standing box, a feeding pipe is horizontally welded to the side edge of the main standing box, and a top vertical plate is vertically and upwards welded to the top surface of the main standing box; an extending vertical groove is vertically formed in the inner side edge ofthe main standing box, a conveying belt is vertically arranged on the inner side edge of the extending vertical groove, a connecting block is horizontally connected to one side edge of the conveyingbelt through a bolt, and a top cover plate is horizontally welded to the end, away from the conveying belt, of the connecting block. The equipment is integrated in design, simple in structure and convenient to operate, a standing treatment mode is adopted, so that the equipment is more energy-saving and environment-friendly, meanwhile, the oil body and the water body are effectively treated separately, and filtering treatment is performed during water body discharge, so that the water body is cleaner, a transmission type filtering mode is adopted, and thus the filter element does not need to be replaced at high frequency.

Owner:苏州科亿嘉科技发展有限公司

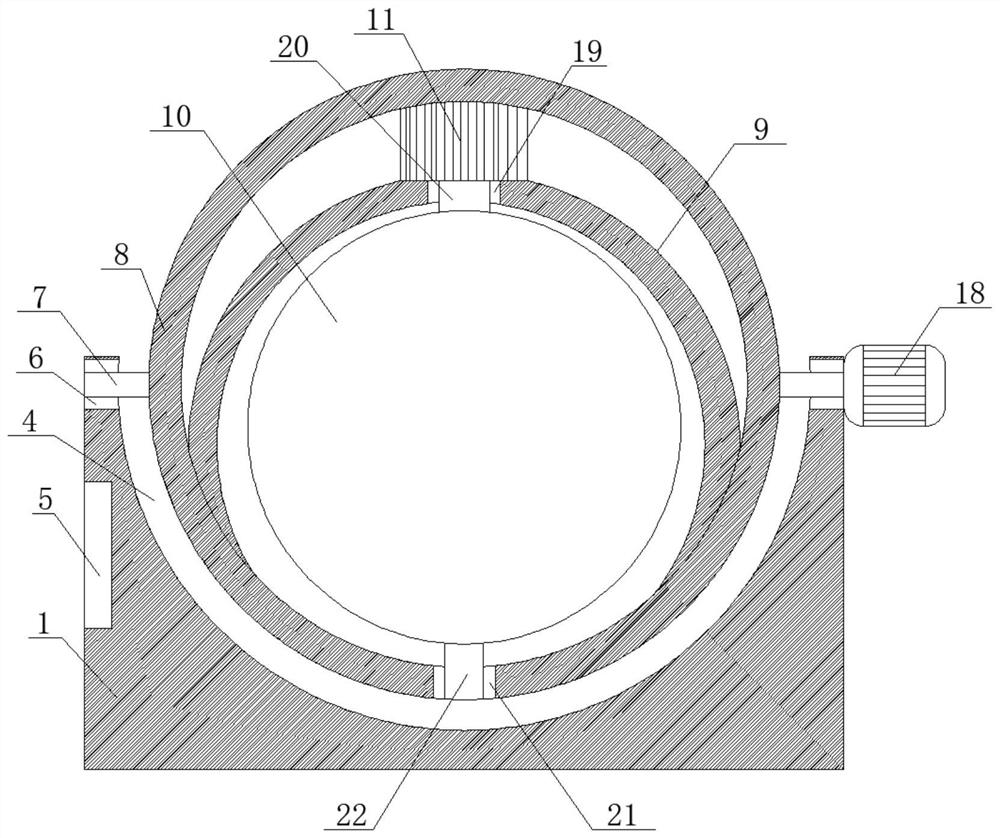

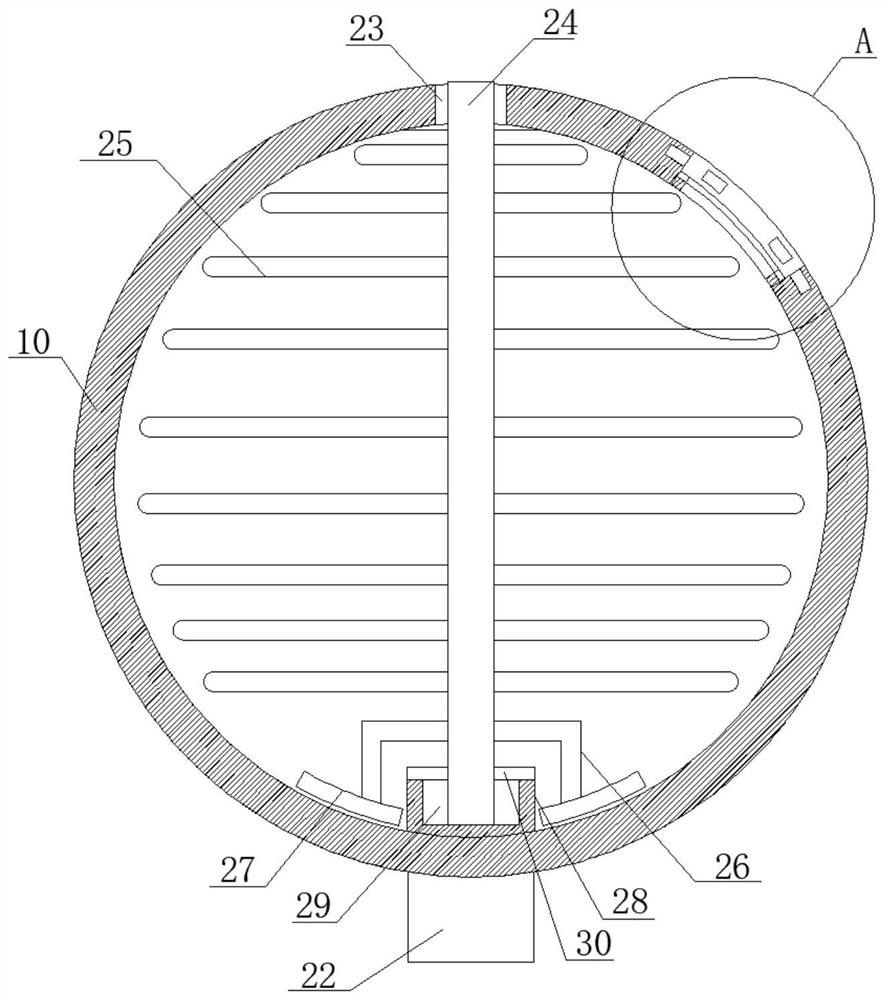

A kind of mixing machine for alloy pc composite material

The invention discloses a mixing machine for alloy PC composite materials, relates to the field of PC composite materials, and comprises a support base, two sides of the support base are symmetrically and horizontally welded with a fixed plate, and the top surface of the fixed plate is provided with a connection Through holes, the top surface of the support base is horizontally provided with an overturning groove, one side of the support base is inlaid with a control panel, and the two sides of the support base are symmetrically fixed and clamped with fixed bearings. The inner side is horizontally inserted with a fixed insertion rod, the inner side of the turning groove is sleeved with a turning ring, the inner side of the turning ring is horizontally welded with an arc-shaped clamping plate, and the inner side of the arc-shaped clamping plate The side socket is connected with a mixing tank body. The integrated structure of the device design of the present invention is simple and easy to operate. The multi-directional rotation makes the internal material mixing more fully. At the same time, the intelligent setting makes the operation easy and convenient for hands-on operation, so that the material mixing is more thorough and efficient.

Owner:聚力防静电科技(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com