Patents

Literature

35results about How to "Integrated structure is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

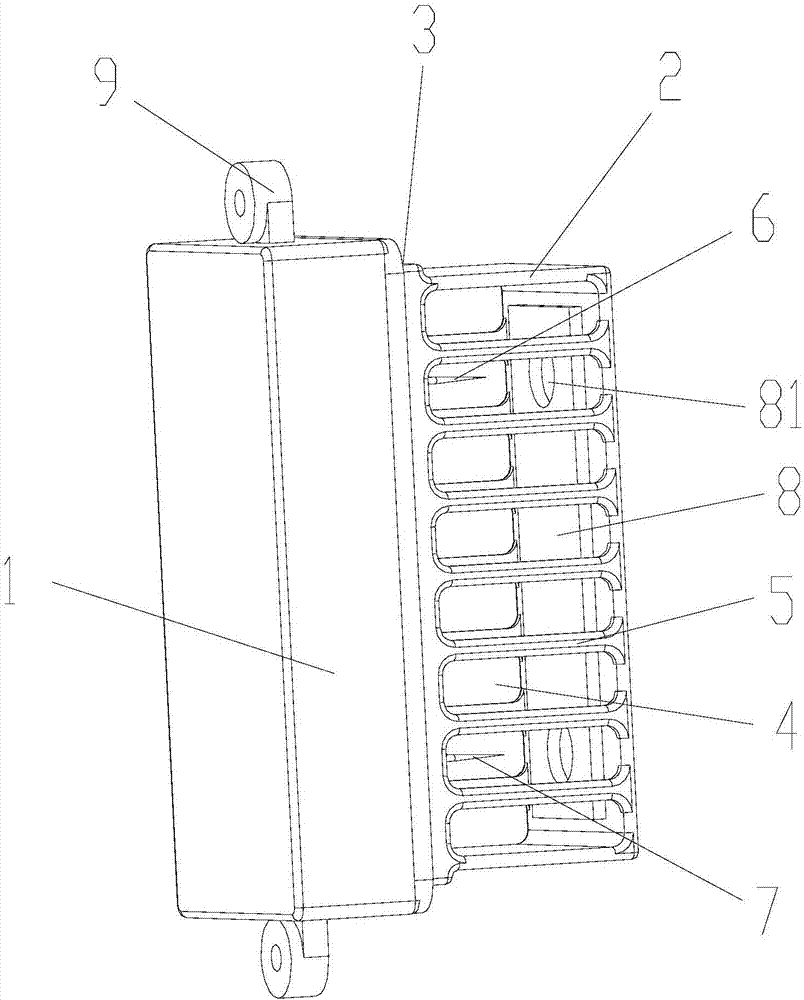

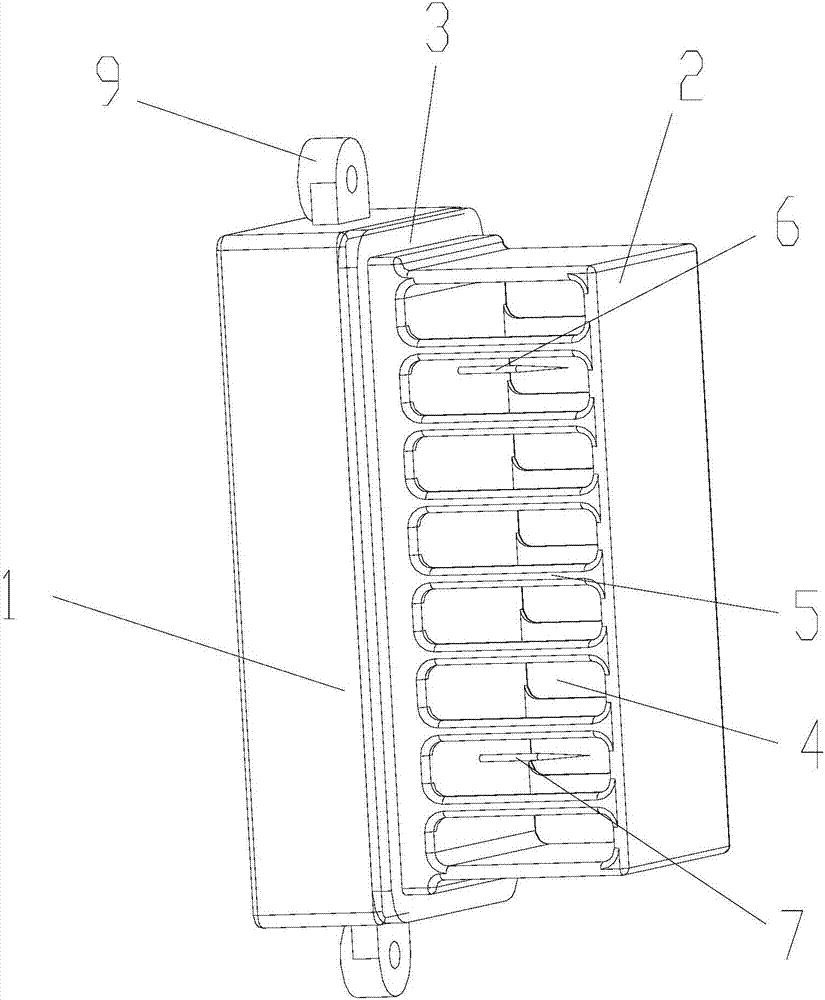

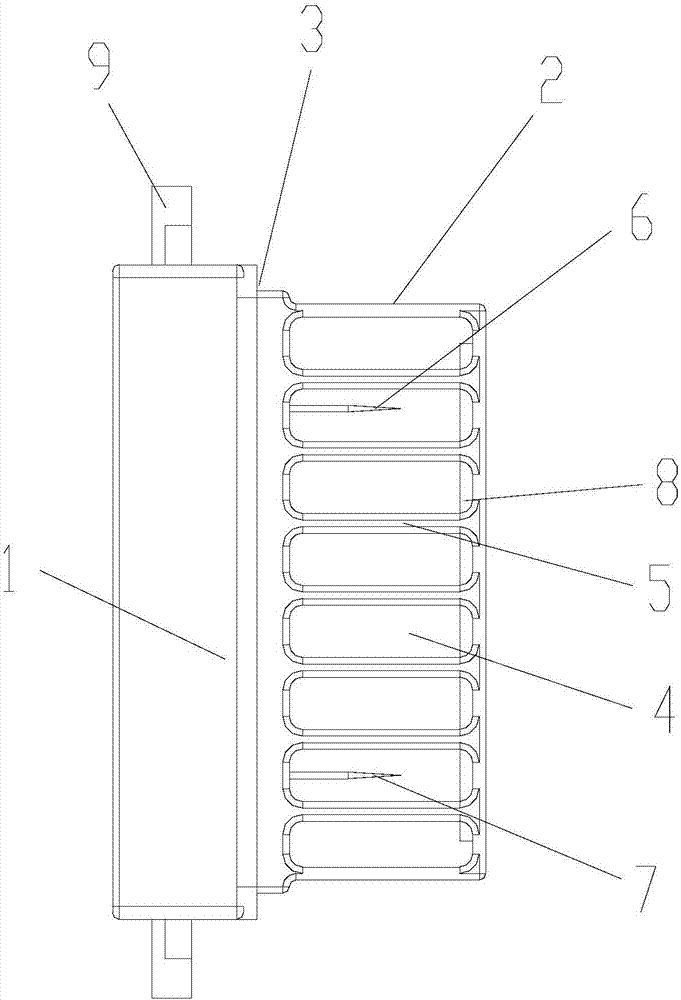

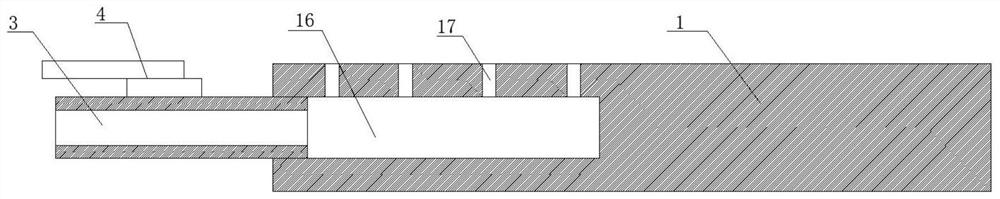

Material packing and material put-in method adopting the material packing

ActiveCN1807196AIntegrated structure is simpleEasy to operateCooking vesselsPackagingEngineeringSingle chamber

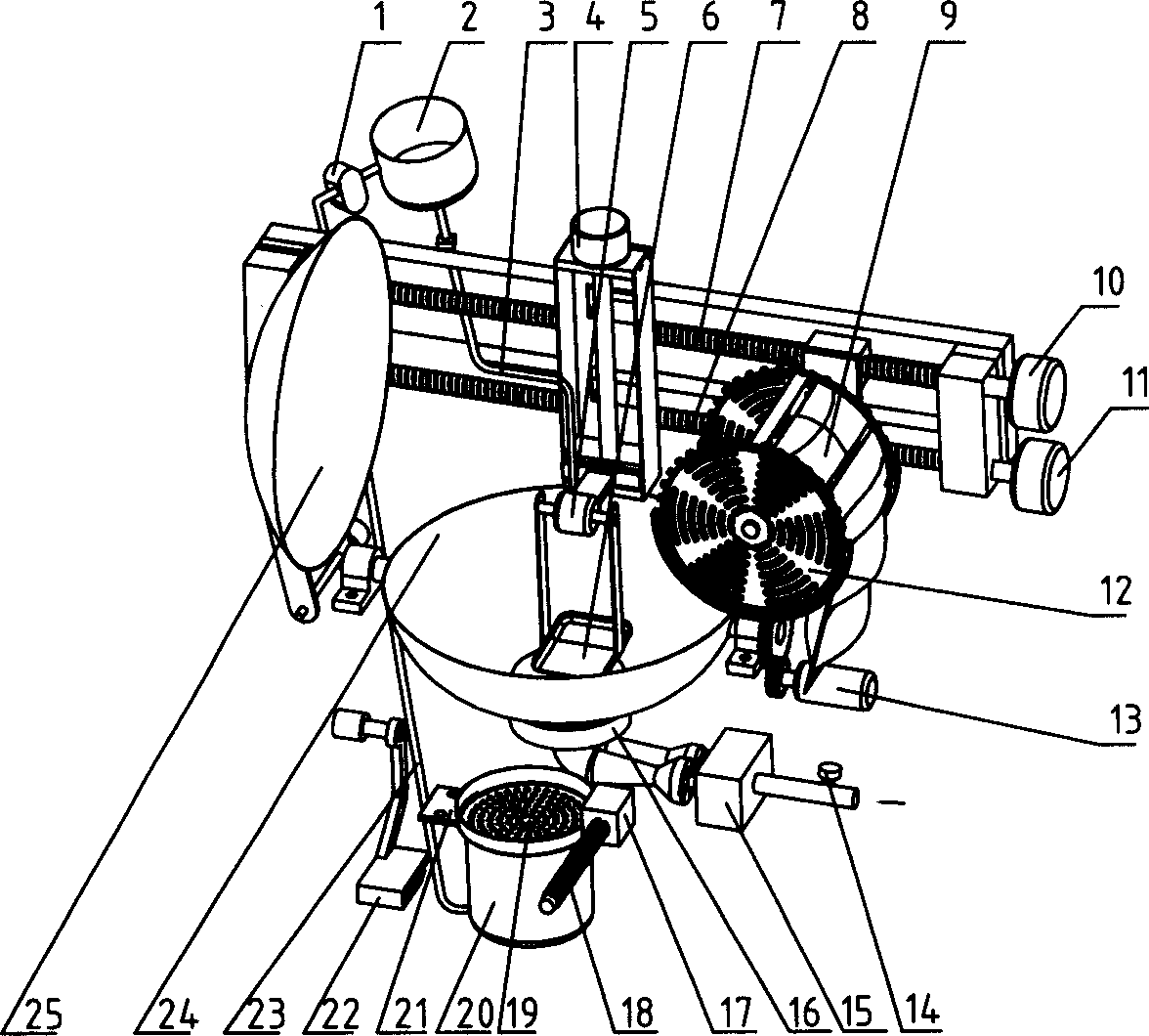

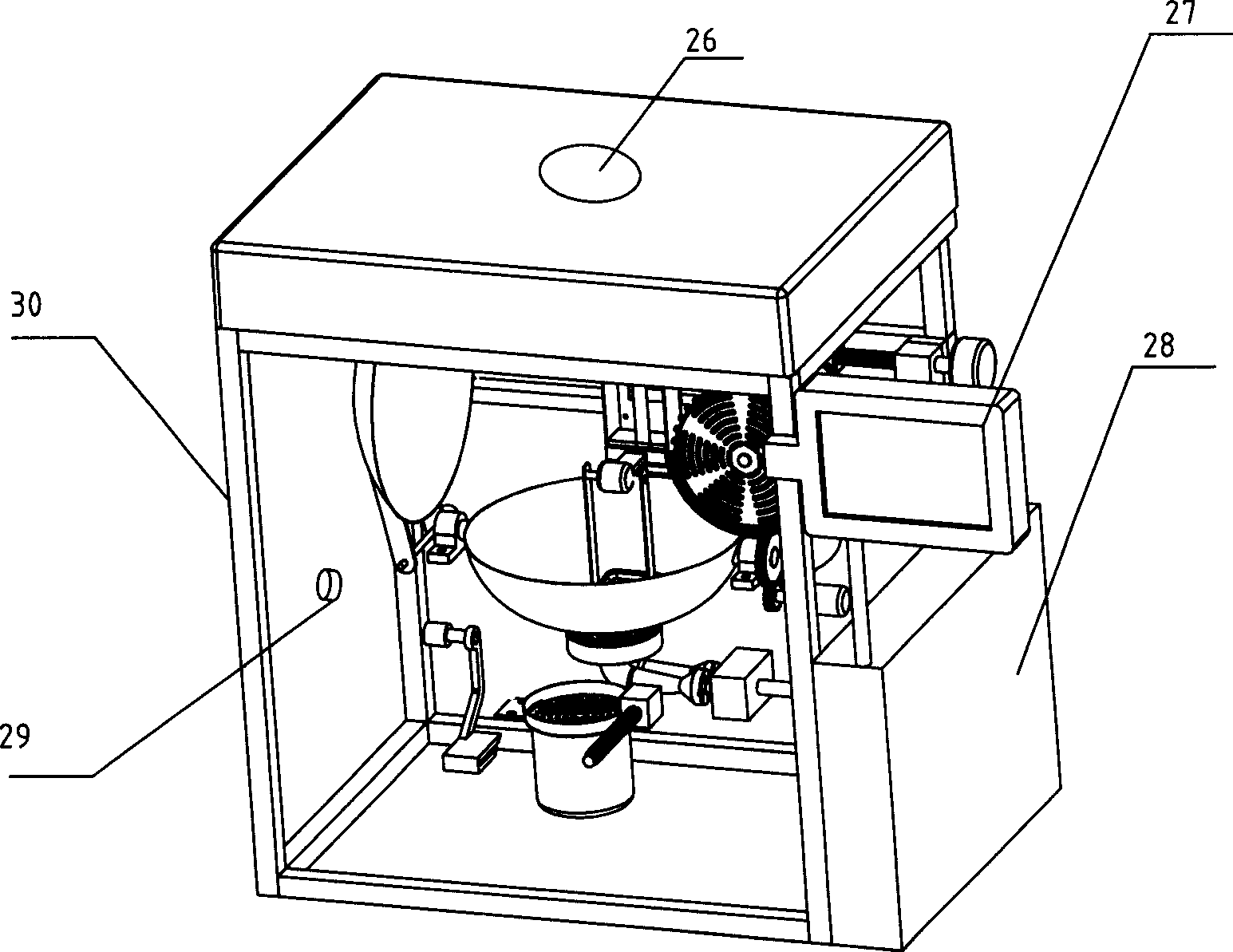

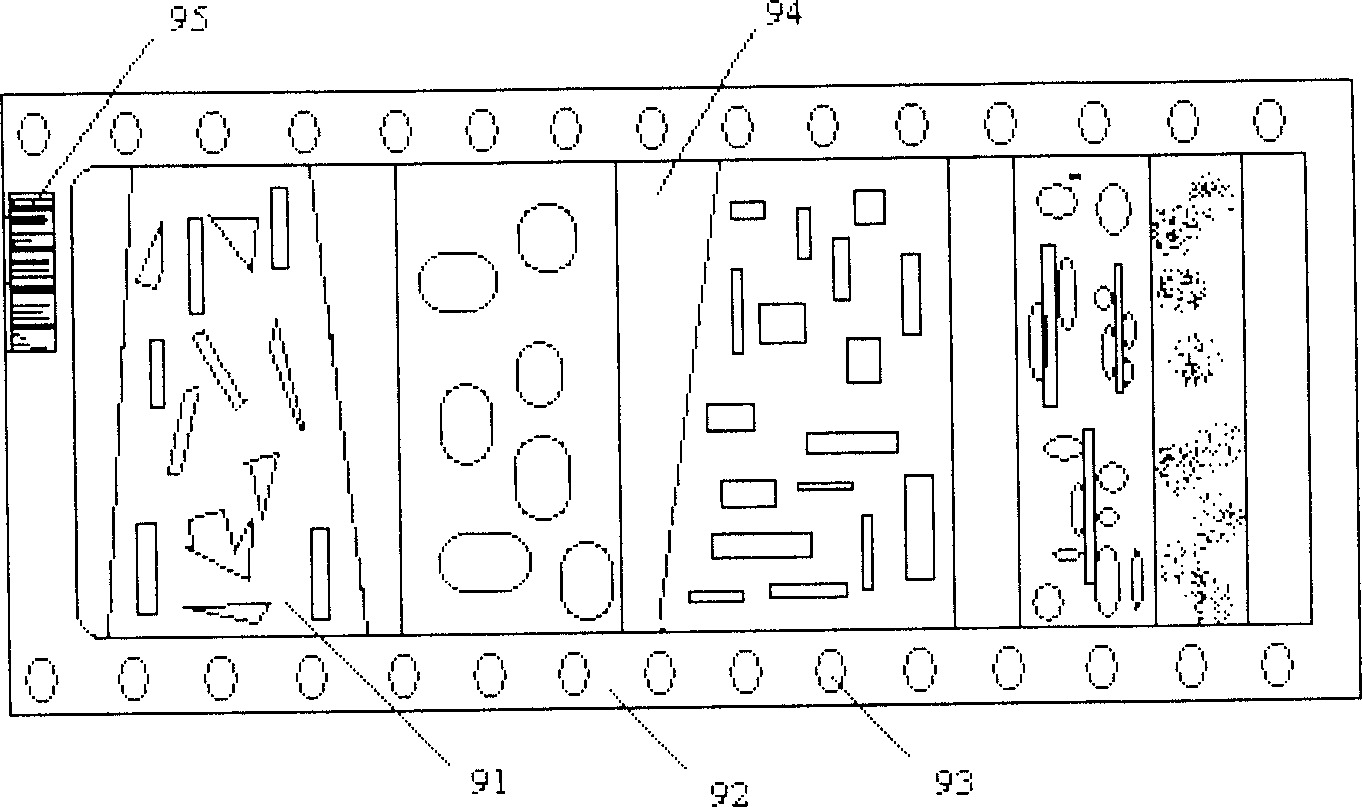

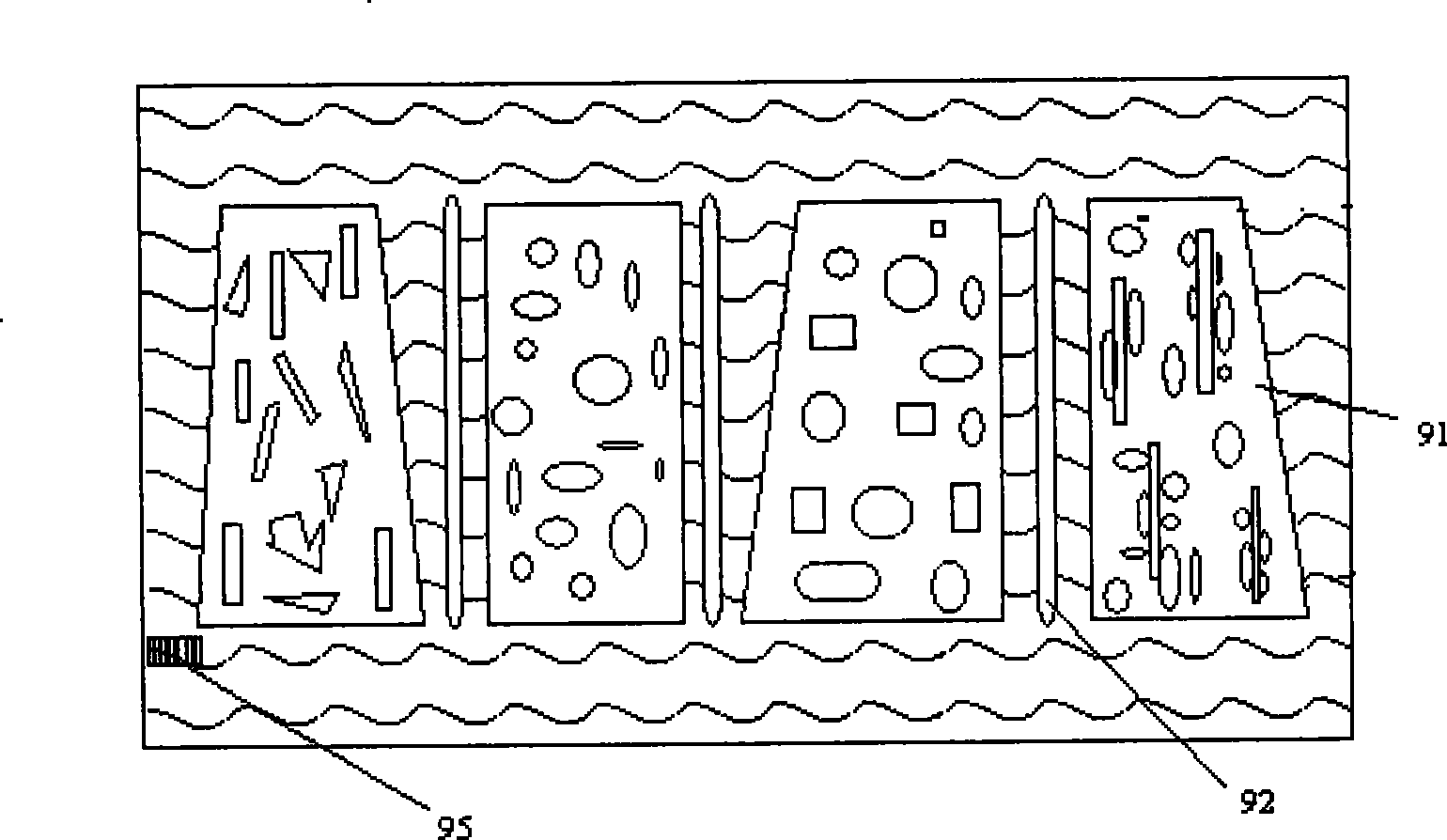

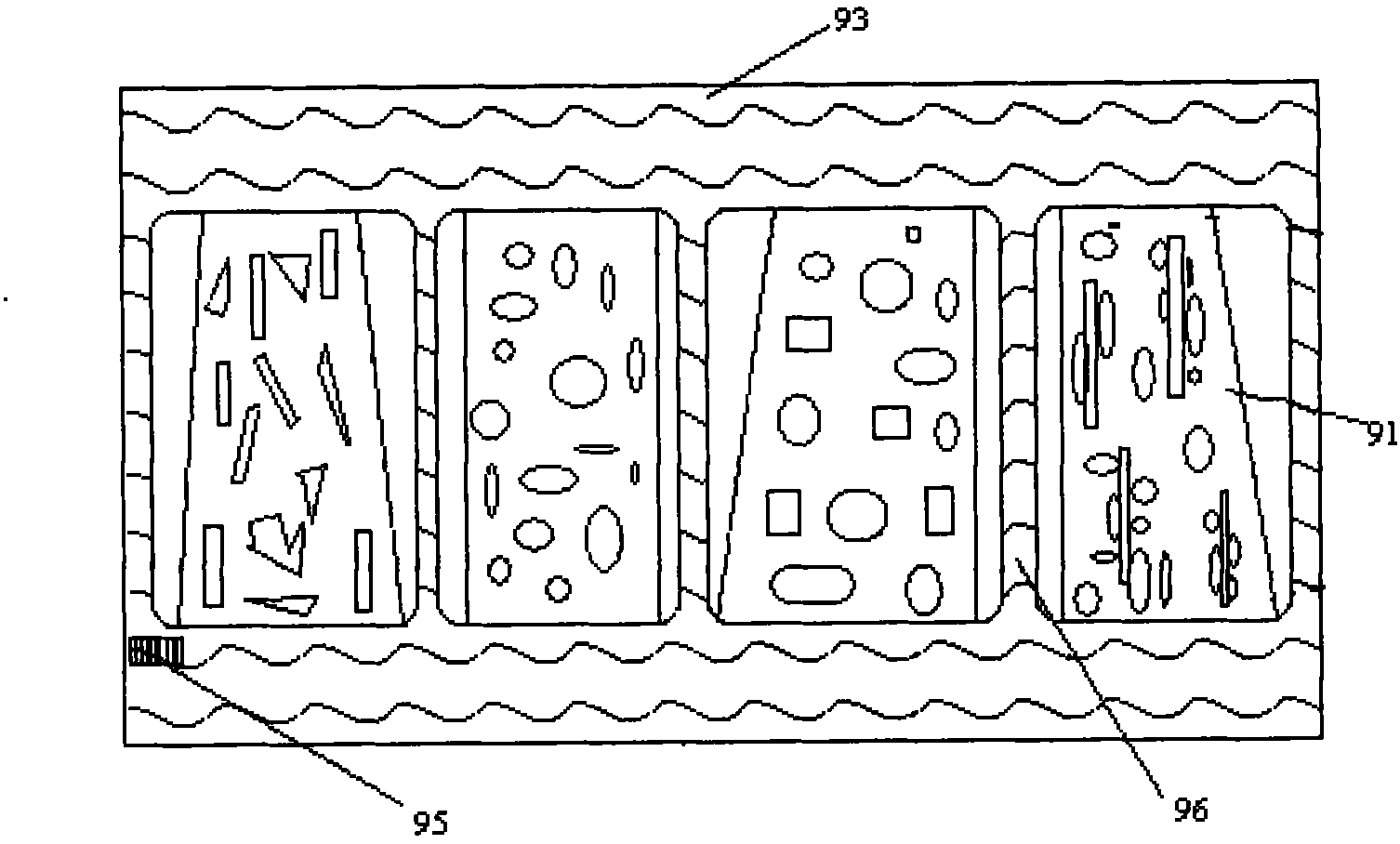

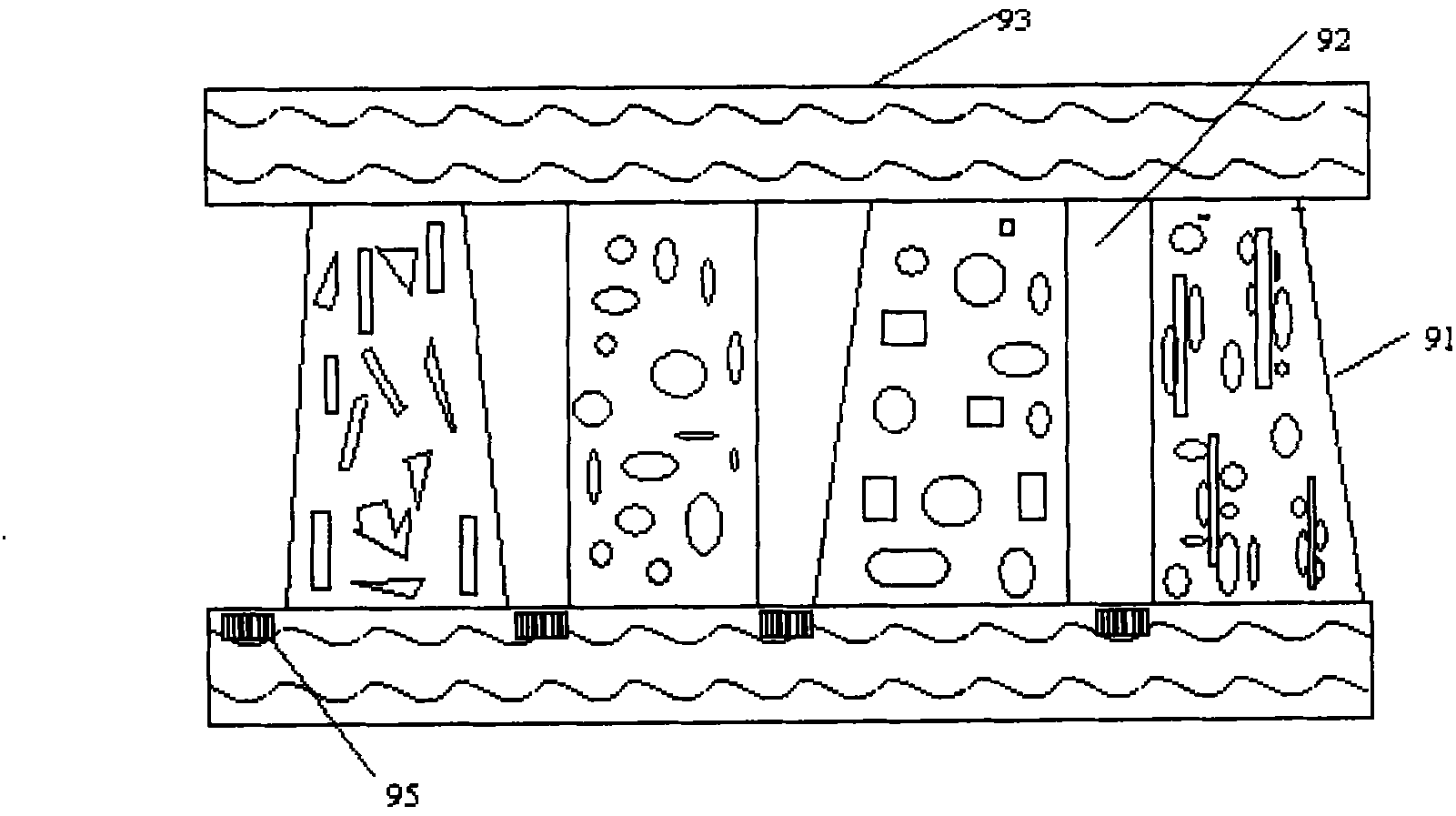

The invention discloses the material package used for material auto throwing system and the throwing method. The material package comprises more than two flexible package bodies, every package body is single-chamber or multi-chamber, the ends of the package bodies are connected with each other through flat or cylinder connector, the bodies are separate, and on the package body or connector there is the information for cooking-vessel information acquisition system. The material package has the advantages of simple structure and easy operation.

Owner:AIC ROBOTICS TECH

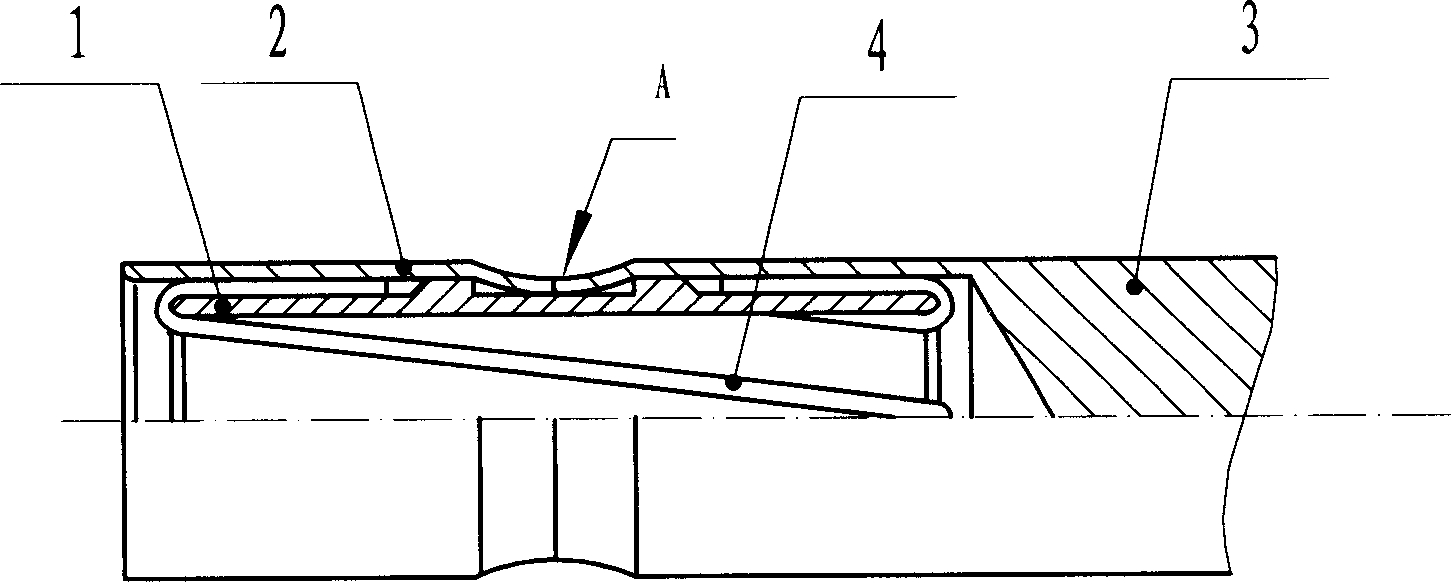

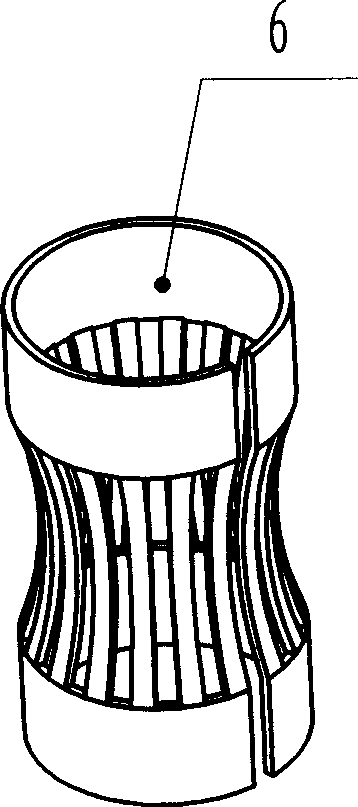

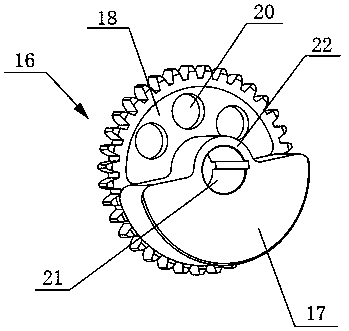

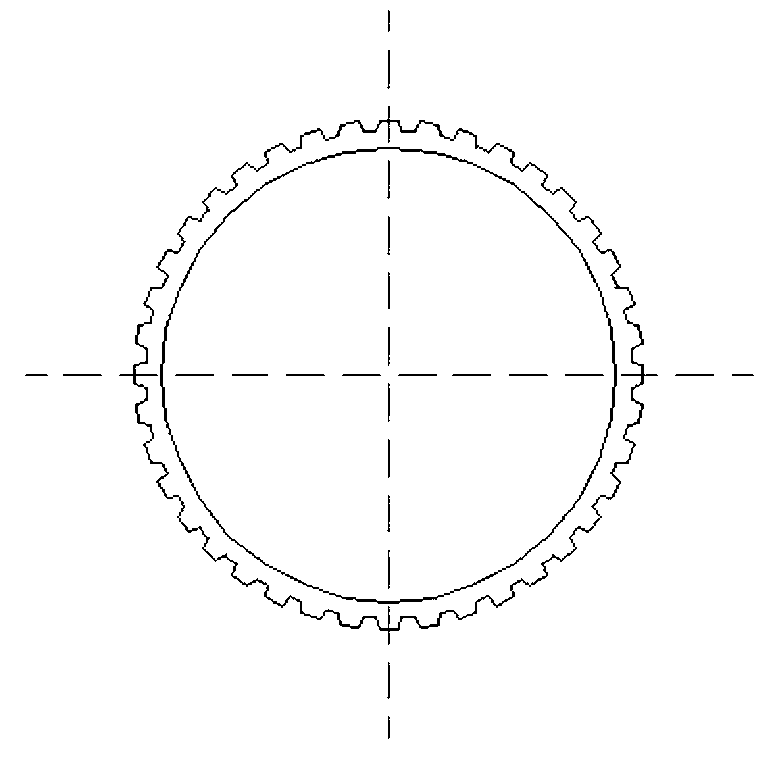

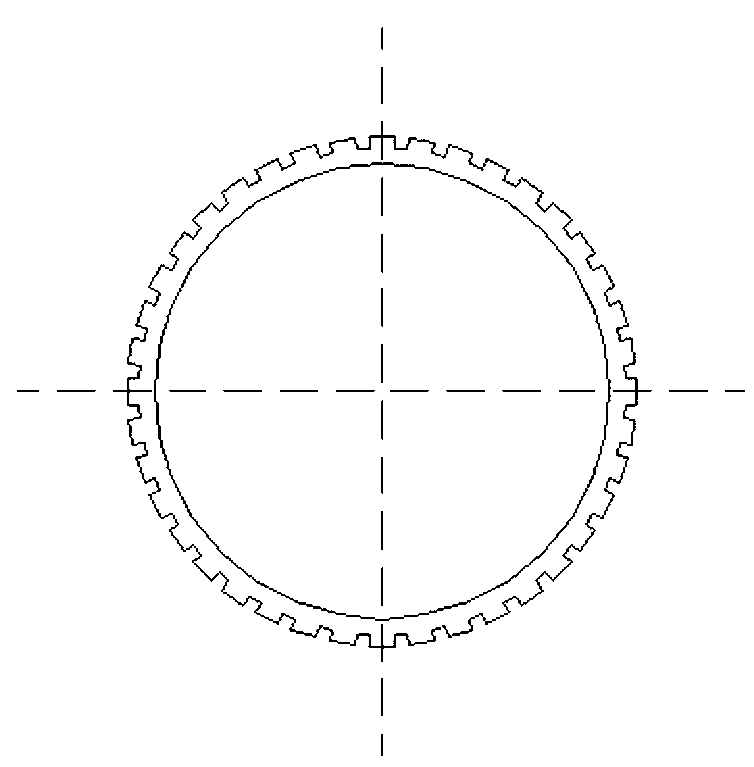

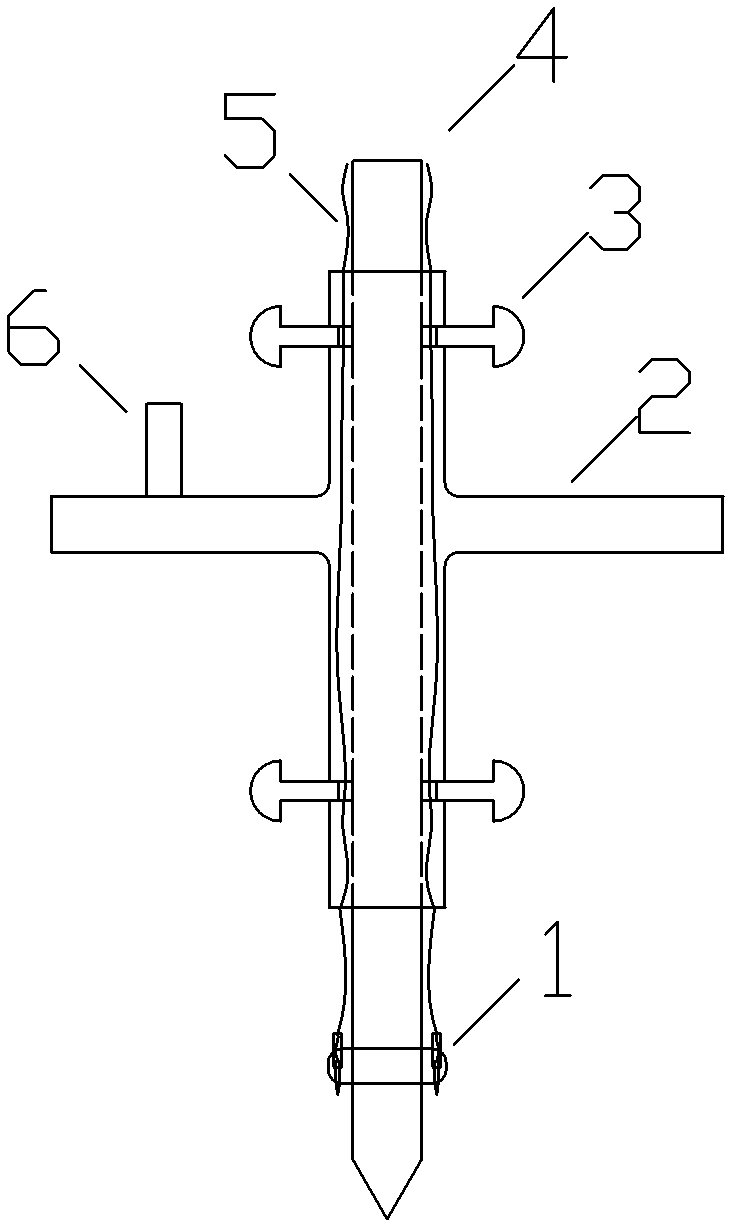

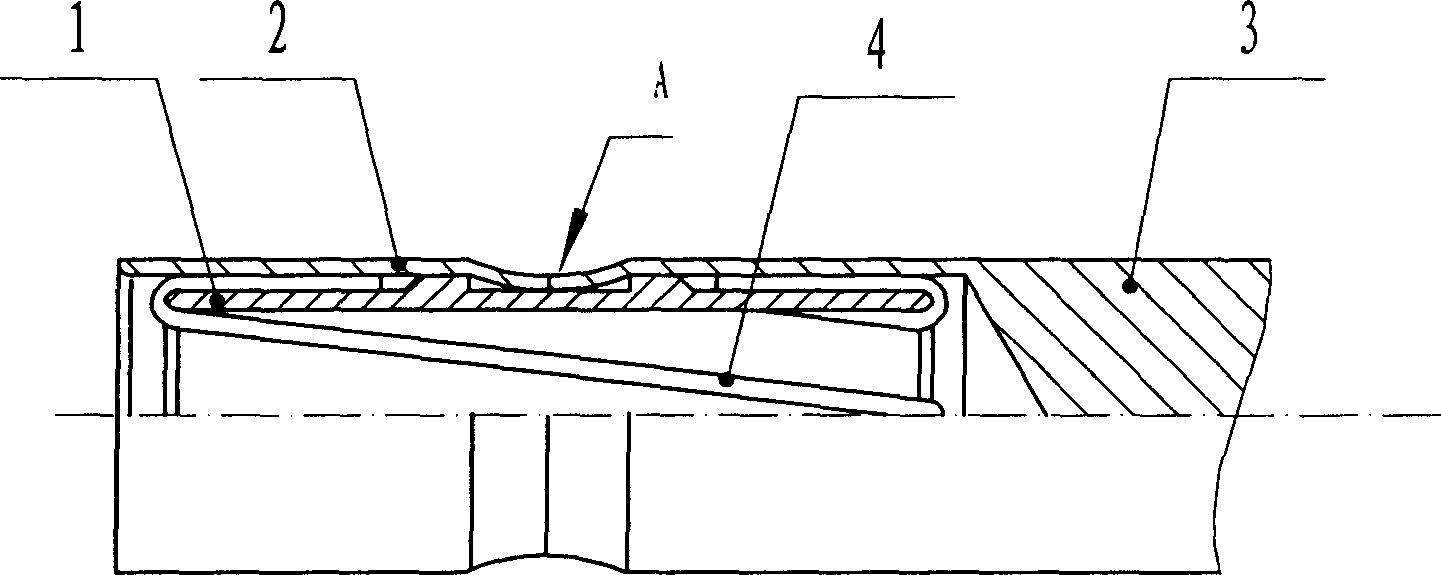

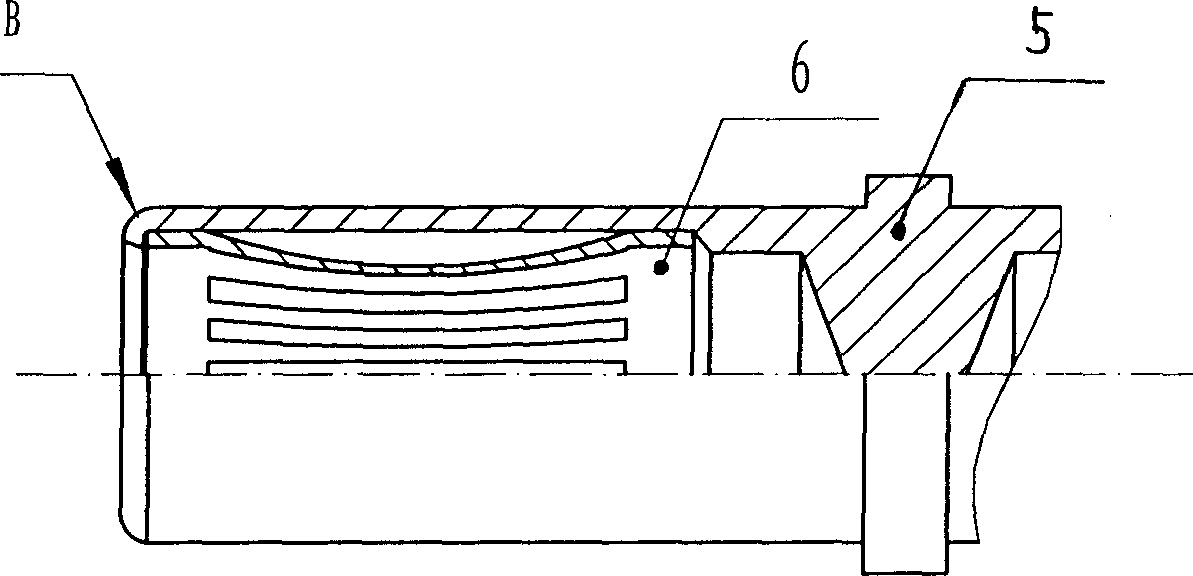

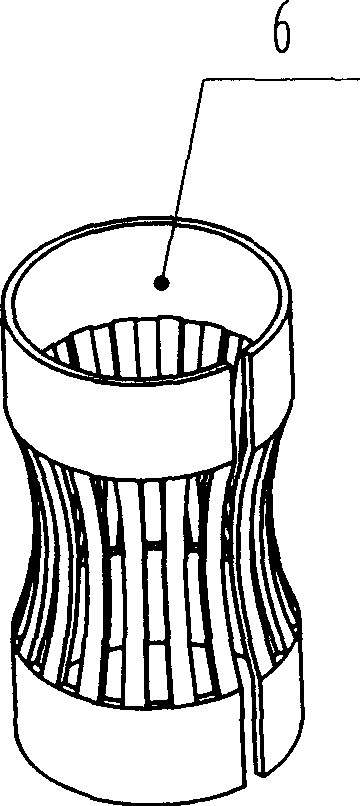

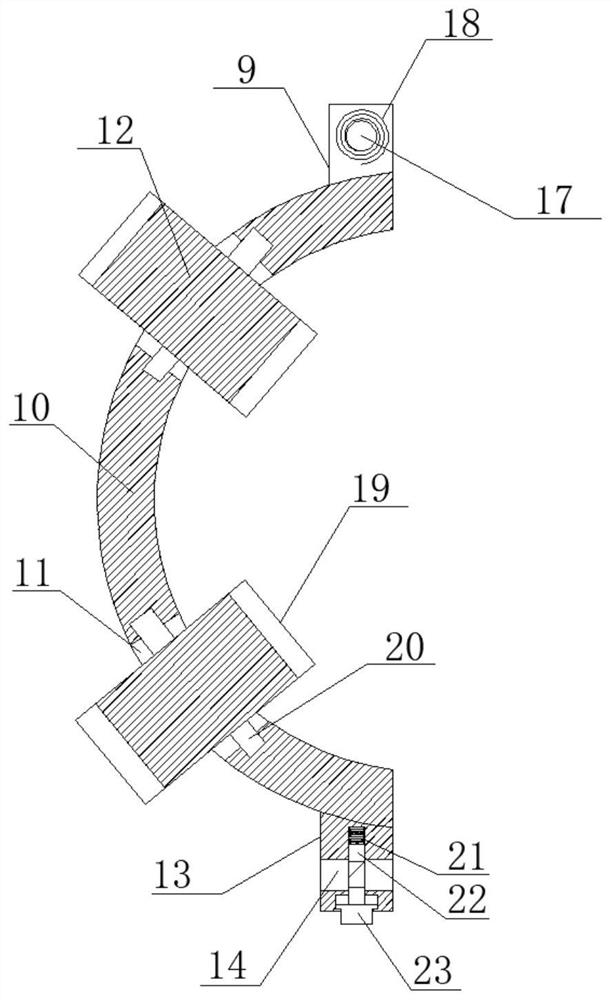

Singl-leaf revolving double-curve crown-strip ring and its process thereof

InactiveCN1438736AReduce volumeIntegrated structure is simpleCoupling contact membersBiomedical engineeringFront cover

Convoluting the elasticity sheets metal punched forms the coronary straps jack contact element so that the manufacturing procedure is simple providing the advantages of low cost, good consistency and being suitable to mass production. The contact between jacks and pins is the contact mode of the multiaspect envelope so as to provide the features of steady dynamic contact resistance, shockproof, antivibration, small contact resistance etc. The structure of the contact element is simple without the front cover, back cover and inner housing, Thus, the size of the contact element is smaller and the wastage of copper material is reduced so as to save copper material as well as human resources.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

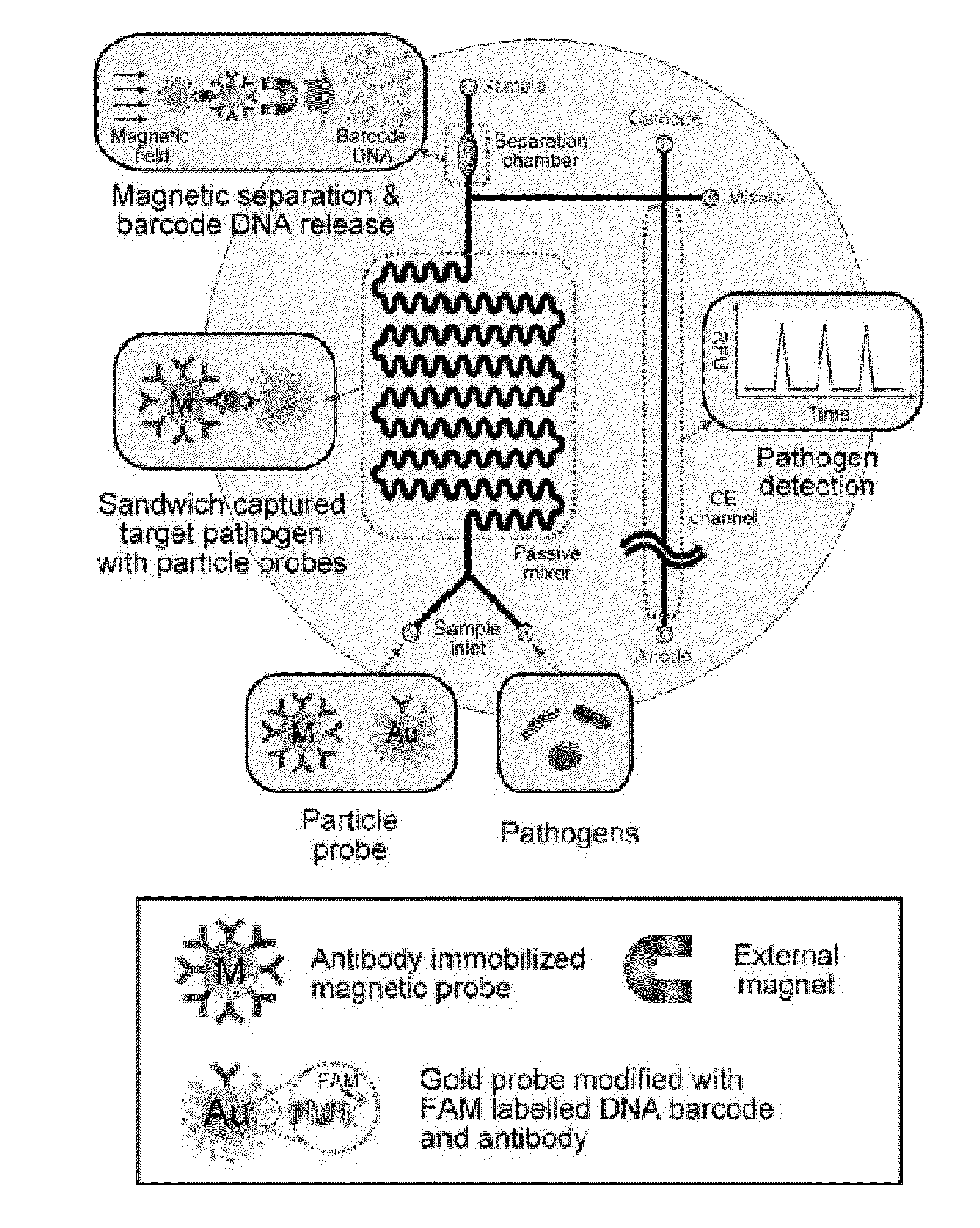

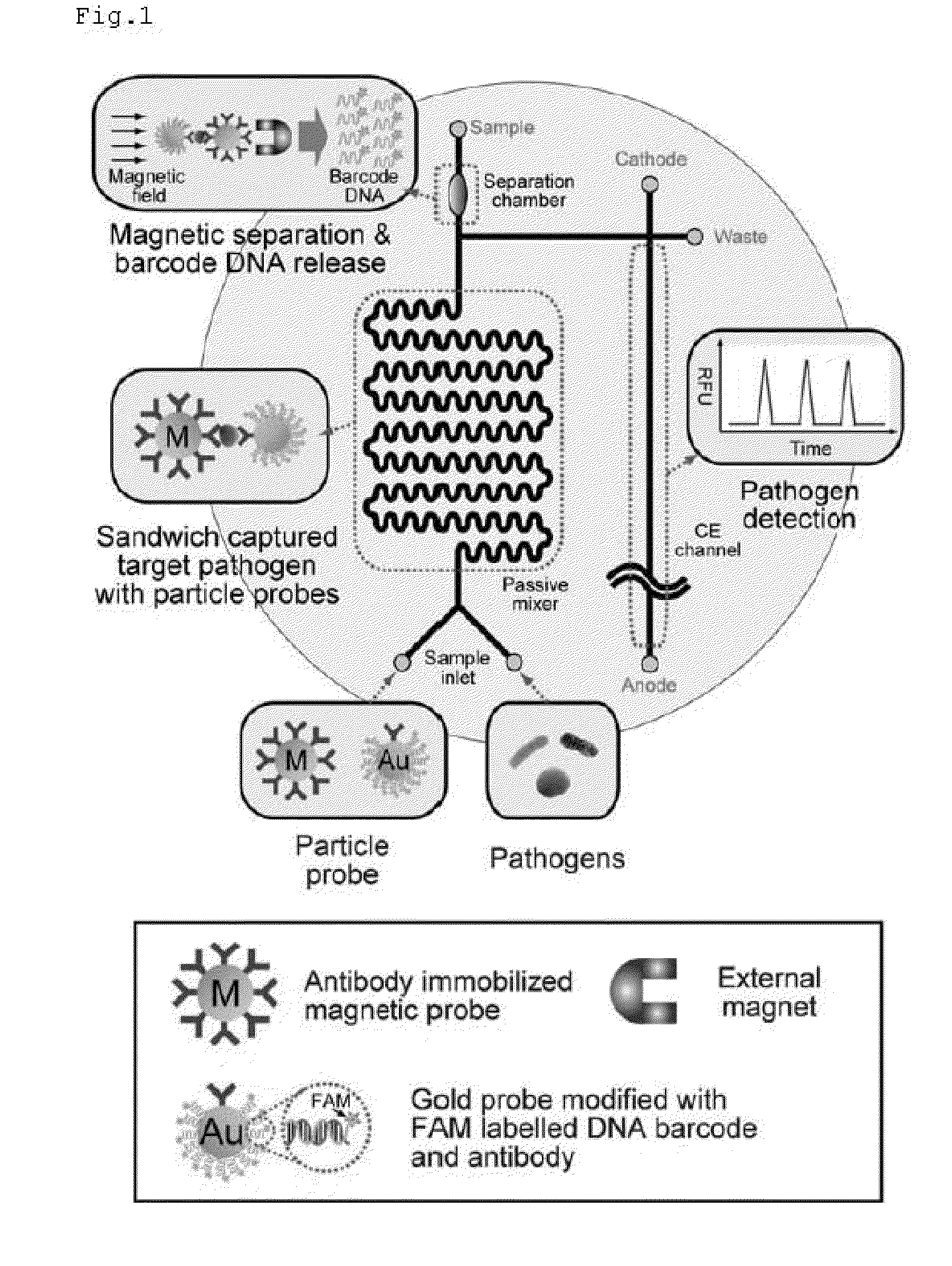

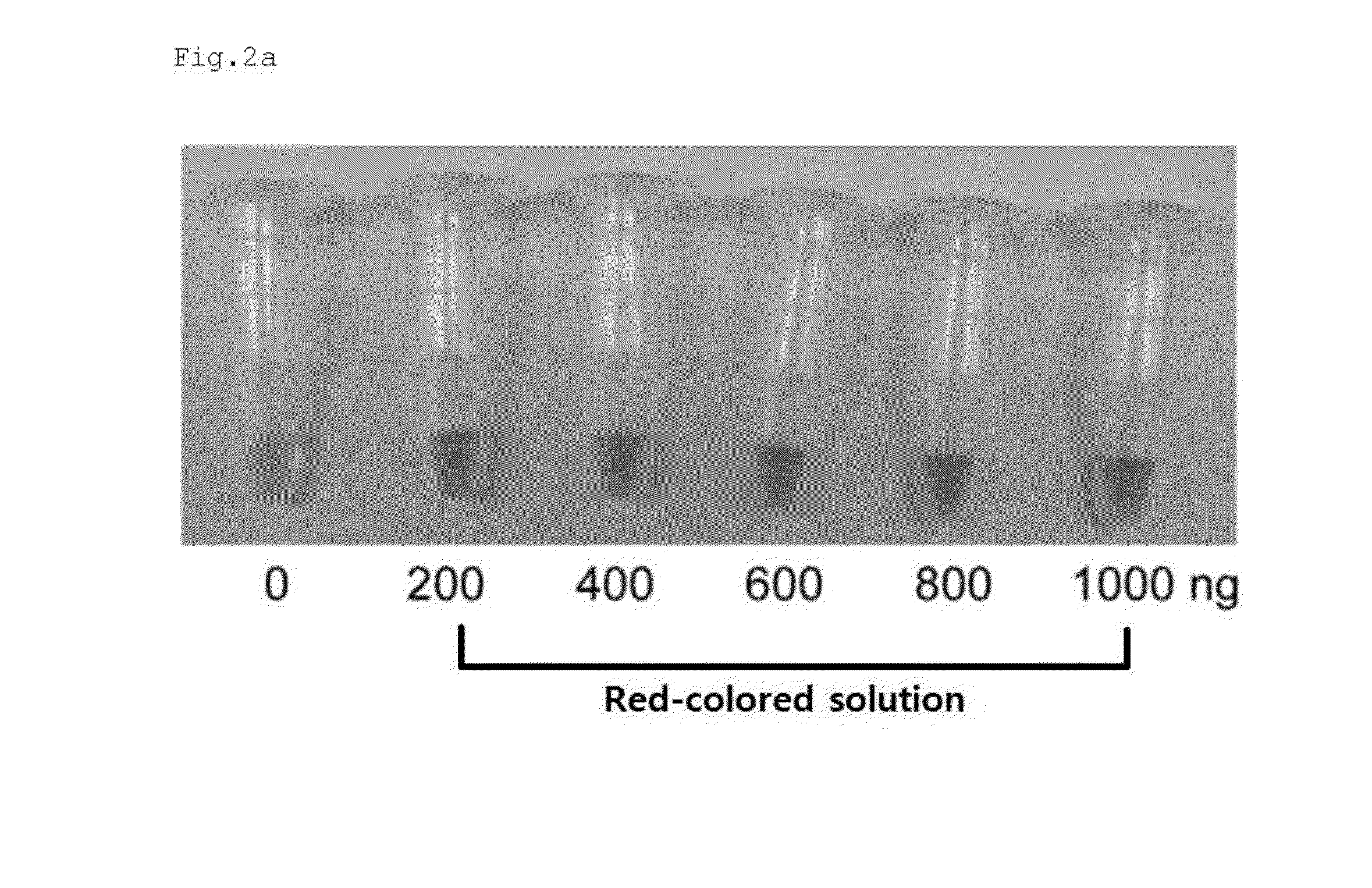

Microdevice for pathogen detection

InactiveUS20130130364A1Integrated structure is simpleImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsCapillary electrophoresisElectrophoresis

There is provided a microdevice for biomaterial detection, including a passive micromixer to mix a biomaterial, a first probe, and a second probe; a magnetic separation chamber connected with the passive micromixer; and a capillary electrophoresis channel connected with the magnetic separation chamber.

Owner:KOREA ADVANCED INST OF SCI & TECH

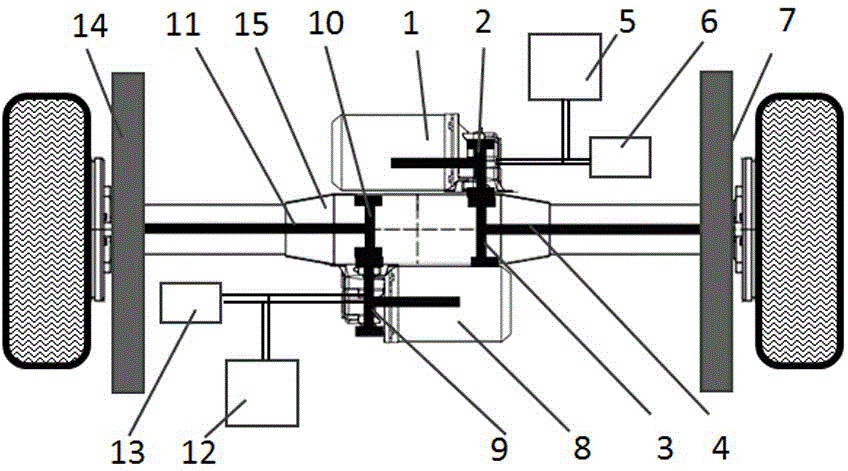

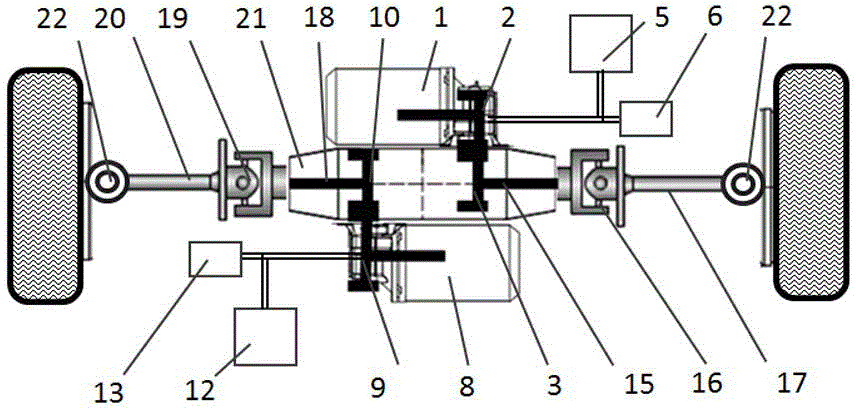

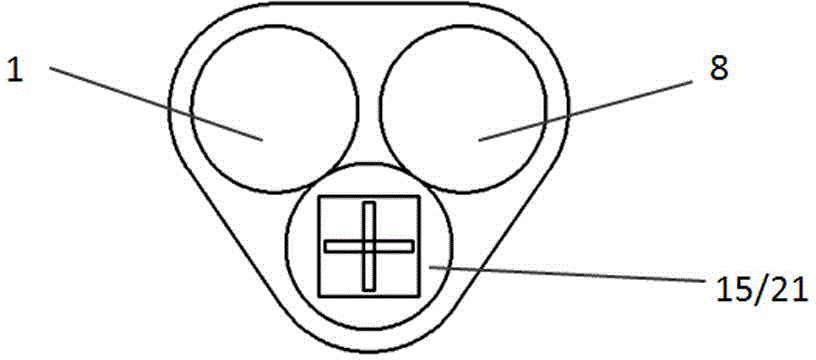

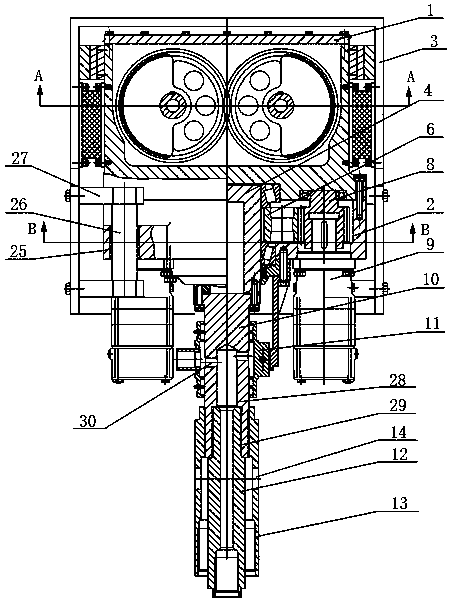

New energy automobile double-motor drive axle

InactiveCN105799491ASimple structureFlexible space arrangementMotor depositionAxle unitsTransaxleSuspension (vehicle)

The invention discloses a new energy automobile double-motor drive axle. The new energy automobile double-motor drive axle drive a left wheel and a right wheel on the same axle by two motors through two gear sets respectively. The double-motor drive axle is provided with two motor systems, and the motors of different powers and rotating speeds can be selected. According to the driving cycles, a vehicle control unit and a motor controller are used for controlling the rotating speeds of the motors, the working efficiency of the motors are brought into full play, and meanwhile the electronic stable control (ESC) function can be achieved. Due to drive of the two motors, the driving force of the single axle can be increased; due to the structure, no differential mechanism is needed, the structure can be simplified due to left and right independent drives, and the dead weight and cost of the traditional drive axle are lowered. Power is provided by two battery packs to the two motors, the service life of batteries is prolonged, and the using safety of the batteries is improved. The double-motor drive axle is of double-wishbone-type and MacPhersan-type suspension two structures.

Owner:KH AUTOMOTIVE TECH CHANGCHUN

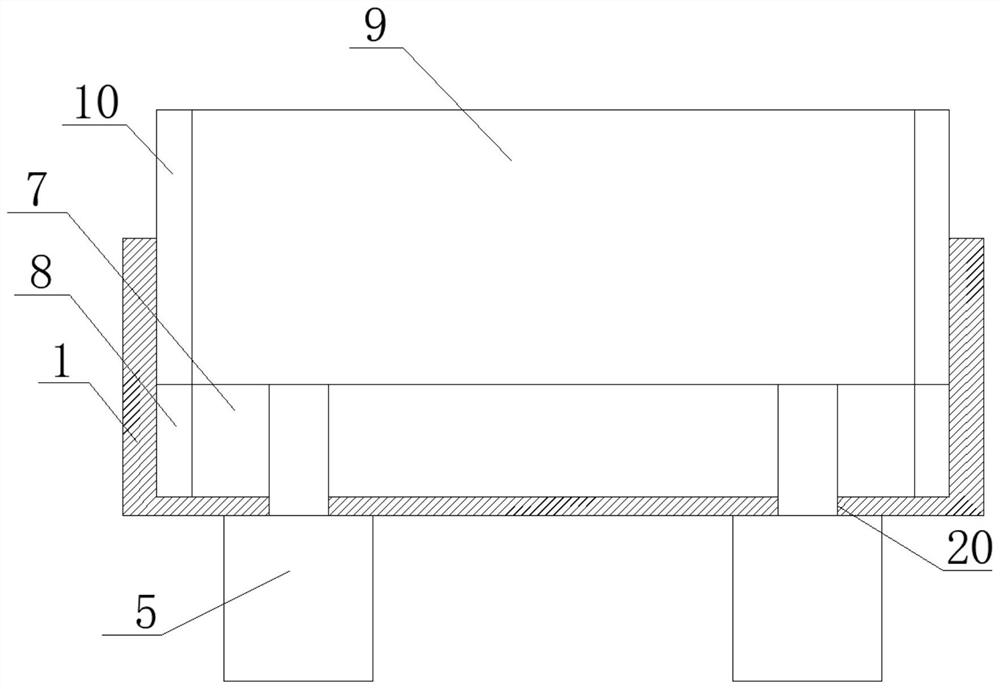

Automatic and uniform sponge gluing device

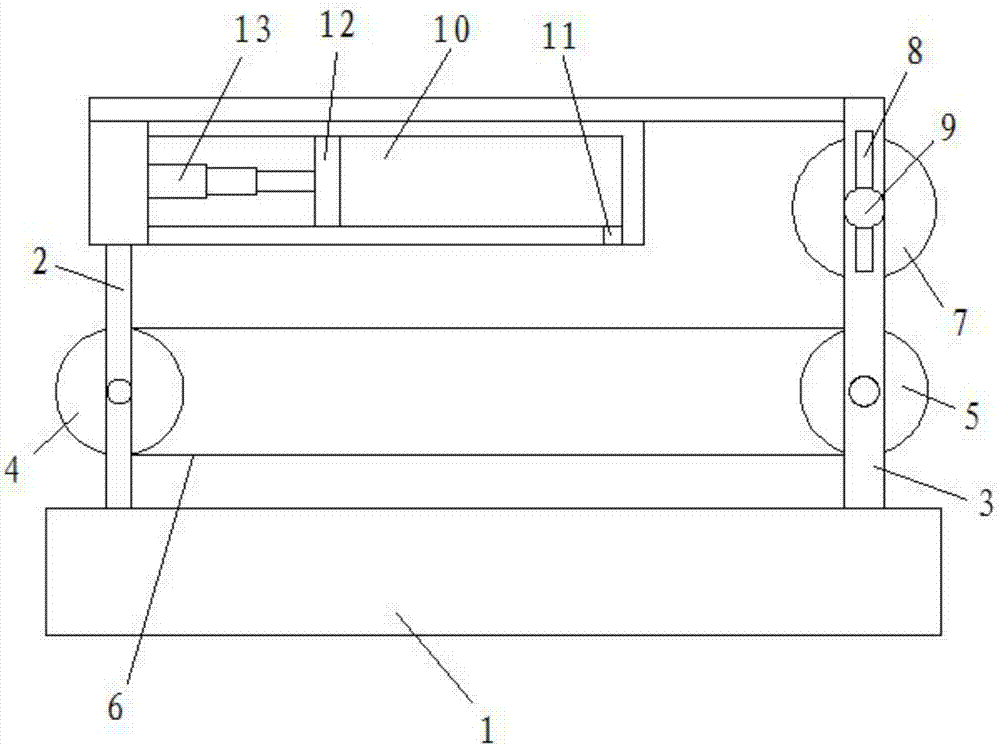

ActiveCN106944311AFully contactedEasy to operateLiquid surface applicatorsCoatingsDrive wheelSoftware engineering

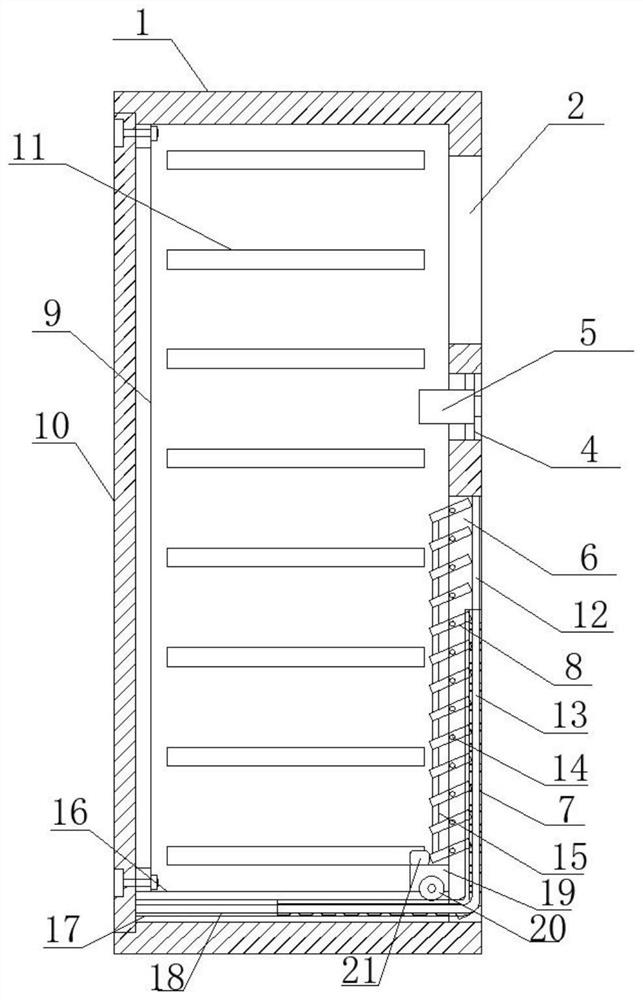

The invention relates to the field of gluing machines, in particular to an automatic and uniform sponge gluing device. The device comprises a base, a left support rod, a right support rod, a driven wheel, a driving wheel, a conveying belt, a rotating wheel, a mobile groove, a fixed button, a glue storage tank, a glue outlet, an extrusion plate and an electric extension rod; the left support rod is arranged above the left side of the base; the right support rod is arranged above the right side of the base; the driven wheel is arranged in the middle section position of the left support rod; the driving wheel is arranged in the middle section position of the right support rod; the glue storage tank is arranged at the top end of the left support rod; the mobile groove is formed in the upper section position of the right support rod; and the rotating wheel is arranged at the upper section of the right support rod. The device is liable to install and operate, has the adjusting function for adapting to sponge pads with multiple sizes and thicknesses, is wide in application range and convenient to use; a glue outlet device is uniform in glue discharge under the pressure of the electric extension rod; the conveying belt can realize continuous operation to achieve high efficiency; and meanwhile, the device is low in cost and higher in practicability.

Owner:华力汽车部件(南通)有限公司

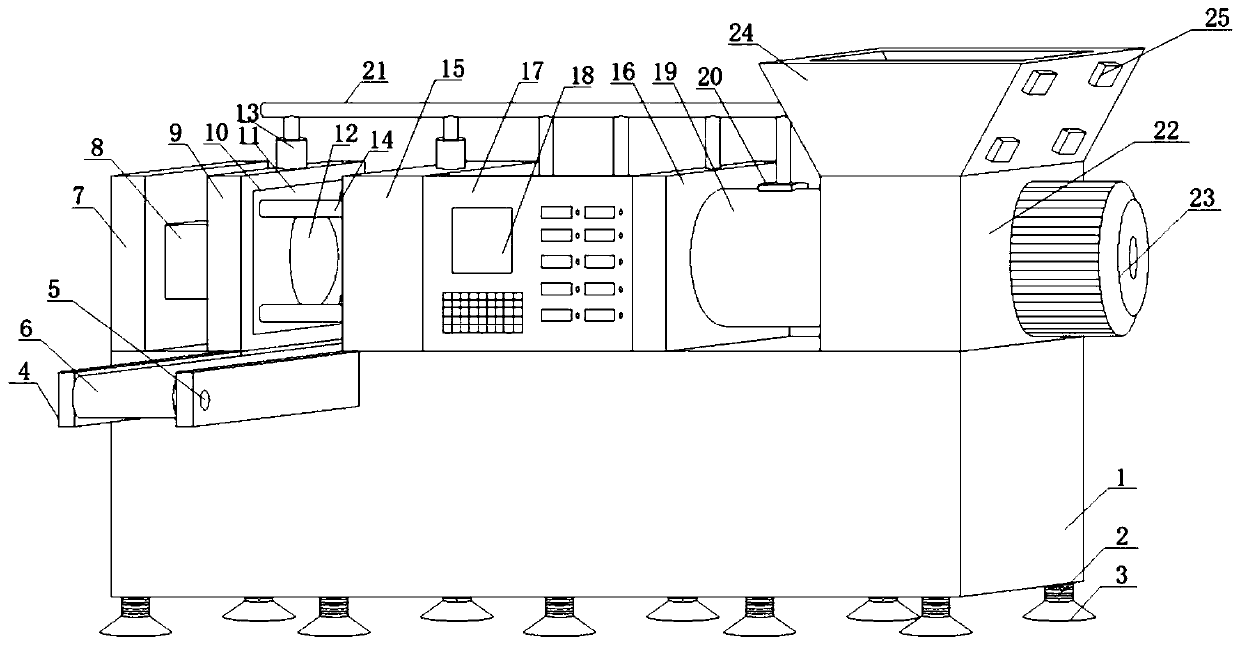

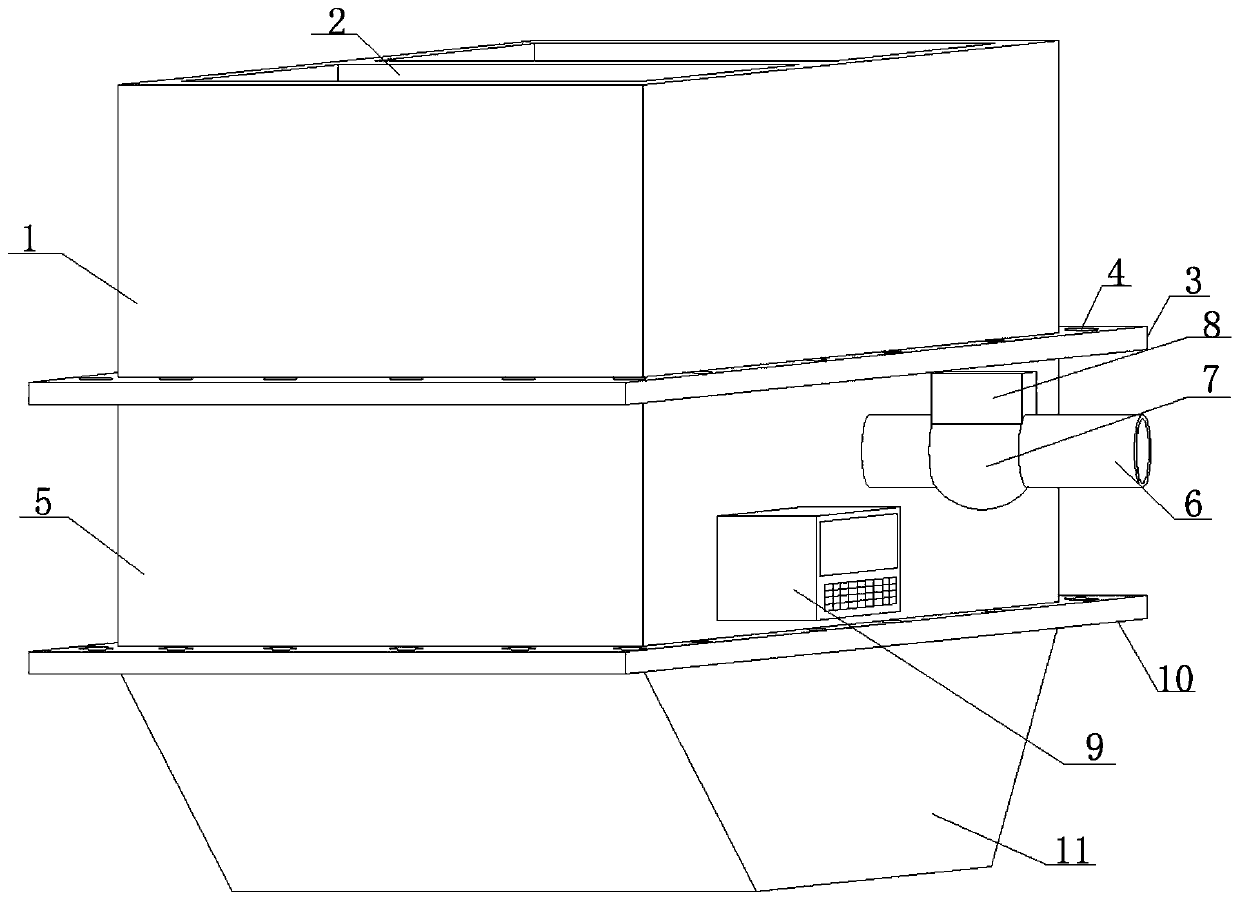

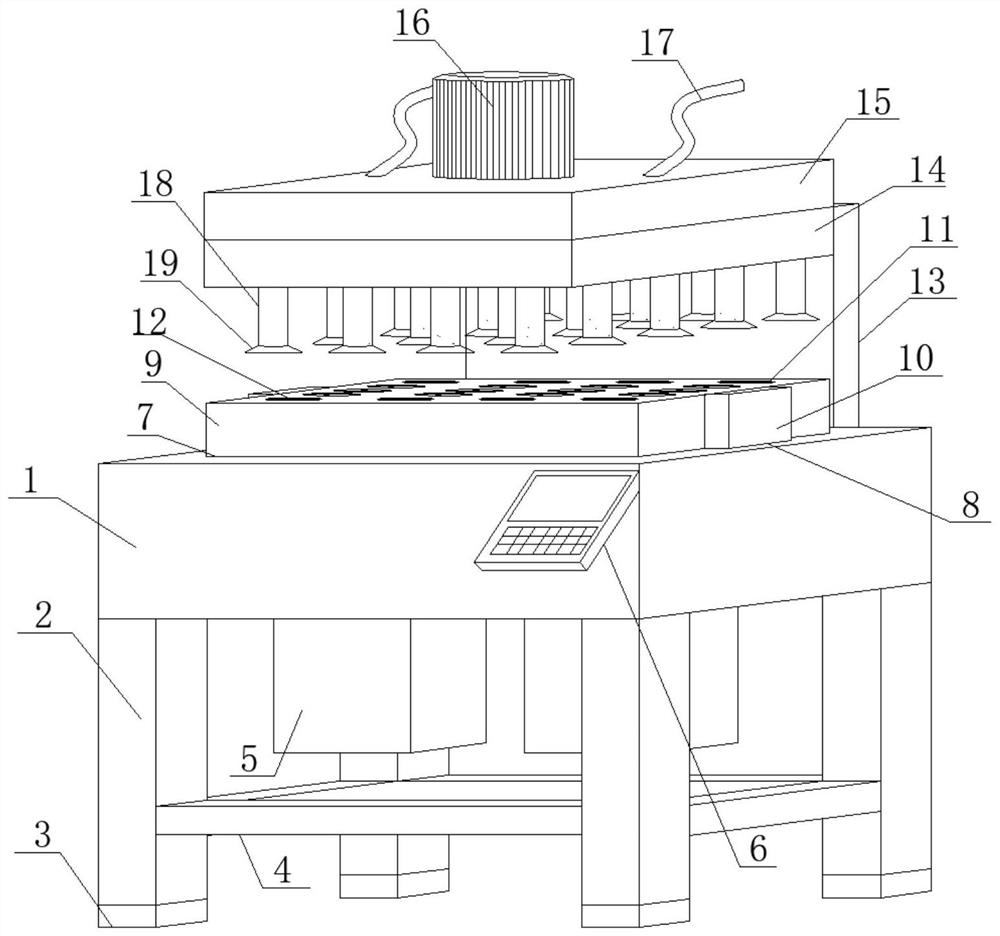

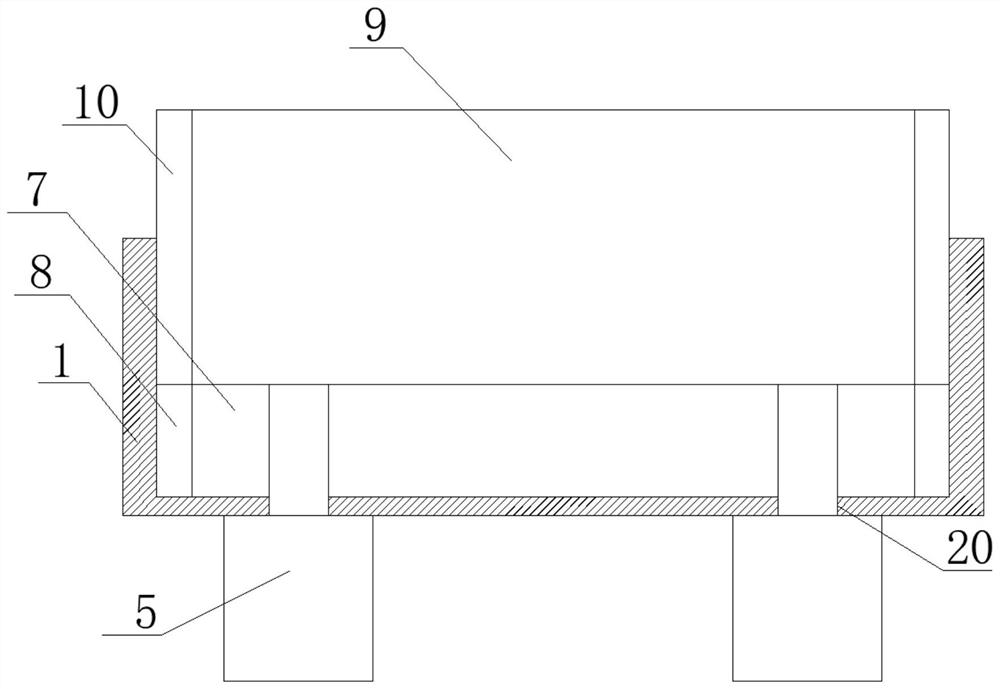

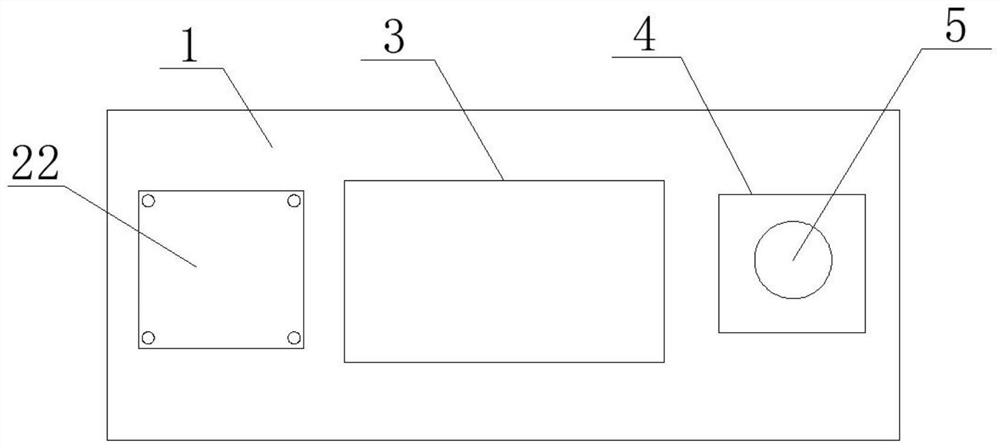

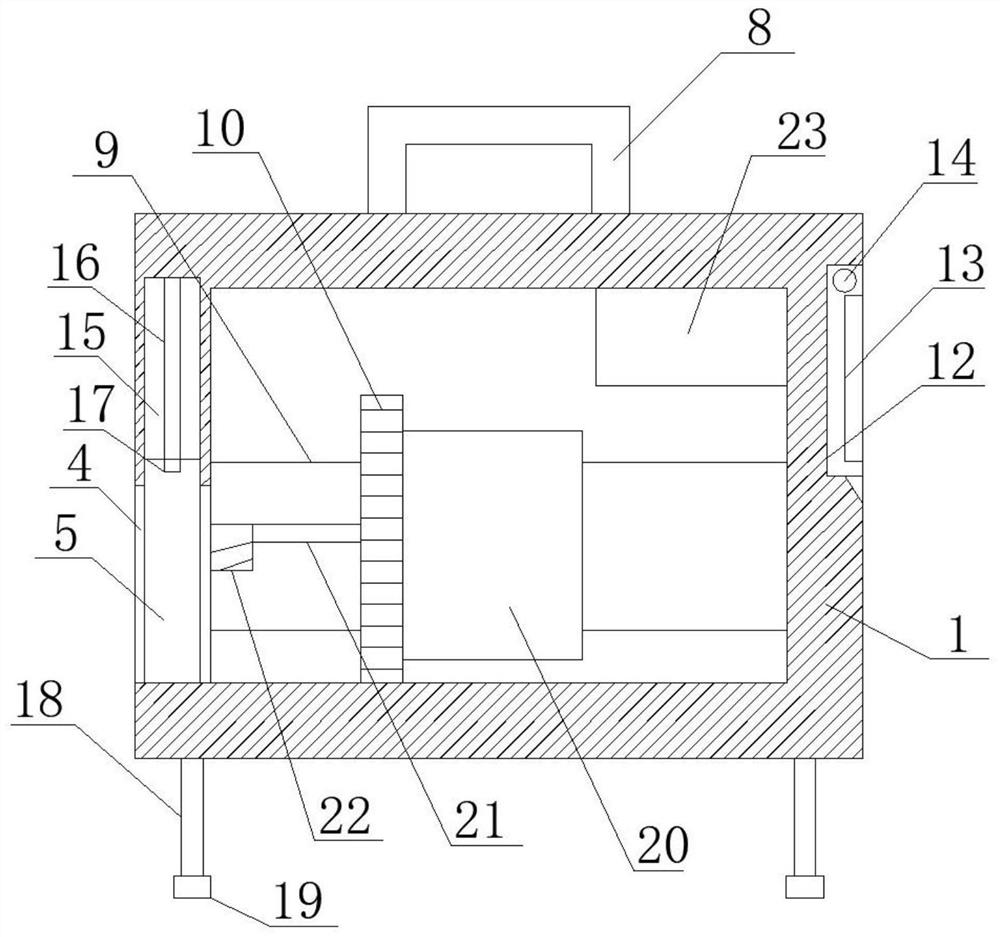

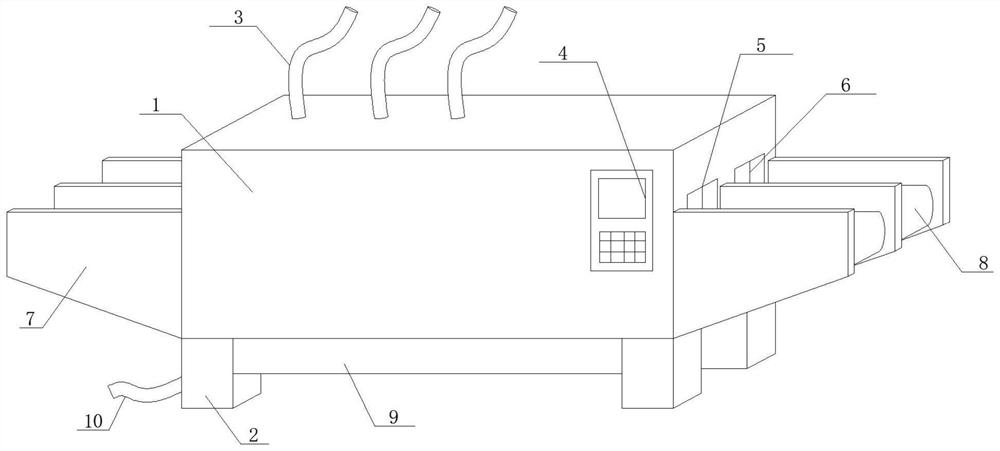

Injection molding machine with automatic monitoring and automatic processing system

The invention discloses an injection molding machine with automatic monitoring and an automatic processing system, and relates to the field of injection molding machines. The machine comprises a supporting bottom box. Supporting threaded rods are vertically connected to the bottom surface of the supporting bottom box in a threaded mode, supporting cushion blocks are fixedly connected to the bottomends of the supporting threaded rods in a sleeving mode, extension side plates are horizontally welded to one side edge of the supporting bottom box, and inserted rods are transversely inserted to the side edges of the extension side plates. A conveyor belt is horizontally arranged at the side edges between the extension side plates, a fixed vertical plate is vertically upwardly connected to thetop surface of the supporting bottom box through bolts, and a pushing cylinder is horizontally connected to the side edge of the fixed vertical plate through bolts. The injection molding machine withautomatic monitoring and the automatic processing system are in an integrated design, simple in structure and convenient to operate, and the overall control is digitized through the adoption of multiple monitoring functions. At the same time, the operation and processing are more convenient and efficient through centralized control function, automatic processing function is achieved, and work efficiency is greatly improved.

Owner:张群花

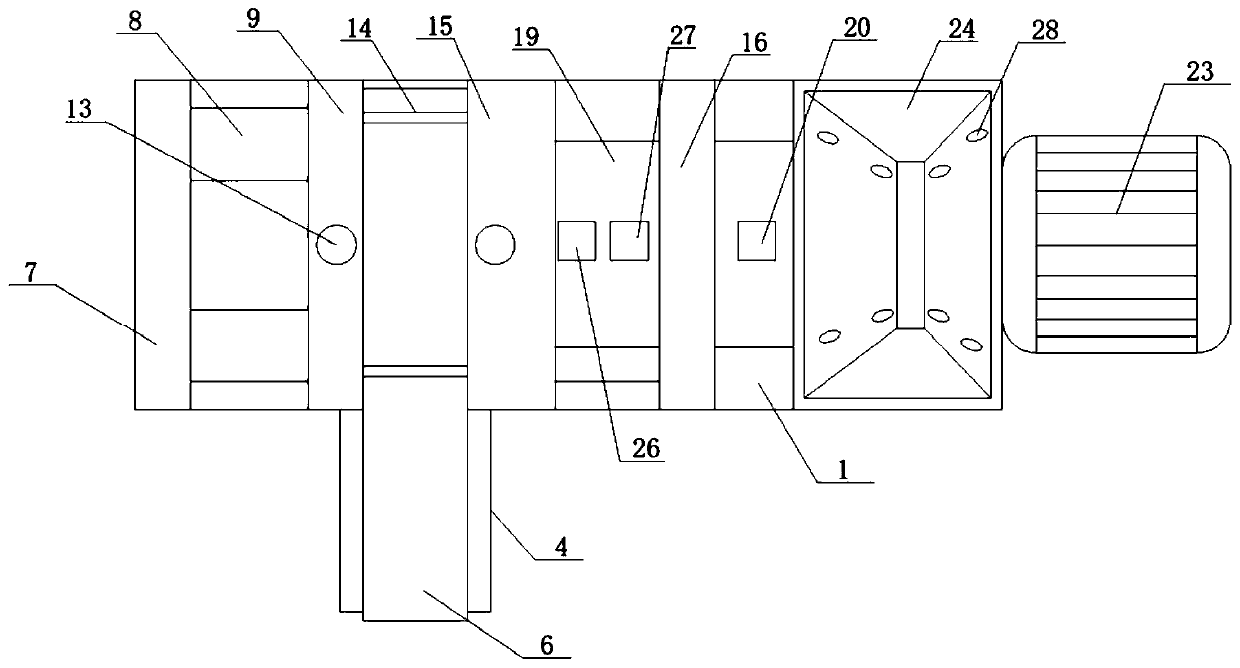

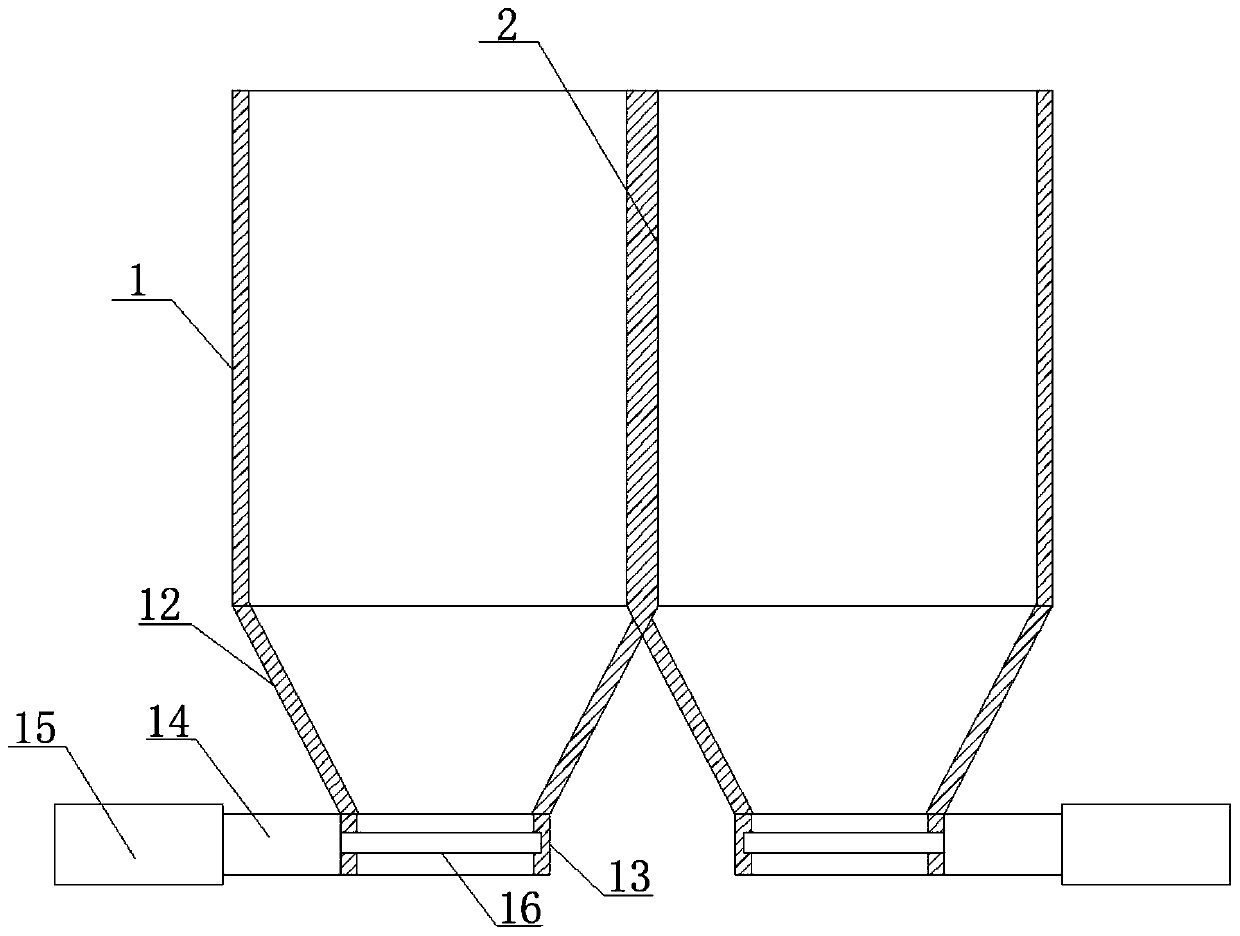

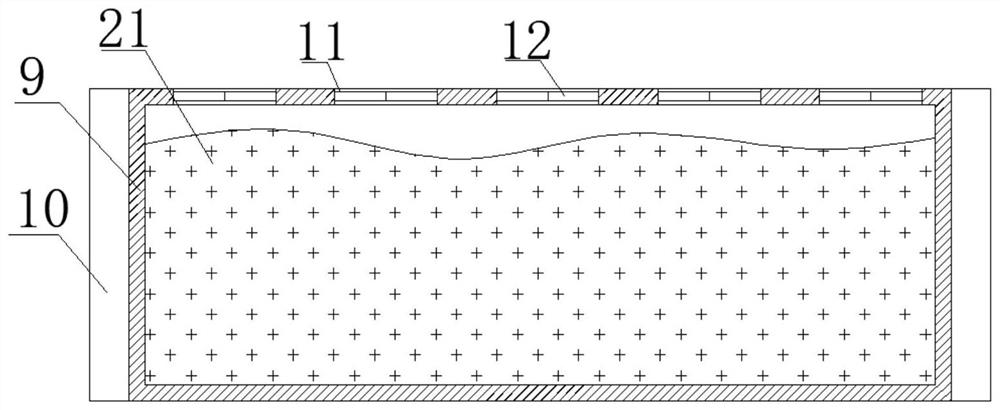

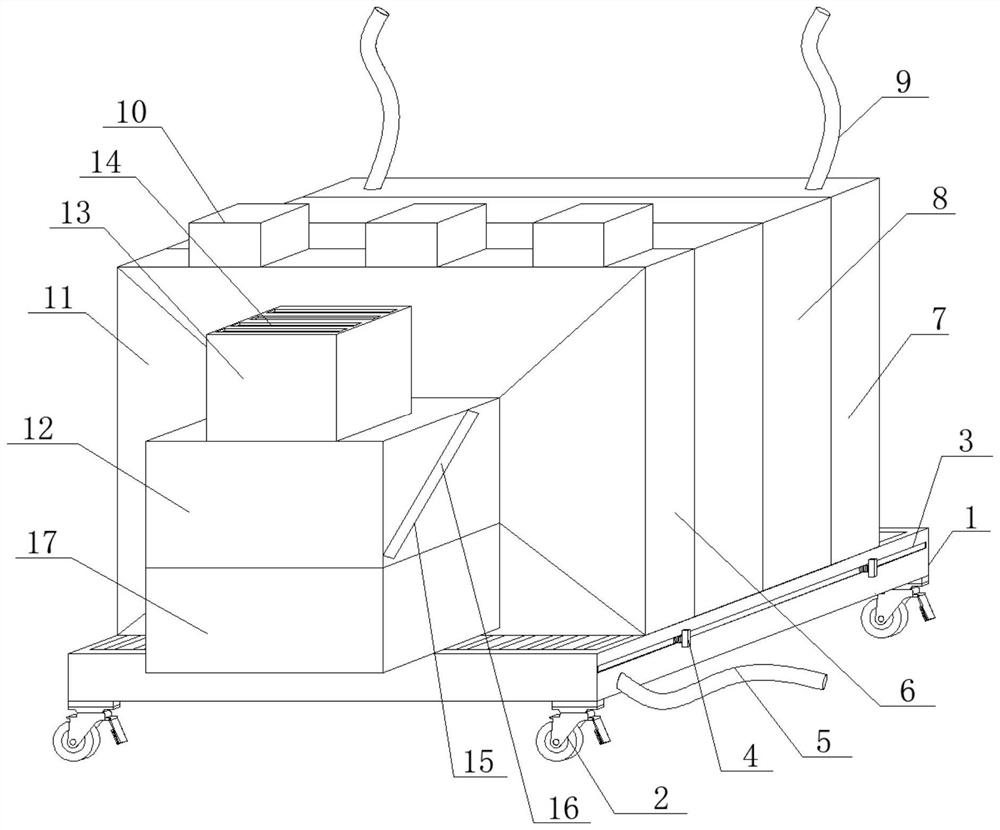

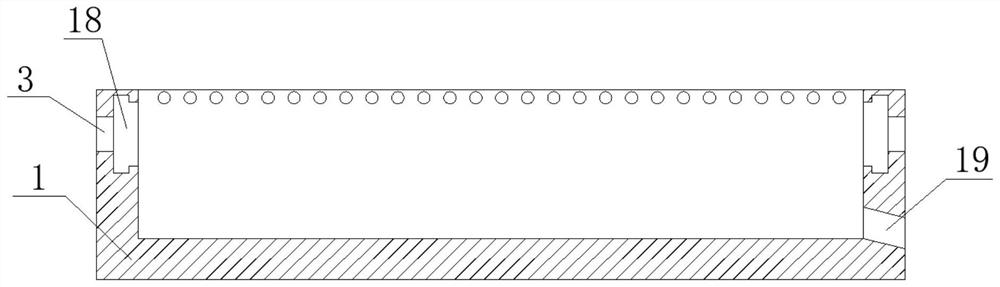

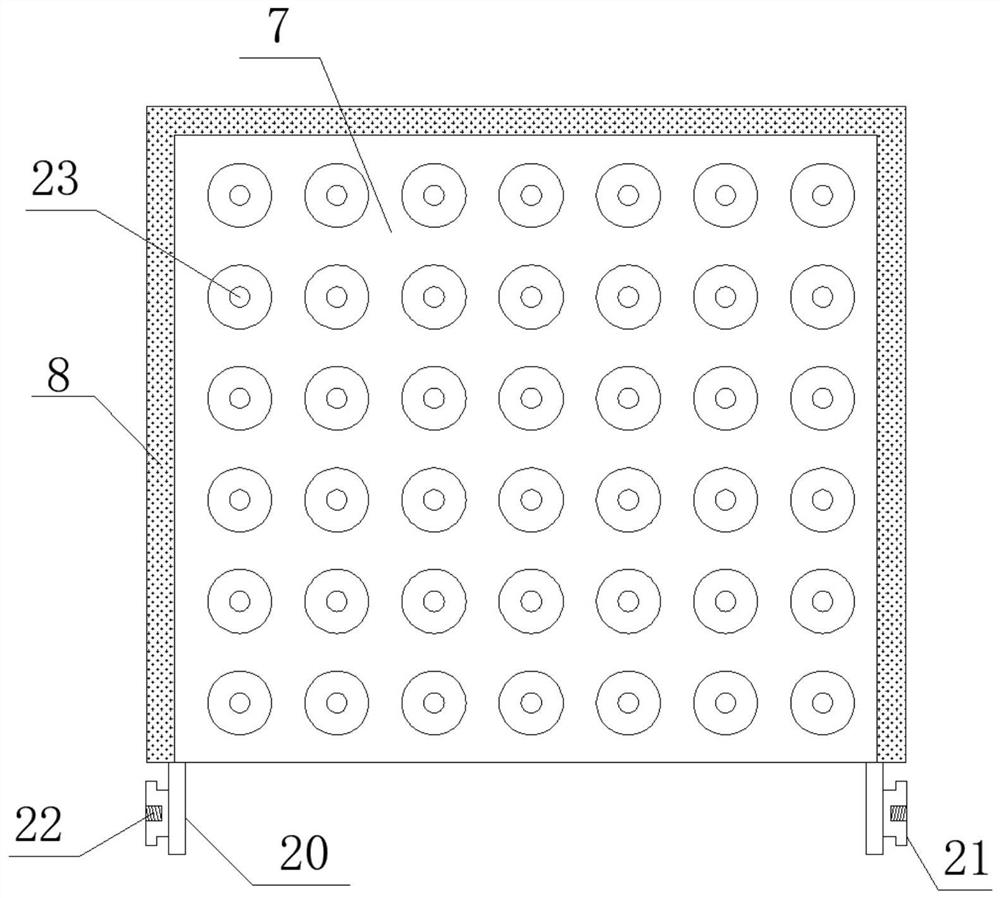

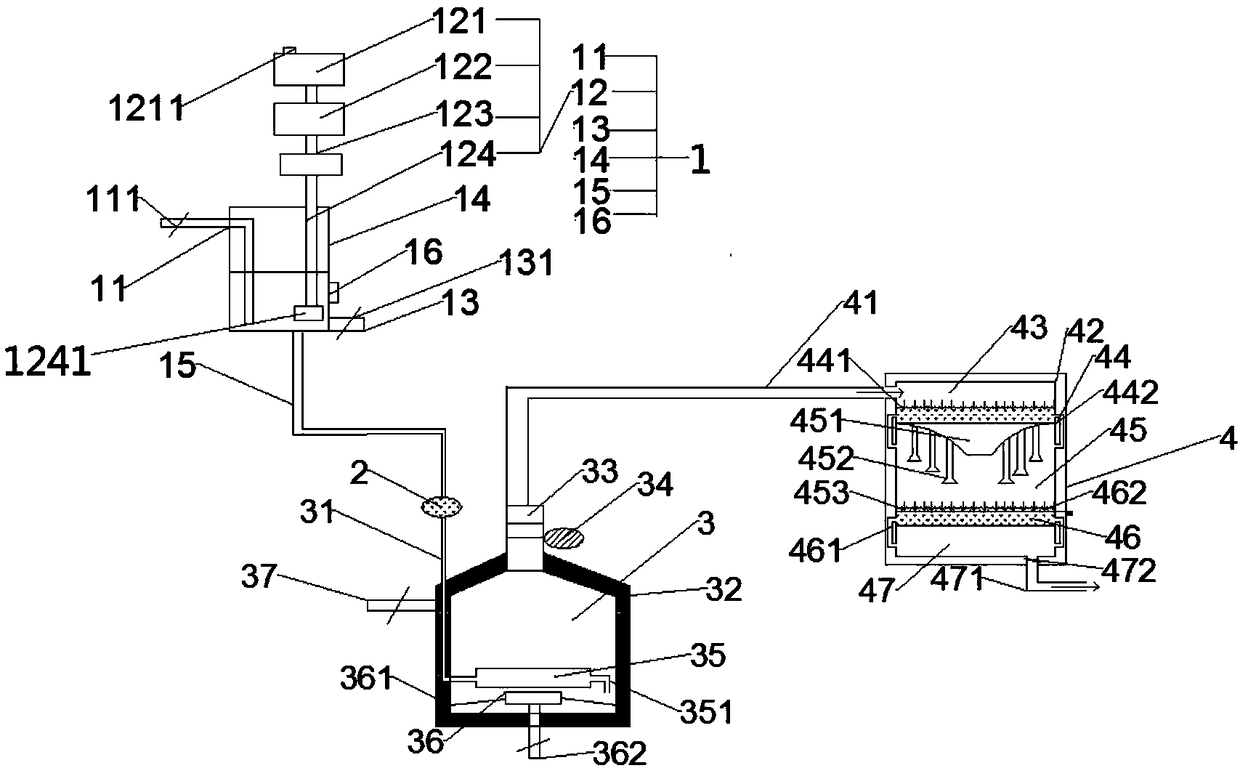

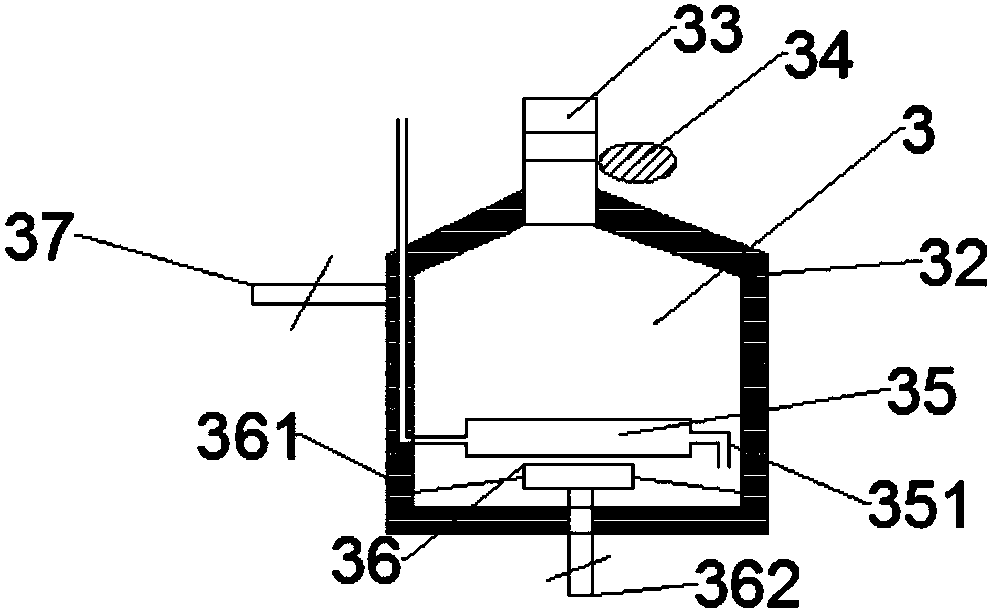

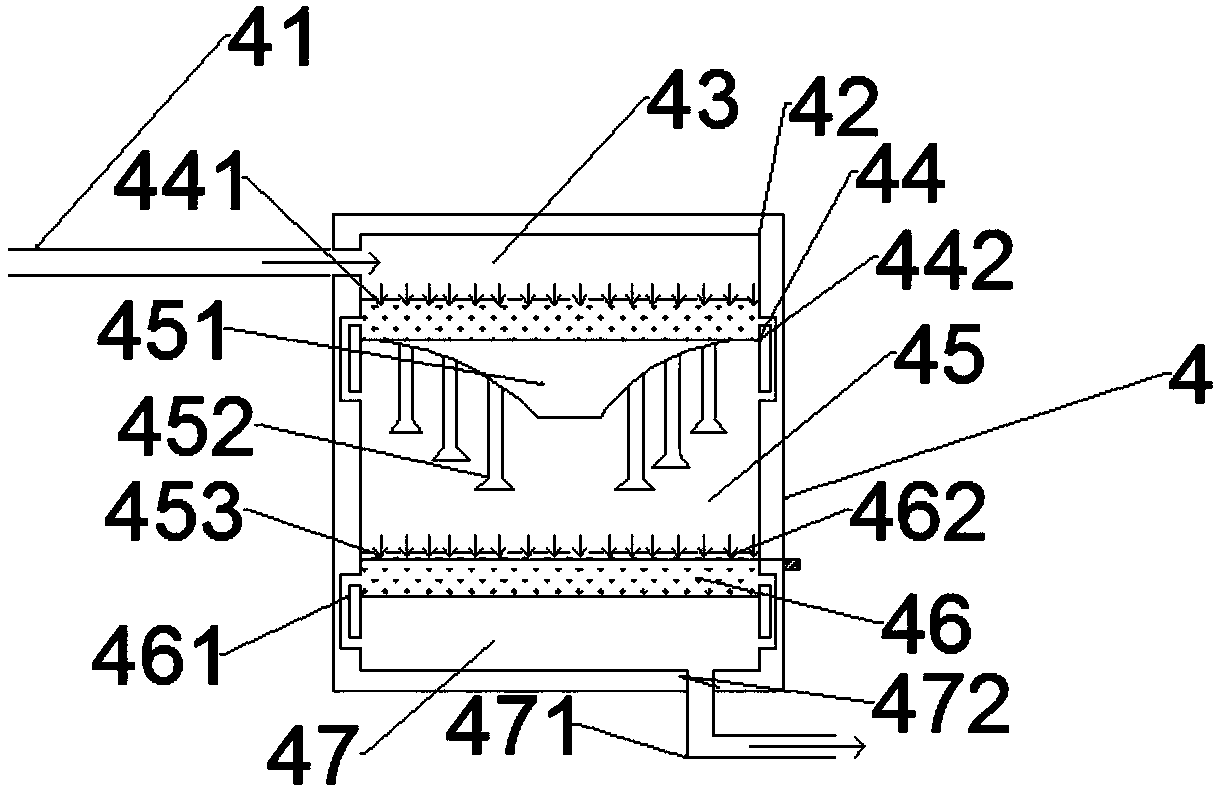

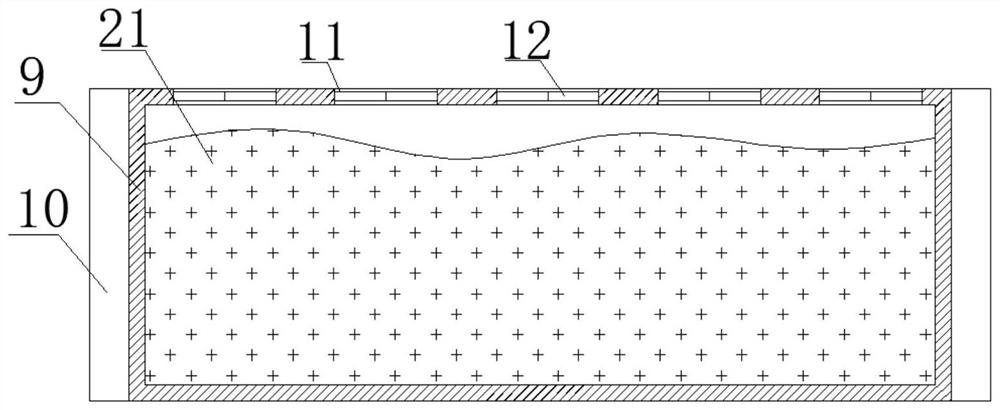

Intelligent concrete matching and feeding device

ActiveCN111452222ASmooth feedingImprove the ratio of work efficiencyMixing operation control apparatusIngredients proportioning apparatusVALVE PORTArchitectural engineering

Owner:赣州中砼机械有限公司

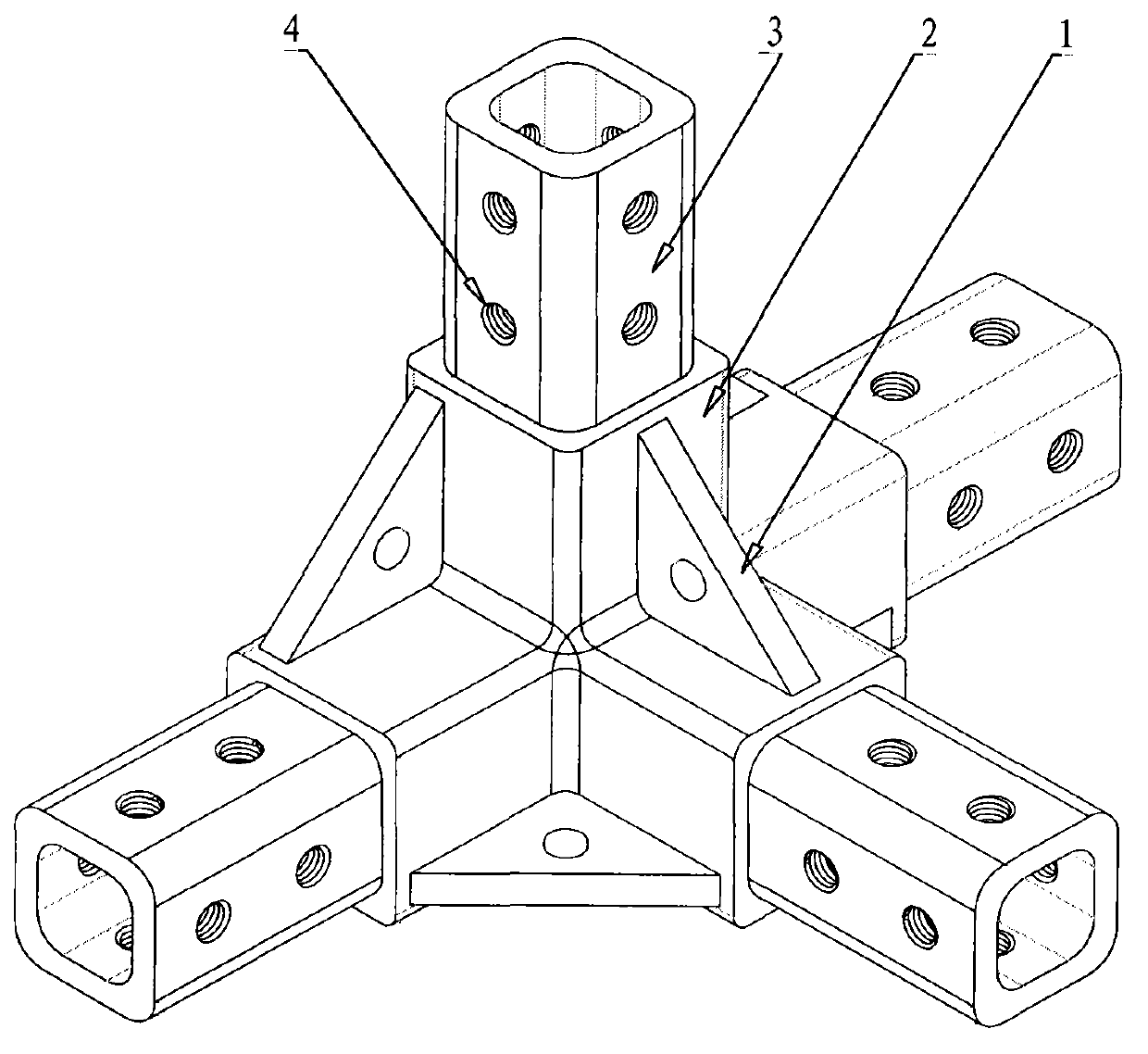

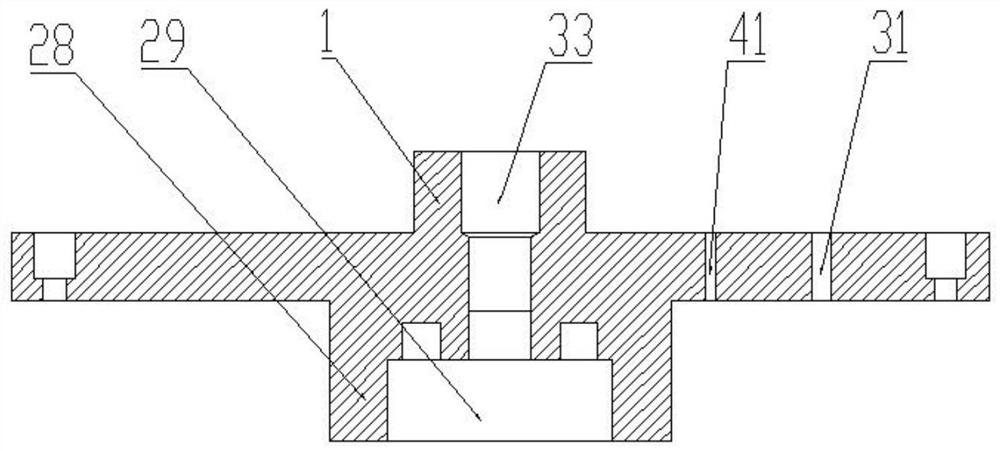

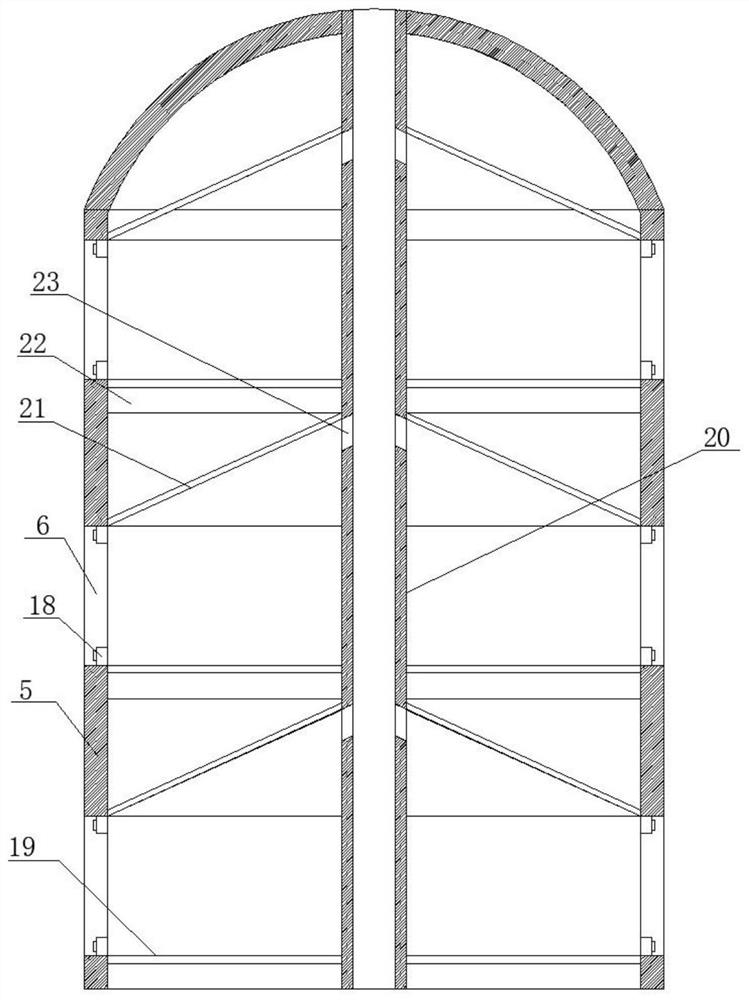

Integrated four-way right-angle pipe joint

InactiveCN102996586AIntegrated structure is simpleEasy to manufactureRod connectionsRight triangleEngineering

The invention discloses an integrated four-way right-angle pipe joint, which is formed by integrating four straight pipe joints positioned on an x axis, a y axis and a z axis, wherein inner holes of the four straight pipe joints are communicated with one another; each straight pipe joint consists of two integrated rectangular pipe bodies with different wall thicknesses; one of two adjacent straight pipe joints is an internal connection pipe body, and the other straight pipe joint is an external extending pipe body; the size of the outer wall of each external extending pipe body is smaller than that of the outer wall of each internal connection pipe body; a difference of the sizes is equal to the wall thickness of a pipe body to be connected; a straight pipe joint is arranged on each of the y axis and the z axis, and two straight pipe joints which oppositely face to each other and are connected with each other through the internal connection pipe body are arranged on the x axis; 2 to 4 threaded through holes are uniformly formed in the middles of the four walls of each external extending pipe body along the axial direction; and the adjacent internal connection pipe bodies are connected with each other through right-angle triangular ribbed plates to form a reinforcement structure. The integrated four-way right-angle pipe joint is an angle connection piece with an integrated structure; positioning insertion and bolt connection are realized by the angle connection piece in a framework of safety equipment; the spliced framework is sheet-type; and combination mounting of a user according to a position on the spot is facilitated.

Owner:沙剑波

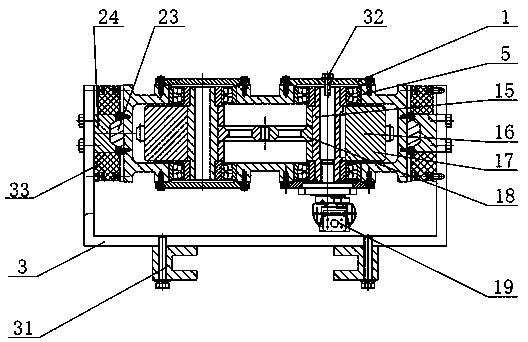

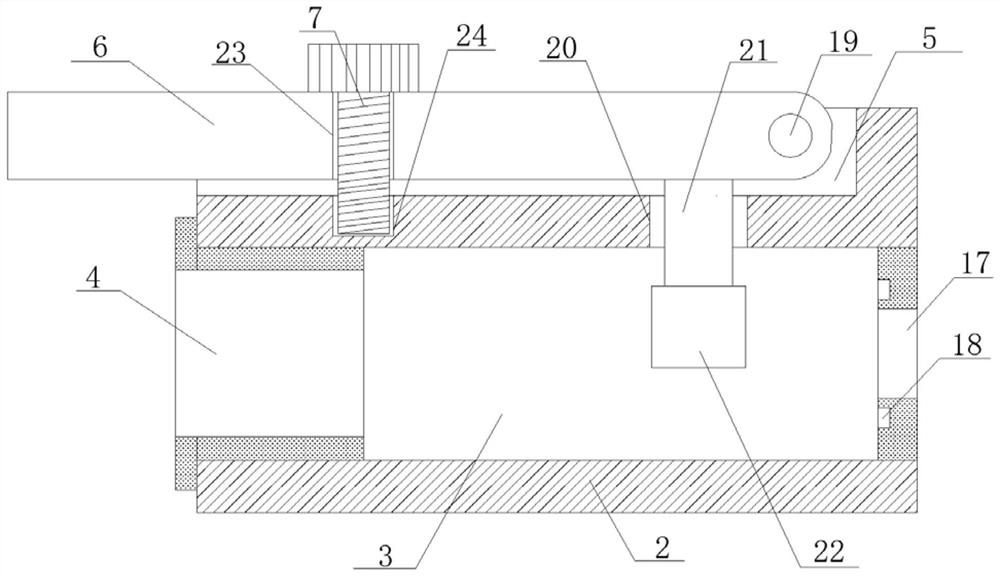

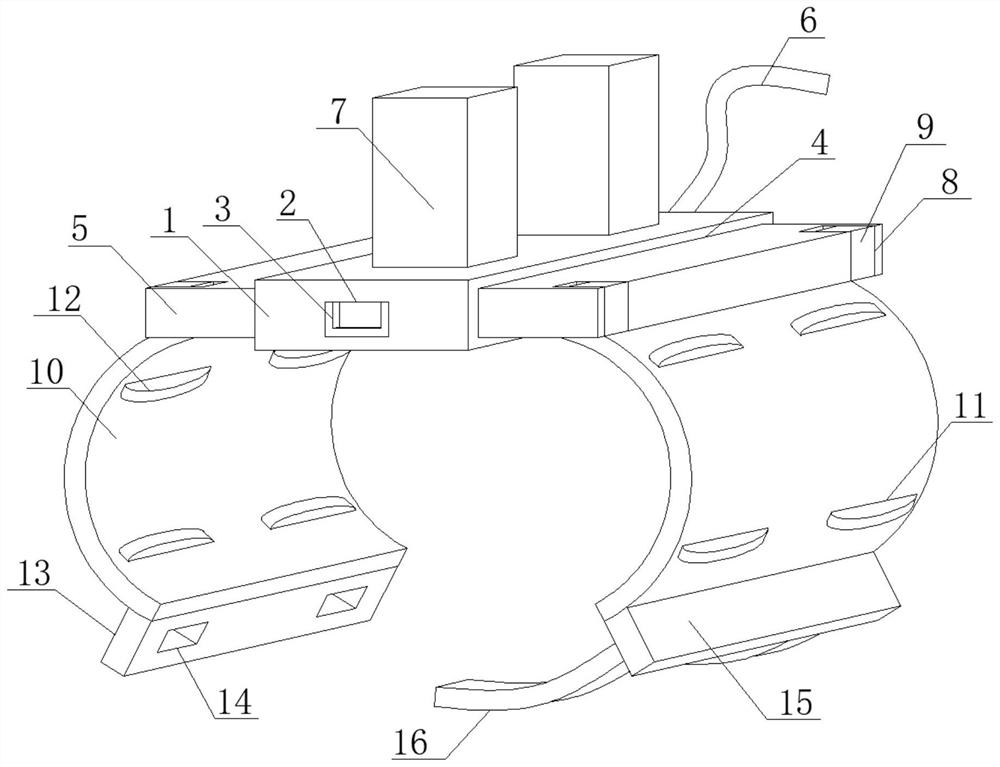

Vibrating type power head device

The invention discloses a vibrating type power head device which includes a vibration assembly and an external box which is arranged outside of the vibration assembly; a guiding mechanism is arrangedbetween the vibration assembly and the external box; the vibration assembly includes a vibration box and a gear box, the front end of the gear box is connected to a drill tool by the output joint, andthe rear end is detachably connected to the vibration box. The vibration box directly drives the gear box and the spindle to vibrate together; the vibration box and the gear box are fixedly connected, ; thus driving the drill tool to vibrate and rotary drilling simultaneously; the damage of the main axle can effectively reduced when the vibration is vibrated, so that the transmission line of thevibration is more reasonable. Moreover, the vibration box and the gear box can ensure that the vibration assembly only take the axial vibration displacement in the axial direction, but restrict the unreasonable vibration in other directions by the guiding mechanism, so that the generate and transmit of the excitation force is stable and reliable, the impact direction is consistent, and the workingefficiency of drilling is improved.

Owner:无锡市安曼工程机械有限公司

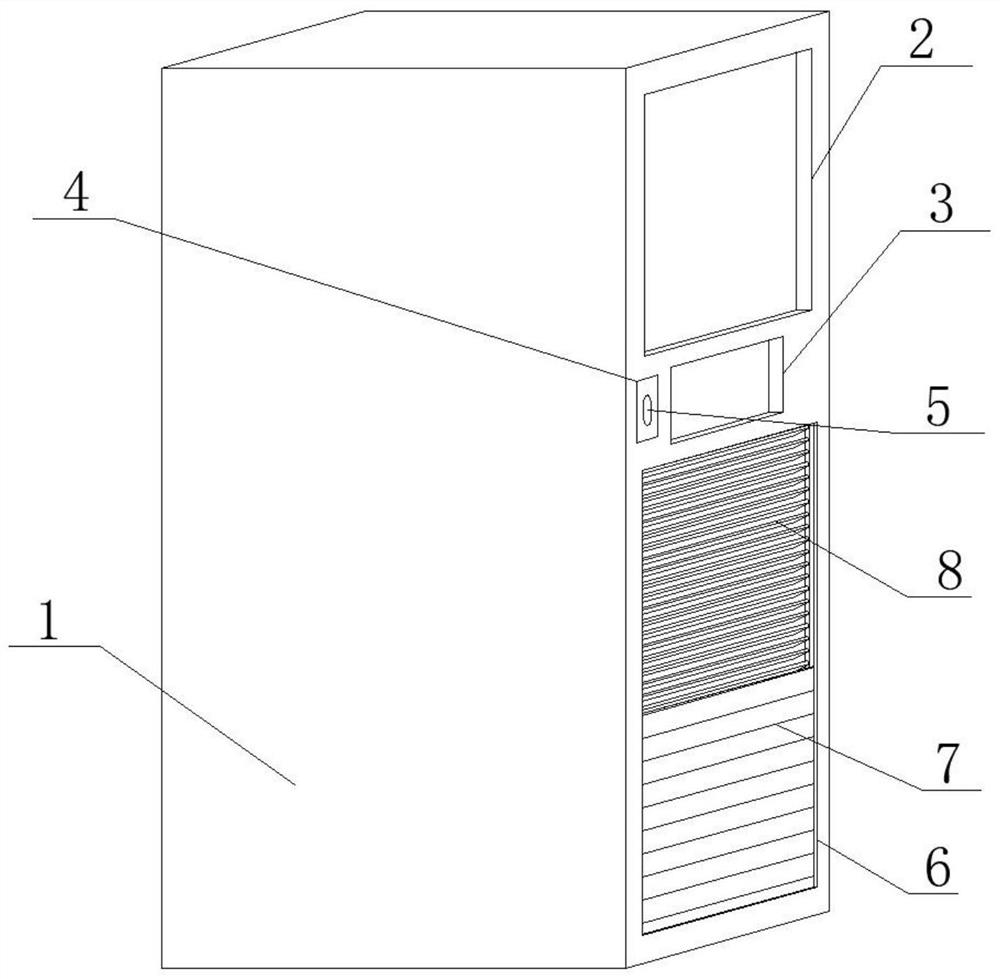

Ion generation device, bacteria removal and odor removal assembly and clothes processing equipment

InactiveCN106953238AIntegrated structure is simpleSmall device sizeElectrical apparatusDeodrantsIonBacteria removal

The invention discloses an ion generation device, a bacteria removal and odor removal assembly and clothes processing equipment. The ion generation device comprises a shell, a control part and an ion generation part, wherein the control part is used for controlling the ion generation part to generate ions, the shell comprises a first shell part and a second shell part, the control part is arranged in the first shell part, the ion generation part is arranged in the second shell part, and the first shell part and the second shell part form an integrated structure. The ion generation device can be conveniently applied to the clothes processing equipment to execute operation of bacteria removal and odor removal and is provided with the simple integrated structure, the control part and the ion generation part are integrated in the shell, thus, the volume of the device can be greatly reduced, and meanwhile, the number of connection wires also can be simplifed.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

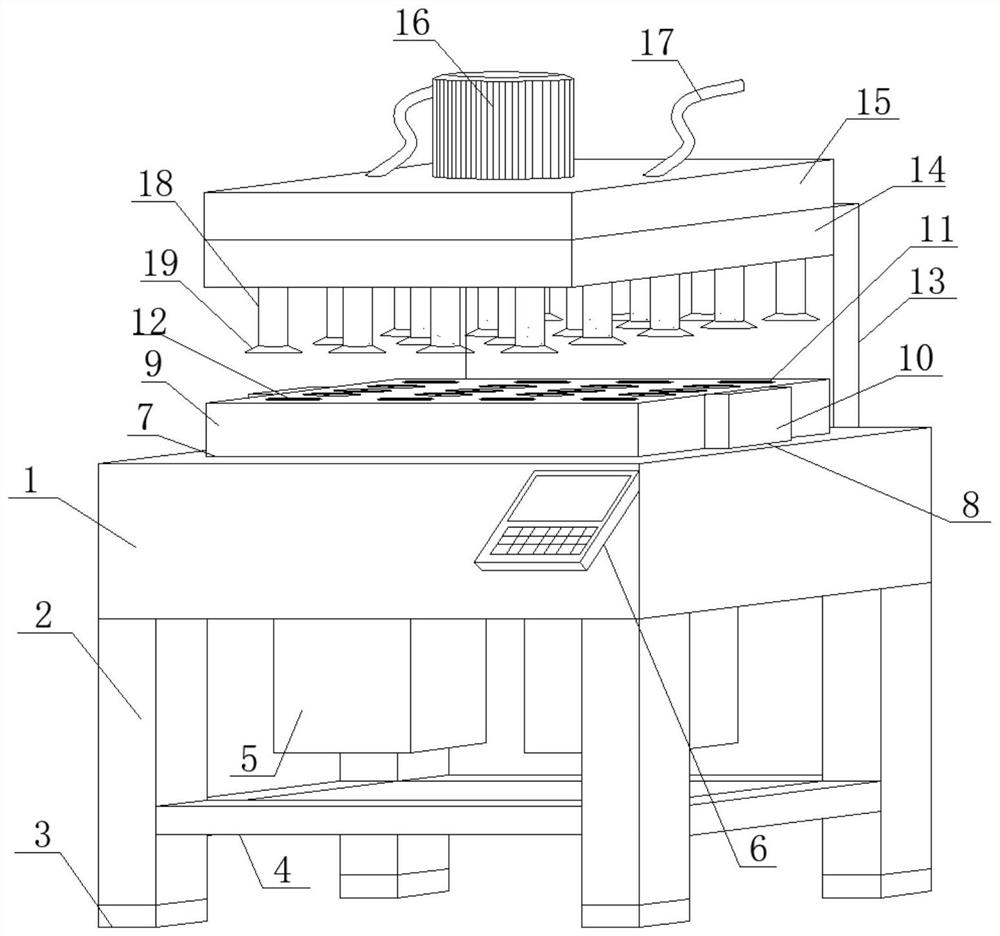

Stainless steel tableware polishing device

ActiveCN112192431AEasy and quick installationSimple structureEdge grinding machinesPolishing machinesStructural engineeringMechanical engineering

The invention discloses a stainless steel tableware polishing device, and relates to the field of tableware polishing. The stainless steel tableware polishing device comprises a fixed box body, wherein a supporting vertical rod is vertically welded downwards on the bottom surface of the fixed box body; a bottom rubber cushion block is fixedly clamped at the bottom end of the supporting vertical rod; a fixed cross rod is horizontally welded on the side edge of the supporting vertical rod; a bottom air cylinder is connected to the bottom surface of the fixed box body through a vertical bolt; a control panel is obliquely welded on one side edge of the fixed box body; a movable groove is horizontally formed in the top surface of the fixed box body; limiting grooves are vertically and symmetrically formed in the two side edges of the movable groove; a processing box body is clamped on the inner side edge of the movable groove; and limiting parts are vertically and symmetrically welded on the two side edges of the processing box body. The stainless steel tableware polishing device is simple in design integrated structure and convenient to operate, the surface of tableware is polished inan all-around and dead-angle-free mode by adopting a sand grain polishing mode, the stainless steel tableware polishing device is more reasonable and efficient, meanwhile, the batch polishing effect can be achieved, and the polishing working efficiency is greatly improved.

Owner:揭阳市东拓家居实业有限公司

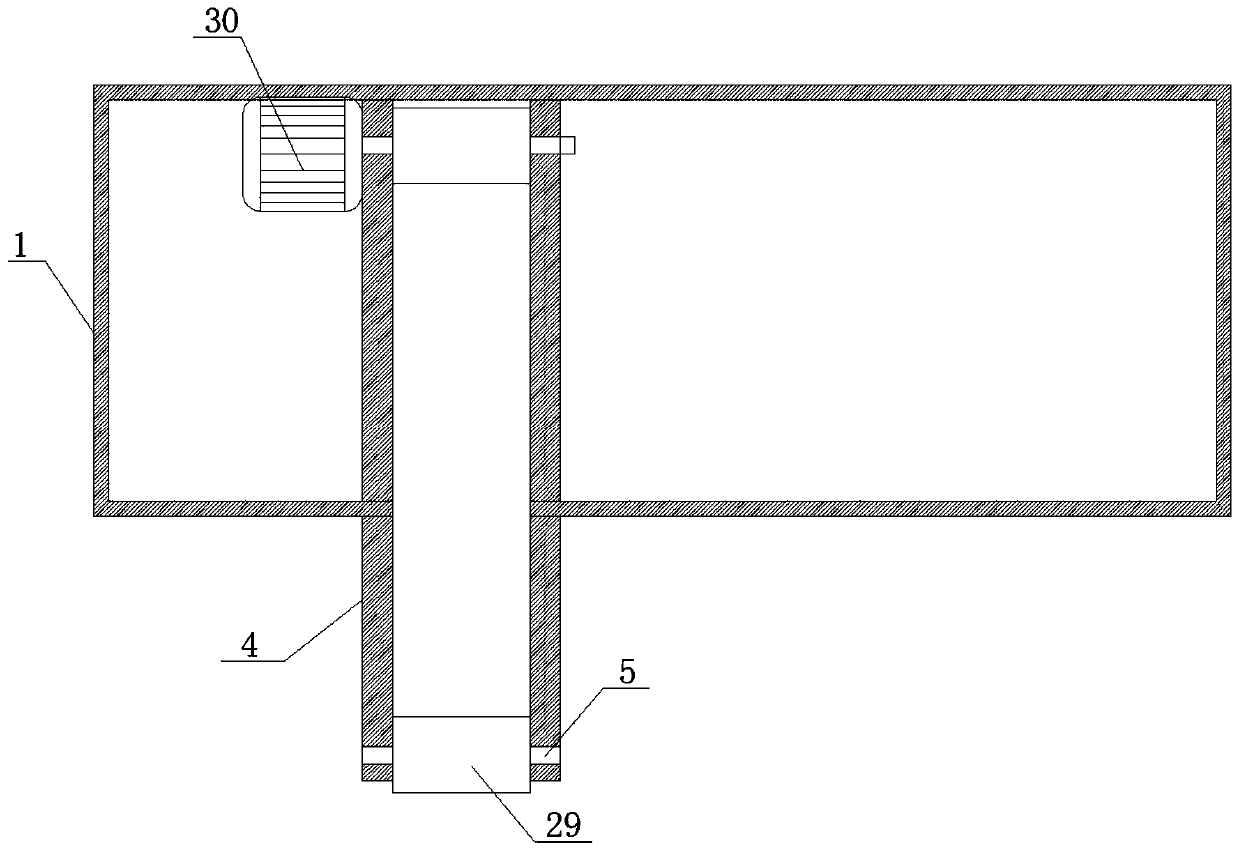

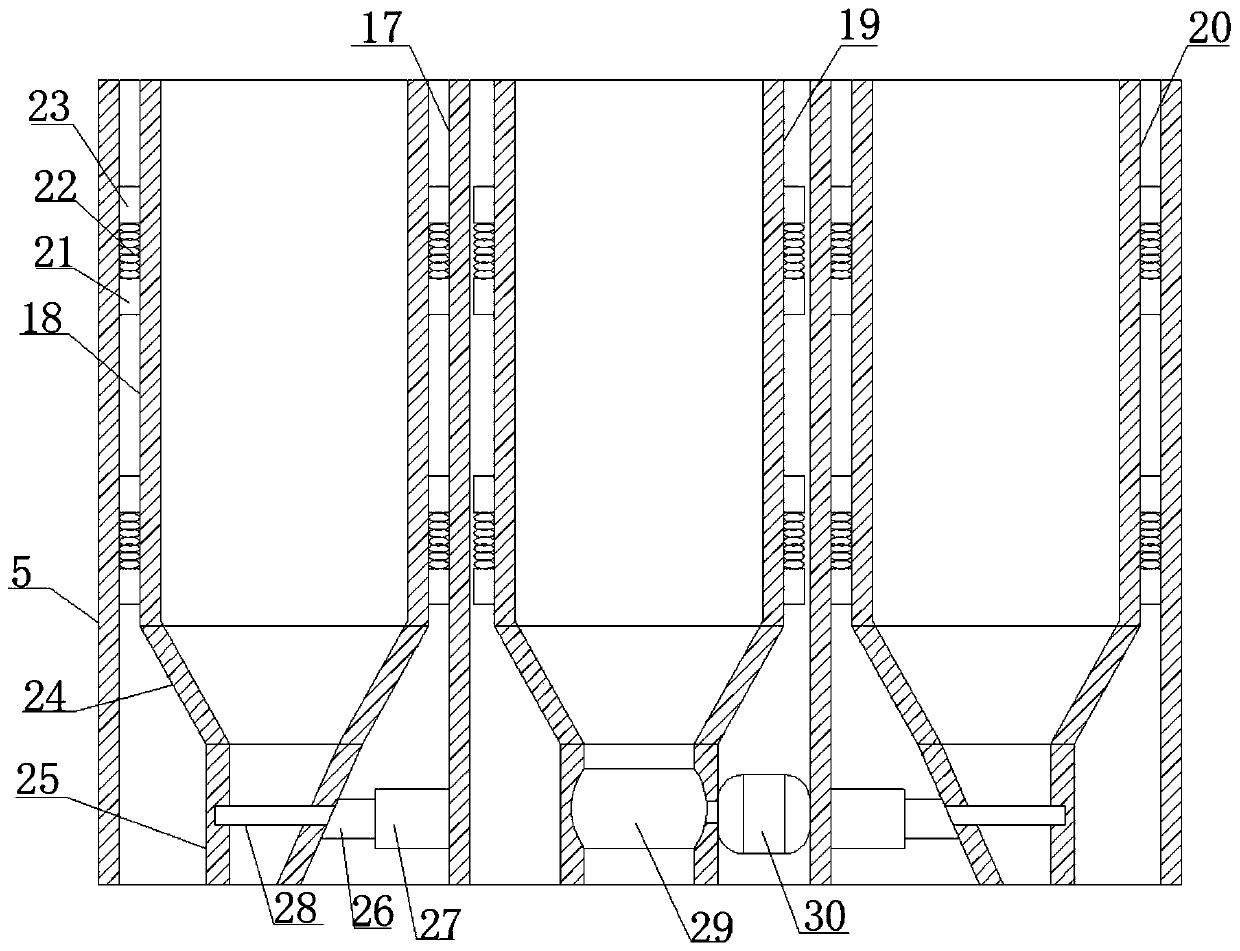

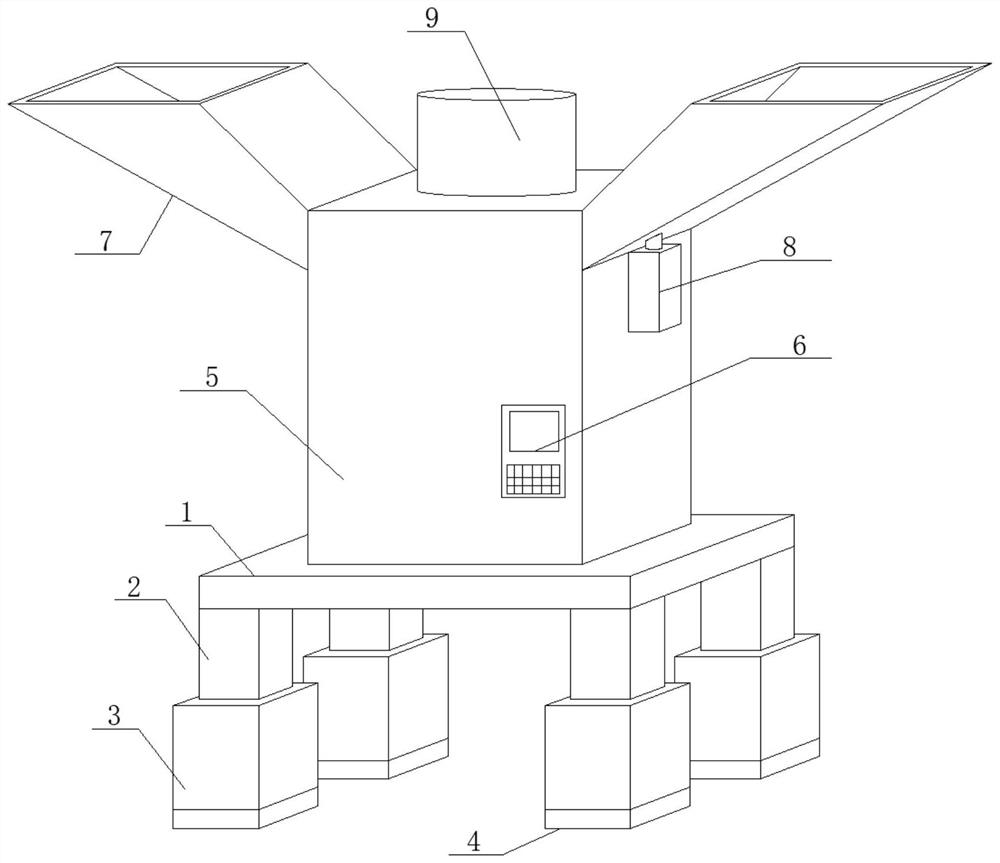

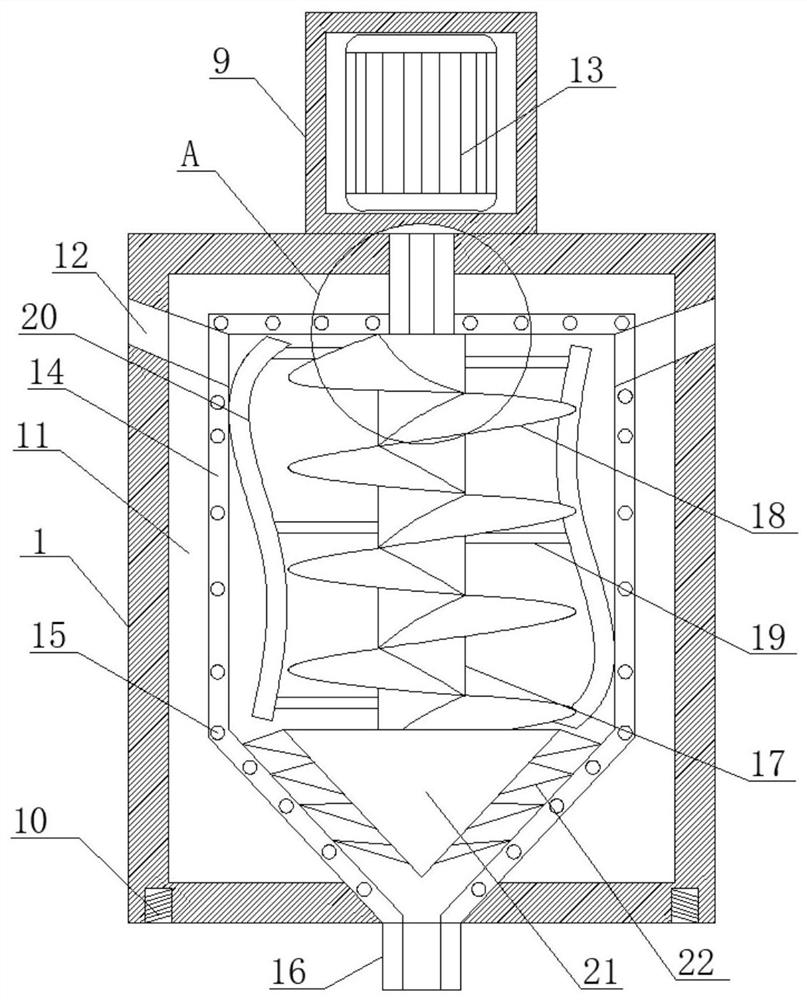

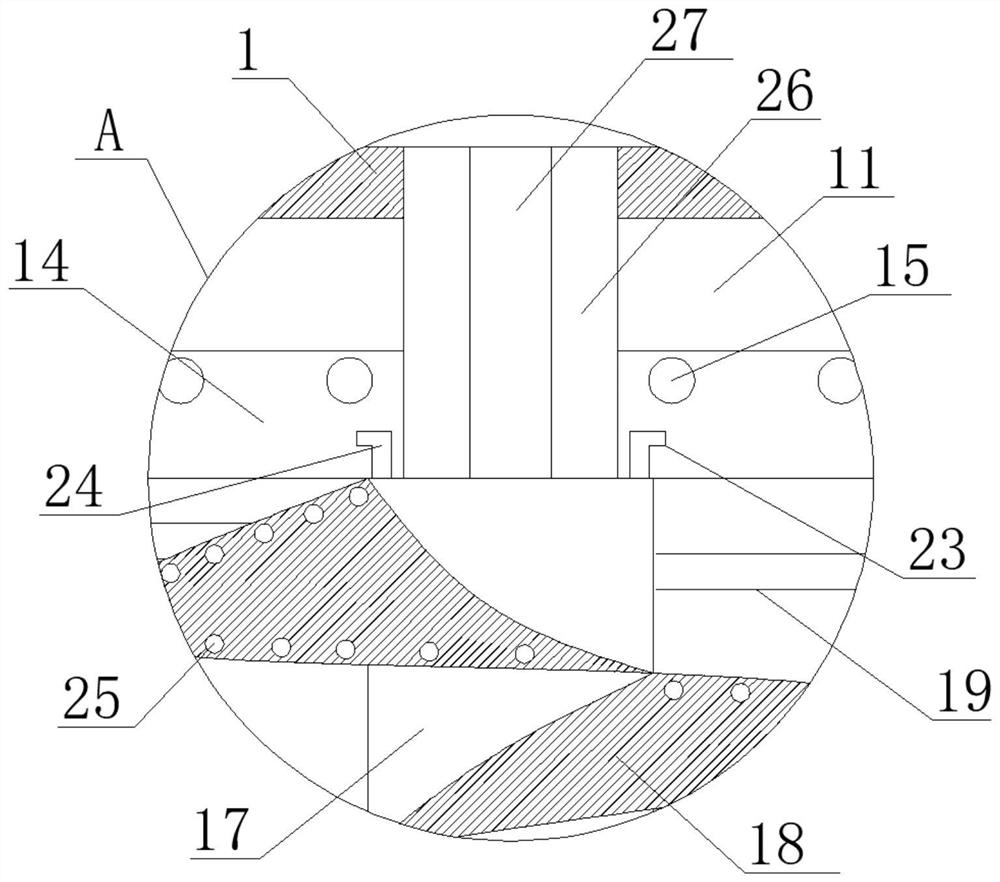

Hot-melting and feeding equipment for PVC pipe production raw materials

The invention discloses hot-melting and feeding equipment for PVC pipe production raw materials, and relates to the field of PVC pipes. The equipment comprises a main supporting plate, the bottom surface of the main supporting plate is vertically and downwards welded with an extension vertical rod, the bottom end of the extension vertical rod is vertically sleeved with a bottom sleeve rod, the bottom surface of the bottom sleeve rod is horizontally and fixedly bonded with a rubber cushion plate, an outer supporting box is vertically connected to the top surface of the main supporting plate through bolts, a control panel is embedded in one side edge of the outer supporting box, feeding hoppers are symmetrically welded to the two side edges of the outer supporting box, outer box bodies are vertically and symmetrically connected to the two side edges of the outer supporting box through bolts, and a top fixing box is connected to the top surface of the outer supporting box through bolts. According to the equipment, the design is integrated, the structure is simple, operation is convenient, heating is uniform and stable without overflowing under the condition that multiple heating and heat preservation structures are adopted, the use efficiency of heat energy is greatly improved, and meanwhile, the scraping and cleaning effects are achieved while stirring is achieved through a spiral structure.

Owner:陈世明

Lengthways outer wing type heat exchange tube

InactiveCN103322847AIntegrated structure is simpleBroaching is easyTubular elementsAerospace engineering

Owner:JIANGYAN YONGSHENG COOLING EQUIP MFG

Air conditioner shell facilitating air conditioner air inlet area adjustment

InactiveCN112628866AEasy to installEasy to moveLighting and heating apparatusNoise suppressionEngineeringBolt connection

The invention discloses an air conditioner shell facilitating air conditioner air inlet area adjustment, and relates to the field of air conditioner shells. The air conditioner shell comprises a main outer shell, an air outlet groove channel is formed in one side edge of the main outer shell, a control plate groove hole is horizontally formed in one side edge of the main outer shell, a clamping hole plate is connected to one side edge of the main outer shell in a clamped mode, a temperature sensing probe is inserted into one side edge of the clamping hole plate, an air inlet channel is vertically formed in one side edge of the main outer shell, a movable sealing plate is clamped to the inner side edge of the air inlet channel, an adjusting guide plate is horizontally arranged on the inner side edge of the air inlet channel, a rear frame body is fixedly welded to the side, away from the air inlet channel, of the main outer shell, and a sealing rear plate is connected to the side, away from the air inlet channel, of the main outer shell through bolts. The device is integrated in design, simple in structure and convenient to operate, more humanization is achieved through the intelligent centralized control design, and control over the air inlet area is more accurate and efficient through the dual regulation and control structure.

Owner:CHUZHOU UNIV

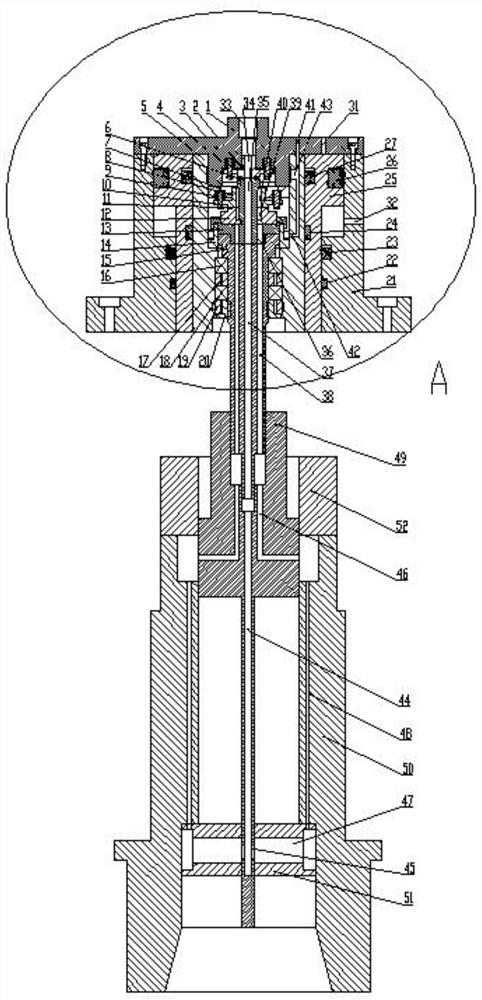

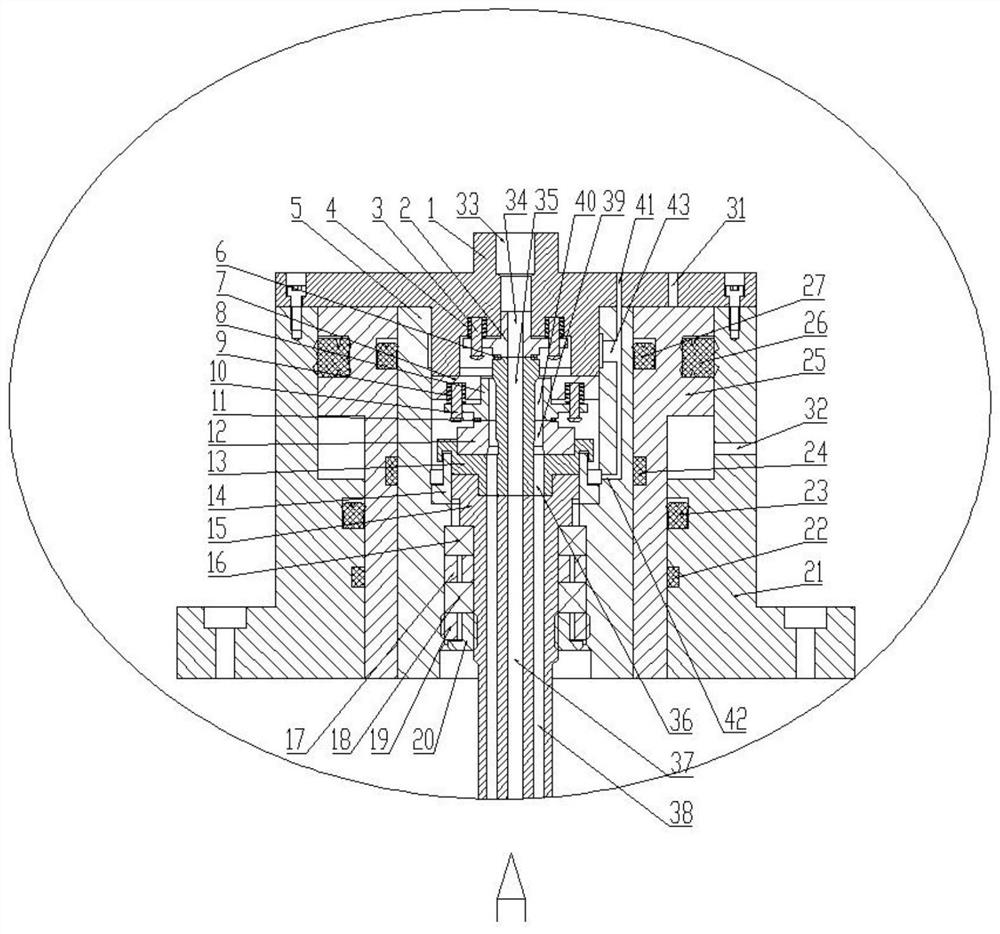

Electric spindle assembly with hydraulic cylinder and center cooling function

ActiveCN113000868AExtended service lifeImprove feverLarge fixed membersMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses an electric spindle assembly with a hydraulic cylinder and a center cooling function. The electric spindle assembly comprises a first channel arranged on an end cover and communicating with a containing cavity, a second channel is arranged on an outer shell and communicates with the containing cavity, and a piston of the hydraulic cylinder can move along the axial direction of an inner shell by introducing hydraulic oil from the first channel or the second channel. A third channel communicates with a fourth channel, a fifth channel and a seventh channel in sequence to form a liquid inlet channel, an eighth channel communicates with a sixth channel, a ninth channel and a tenth channel in sequence to form a liquid outlet channel, and a twelfth channel communicates with the liquid outlet channel through an abutting gap between a limiting sleeve and a spacer bush; and a thirteenth channel communicates with the liquid inlet channel through a gap between a raised shaft and a top end gland. The hydraulic cylinder piston for controlling a broach device and a center cooling structure for cooling the interior of the electric spindle are combined together, so that the integrated structure is more compact, cooling liquid can enter through a single channel and exit through multiple channels, and then the cooling efficiency is improved.

Owner:宁波天控五轴数控技术有限公司

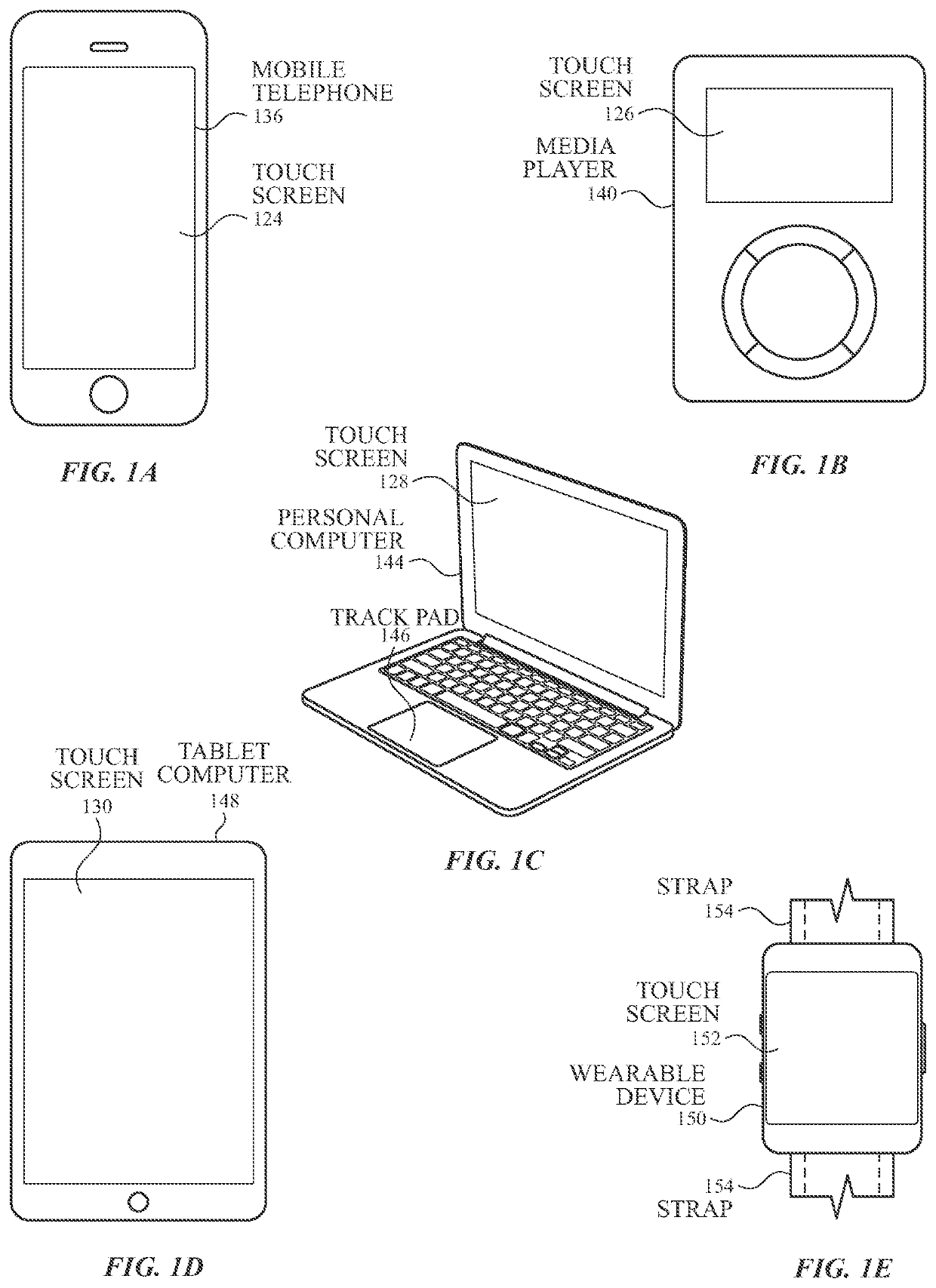

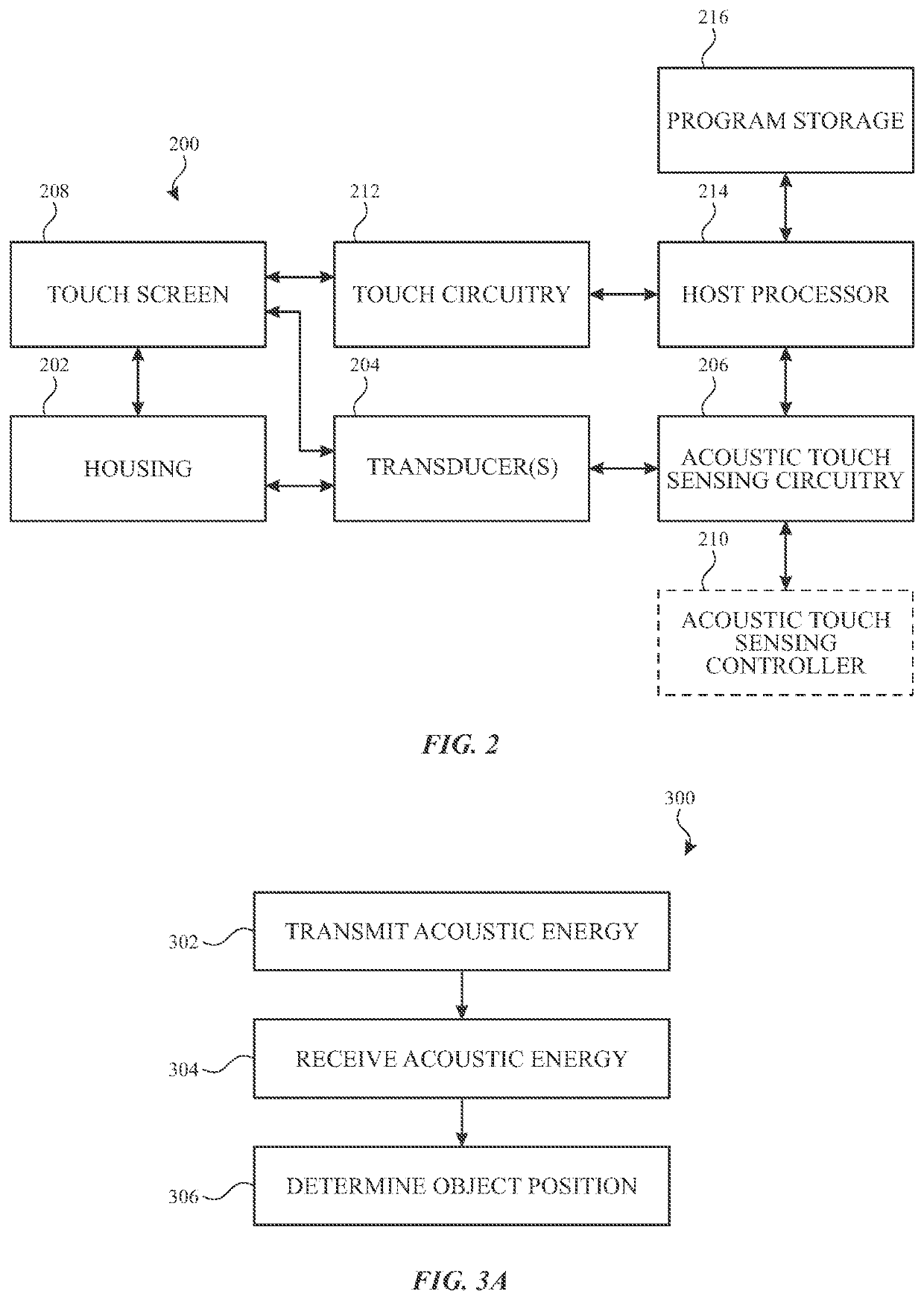

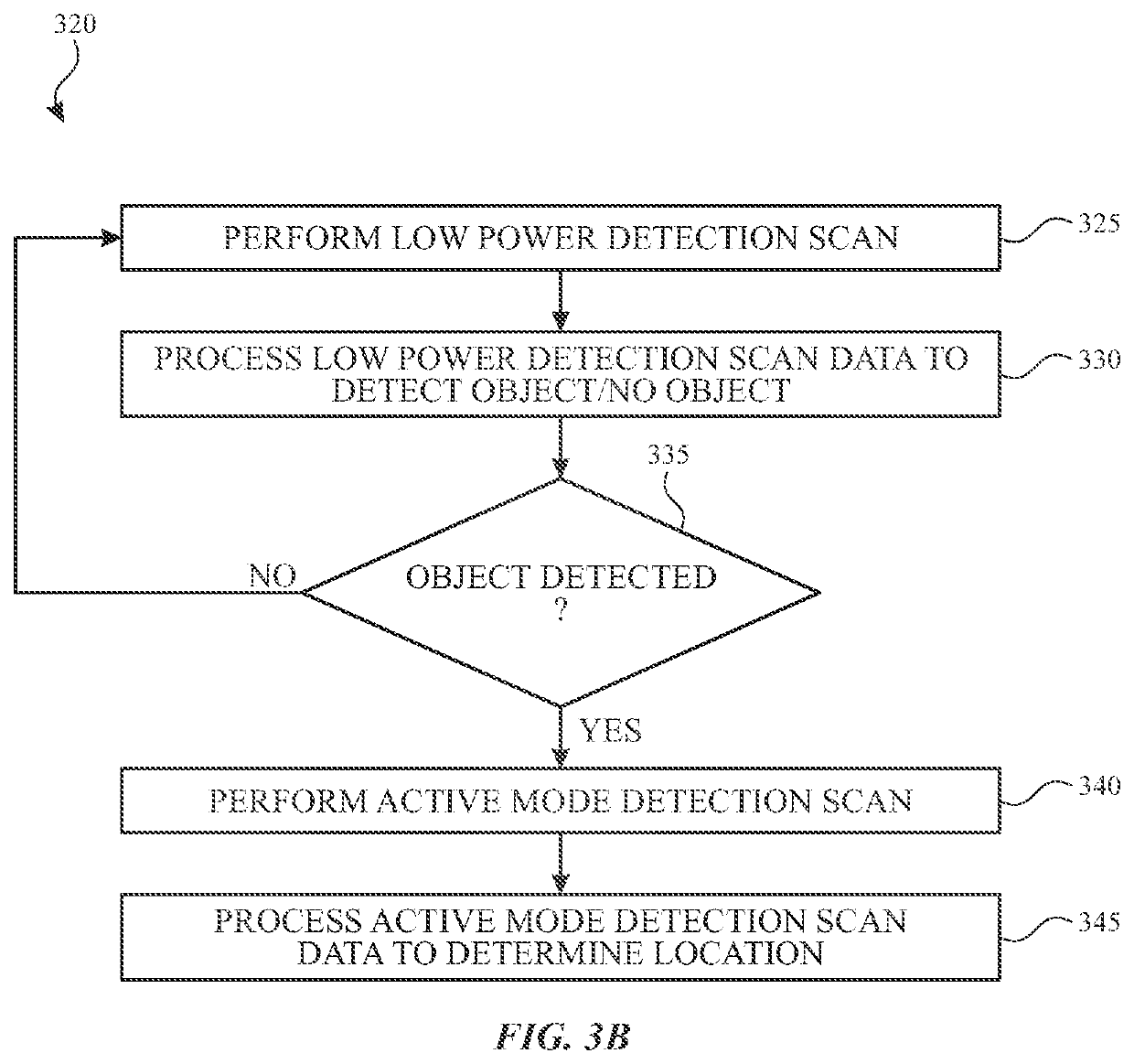

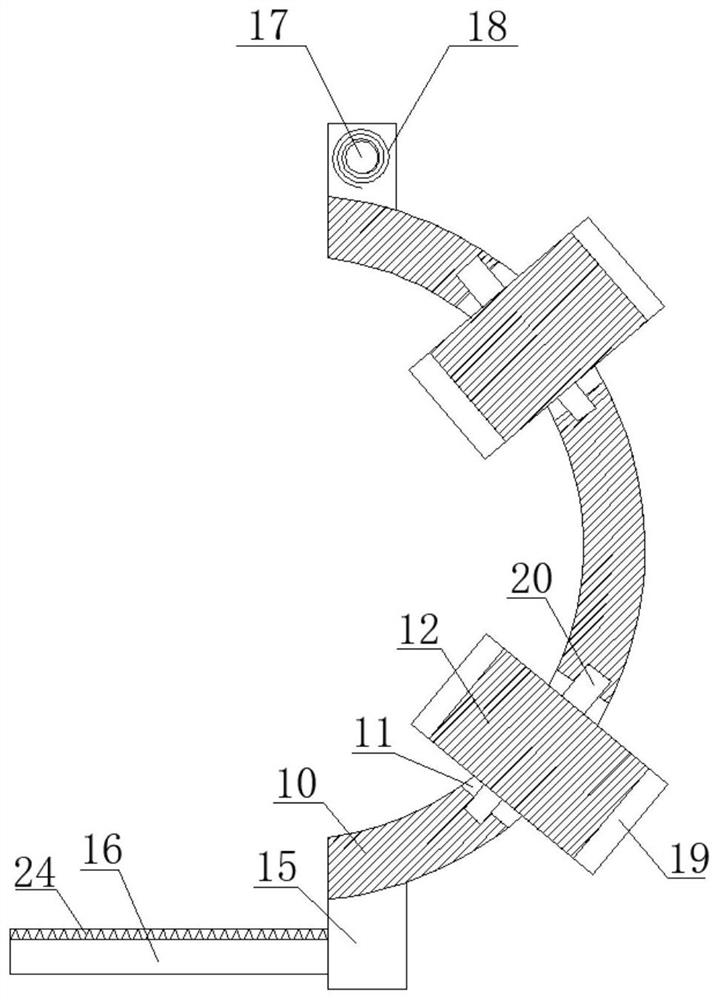

Annular piezoelectric structure for ultrasonic touch sensing

ActiveUS20200042130A1Integrated structure is simpleImproves Structural IntegrityCasings with display/control unitsElectronic switchingTouch SensesTransducer

Acoustic touch sensing systems can include a mechanically integrated structure including multiple acoustic transducers. For example, an annular structure including one or more piezoelectric segments can be fabricated and then coupled to a front crystal / cover glass. A single structure can simplify the structural integration of the device, can provide a mechanically reliable and stable structure for improved structural integrity of the system, and can provide for improved water sealing for a waterproof or water resistant device. The piezoelectric material in the annular structure can be shear poled such that a poling direction of the piezoelectric material can follow the curvature of the annular piezoelectric structure.

Owner:APPLE INC

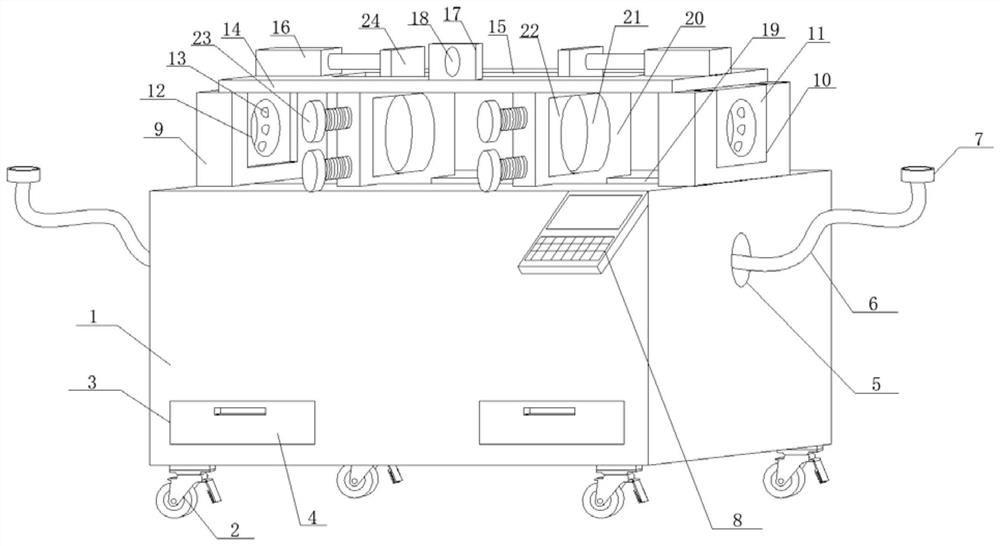

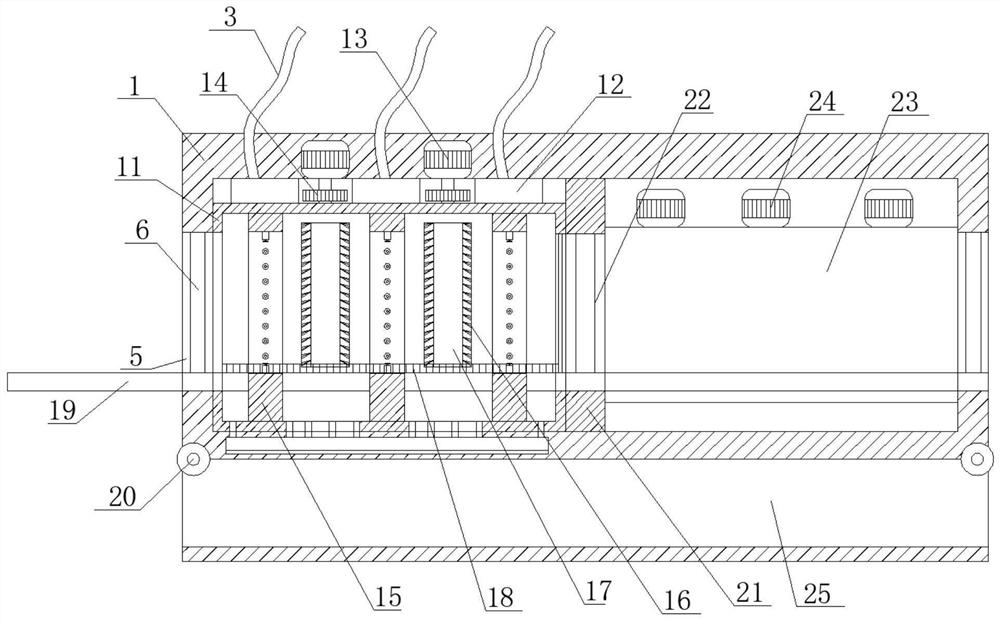

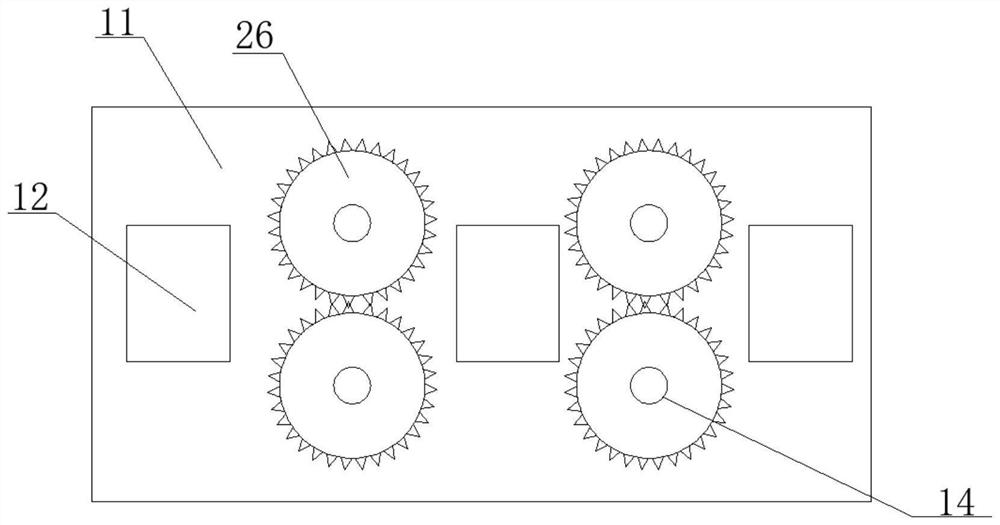

Induction curing heating equipment

The invention discloses induction curing heating equipment, and relates to the field of heating equipment. The induction curing heating equipment comprises a main outer box body, rolling wheels are connected to the bottom face of the main outer box body through bolts, brake plates are arranged on the side edges of the rolling wheels, an extending through groove is formed in one side edge of the main outer box body, and a sealing cover plate is clamped to the top face of the inner side of the extending through groove; a buckling groove is horizontally formed in the side edge of the sealing cover plate, a gradienter is horizontally embedded in the top face of the main outer box body, a handle rod is connected to the top face of the main outer box body through bolts, side through grooves are symmetrically formed in the two side edges of the main outer box body, and a shifting rotary disc is arranged on the inner side edge of the main outer box body; and adjusting pressing blocks are symmetrically connected to the two side edges of the main outer box body in a clamped mode. According to the device, the integrated structure is designed, operation is easy and convenient, the equipment height and the heating angle can be adjusted at will under the condition that an adjustable structure is adopted, and meanwhile the conditions of collision damage and accidental injury are avoided due to the adoption of a storage structure.

Owner:江文坚

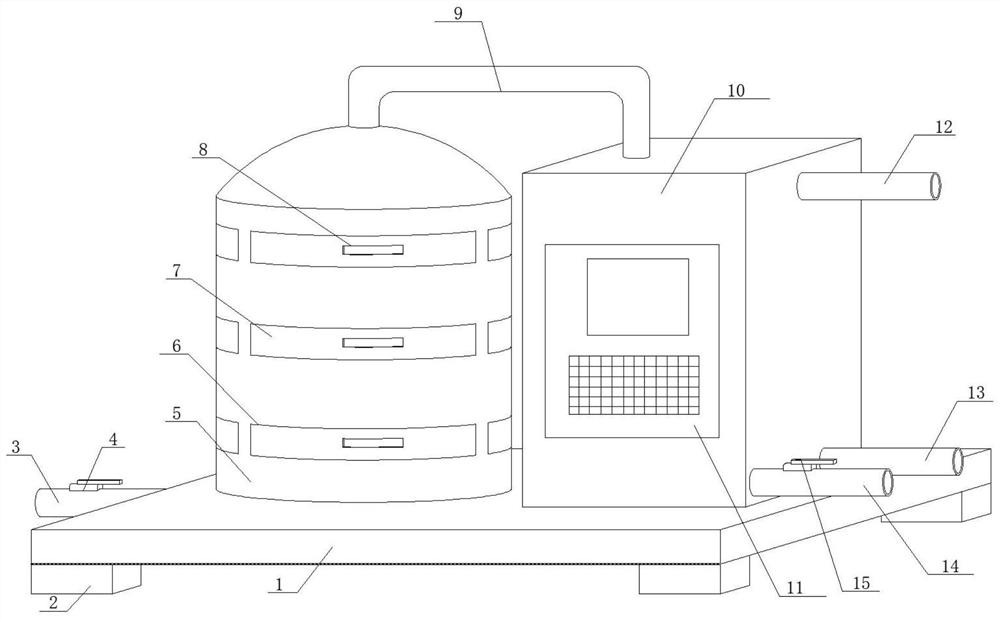

Efficient essential oil extraction production equipment

InactiveCN112080344ASimple structureEasy to operateEssential-oils/perfumesProcess engineeringEssence oil

The invention discloses efficient essential oil extraction production equipment, and relates to the field of essential oil production. The efficient essential oil extraction production equipment comprises a supporting bottom supporting plate, a bottom supporting block is fixedly welded to the bottom surface of the supporting bottom supporting plate, one side edge of the bottom supporting block isin horizontal threaded connection with a steam inlet pipe, and the outer side edge of the steam inlet pipe is in bolted connection with a steam valve; an evaporation tank body is welded to the top face of the supporting bottom supporting plate in a vertically upward mode, inserting through grooves are evenly formed in the outer side edge of the evaporation tank body, a storage drawer is horizontally inserted into the inner side edges of the inserting through grooves, a connecting groove is formed in the center of the outer side edge of the storage drawer, and a steam connecting pipe is vertically welded to the top end of the evaporation tank body. The device is integrated in design, simple in structure and convenient to operate, the working efficiency during refining is greatly improved byadopting a multi-layer smoking effect, meanwhile, the condensation effect is better due to the design of the circulating condensation device, and the essential oil production efficiency and quality are greatly improved.

Owner:陈玉团

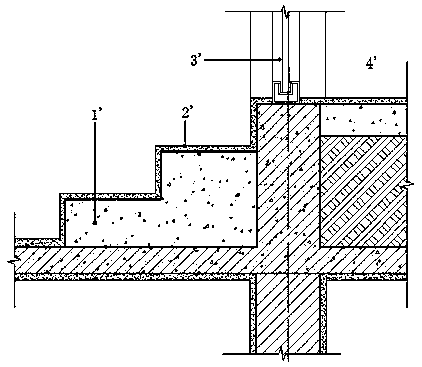

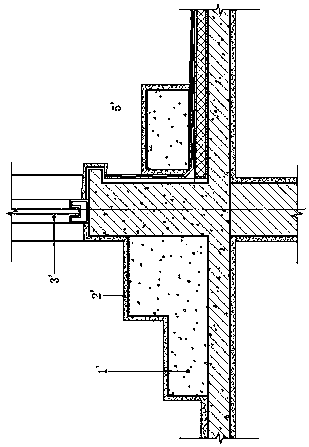

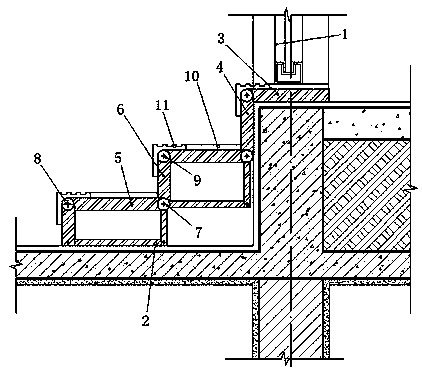

Integrated finished steel structure door sleeve product

InactiveCN110242157ASafety threshold stepsEasy maintenanceWindow/door framesSills/thresholdEngineeringFace sheet

The invention discloses an integrated finished steel structure door sleeve product, which comprises a steel structure door body, a hinge pedal and hinge supports. The hinge pedal comprises a mounting fixing part, a mounting connecting part and a folding step part which are fixedly arranged at the bottom of the steel structure door body; the folding step part is composed of a plurality of step assemblies, and each step assembly comprises a step panel, a step supporting plate and a step hinge shaft; panel hinge shafts are arranged at the edges of the sides, parallel to the step hinge shafts, of the step panels, and supporting plate hinge shafts are arranged at the edges of the sides, parallel to the step hinge shafts, of the step supporting plates; and the bottom of each step assembly is provided with the corresponding set of hinge supports, and each set comprises the two corresponding hinge supports which are mutually hinged, wherein the edges of the sides, parallel to hinged shafts, of the two hinge supports are connected with the corresponding panel hinge shaft and the corresponding supporting plate hinge shaft correspondingly. Doorsill steps of a waterproof room can be obtained without the need of concrete construction work.

Owner:CHINA RAILWAY URBAN PLANNING & DESIGN INST

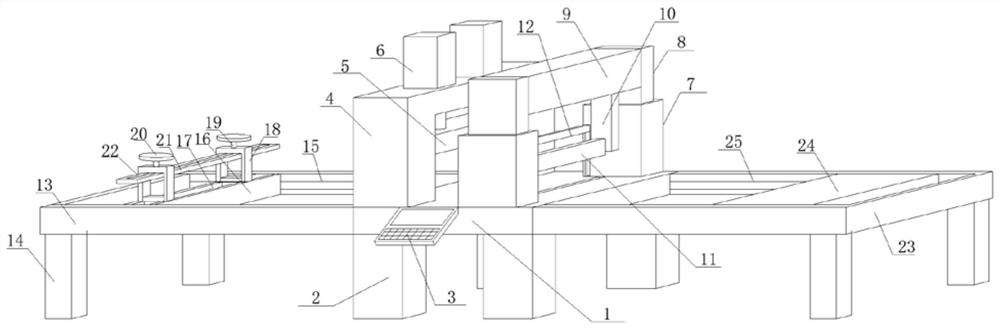

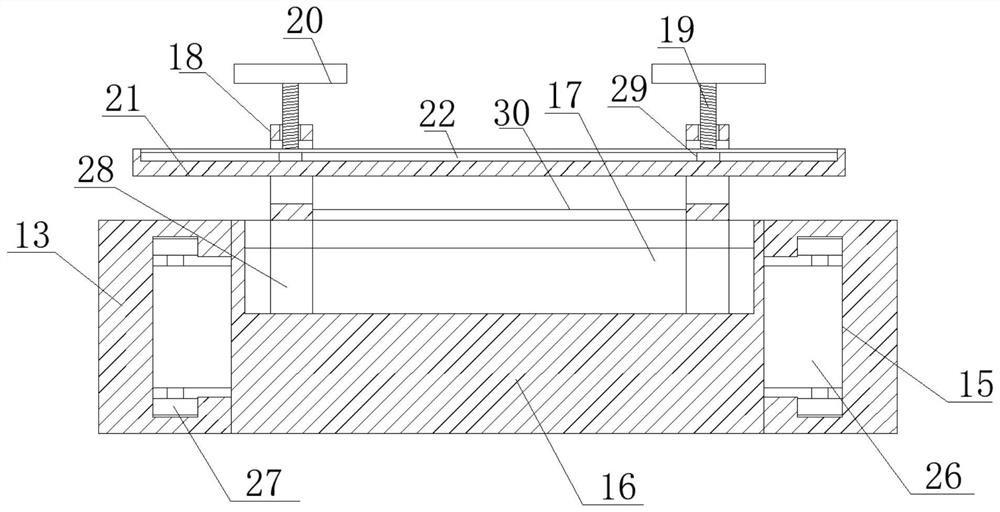

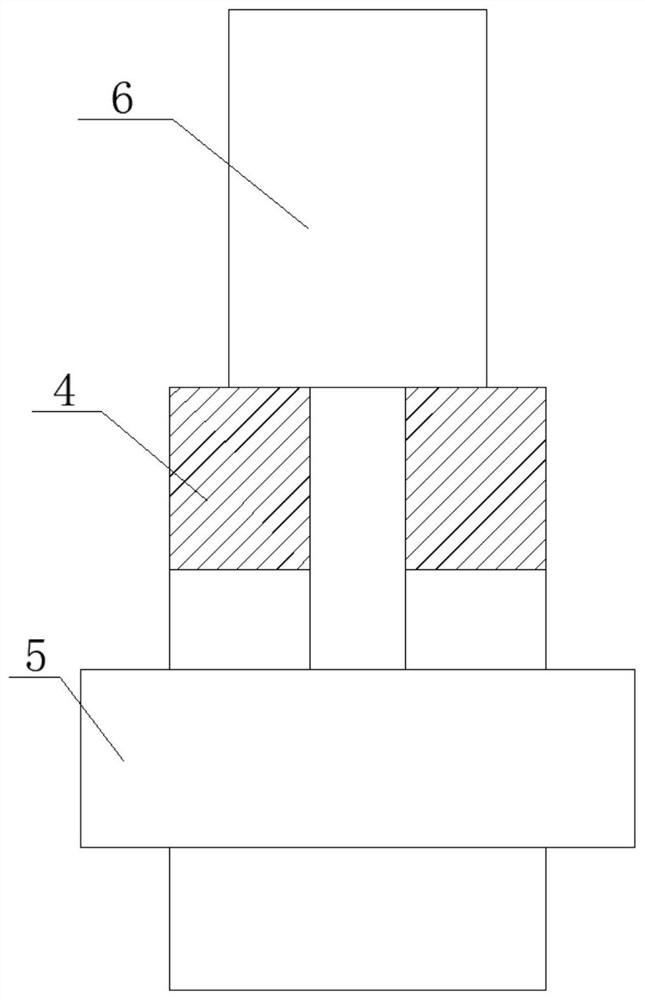

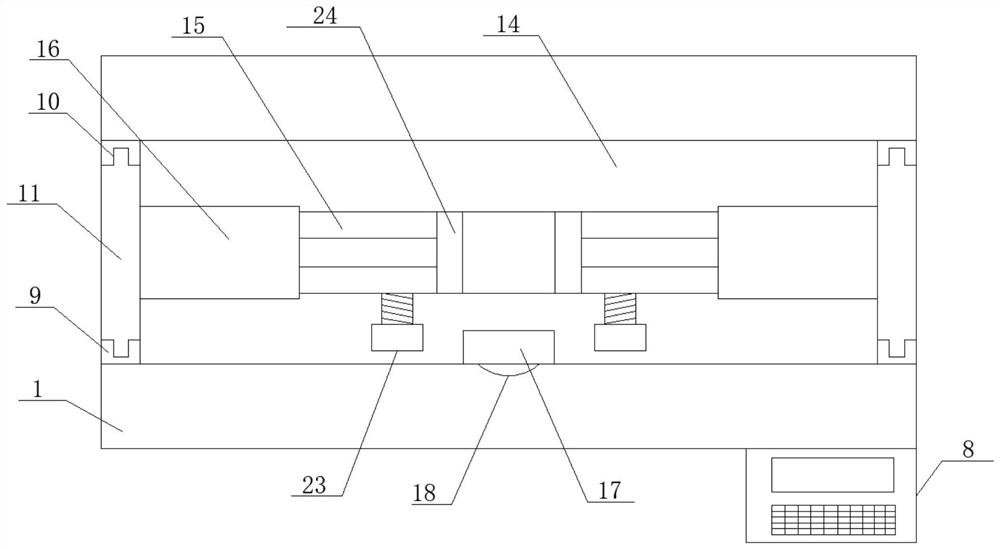

Metal material machining device

InactiveCN113182606ASatisfy fixationReduce investmentMetal sawing devicesMeasurement/indication equipmentsMetallic materialsMaterials processing

The invention discloses a metal material machining device, and relates to the field of metal materials. The metal material machining device comprises a fixed bottom plate, wherein supporting vertical rods are vertically and downwards welded to the bottom face of the fixed bottom plate; a control panel is obliquely welded to one side edge of the fixed bottom plate; a fixed top block is welded to the top face of the fixed bottom plate; an extrusion plate is horizontally arranged on the inner side edge of the fixed top block; a pushing and pressing air cylinder is connected to the top face of the fixed top block through a bolt; bottom sleeve rods are vertically and upwards welded to the top face of the fixed bottom plate; extending vertical rods are vertically and upwards inserted into the top ends of the bottom sleeve rods; a top box body is horizontally welded to the side edge between the extending vertical rods; and extending side rods are vertically and downwards welded on the bottom surface of the top box body. According to the device provided by the invention, the design is integrated, the structure is simple, operation is convenient, product discharging is faster and more efficient by adopting the intelligent automatic measuring and cutting procedure, meanwhile, labor input is greatly reduced in a more time-saving and labor-saving mode, and the requirement for market development is met.

Owner:宿迁小鲤工业设计有限公司

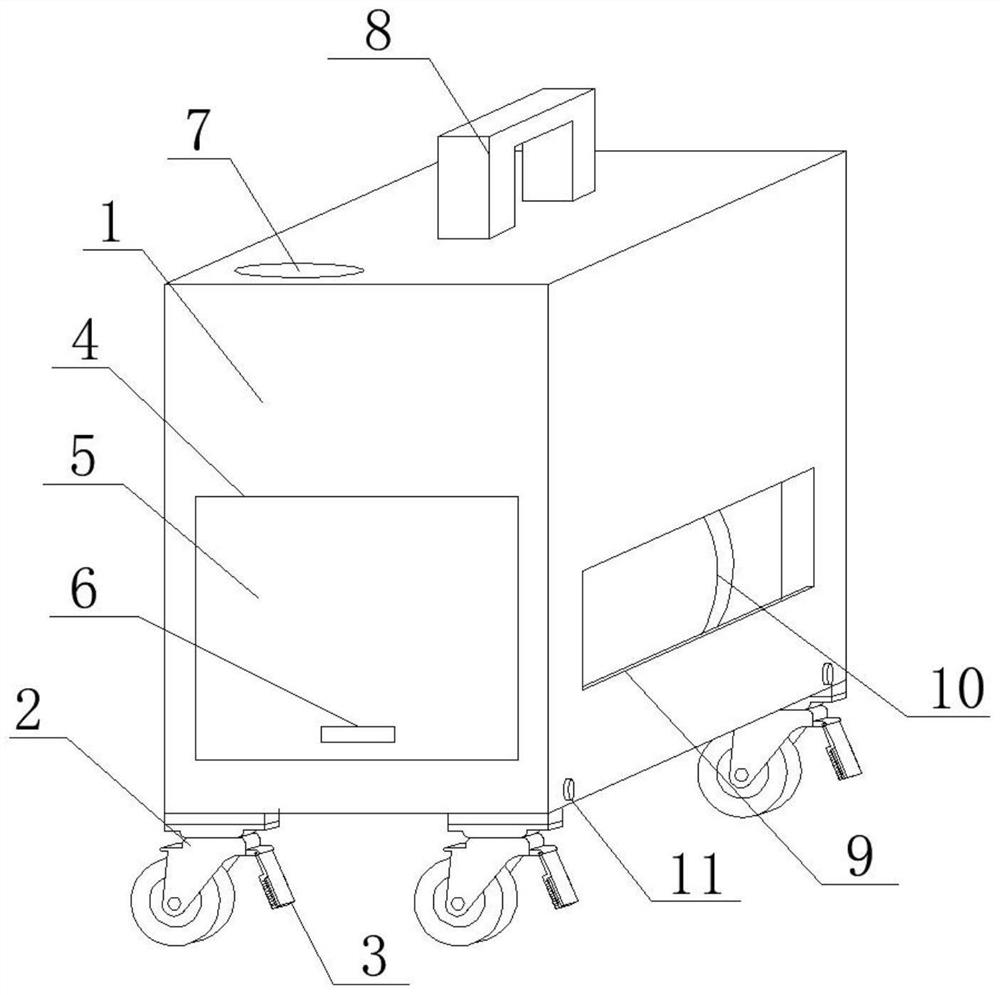

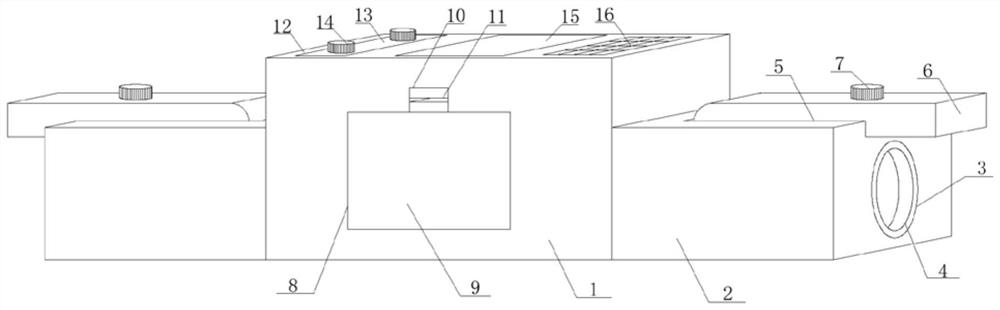

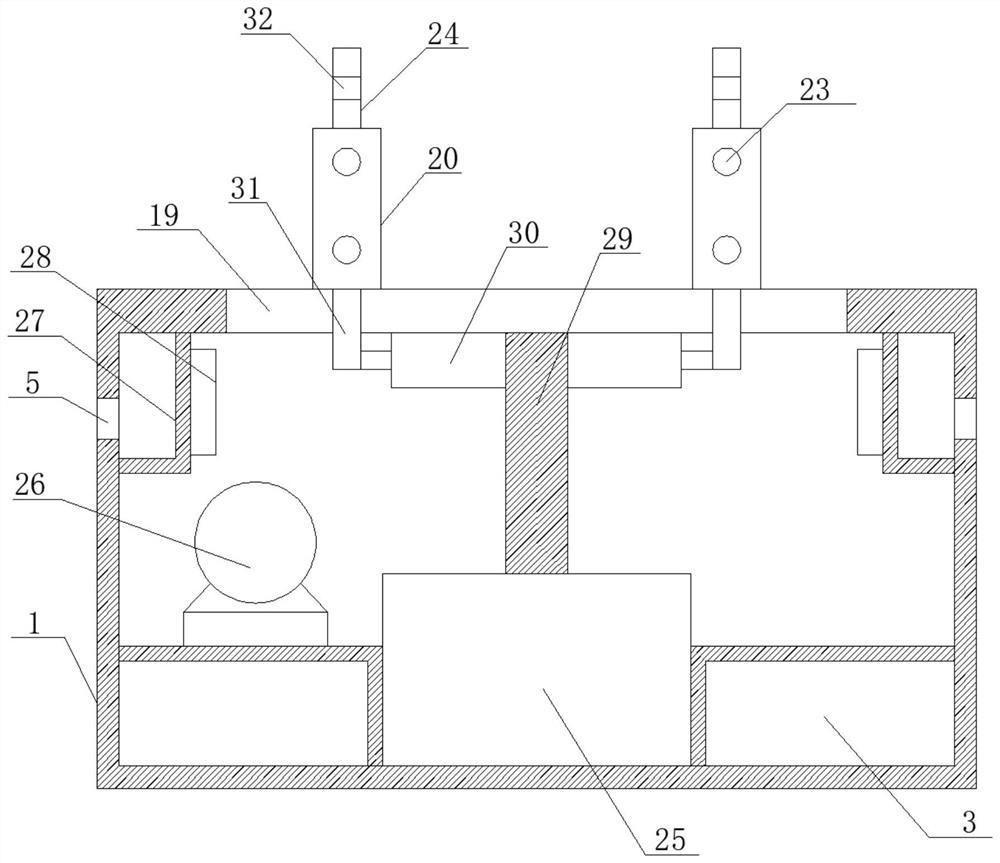

Efficient cleaning device for air conditioning equipment evaporator

InactiveCN113310343AEasy to carryEasy to moveFlush cleaningRotary device cleaningSewageAir conditioning

The invention discloses an efficient cleaning device for an air conditioning equipment evaporator, and relates to the field of air conditioning evaporators. The efficient cleaning device comprises a supporting bottom box, moving rollers are connected to the bottom face of the supporting bottom box through bolts, fastening sliding grooves are symmetrically and horizontally formed at the two side edges of the supporting bottom box, and fastening screws are horizontally inserted into the inner side edges of the fastening sliding grooves; and a blow-off pipe is inserted into the side edge of the supporting bottom box, a collecting box is in butt joint with the top surface of the supporting bottom box vertically upwards, a flushing box is in butt joint with the top surface of the supporting bottom box vertically upwards, a colloid plate is fixedly clamped to the side edge between the collecting box and the flushing box, and a water inlet pipe is inserted into the top surface of the flushing box. The device is integrated in design, simple in structure and convenient to operate, evaporators of various specifications can be cleaned by adopting a clamping type cleaning manner, meanwhile, cleaning is more thorough through scrubbing while flushing is conducted, and the situation that sewage overflows everywhere to cause pollution is avoided due to the butt joint type air suction design.

Owner:六安长芯智能科技有限公司

An easy-to-install smart water meter

ActiveCN111457981BPrevent rolloverHigh degree of intelligenceVolume indication and recording devicesSmart waterControl theory

The invention discloses an easy-to-install smart water meter, which relates to the field of water meters, and includes a supporting main board, two sides of the supporting main board are horizontally welded with extended counter-boards, and one end of the extended counter-board is horizontally provided with a plug-in connection hole, so The plug-in connection hole is fixedly connected with a port ring at the end far away from the supporting main board, and the top surface of the extending opposite board is horizontally provided with a movable card slot, and the inner side of the movable card slot is horizontally connected with a flip lever. The top surface of the turning rod is vertically inserted with a fixed screw. The integrated structure of the device design of the present invention is simple and convenient to operate. The data can be transmitted to the client in real time to facilitate observation and monitoring. At the same time, it can also filter the water body for later use, which greatly improves the intelligence of the water meter and is conducive to the development needs of the current society.

Owner:宁夏隆基宁光仪表股份有限公司

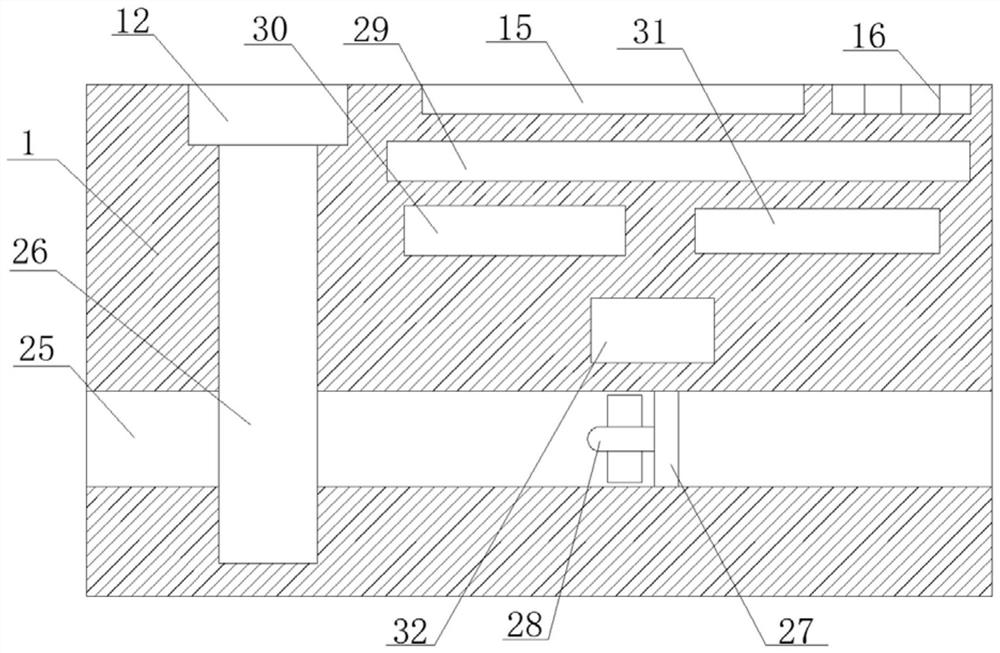

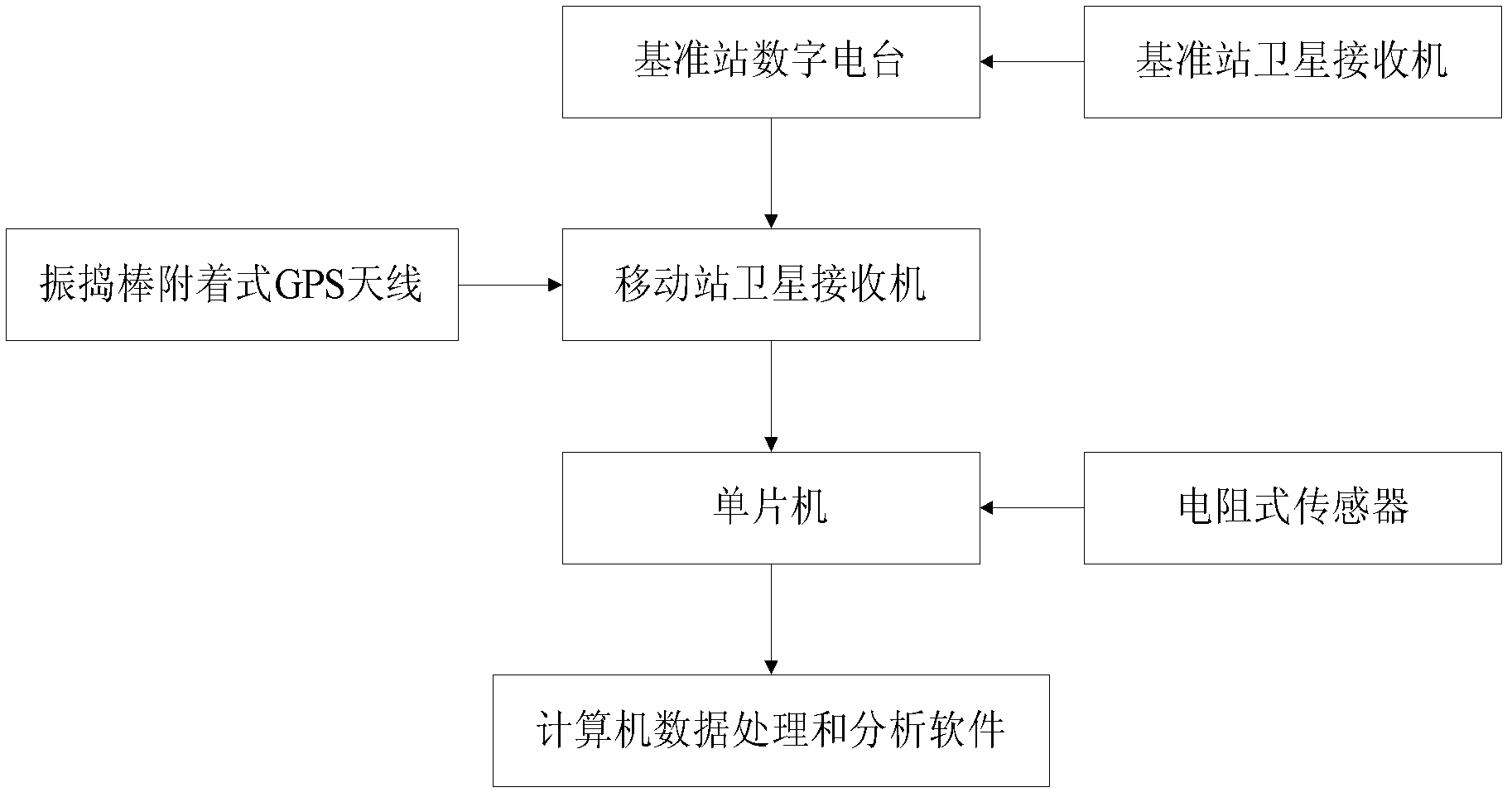

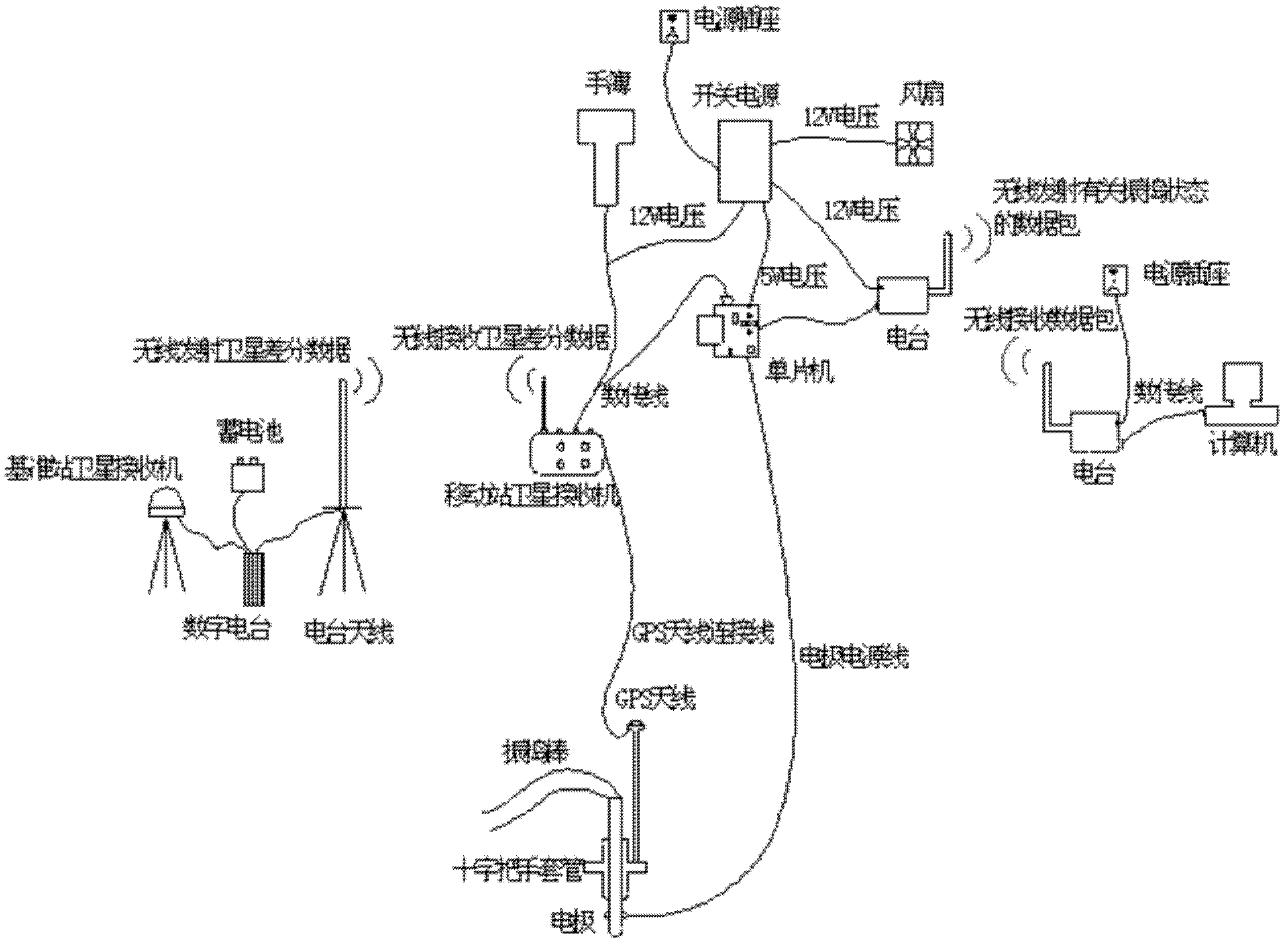

Method for measuring concrete vibrating time in real-time

ActiveCN102507658BRealize real-time monitoringIntegrated structure is simpleMaterial resistanceEngineeringElectric potential

The invention discloses a method for measuring concrete vibrating time in real-time, which comprises the following steps: firstly, an electrode used for measuring electric potential of to-be-measured concrete is mounted at a head of a spud vibrator; and then, the electrode is connected with a single chip through a power cord; the single chip collects and analyzes electric potential values fed back by the electrode when the spud vibrator is inserted in and pulled out of the to-be-measured concrete, and calculates the vibrating time t of the spud vibrator, so as to feed back the vibrating time for the spud vibrator to be inserted in and pulled out of the to-be-measured concrete in real-time. Therefore, the method utilizes the differences existing in the electric potential values when the spud vibrator is inserted in and pulled out the concrete, so as to monitor the time interval that the spud vibrator is inserted in and pulled out of the concrete, i.e. the vibrating time, and relatively accurately calculate the vibrating time of the spud vibrator in the to-be-measured concrete, and provide indispensable important technical parameters for acquiring the pouring and the vibrating states of the concrete in real-time in an visualized manner.

Owner:HOHAI UNIV

Single-leaf revolving double-curve crown-strip ring and its process thereof

InactiveCN1224138CReduce volumeIntegrated structure is simpleCoupling contact membersElectrical resistance and conductanceHigh volume manufacturing

Convoluting the elasticity sheets metal punched forms the coronary straps jack contact element so that the manufacturing procedure is simple providing the advantages of low cost, good consistency and being suitable to mass production. The contact between jacks and pins is the contact mode of the multiaspect envelope so as to provide the features of steady dynamic contact resistance, shockproof, antivibration, small contact resistance etc. The structure of the contact element is simple without the front cover, back cover and inner housing, Thus, the size of the contact element is smaller and the wastage of copper material is reduced so as to save copper material as well as human resources.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Automatic incineration disposal system

PendingCN108253435AHigh degree of automationEasy to operateGas treatmentEmission preventionFlue gasControl system

The invention discloses an automatic incineration disposal system. The automatic incineration disposal system is an integrated device and comprises a front dechlorination device, a drying and filtering system, an incineration device, a tail gas disposal device and a PLC control system. The front dechlorination device and the tail gas disposal device are automatically controlled by the PLC controlsystem. The tail gas disposal device is of an integrated structure and is sequentially provided with a first cavity, a first filtering layer, a middle spraying type desulfuration layer, a second filtering layer and a bottom flue gas purification pond from top to bottom. Compared with the prior art, the automatic incineration disposal system has the follow advantages that a front automatic dechlorination system and a rear tail gas disposal system are controlled by a PLC, the automation degree is high, operation is convenient and fast, equipment corrosion is reduced, and incineration efficiencyis improved; the integrated structure is quite simple, cost losses of combination of multiple kinds of equipment are reduced, energy saving and loss reducing are achieved, and the tail gas disposal effect is good; and through integrated arrangement, equipment space is reduced, and operation efficiency is improved.

Owner:江苏华本环境科技有限公司

A stainless steel tableware grinding device

ActiveCN112192431BQuick installationImprove work efficiencyEdge grinding machinesPolishing machinesCutleryStructural engineering

The invention discloses a stainless steel tableware grinding device, which relates to the field of tableware grinding, and comprises a fixed box body, the bottom surface of the fixed box body is welded vertically downward with a support pole, and the bottom end of the support pole is fixedly clamped with a Bottom rubber block, the side of the support pole is horizontally welded with a fixed cross bar, the bottom surface of the fixed box is vertically connected to the bottom cylinder with bolts, and the side of the fixed box is obliquely welded with a control panel , the top surface of the fixed box is horizontally provided with movable slots, the two sides of the movable slot are vertically and symmetrically provided with limiting slots, the inner side of the movable slot is clamped with a processing box, and the processing The two sides of the box body are vertically symmetrically welded with limited positions. The integrated structure of the device design of the present invention is simple and easy to operate, and the grinding method of sand grains is used to make the surface of the tableware be polished in all directions without dead ends, which is more reasonable and efficient, and at the same time, it can be polished in batches, which greatly improves the grinding work. efficiency.

Owner:揭阳市东拓家居实业有限公司

Electric power system maintenance device

InactiveCN113394736AEasy to installPrevent slippingOverhead installationElectric power systemElectric cables

The invention discloses an electric power system maintenance device, and relates to the field of electric power system maintenance, the electric power system maintenance device comprises a fixed transverse plate, one end of the fixed transverse plate is provided with an end sleeve groove, the inner side edge of the end sleeve groove is provided with an overturning buckle, and the two side edges of the fixed transverse plate are symmetrically provided with side sleeve connection grooves; an extending side plate is horizontally inserted into the inner side edge of the side sleeving groove, a main power line is inserted into the end, away from the end sleeving groove, of the fixing transverse plate, a top fixing box is connected to the top face of the fixing transverse plate through a bolt, a side overturning groove is formed in the side edge, away from the fixing transverse plate, of the extending side plate, an overturning block is clamped to the inner side edge of the side overturning groove, an arc-shaped turning plate is horizontally welded to one end of the turning block. The device is integrally designed, is simple in structure, is convenient to operate, is simpler and more convenient by adopting a buckling surrounding mode, can be suitable for cables of various specifications, is quicker and more efficient by adopting a hammering mode to break ice, and is safer during operation.

Owner:杭州迦北科技有限公司

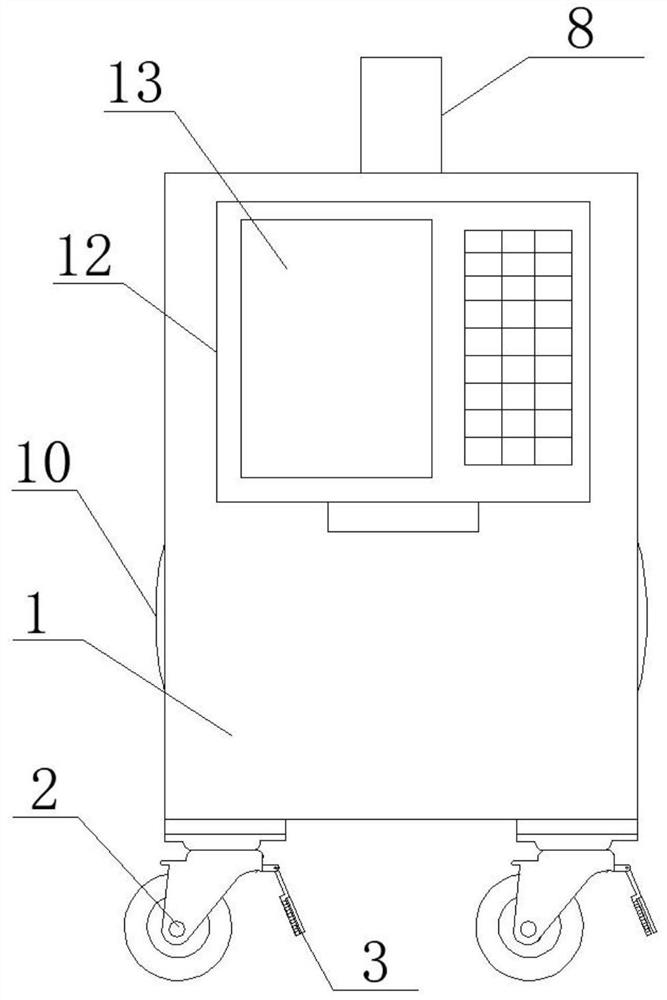

Communication cable detector

InactiveCN111707550AEasy to fixEasy to carryMaterial strength using tensile/compressive forcesElectric cablesBolt connection

The invention discloses a communication cable detection machine, and relates to the field of communication cables. The machine comprises a main box body, wherein the bottom surface of the main box body is in bolted connection with moving rollers; drawer grooves are horizontally and symmetrically formed in one side edge of the main box body; a storage drawer is horizontally inserted into the innerside edge of the drawer groove; clamping groove holes are symmetrically formed in the two side edges of the main box body; a transmission line is inserted into the inner side edge of the clamping groove hole; one end of the transmission line is fixedly sleeved with a butt joint; a control panel is obliquely welded to one side edge of the main box body. The top surface of the main box body is vertically and upwards connected with a side supporting plate through a bolt; and clamping grooves are formed in the side edges of the side supporting plates. The machine is integrated in design, simple instructure and convenient to operate; a push-pull force is more uniform and efficient under the multi-direction pushing effect; meanwhile, detection is more direct and efficient, detection becomes convenient, rapid and accurate, detection is more complete and rapid through more intelligent design, and the detection efficiency is greatly improved.

Owner:杭州三泽科技有限公司

Material packing and material put-in method adopting the material packing

ActiveCN1807196BIntegrated structure is simpleEasy to operateCooking vesselsPackagingEngineeringSingle chamber

The invention discloses the material package used for material auto throwing system and the throwing method. The material package comprises more than two flexible package bodies, every package body is single-chamber or multi-chamber, the ends of the package bodies are connected with each other through flat or cylinder connector, the bodies are separate, and on the package body or connector there is the information for cooking-vessel information acquisition system. The material package has the advantages of simple structure and easy operation.

Owner:AIC ROBOTICS TECH

Shell cleaning device for air conditioner compressor production

InactiveCN114247691ASimple design and integrated structureIntegrated structure is simpleDrying gas arrangementsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses a shell cleaning device for air conditioner compressor production, and relates to the field of air conditioner compressors, the shell cleaning device comprises a treatment main box, a supporting vertical rod is vertically and downwards welded to the bottom surface of the treatment main box, a feeding pipeline is inserted into the top surface of the treatment main box, and a control mainboard is embedded into one side edge of the treatment main box; transmission channels are symmetrically formed in the two side edges of the treatment main box, isolation rubber plates are fixedly connected to the inner side edges of the transmission channels in a clamped mode, supporting side plates are vertically welded to the two side edges of the treatment main box, a material conveying belt is arranged on the side edge between the supporting side plates, and a collecting box body is horizontally connected to the bottom face of the treatment main box in a clamped mode. A blow-off pipe is inserted into the side edge of the collecting box body, and the inner side edge of the treatment main box is in bolted connection with a cleaning main box. The device is integrated in design, simple in structure and easy and convenient to operate, cleaning is more thorough by adopting a washing and sweeping cleaning mode, and meanwhile, the cleaning efficiency is greatly improved by adopting a drying integrated design.

Owner:何顺养

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com