Integrated finished steel structure door sleeve product

A steel structure and door cover technology, applied in the direction of door leaves, windows/doors, building components, etc., can solve the problems of inconvenient maintenance, affecting the overall effect, and inadequate construction, etc., to achieve convenient transportation and installation, beautiful overall effect, and durability high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

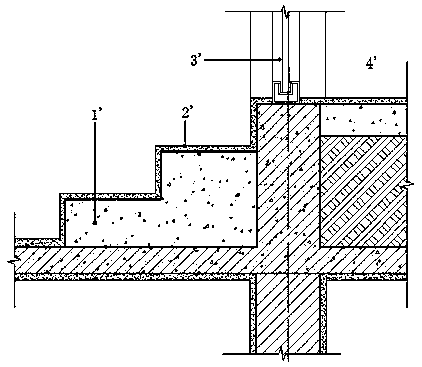

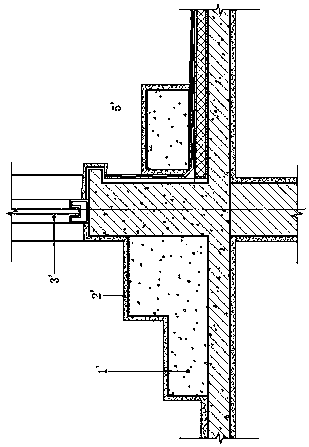

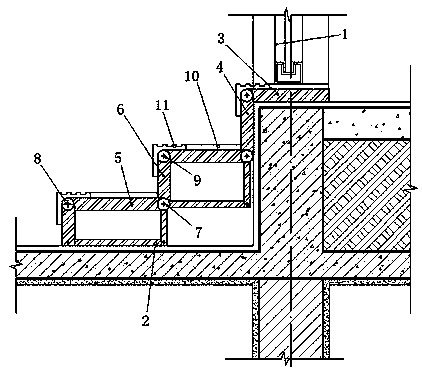

[0021] refer to image 3 , image 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0022] This embodiment provides an integrated steel structure door cover for an underground construction equipment room, including a steel structure door body 1, a hinge pedal and a hinge bracket 2; The installation and fixing part 3, the installation and connection part 4 hinged with the installation and fixing part 3, and the folding step part that is hinged with the installation and connection part 4, the folding steps are composed of several step components, each of the steps The assembly includes a step panel 5, a step support plate 6, and a step hinge shaft 7 that hinges the step panel 5 and the step support plate 6, and the side of the step panel 5 parallel to the step hinge axis 7 The edge is provided with a panel hinge shaft 8, and the side edge of the step support plate 6 parallel to the step hinge axis 7 is provided with a support plate hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com