Hot-melting and feeding equipment for PVC pipe production raw materials

A technology for PVC pipes and feeding equipment, applied in the field of PVC pipes, which can solve problems such as unfavorable replacement and conversion, affect processing and use, and reduce production efficiency, achieve uniform heating and stability without spillage, improve use convenience, and improve use efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

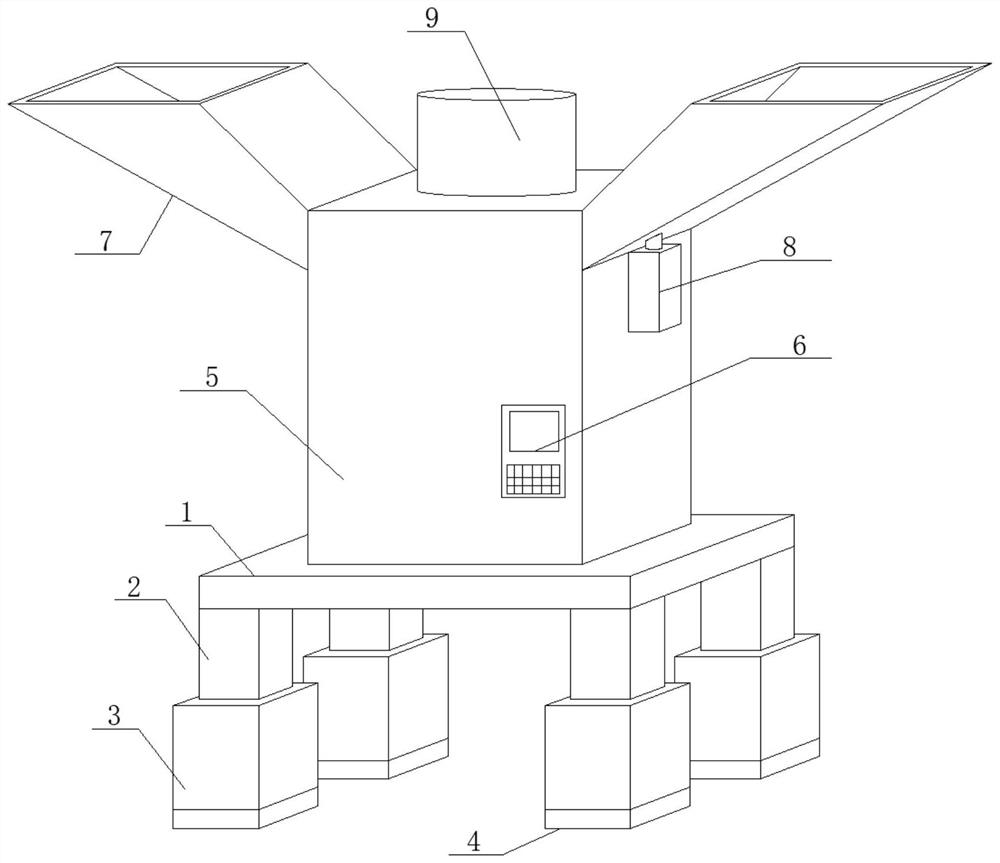

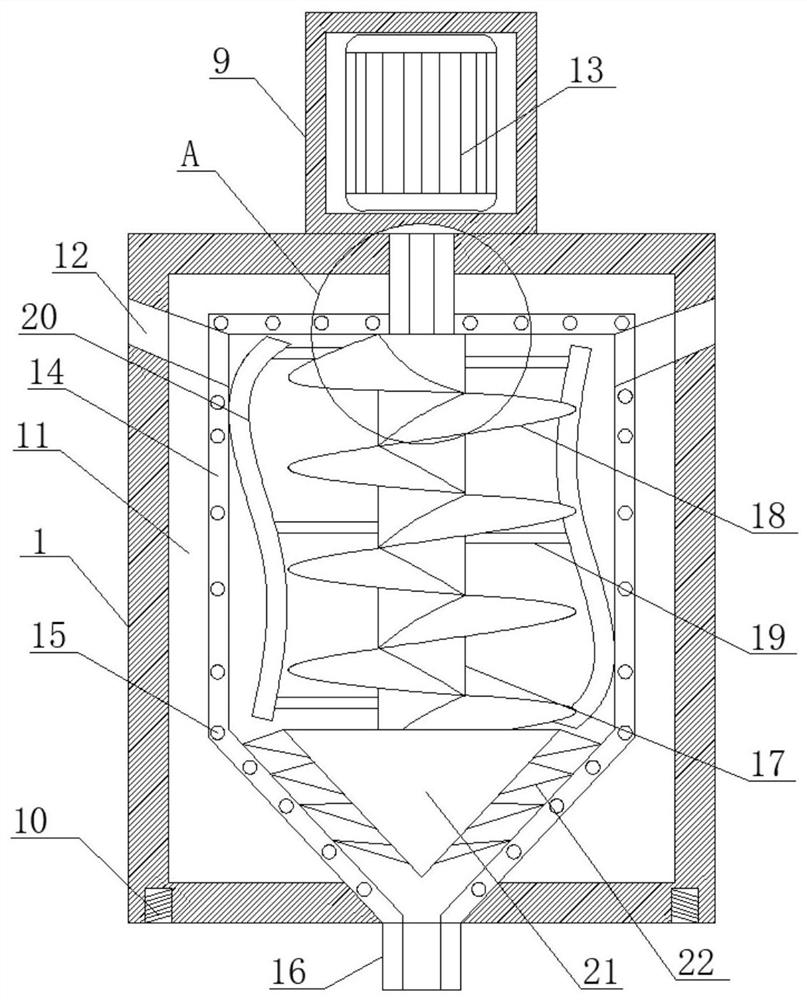

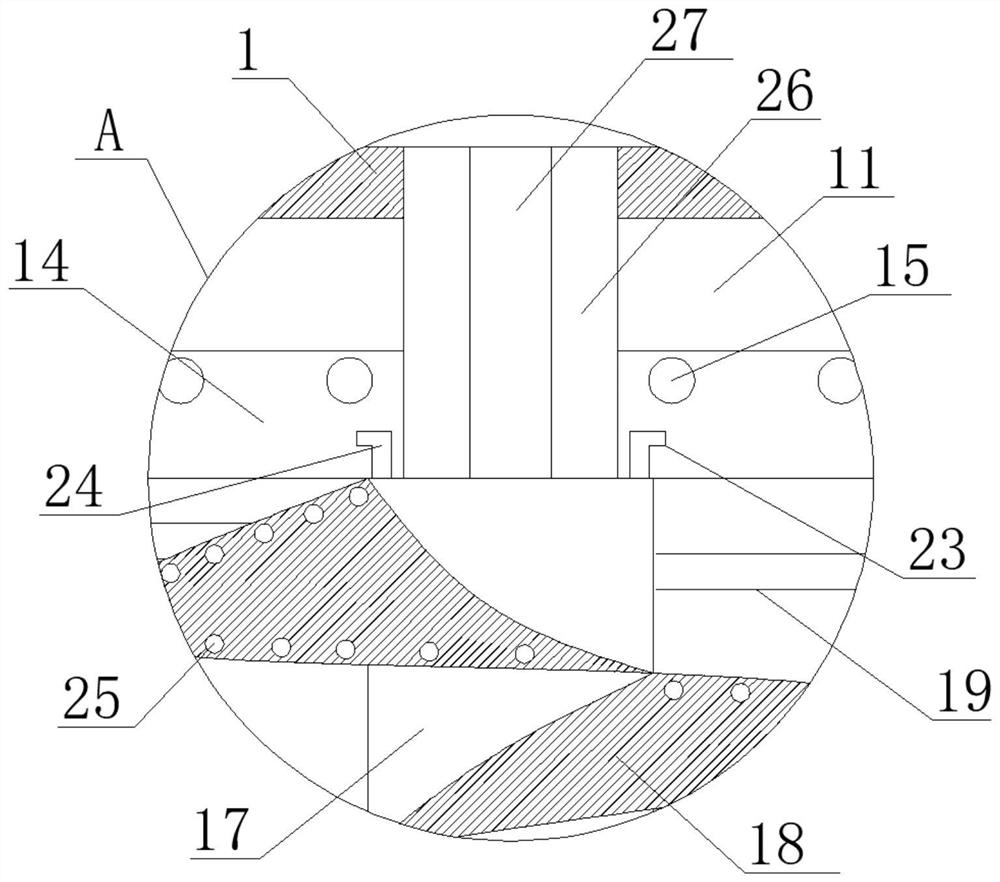

[0027] see Figure 1-2, in an embodiment of the present invention, a PVC pipe production raw material hot-melt feeding equipment, including a main support plate 1, the bottom surface of the main support plate 1 is welded vertically downward with an extension pole 2, and the bottom end of the extension pole 2 is vertical Bottom cover rods 3 are socketed, and the bottom surface of bottom cover rods 3 is horizontally fixedly bonded with rubber pads 4, and the number of extending vertical rods 2 is four, and the four extending vertical rods 2 are arranged in parallel with each other. The top of the root extension pole 2 is fixed vertically upward on the four corners of the bottom surface of the main support plate 1, and the number of the bottom sleeve poles 3 is kept consistent with the number of the extension poles 2, and they are set in one-to-one correspondence with each other. The rubber backing plate 4 is made of hard rubber material, and the top surface of the main support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com