Efficient essential oil extraction production equipment

A technology for essential oil extraction and production equipment, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of reduced product availability, waste of resources, waste of raw materials, etc., and achieves improved efficiency and quality, improved work efficiency, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

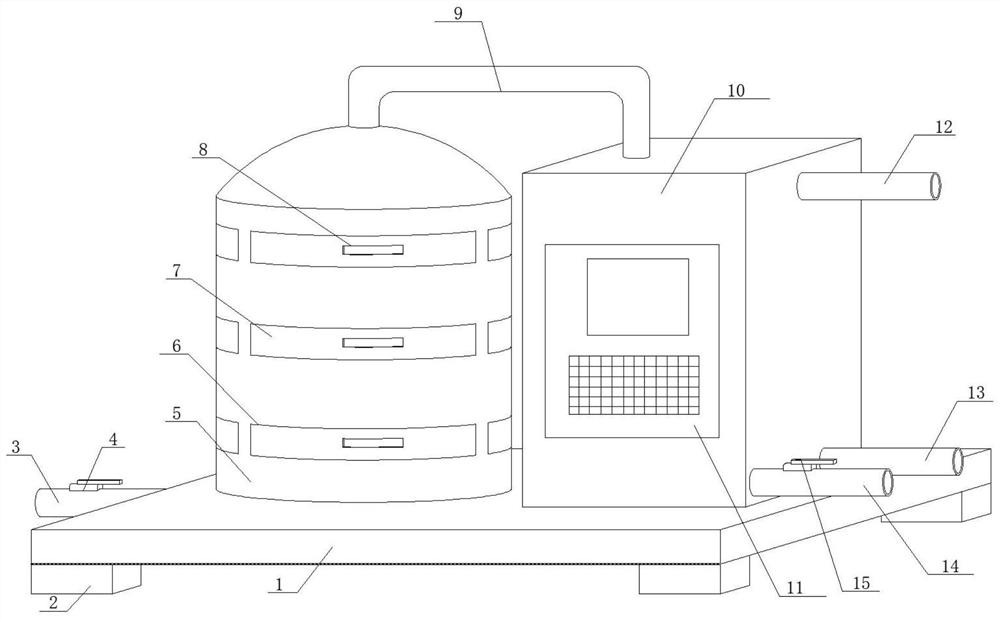

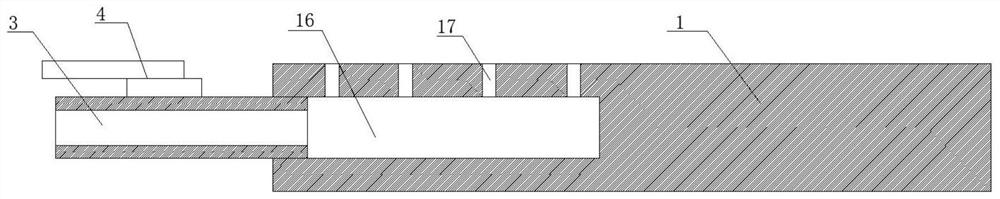

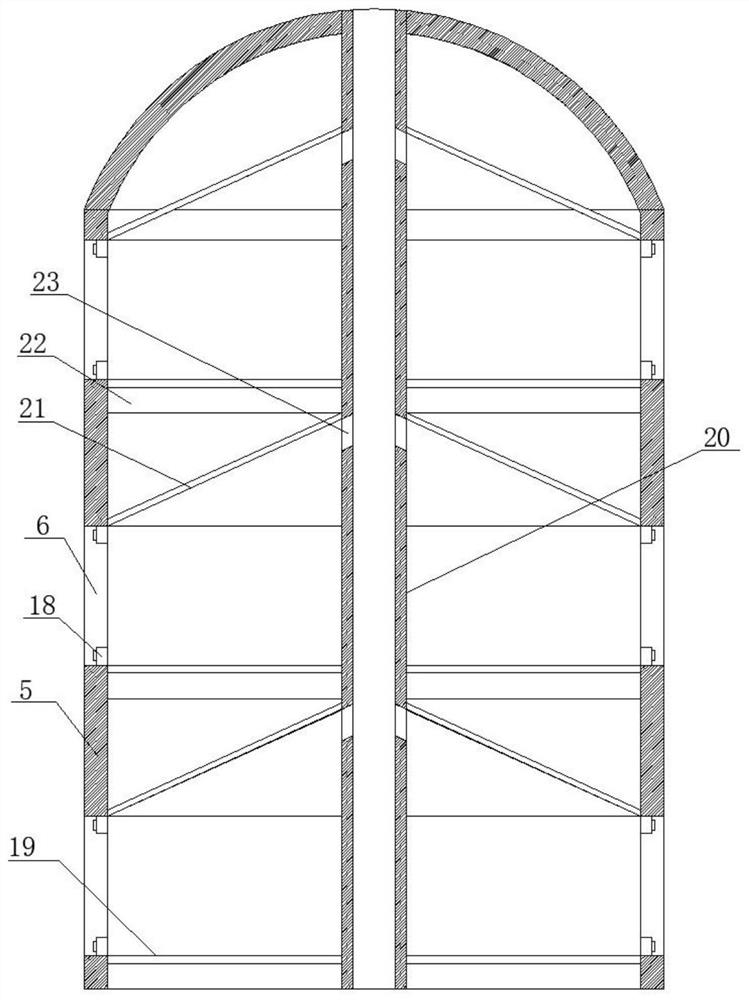

[0028] see Figure 1-2 , in an embodiment of the present invention, a high-efficiency essential oil extraction production equipment includes a supporting bottom pallet 1, a bottom supporting block 2 is fixedly welded on the bottom surface of the supporting bottom pallet 1, and one side of the bottom supporting block 2 is horizontally threaded. The steam inlet pipe 3 is connected with a steam valve 4 by bolts on the outer side of the steam inlet pipe 3, and the number of bottom support blocks 2 is several, and a plurality of bottom support blocks 2 are all fixedly arranged on the bottom surface of the support bottom supporting plate 1 close to At the edge position, one end of the steam inlet pipe 3 is threadedly connected to the inner side of the opening end of the main steam passage 16, and the inside of the steam inlet pipe 3 is kept connected with the inside of the main steam passage 16, and the steam inlet pipe 3 Vertically arranged at the center of one side of the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com