Injection molding machine with automatic monitoring and automatic processing system

An automatic monitoring and processing system technology, applied in the field of injection molding machines, can solve the problems of wasting manpower and material resources, reducing work efficiency, reducing production needs, and unfavorable industrial development, etc., and achieves the effects of easy observation, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

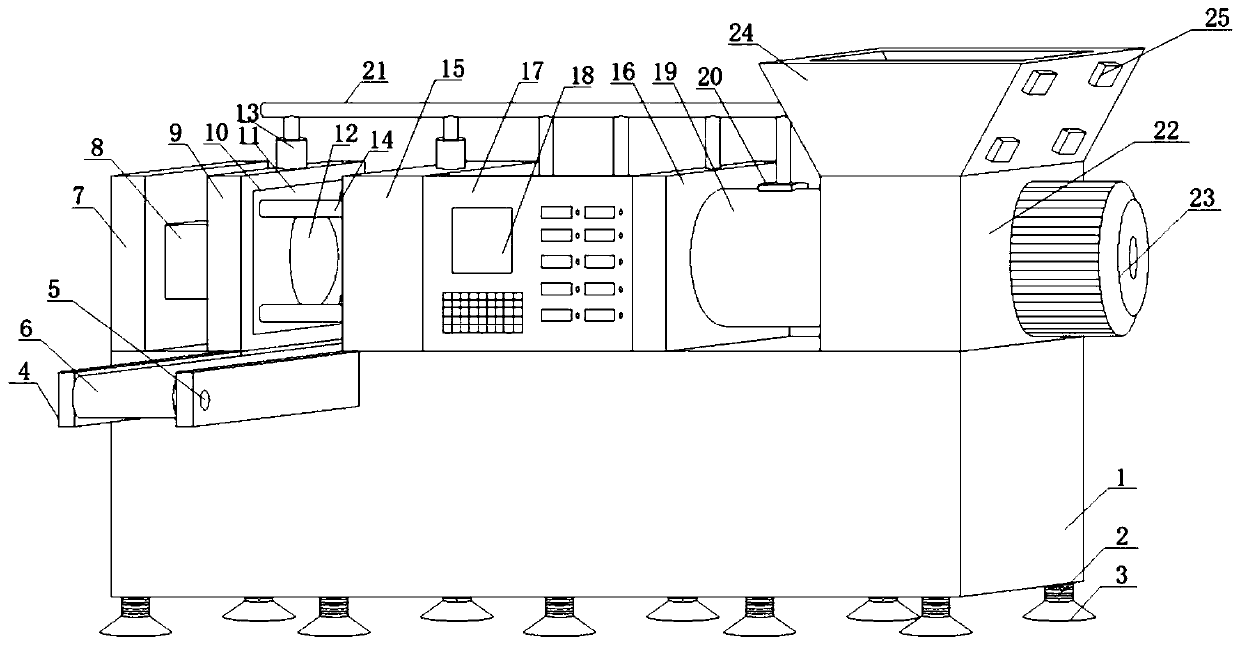

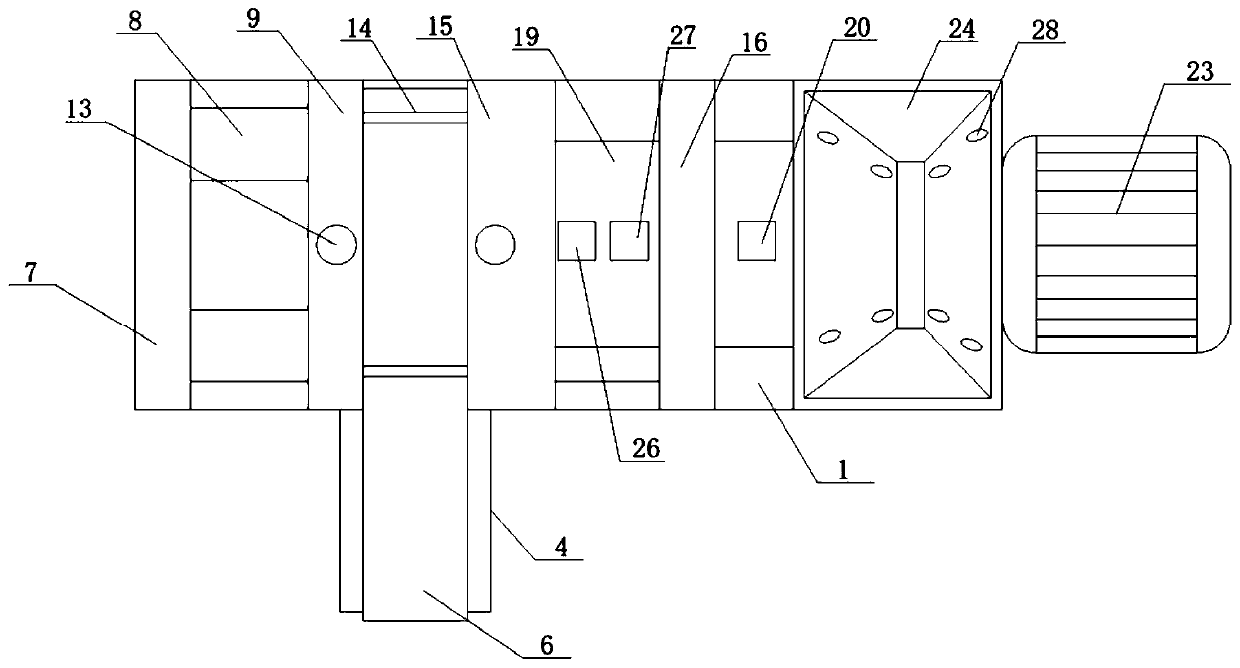

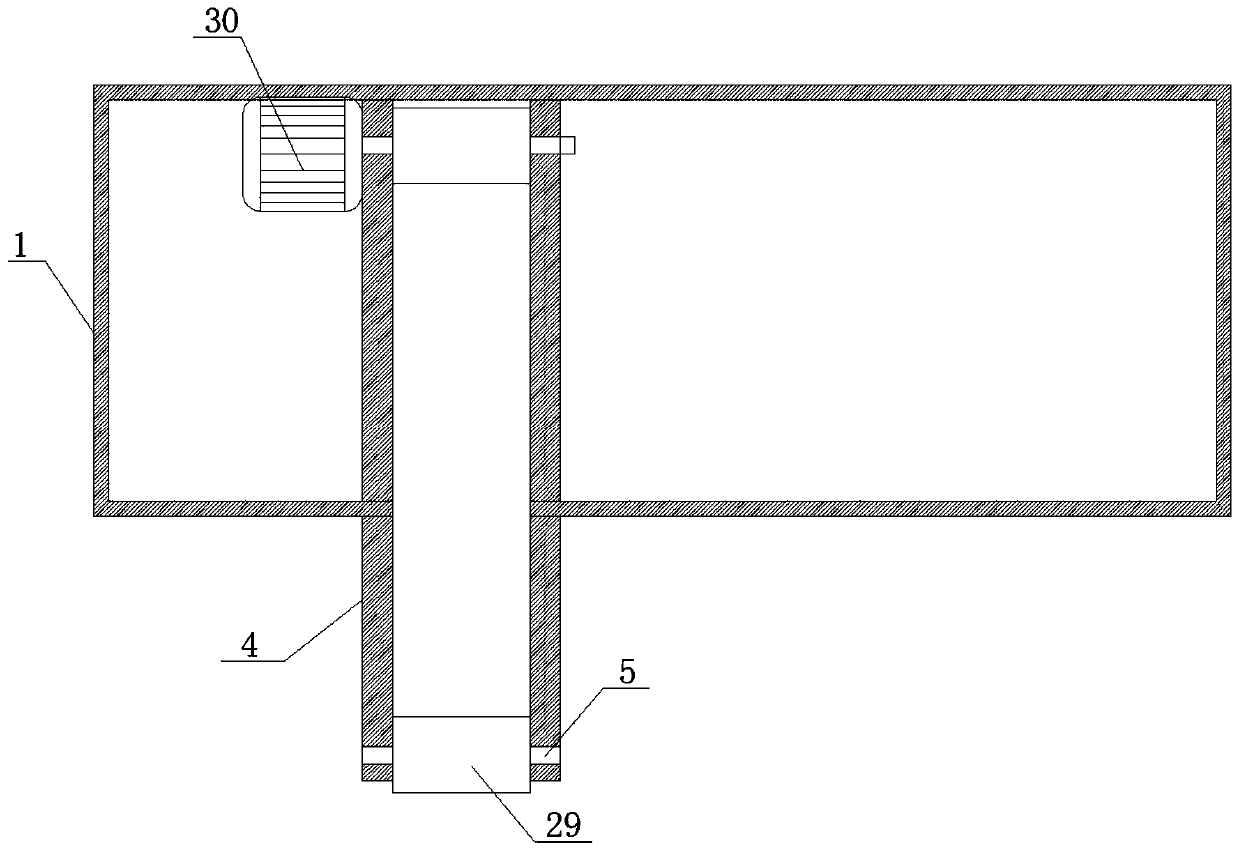

[0028] see Figure 1-2 , in an embodiment of the present invention, an injection molding machine with automatic monitoring and an automatic processing system, including a support bottom box 1, the bottom surface of the support bottom box 1 is vertically threaded with a support screw 2, and the bottom end of the support screw 2 is fixedly socketed There are support pads 3, the number of support screws 2 is several, and a plurality of support screws 2 are arranged in parallel with each other on the bottom surface of the support bottom box 1 near the edge position, the number of support pads 3 is the same as the number of support screws 2 The number is consistent, and a plurality of support pads 3 are made of hard rubber material. One side of the support bottom box 1 is horizontally welded with an extended side plate 4. The number of extended side plates 4 is two, and the two extended side plates The plates 4 are arranged parallel to each other on the side of the supporting botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com