Material packing and material put-in method adopting the material packing

A material and packaging technology, which is applied in the field of material packaging and material delivery using this material packaging, can solve problems such as hot oil and soup splashing, complex opening structure, and poor feeding effect, and achieve accurate feeding timing and simple and convenient operation , the effect of simple structure and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

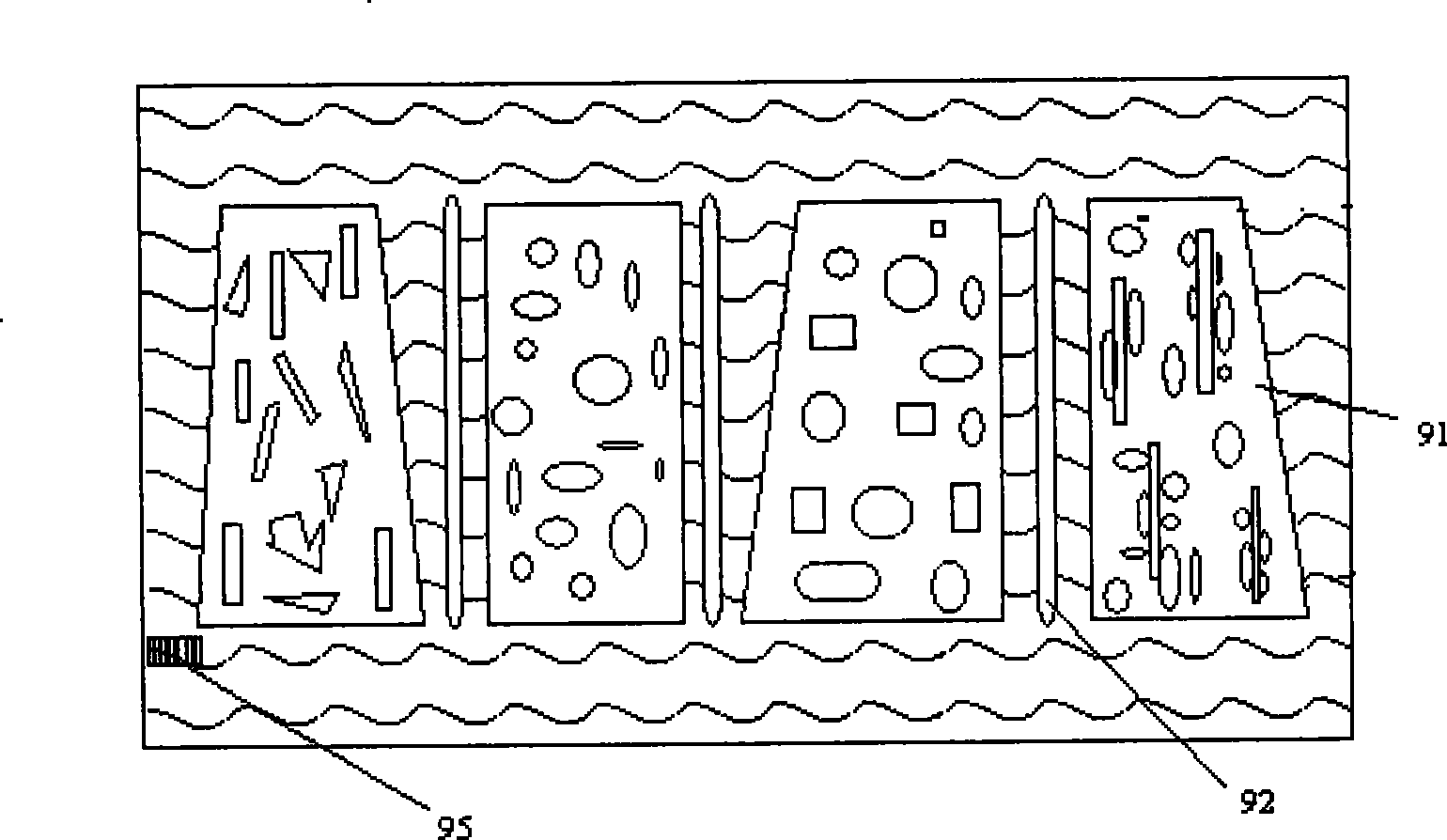

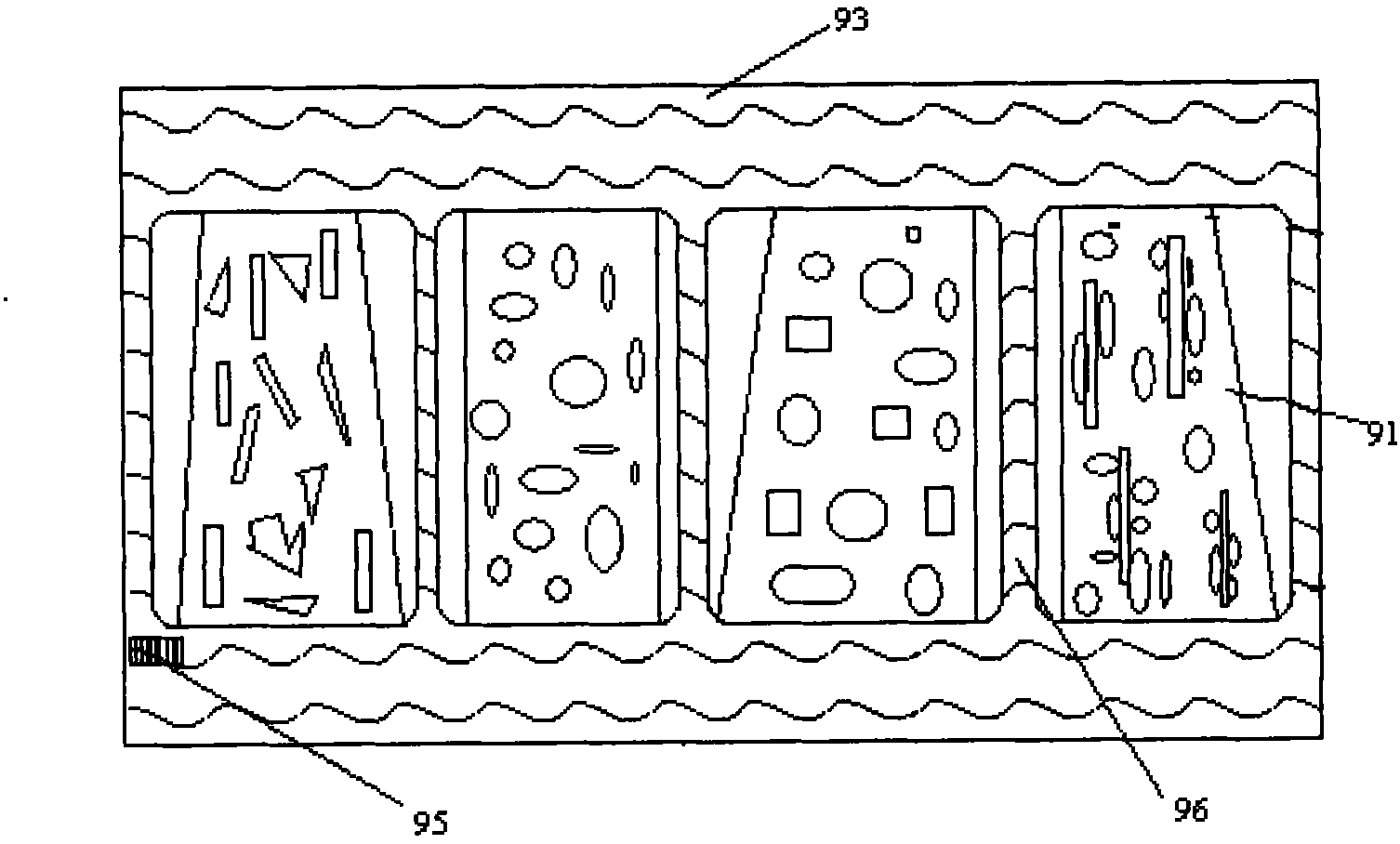

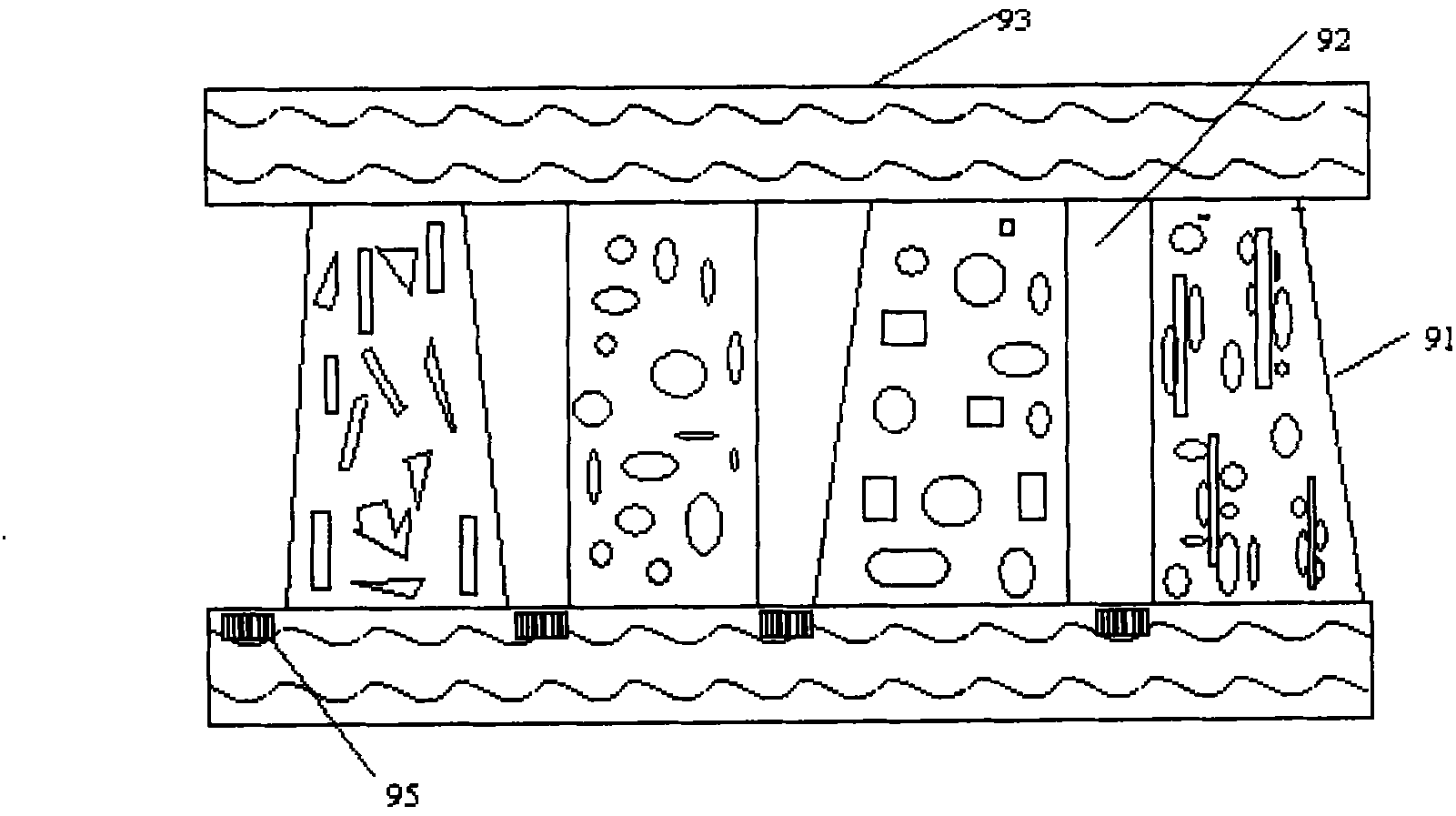

[0038] figure 1 and figure 2 Shown is a kind of automatic cooking machine that adopts the material delivery method and material packaging of the present invention. Among them, 24 is the pot body; 25 is the pot cover, which is installed on the moving device and can be opened and closed automatically; 16 is the combustion head; 15 is the gas flow automatic adjustment device; 4, 5, 6, 8, 11 form an automatic turning system; 9 It is material packing, is fixed on the material packing fixing device 12, and motor 10 and screw rod 7 are the driving device of material feeding system; 14 is gas pressure sensor, and 29 is ambient temperature sensor; 17-22 forms lubricating oil system; 1, 2, 3 and 23 are cooking oil recovery and delivery system; 26 is a range hood, 27 is a display, 28 is a computer control system, and 30 is a frame.

[0039] Figure 4 Shown is to realize a kind of material feeding device of the present invention. A barcode scanner is installed on the material packagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com