Automatic incineration disposal system

A technology of treatment system and incinerator, applied in the field of automatic incineration treatment system, can solve the problems of complicated structure, high equipment cost and short service life of post-installed waste gas treatment device, so as to improve operation efficiency, good effect and reduce equipment corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

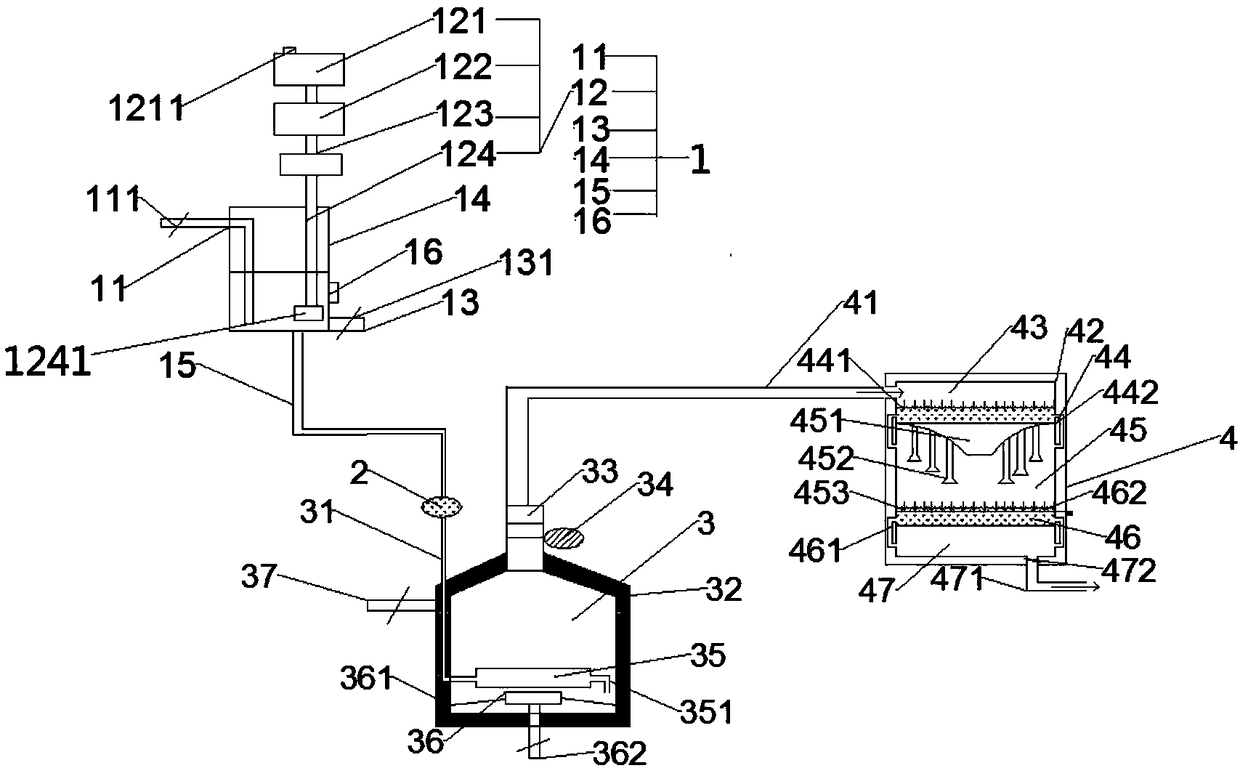

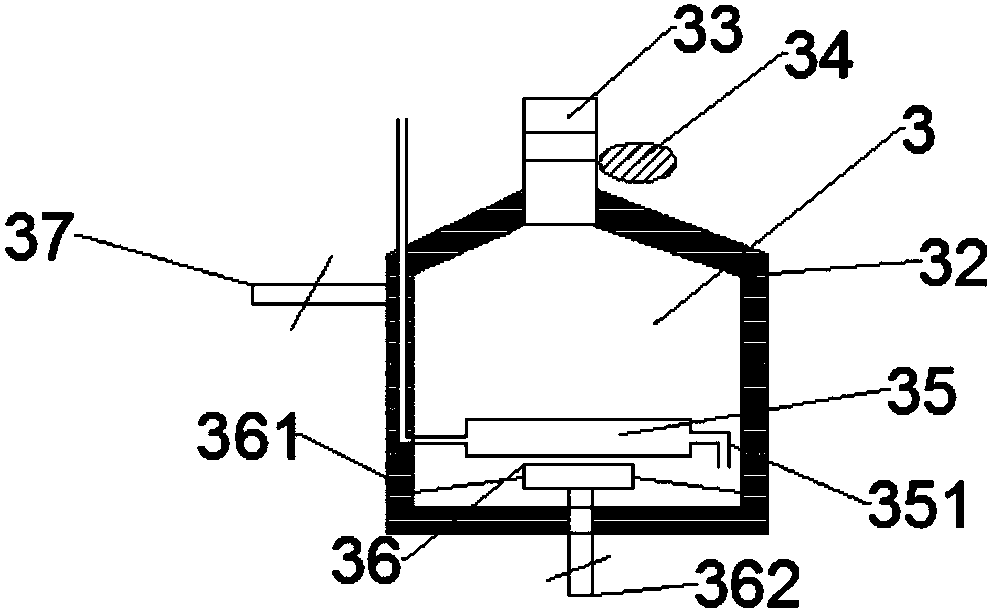

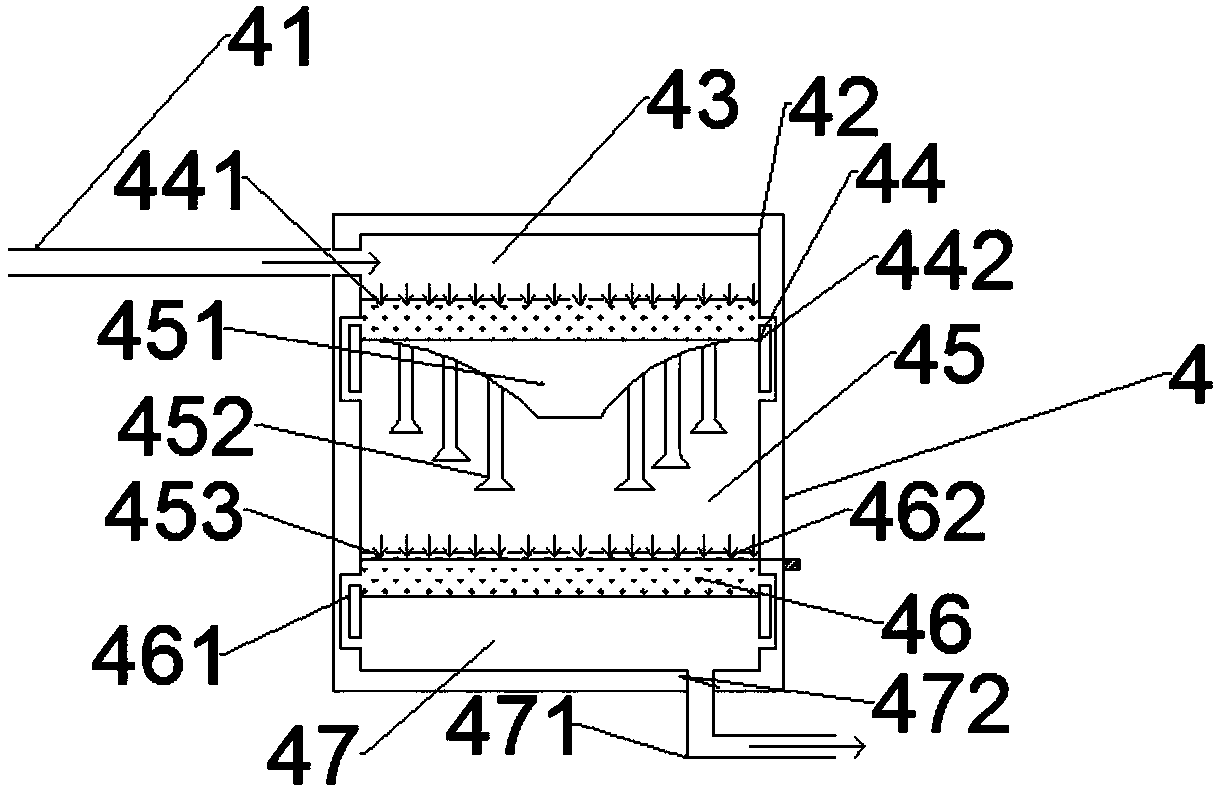

[0029] see Figure 1-Figure 4 As shown, the present invention discloses an automatic incineration treatment system, which is an integrated device, including a pre-chlorination device 1, a dry filtration system 2, an incineration device 3, a tail gas treatment device 4 and a PLC control system 5;

[0030] The pre-chlorination device 1 includes a liquid storage tank 14, an organic waste gas inlet pipe 11, an automatic dosing device 12, a waste liquid outlet 13, and a first organic waste gas outlet pipe 15; the automatic dosing device 12 includes a liquid medicine Metering system 121, solution preparation system 122, metering dosing system 123 and dosing pipeline 124; in order to strengthen the dechlorination and mixing effect of the medicine liquid, the organic waste gas inlet pipeline 11 is provided with a first valve 111, and the bottom end It extends below the liquid level in the liquid storage tank 14 ; the bottom end of the dosing pipeline 124 is provided with a stirring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com