Singl-leaf revolving double-curve crown-strip ring and its process thereof

A hyperboloid, crown band technology, applied to contact parts and other directions, can solve the problems of uniform enveloping of wire springs, increased cost, complex processing technology, etc., to achieve stable dynamic contact resistance, easy management and production, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

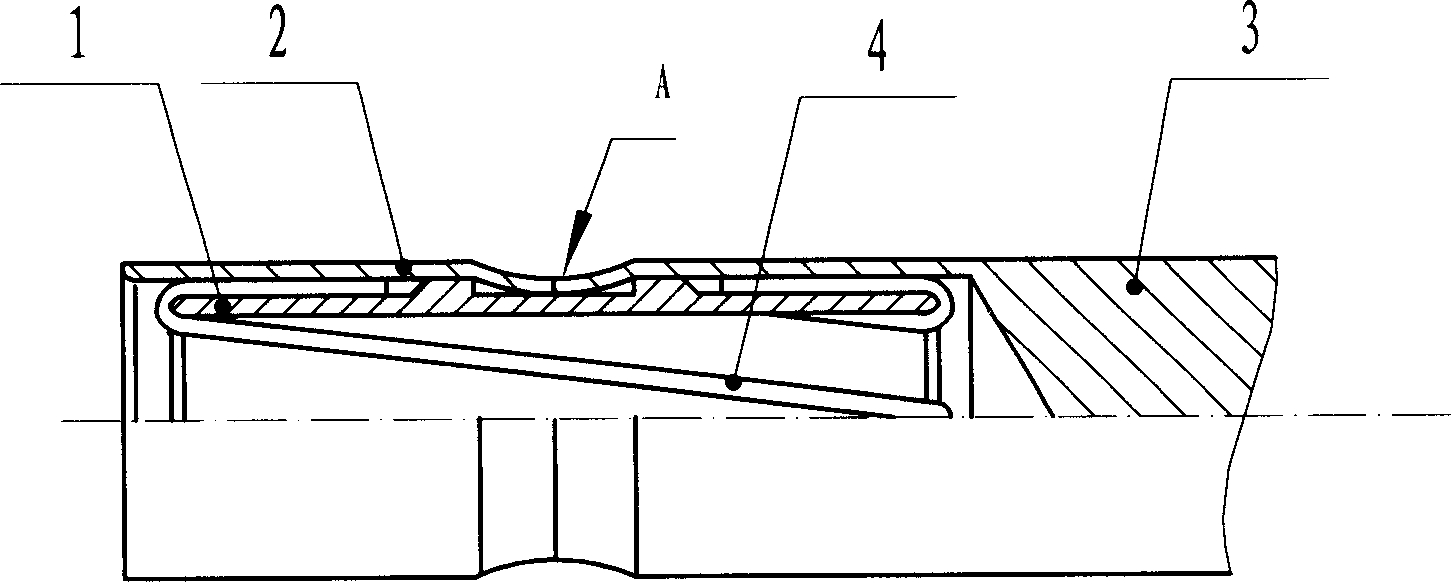

[0030] figure 1 The structure of the traditional wire spring jack contact shown includes: an inner sleeve (1), an elastic wire (4), a front sleeve (2), and a rear sleeve (3). The inner sleeve (1) is equipped with a group of elastic metal wires (4) arranged in a single-leaf rotary hyperboloid, the two ends of which are respectively clamped by the front sleeve (2) and the rear sleeve (3), and the front sleeve (2) and the rear sleeve (3) The sleeve (3) is connected into one body through crimping (at A) to form an outer jacket, thereby forming a traditional single-leaf rotary hyperboloid wire spring socket contact.

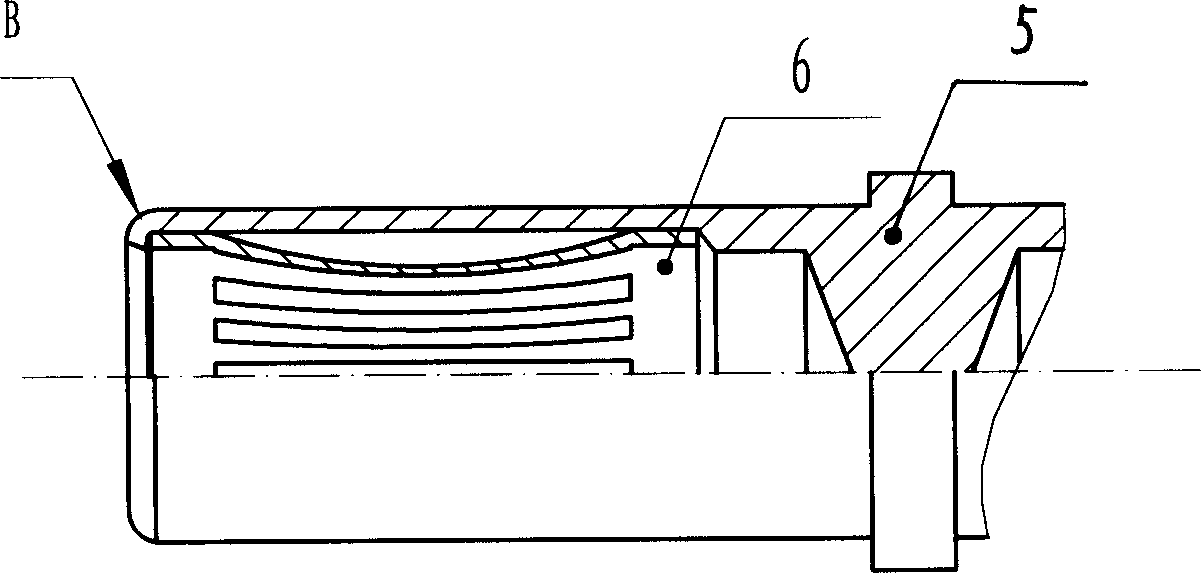

[0031] figure 2 The crown band socket contact piece shown is coaxially equipped with a crown band ring (6) inside the outer sleeve (5), and the port closes to its axis (at B) so that the crown band ring (6) cannot come out .

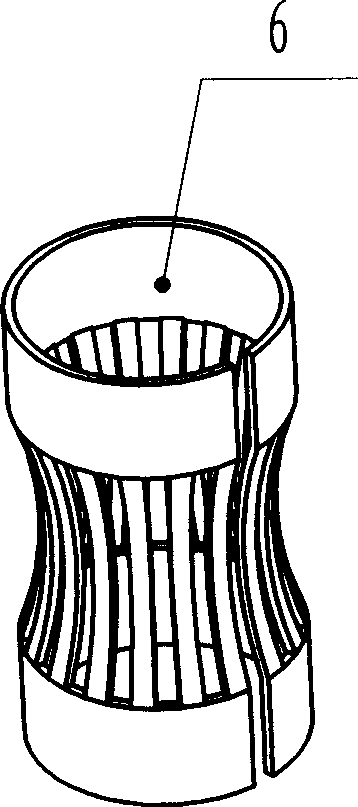

[0032] image 3 Shown is the axonometric view of the existing crown ring. The elastic metal sheet is stamped and divided into a fence shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com