Coring drill and coring machine suitable for asphalt pavement

A technology of asphalt pavement and core drilling, which is applied in the direction of sampling devices, etc., can solve the problems of inability to injure personnel, troublesome maintenance, unstable center of gravity, etc., and achieve the effect of fast and convenient transportation, easy and efficient installation and replacement, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

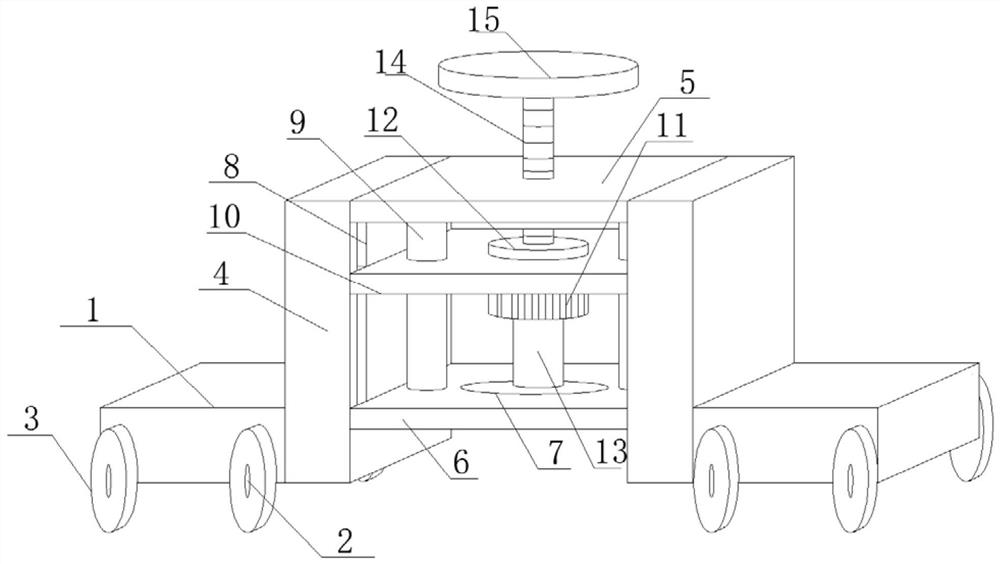

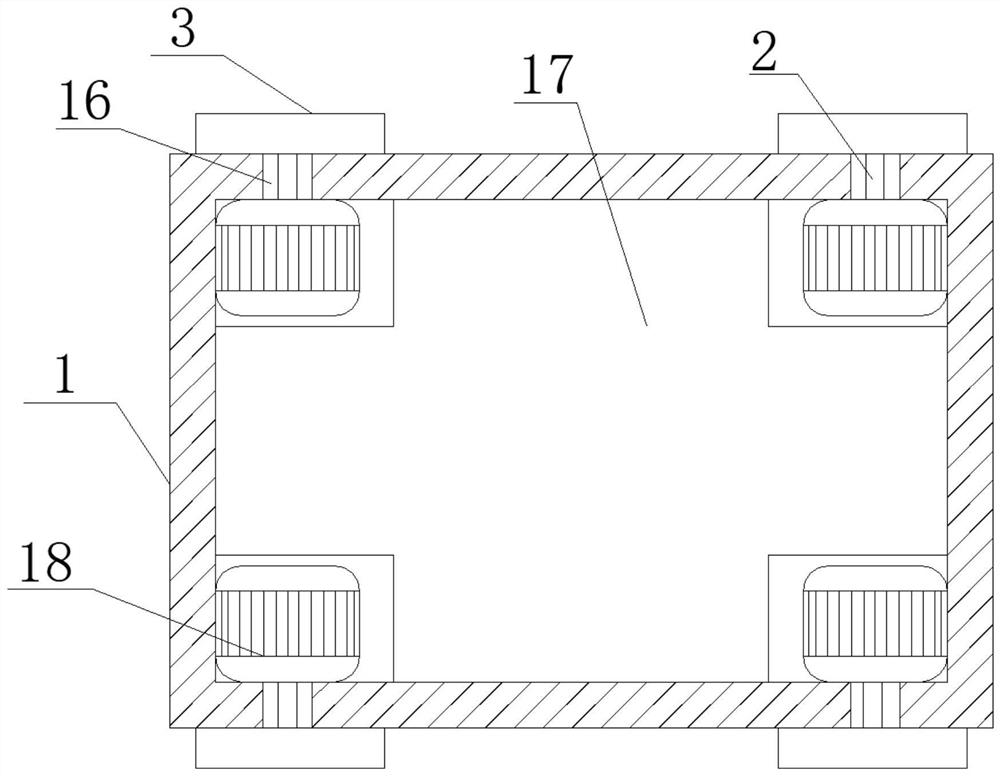

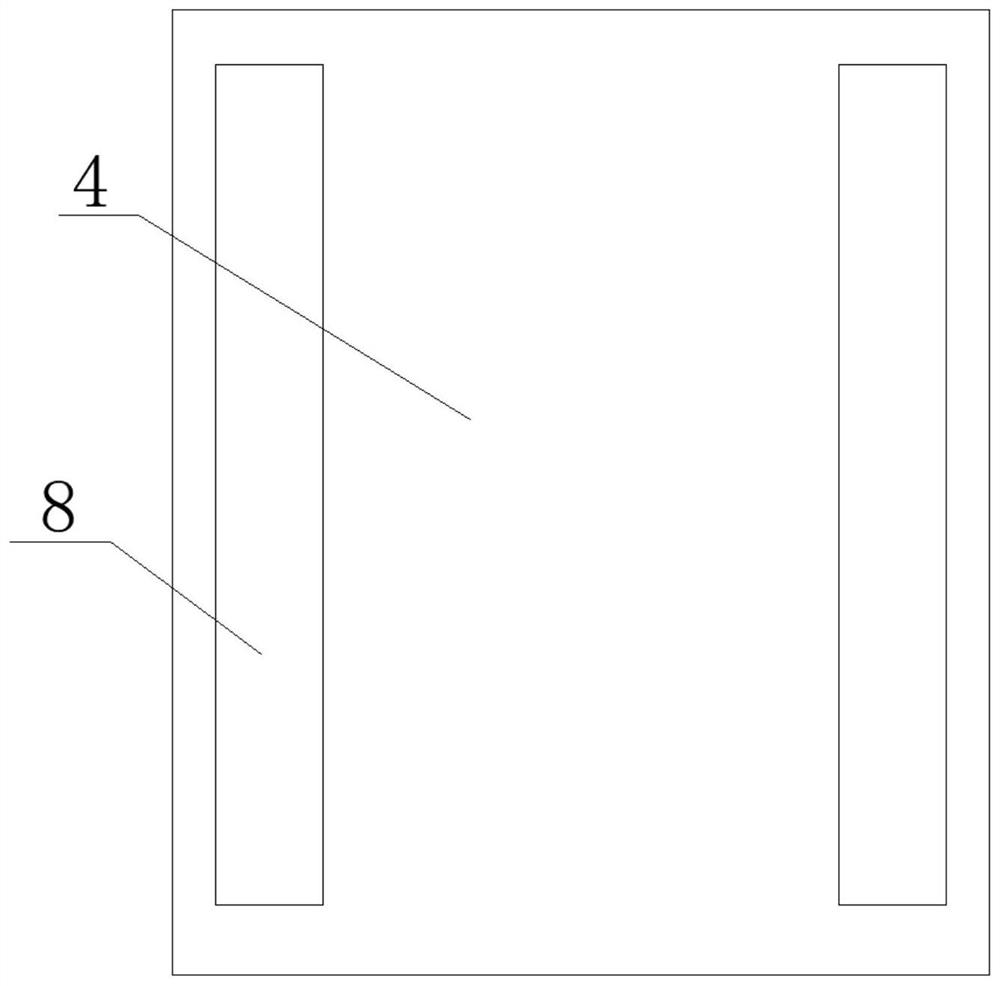

[0028] see Figure 1-3, in an embodiment of the present invention, a coring drill and a coring machine suitable for asphalt pavement, including a fixed bottom box 1, drive shafts 2 are inserted symmetrically on both sides of the fixed bottom box 1, and the fixed bottom box 1 The number is two, and the two fixed bottom boxes 1 are arranged symmetrically and horizontally with each other. The number of transmission shafts 2 is eight, and the eight transmission shafts 2 are arranged symmetrically in groups of four on the fixed bottom. The two sides of the box 1 are close to the corners, and the plug-in ends of the eight transmission shafts 2 are horizontally welded to the output end of the transmission motor 18. The outer sides of the transmission shafts 2 are fixedly sleeved with rolling wheel bodies 3, fixed The sides of the bottom box 1 are vertically welded with support side plates 4, the sides between the support side plates 4 are horizontally welded with fixed top plates 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com