Fast snapping zipper and its elements

A zipper and stable technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problems of poor occlusal stability, disengagement of the teeth, poor occlusal stability, etc., to improve the occlusal stability and small radius , easy to bend outwards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

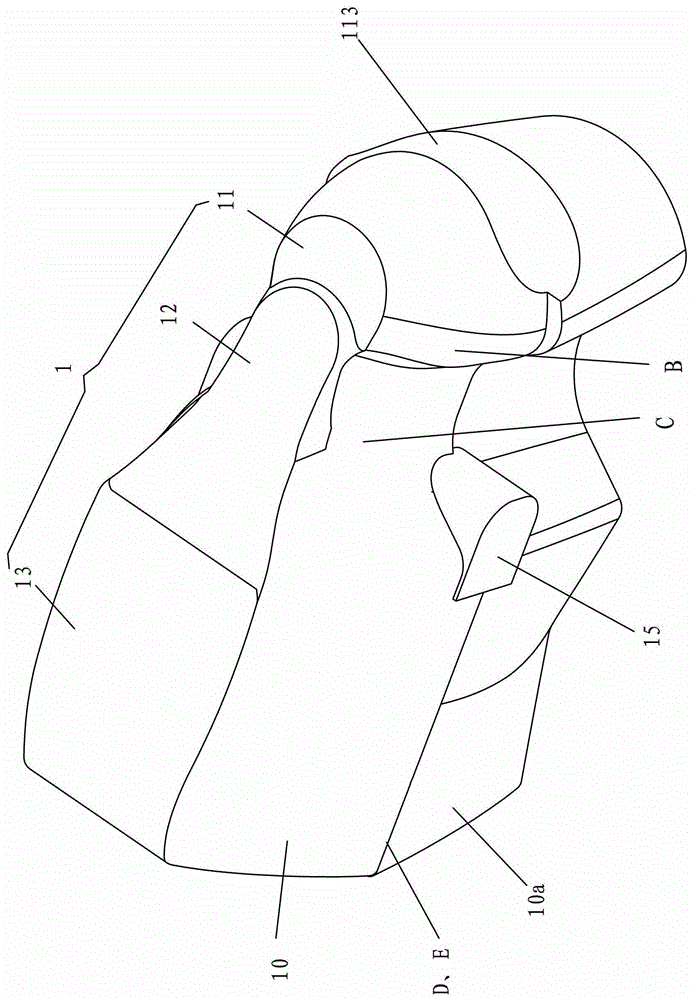

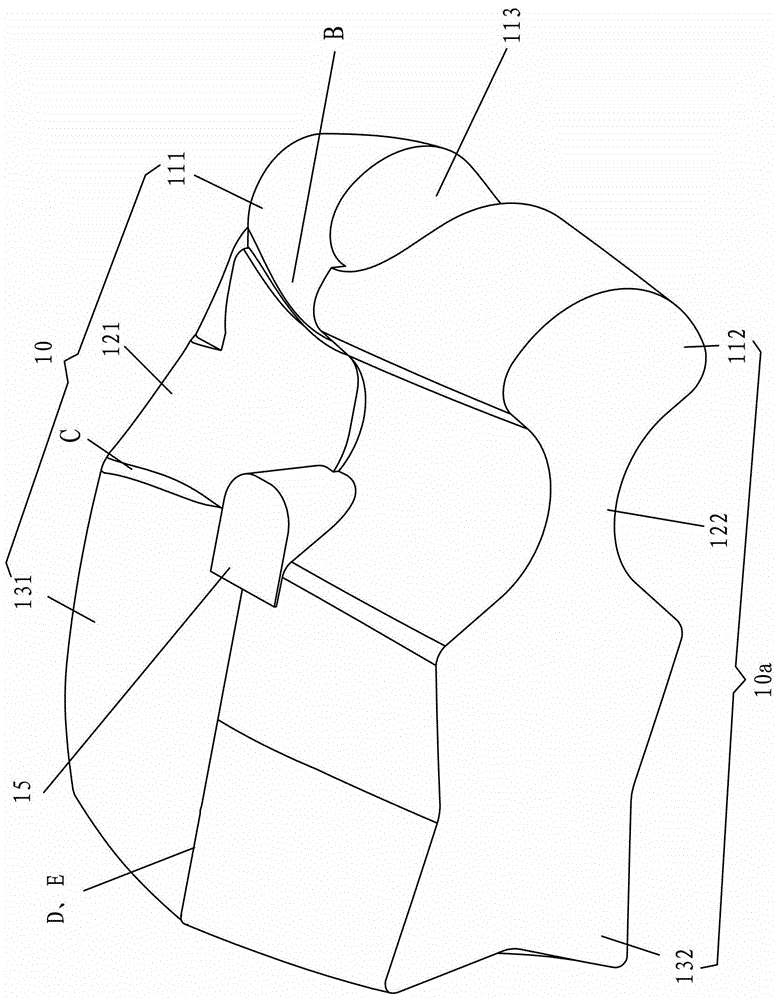

[0054] Taking the curved surface connecting the top surface of the outer tooth head 111 and the top surface of the inner tooth head 112 as the side, when the outer tooth head 111 shrinks from the inside to the outside, the above-mentioned side of the outer tooth head 111 forms an inwardly curved head arc surface B, Inward bending means bending towards the center of the outer tooth head 111, and the inner bending radius of the head arc surface B is about 1.4-2.5mm, such as Figure 11 , 12 shown. When the zipper is pulled and bent outward, since the outer tooth head 111 shrinks sharply from the inside to the outside, the arc surface B of the head is inwardly curved, that is, it bends toward the center of the outer tooth head 111, thereby forming a certain space for concession, which will not The contact against the chain elements will not produce interference force that will disengage the engaged chain elements, thereby improving the stability of the bite of the zipper in the o...

Embodiment 2

[0060] The outer teeth 10 have a symmetrical shape, and the inner teeth 10a also have a symmetrical shape, which is convenient for manufacturing and molding.

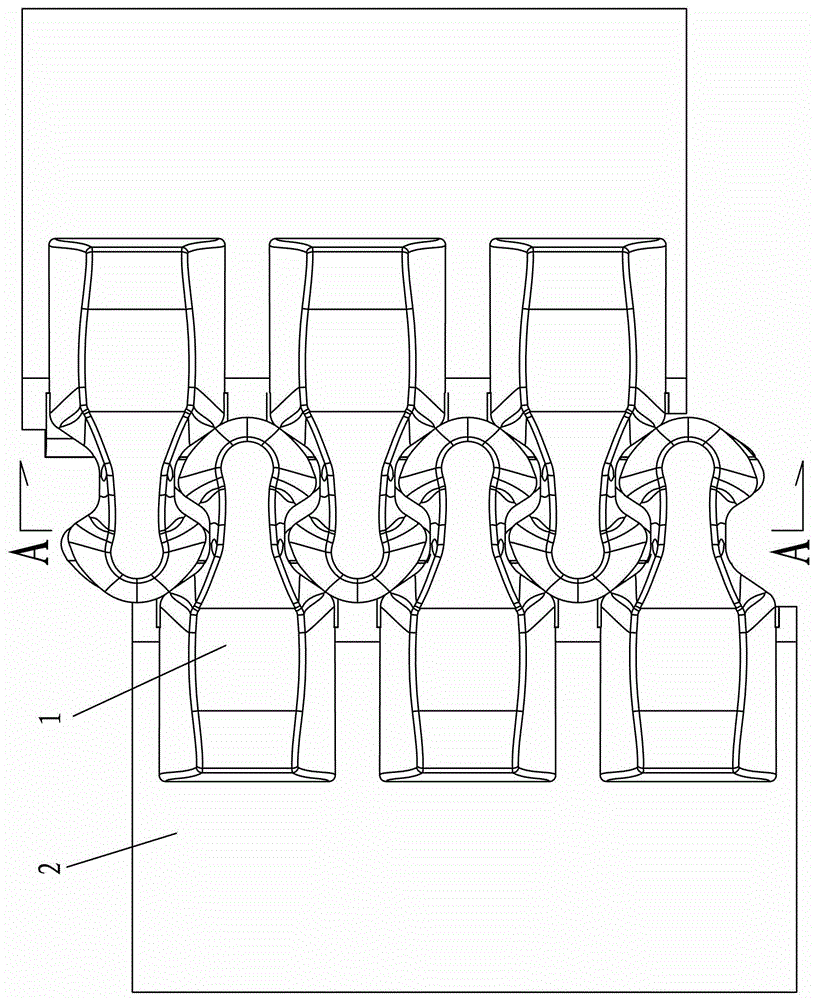

[0061] In addition, the outer teeth 10 and the inner teeth 10a are mutually symmetrical structures. When the zipper is in the engaged state, along the figure 1 The sectional view of the A-A direction shown in Figure 9 shown. Since the outer teeth 10 and the inner teeth 10a are symmetrical to each other, it is convenient to manufacture and shape. The outer teeth 10 and the inner teeth 10a are mutually asymmetrical structures, when the zipper is in the engaged state along the figure 1 The sectional view of the A-A direction shown in Figure 10 shown.

Embodiment 3

[0063] The tooth head 11 is convex, the tooth neck 12 is concave, and the tooth tail 13 gradually shrinks toward its tail. Under the condition that the shape of the outer tooth 10 remains unchanged, the shape of the inner tooth head 112 of the inner tooth 10a is the same as that of the outer tooth head 111, and the inner tooth tail 132 can be elliptical, concave in the middle, or polygonal in convex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com