Fixing device for electrode batch processing

A fixed device, batch processing technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor product consistency, waste of a lot of man-hours, single electrode processing method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

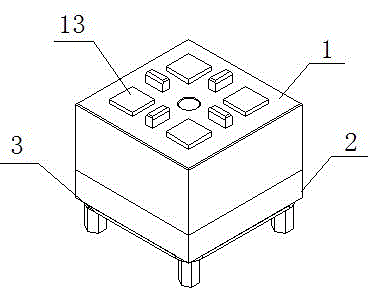

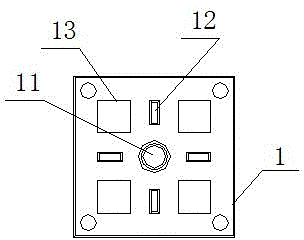

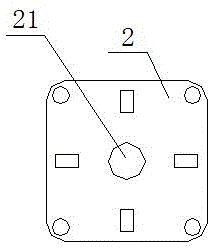

[0011] As shown in the figure, a fixing device for batch processing electrodes, which includes a fixture plate 1, a backing plate 2, and a positioning block 3, the backing plate 2 is fixed under the fixture plate 1 with screws, and the positioning block 3 is fixed with screws Under the backing plate 2, the center of the jig plate 1 is provided with a screw hole 11, two groups of rectangular bosses 12 are symmetrically distributed around the screw hole 11, and two groups of square bosses 13 are symmetrically distributed between the rectangular bosses 12, and the backing plate 2 The center is provided with a screw through hole 21 . Steps are provided on the opposite inner sides of the rectangular boss 12 and the square boss 13 .

[0012] When in use, the bottom of the electrode 4 is first milled out to match the grooves of the shape of the rectangular boss 12 and the sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com