Novel workpiece clamping device

A workpiece holder and a new type of technology, applied in the direction of grinding workpiece supports, etc., can solve problems such as affecting machining accuracy and machining efficiency, grinding texture, and inability to effectively utilize the usable area of the grinding head, so as to improve the effective utilization rate and improve the The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

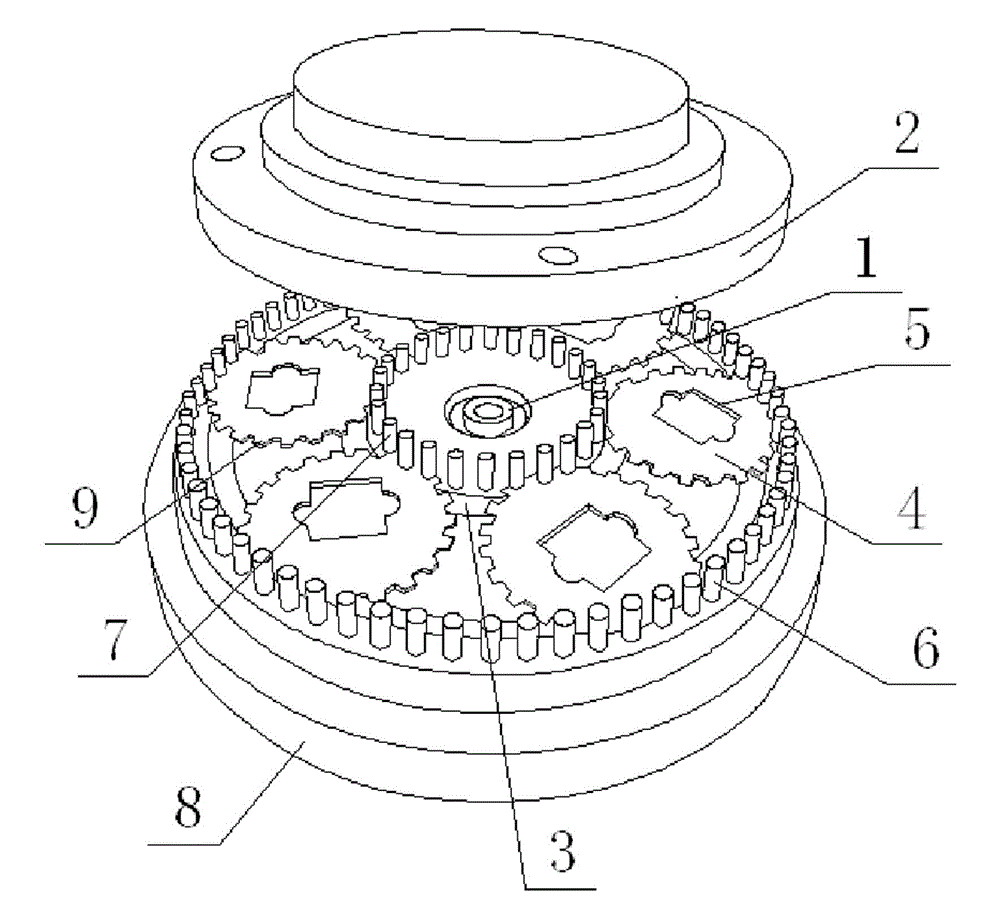

[0015] Such as figure 1 As shown, a new type of workpiece clamping device is mainly composed of a main shaft 1, an upper grinding wheel 2, a lower grinding wheel 3, a fixed ring 8 and a plurality of workpiece clamping wheels 4. The keyway, the main shaft 1 is set in the middle of the lower grinding wheel 3, the middle of the workpiece holding wheel 4 is provided with a clamping groove 5 for clamping the workpiece, the lower grinding wheel 3 is set in the fixed ring 8 and coaxial with the fixed ring 8 , the upper grinding wheel 2 is arranged directly above the fixed ring 8 and opposite to the lower grinding wheel 3, the lower grinding wheel 3 meshes with six workpiece holding wheels 4, the axes of each workpiece holding wheel 4 are evenly distributed along the circumference, and multiple workpieces The clamping wheel 4 is engaged with the lower grinding wheel 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com