Variable-spacing picking and placing device

A pick-and-place device and variable pitch technology, applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of low reliability of consistent action, easy aging of gas circuit components, high environmental requirements, etc., and achieve low cost and low occupation. Less space and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

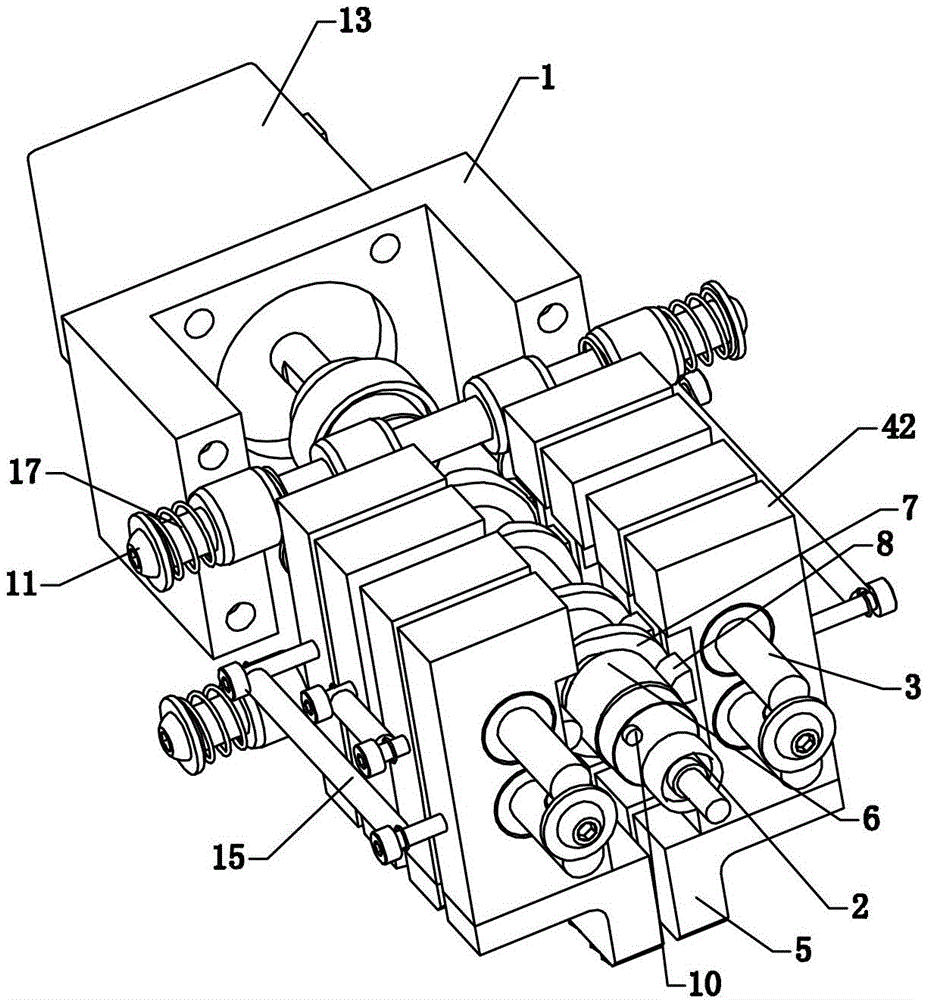

[0033] Such as figure 1 As shown, the variable-pitch pick-and-place device includes a frame 1. A camshaft 2 driven by a power device is rotatably installed on the frame 1, and two clamping jaw seat mounting shafts parallel to the camshaft 2 are provided on both sides of the camshaft 2 3. Each clamping jaw seat mounting shaft 3 is equipped with two clamping jaw seats 4, the clamping jaw seats 4 on the two clamping jaw seat mounting shafts 3 are arranged in pairs, and the pair of two clamping jaw seats 4 constitute a clamp Claw seat group, such as Figure 5 As shown, each clamping jaw base 4 is equipped with a clamping jaw unit 5, two clamping jaw units 5 on each clamping jaw base group constitute a pair of clamping jaws, and the camshaft 2 is fixedly installed for each A plate cam 6 that opens and closes between the two gripper seats 4 of a gripper seat group and an end cam 7 for separating and closing each gripper seat group and group along the axial direction of the camshaft, ...

Embodiment 2

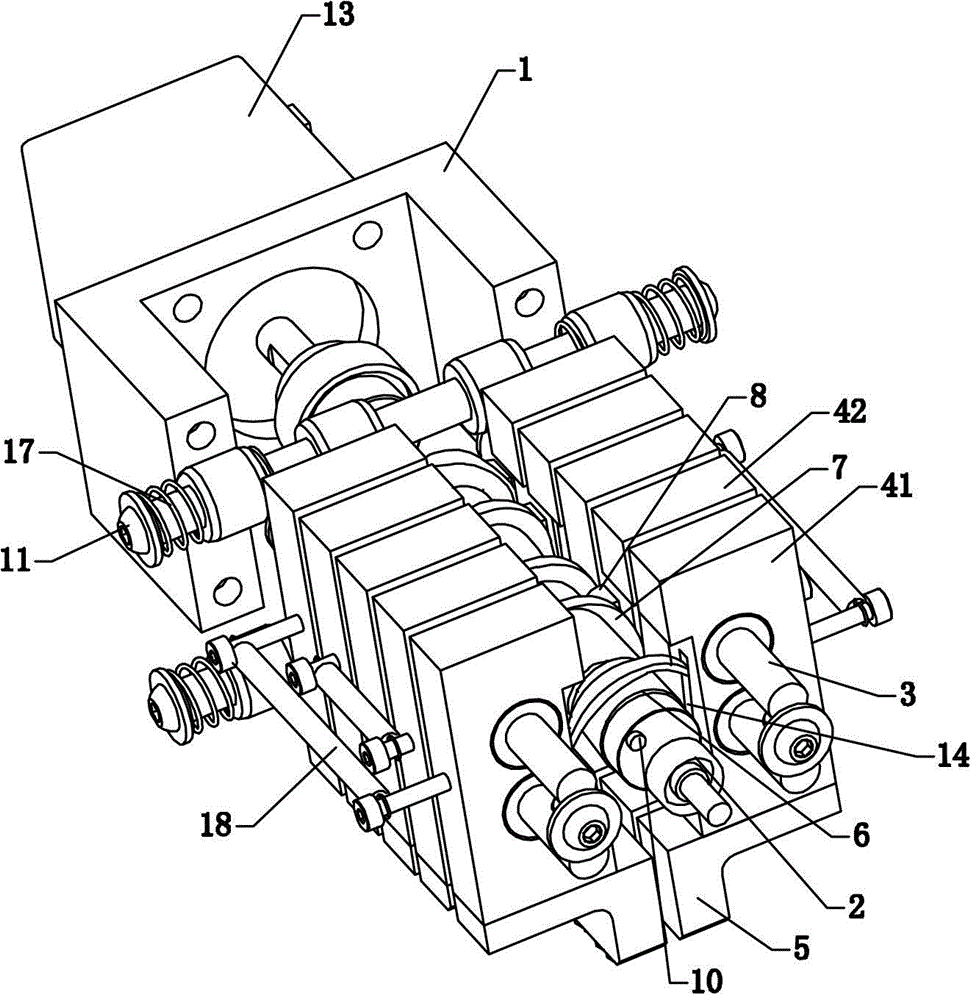

[0041] Such as figure 2 As shown, a variable-pitch pick-and-place device has basically the same structure as the first embodiment. The difference is that the clamping jaw holder group includes a fixed jaw holder group and a plurality of movable jaw holder groups, and several movable jaw holders The seat set is arranged on the same side of the fixed jaw seat set, and the fixed jaw seat set is limited along the axial direction of the camshaft 2. The fixed jaw seat 41 is provided with a limiting slot 14, and the plate cam 6 is restrained and installed in the limiting slot 14 Inside, an end face cam is provided between the two movable jaw seats 42 of each movable jaw seat group, and the two movable jaw seats 42 of each movable jaw seat group are provided with flanges that abut the end face cams In this embodiment, the fixed jaw seat 41 only opens and closes, and no displacement occurs in the axial direction. The movable jaw seat 42 opens and closes and also produces displacement in...

Embodiment 3

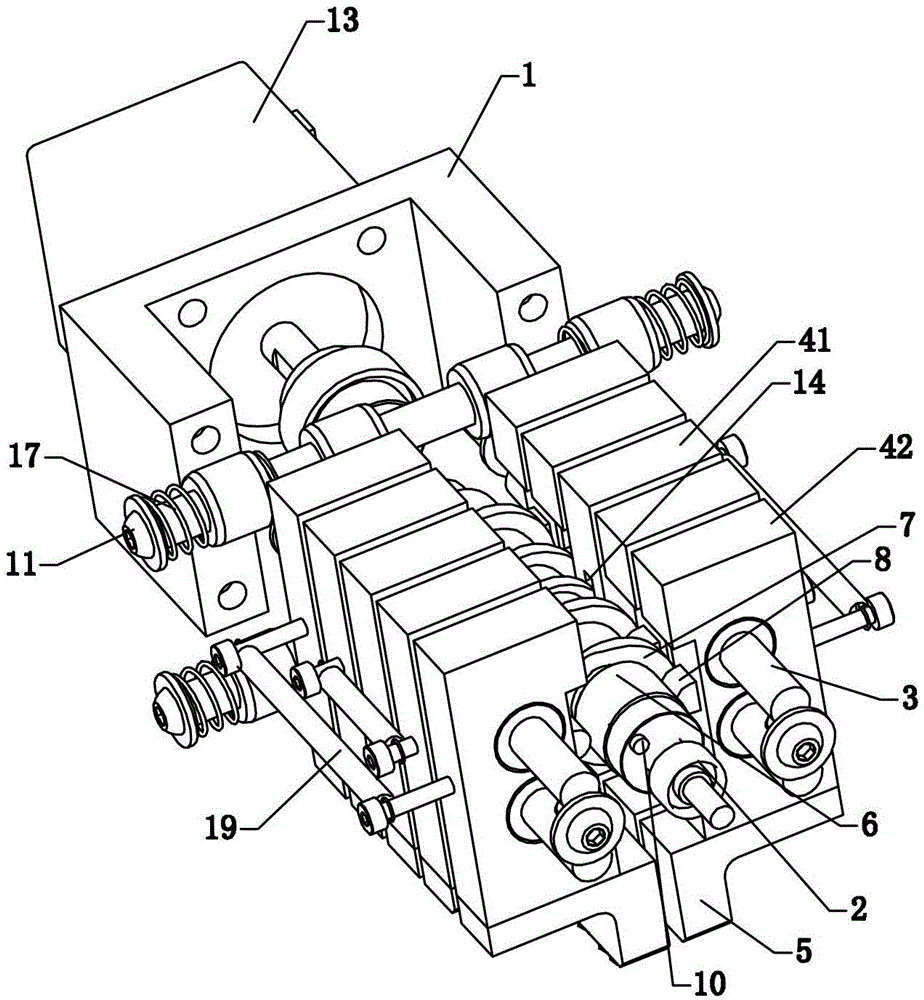

[0043] Such as image 3 , Figure 4 with Figure 5 Shown together, a variable pitch pick-and-place device, its structure is basically the same as the second embodiment, the difference is that as a preferred structure instead of sliding sleeve, the two clamping jaw seat mounting shafts 3 are respectively mounted on a sliding seat 16, at this time, the first reset mechanism is arranged between the two sliding seats 16, each sliding seat 16 is provided with a clamping jaw seat installation cavity, the clamping jaw seat mounting shaft 3 passes through the clamping jaw seat installation cavity, and the fixing clip The jaw seat 41 and several movable jaw seats 42 are installed in the installation cavity of the jaw seat. Based on the above structure, the first reset mechanism includes a spring limit post 11 installed on the frame 1, and two sliding seats 16 are slidably installed on the spring On the limit post 11, a second compression spring 17 is provided between each sliding seat 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com