Fiber winding apparatus and winding molding method thereof

A winding device and fiber technology, applied in the field of fiber winding tooling, can solve the problem that the fiber winding equipment cannot use workpieces with different diameters, and achieve high precision and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Please refer to the accompanying drawings, and the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0029] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

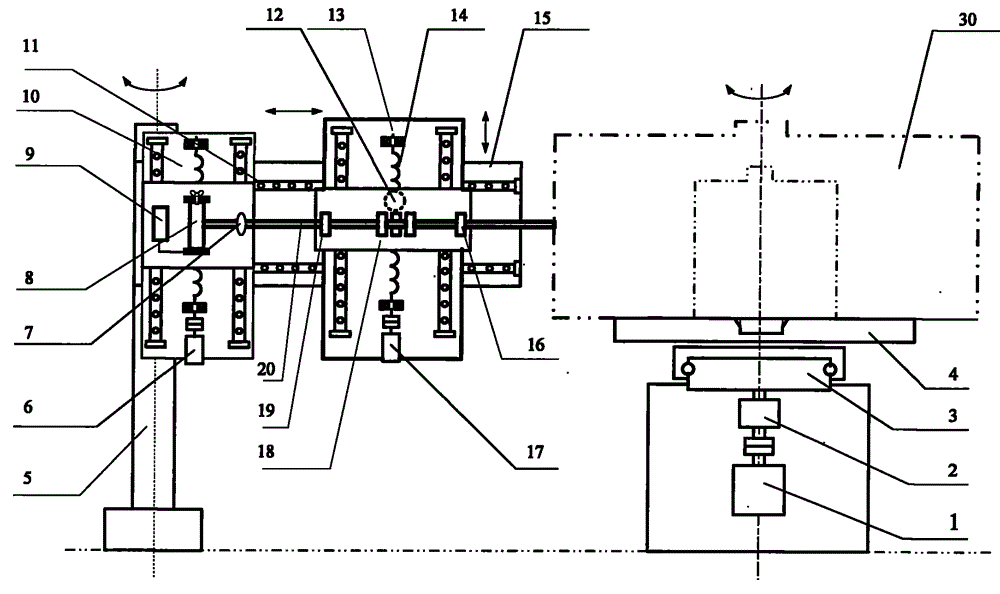

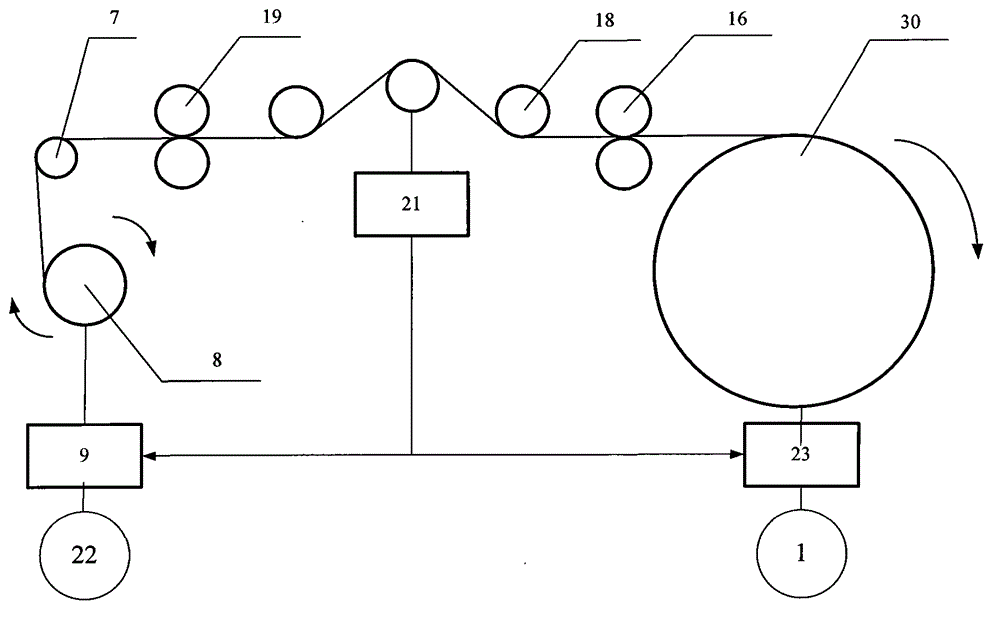

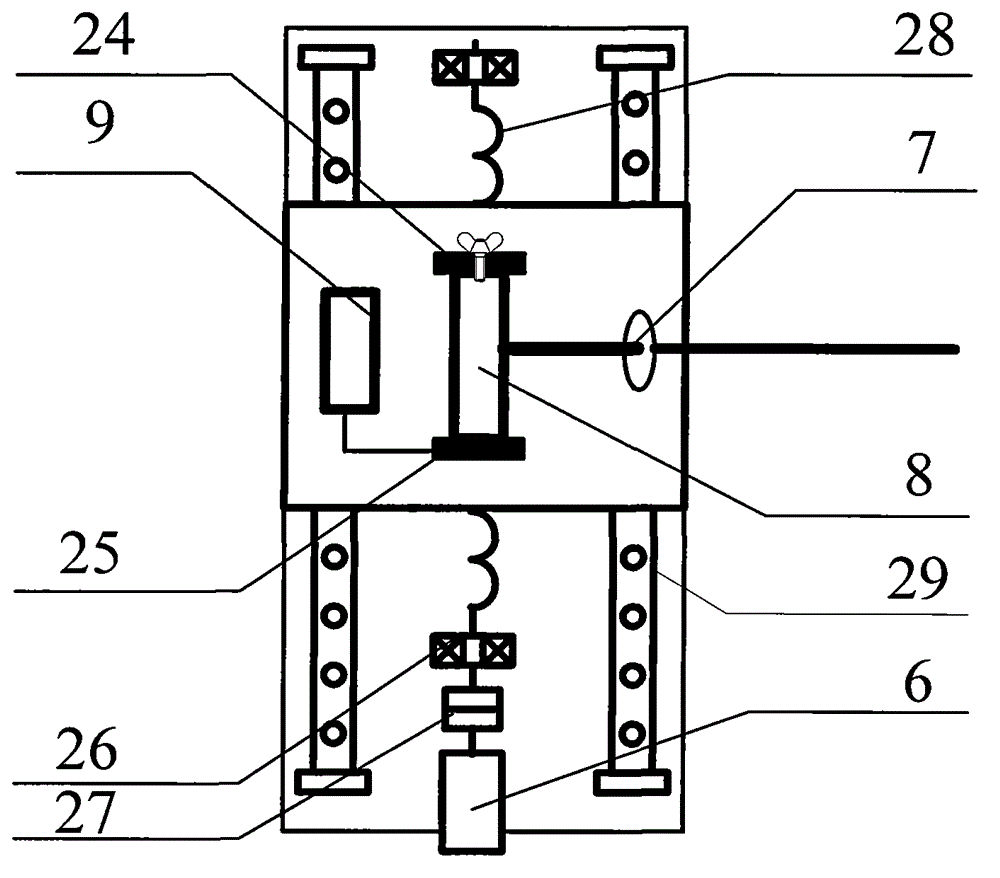

[0030] combine figure 1 ,exist figure 1 Among them, there is a Mitsubishi AC servo motor 1 with a precision reducer 2 in the workbench, and the AC servomotor 1 is connected to the slewing support 3, and a first workbench 4 is fixed on the slewing support 3, and the workpiece is fixed on the first workbench 4, so that The AC servo motor 1 can drive the workpiece to rotate. Fix a rotating column 5 on the designed distance position, fix a horizontal linear guide rail 11 on the rotating column 5, on the horizontal linear guide rail 11, two workbenches are housed, i.e. the second workbench 10 and the first Three workbenches13. By controlling the positions of the two w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com