Manufacturing method of environment-friendly container with 3D color printing picture and environment-friendly container

A color printing, container technology, applied in the direction of containers, rigid containers, packaging, etc., can solve the problems of too many raw materials, adverse health effects, and the structure is not strong enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

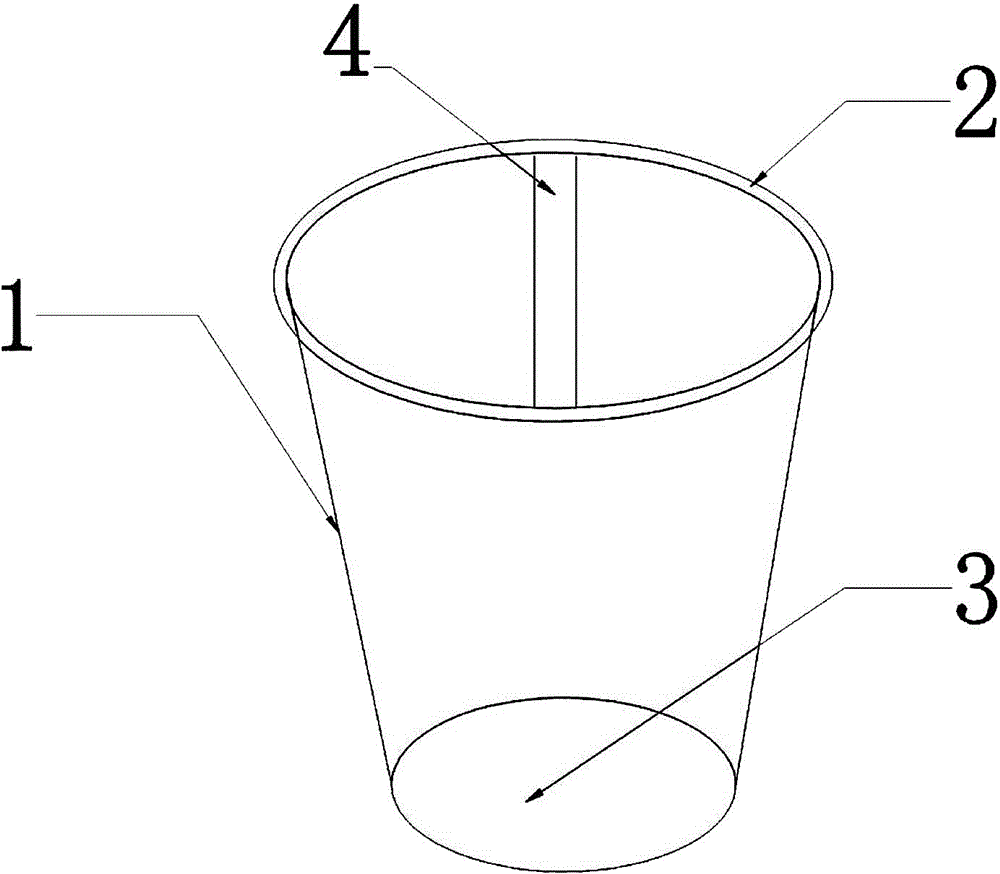

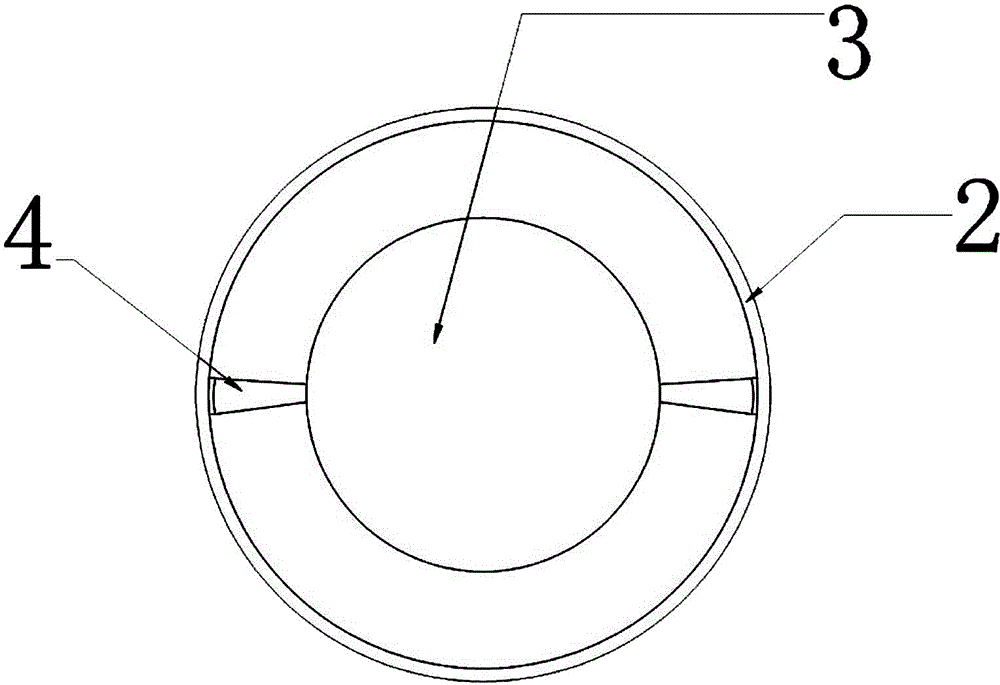

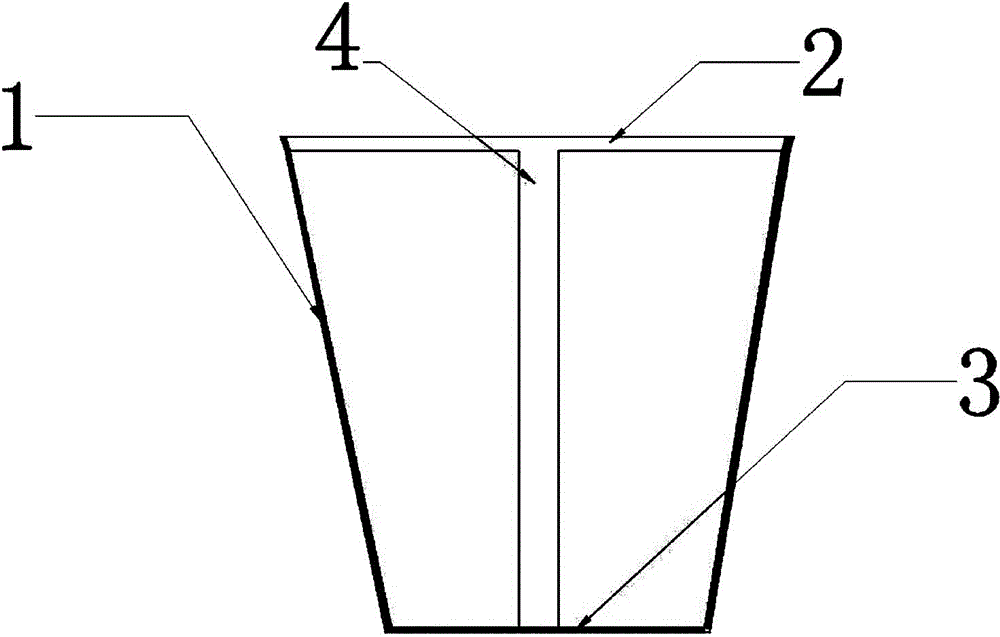

[0030] see Figure 1-4 As shown, the present invention relates to a method of making an environmentally friendly container with 3D color printing and its container.

[0031] An environmentally friendly container with a 3D color printing image, comprising a fan-shaped container body 1 with a 3D color printing image after unfolding, an injection molding ring 2 at the container mouth, a container bottom 3, and two injection molding reinforcing ribs 4 provided on the inner wall of the container body 1, One of the injection molding reinforcement ribs 4 is at the junction of the side of the container body 1, and the other injection molding reinforcement rib 4 is a mirror image and is arranged on the inner wall of the container body 1. The width of the injection molding reinforcement rib 4 is 3-15mm, and its depth is the same as that of the container body. The depth of the body 1 is the same. The color container body 1 is a single-layer sheet, including a layer of film and a transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com